TE Connectivity 2255143-1 User manual

Other TE Connectivity Tools manuals

TE Connectivity

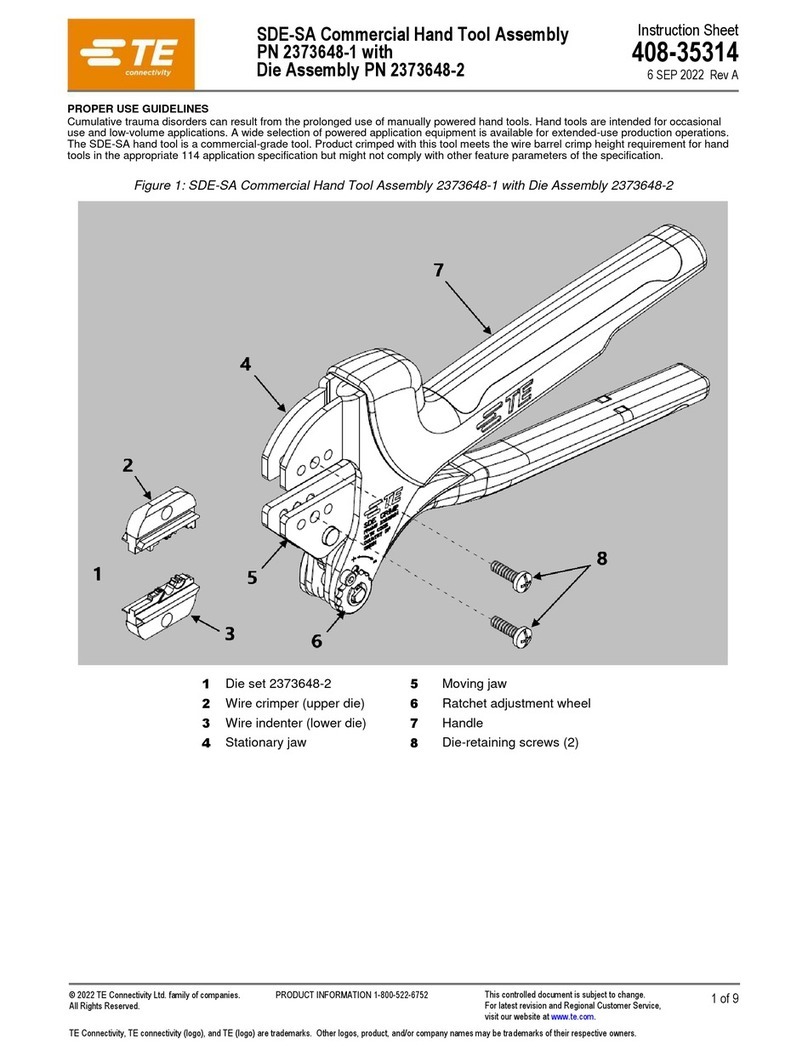

TE Connectivity SDE-SA User manual

TE Connectivity

TE Connectivity 2255140-1 User manual

