408-10380

2of 3

Rev C

3.2. Application Tool

Power for the seating tool must be provided by

application tools (with a ram) capable of supplying a

downward force of 24.5 N [5.5 lb] per contact.

Manual Electric Servo Press (MEP 6T) 2-1399500-5

and Bench Top Electric Servo Presses (BMEP 3T)

1-1399400-5 and (BMEP 5T) 2-1399401-4 are

available for this seating tool. For press information,

visit the press-fit assembly equipment website at

http://tooling.te.com/pressfit.asp.

Over-driving of the cage assembly will deform

parts critical to the quality of the connection.

Maximum force occurs prior to thecage assembly

bottoming on the pc board.

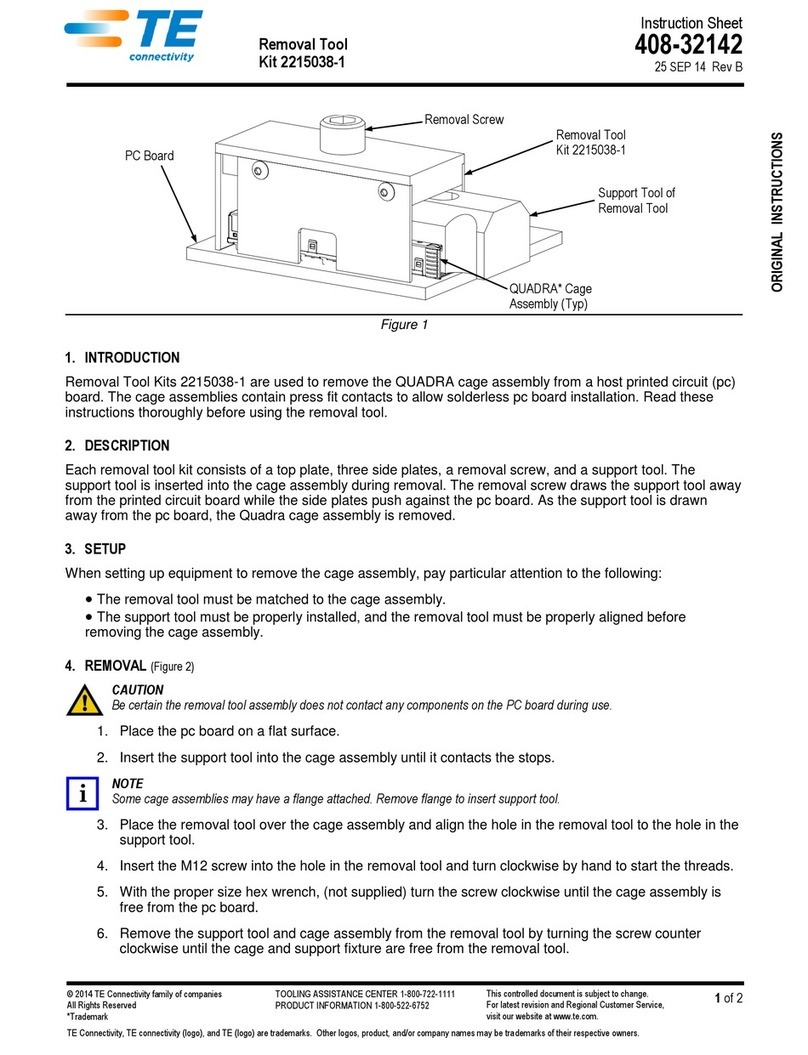

4. SETUP

When setting up equipment to seat the cage

assembly, pay particular attention to the following:

•the seating tool must be matched to the cage

assembly

If the seating tool and cage assembly are

mismatched or are improperly aligned, damage

could occur to the tooling, cage assembly, or both

•light pipes and/or heatsinks MUST NOT be

assembled onto the cage assembly.