TE Connectivity

TE Connectivity SDE-SA User manual

TE Connectivity

TE Connectivity CERTI-CRIMP II Reference guide

TE Connectivity

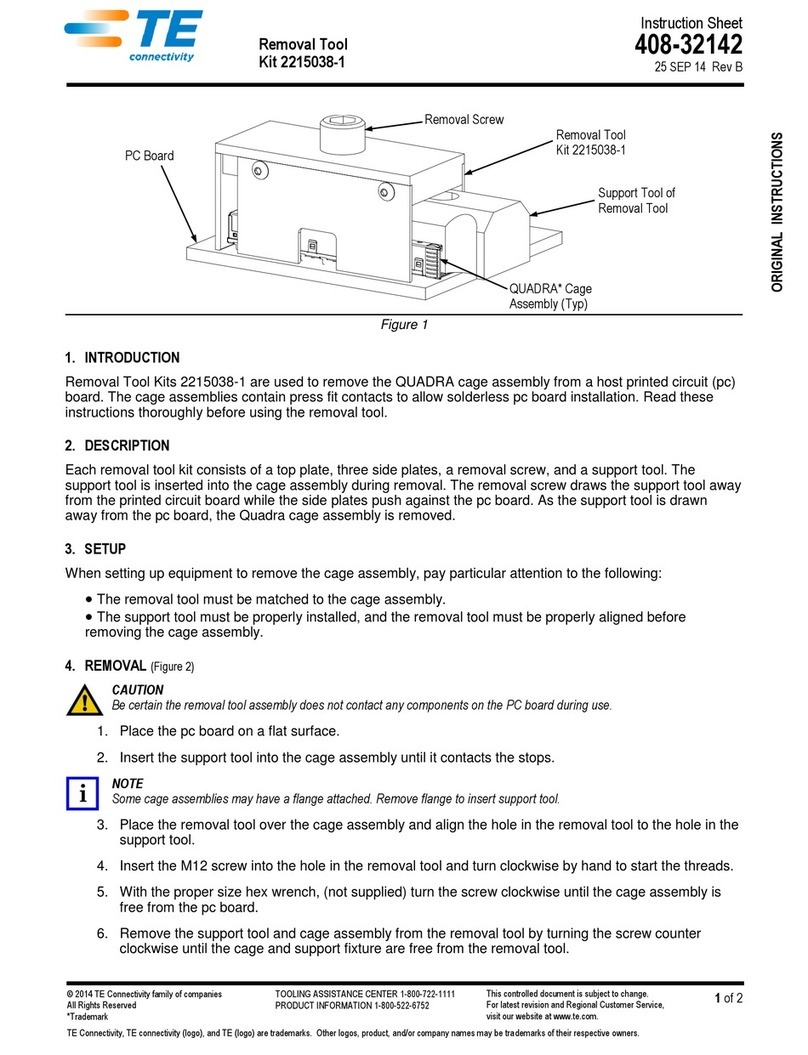

TE Connectivity 2215038-1 User manual

TE Connectivity

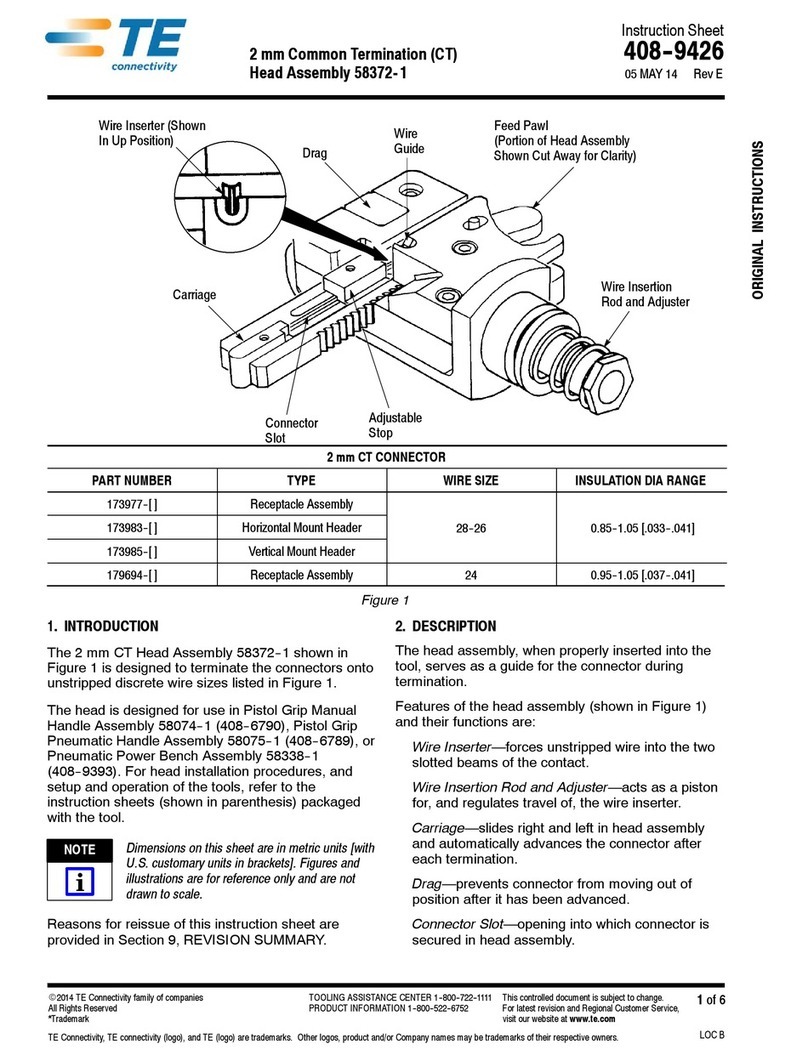

TE Connectivity 58372- 1 User manual

TE Connectivity

TE Connectivity PRO-CRIMPER III User manual

TE Connectivity

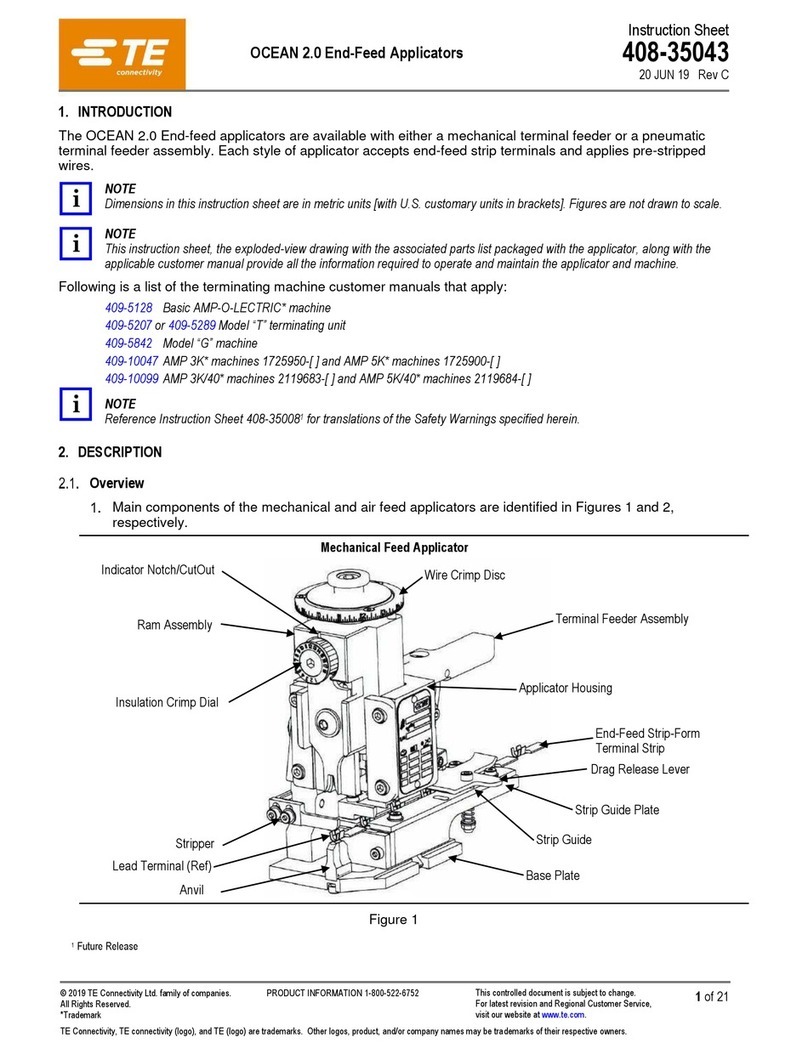

TE Connectivity OCEAN 2.0 User manual

TE Connectivity

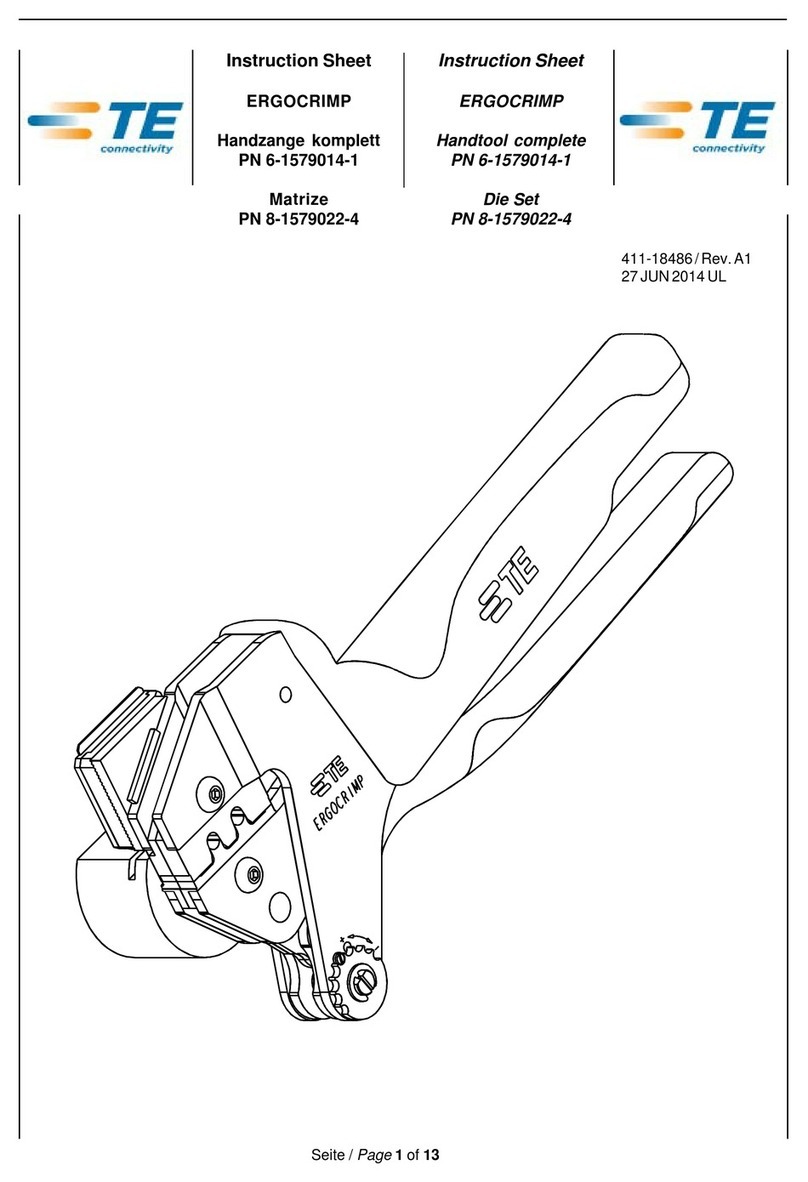

TE Connectivity ERGOCRIMP 6-1579014-1 User manual

TE Connectivity

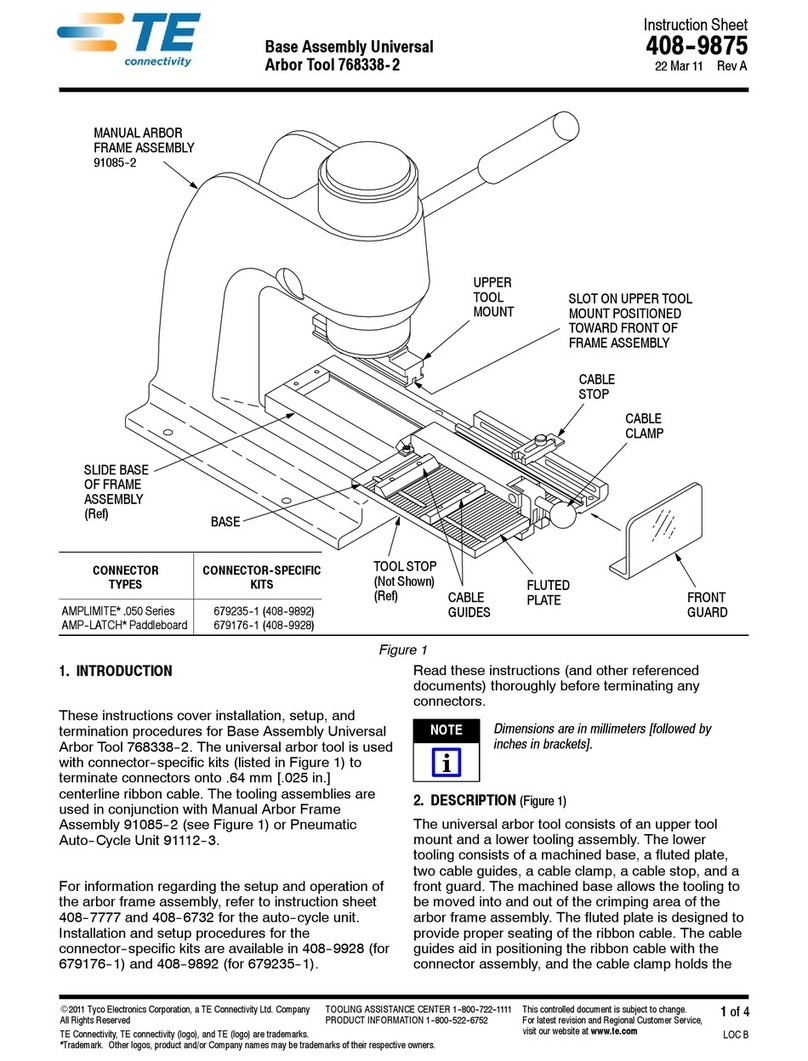

TE Connectivity 768338-2 User manual

TE Connectivity

TE Connectivity TERMI-POINT 59865-1 Reference guide

TE Connectivity

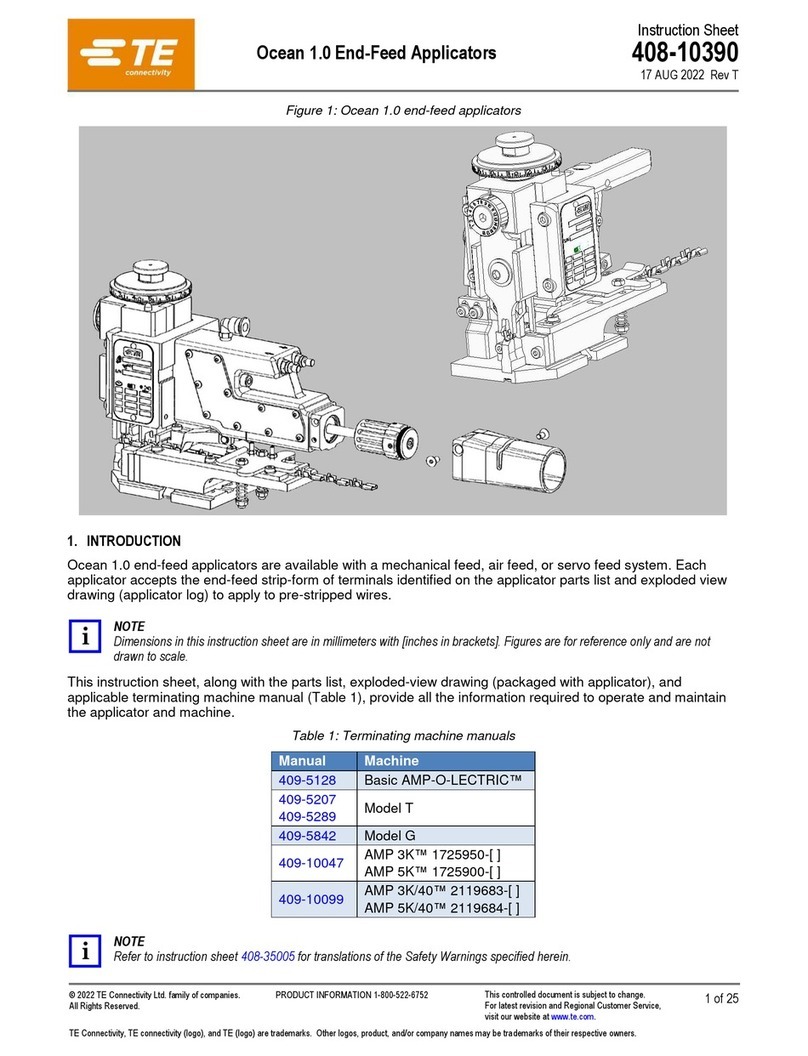

TE Connectivity Ocean 1.0 User manual

TE Connectivity

TE Connectivity CERTI- LOK Hand Tool Frame Assembly 169400 User manual

TE Connectivity

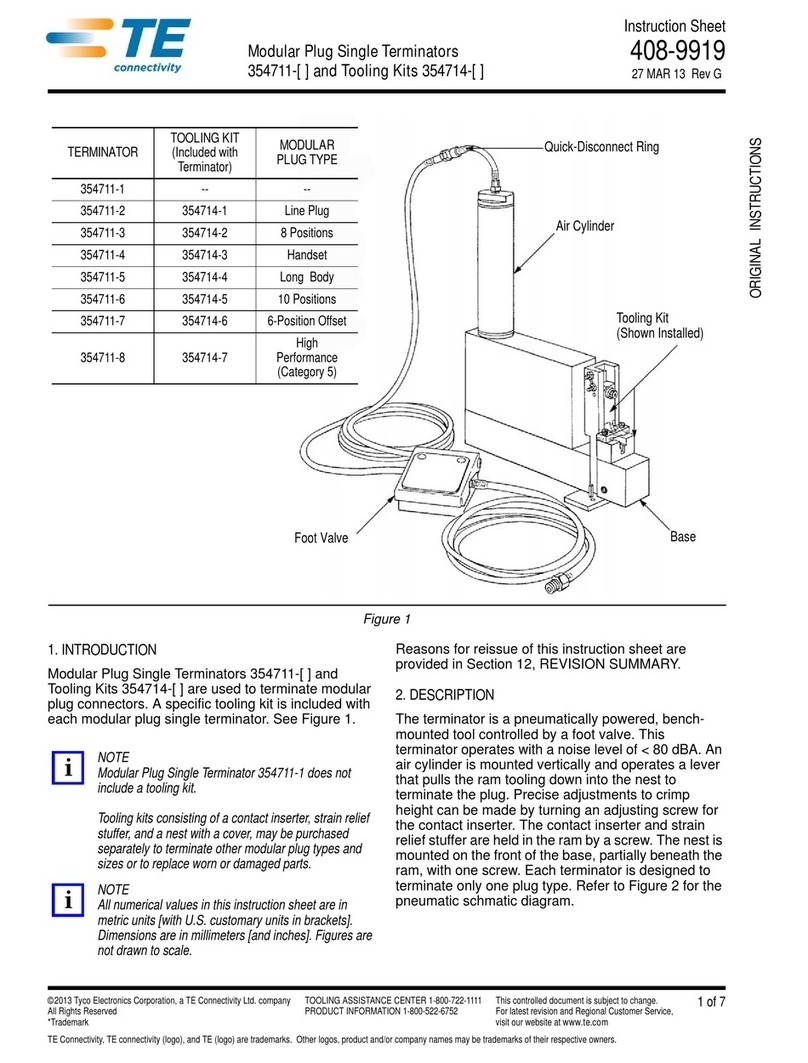

TE Connectivity 354711-1 User manual

TE Connectivity

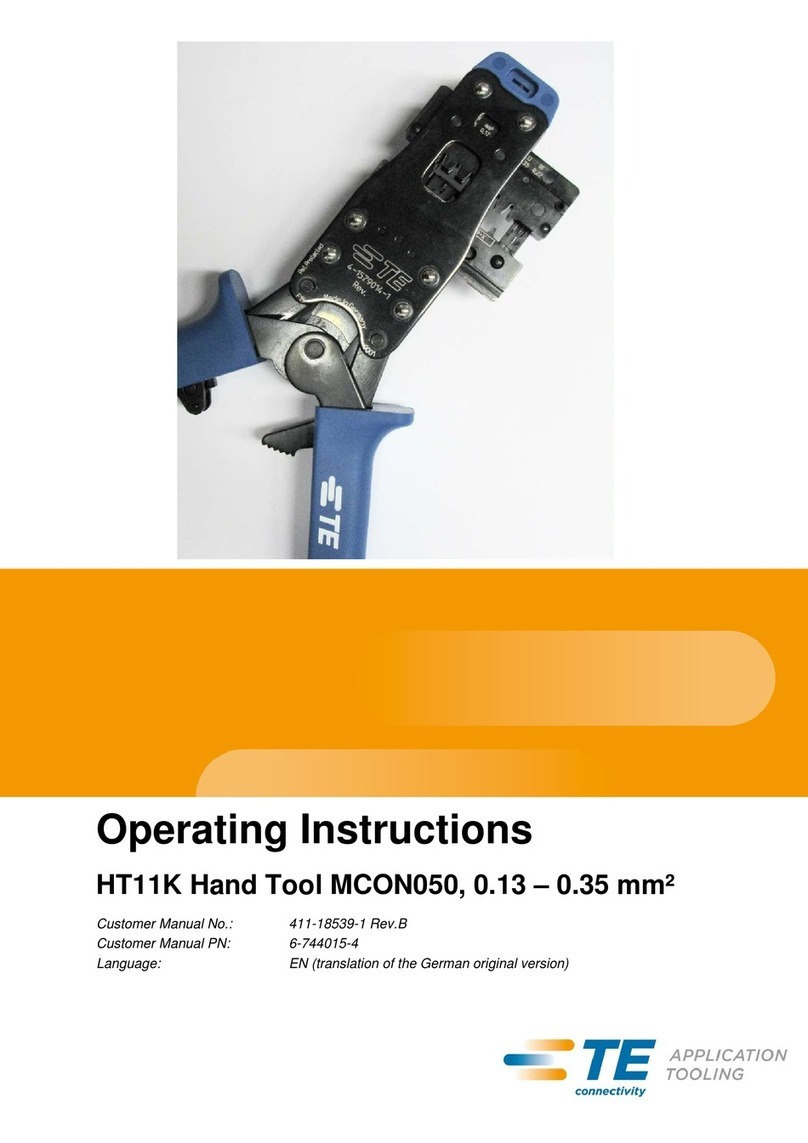

TE Connectivity HT11K User manual

TE Connectivity

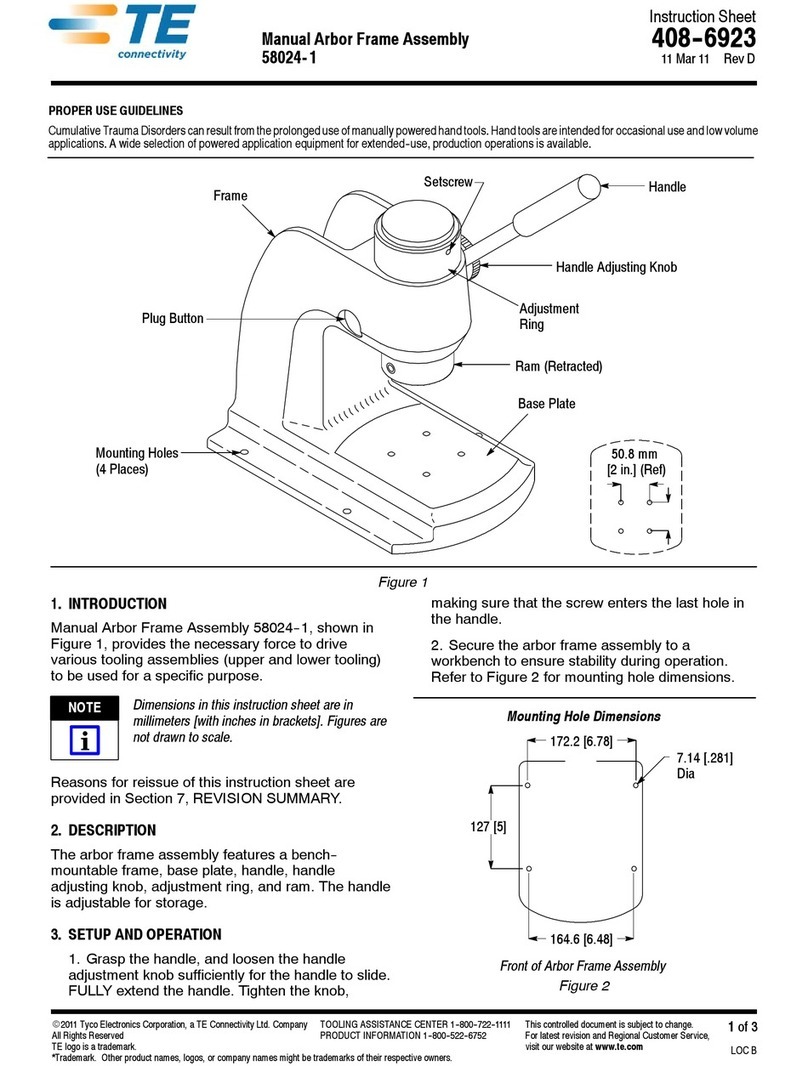

TE Connectivity 58024-1 User manual

TE Connectivity

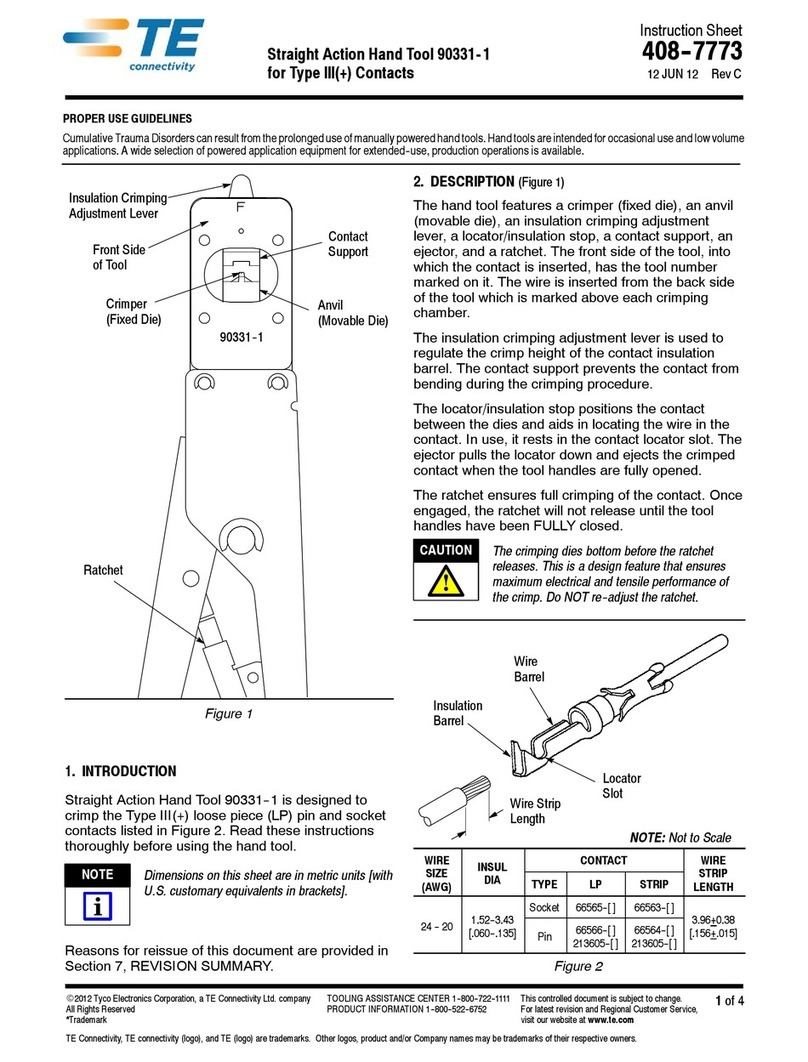

TE Connectivity 90331- 1 User manual

TE Connectivity

TE Connectivity 1725062-1 User manual

TE Connectivity

TE Connectivity 734185-1 User manual

TE Connectivity

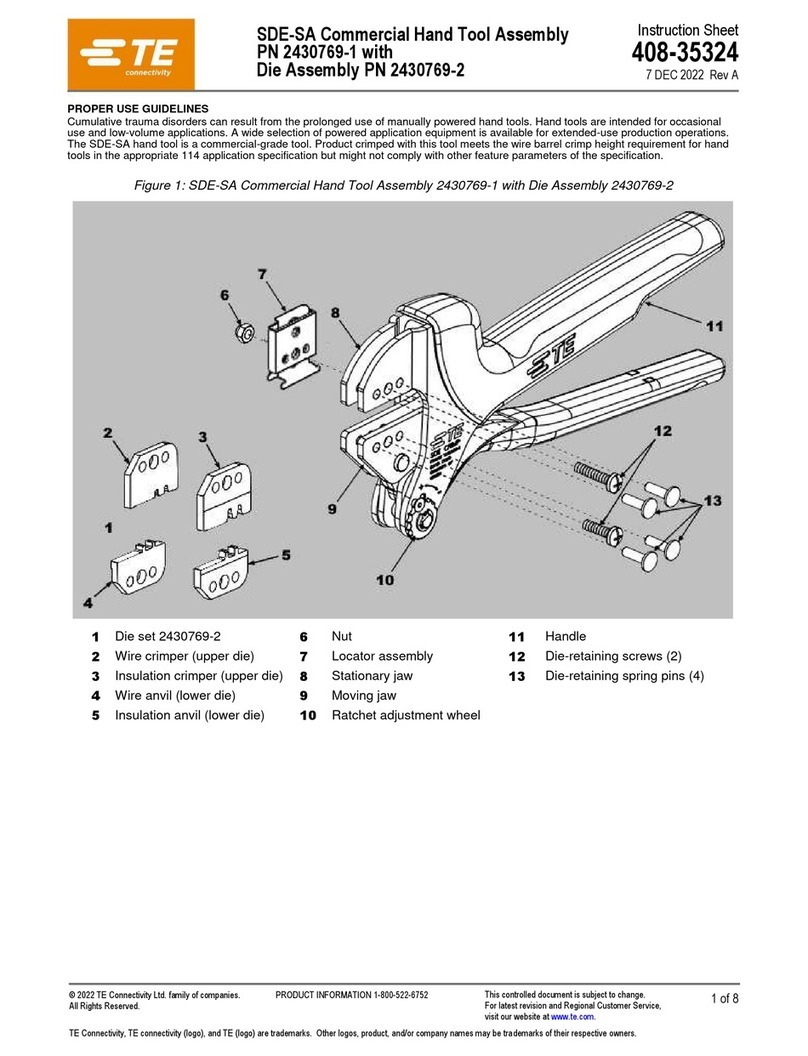

TE Connectivity 2430769-1 User manual