•the wall support must be properly installed, and

the seating tool, cage assembly, and application

tool ram must be properly aligned before cycling

the application tool

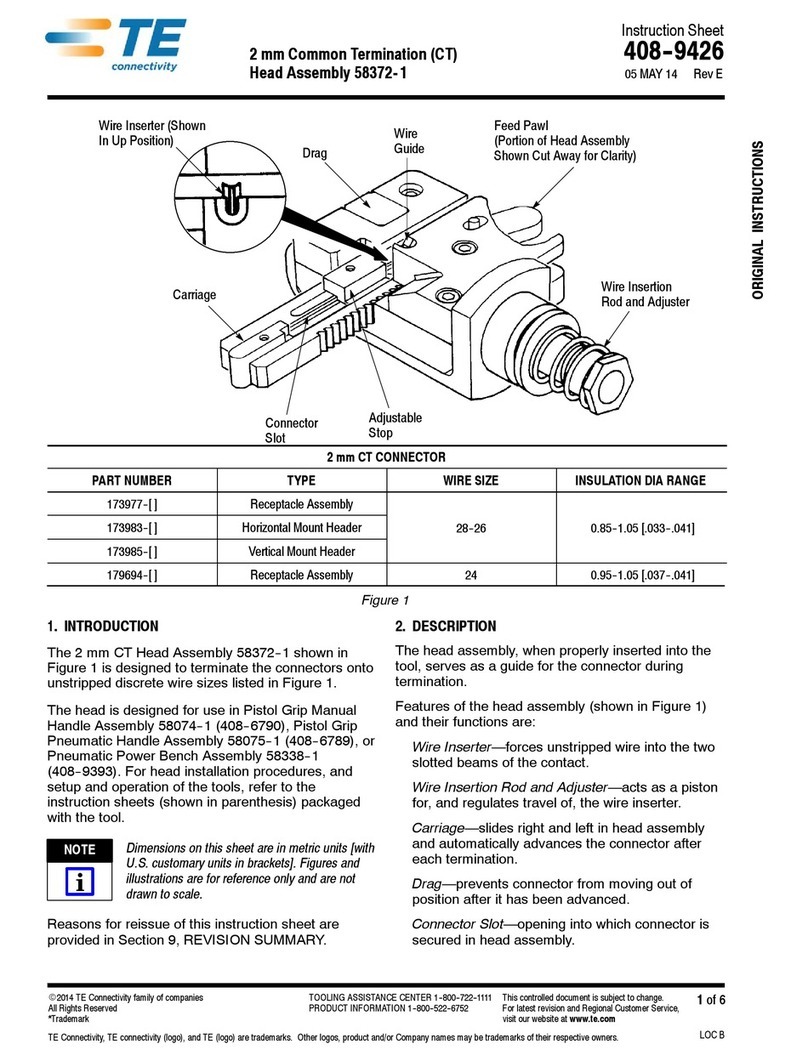

1. Set the tool seating height to the dimension

shown in Figure 2 (application tool shut height

will equal the tool seating height PLUS the

combined thicknesses of the pc board and

support fixture). After seating, a gap of no more

than 0.10 mm between the cage assembly

standoffs and the pc board is allowed.

Use the tool seating height as a referencestarting

point. This height may need to be adjusted to

obtaintheamount allowed(maximumof0.10mm)

between the standoffs of the cage assembly and

the pc board.

2. Slide the wall support into the ports of the

cage assembly until the wall support is secure.

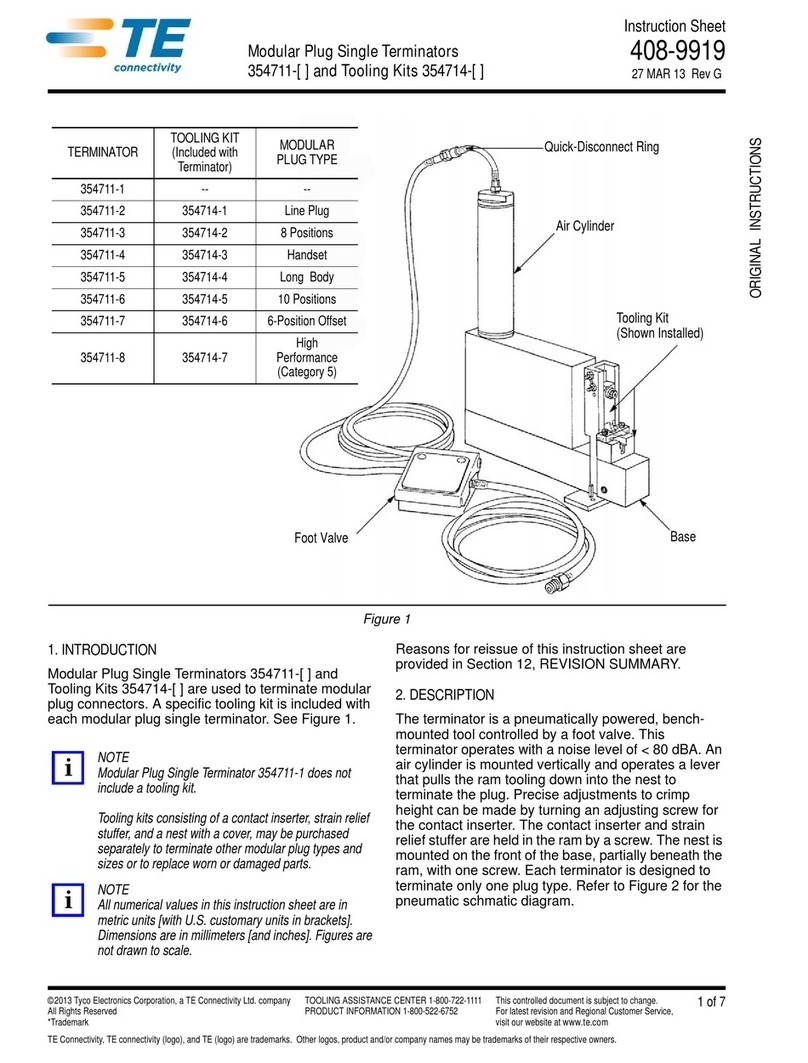

5. SEATING(See Figure 2)

The connector must be mounted on the pc board

BEFORE seating the cage assembly.

1. Place the pc board on the support fixture.

2. Orient the seating tool over the cage

assembly so that the back is aligned with the

back of the cage assembly. Then lower the

seating tool onto the cage assembly, making

sure that the cutouts slide over the protruding

components of the cage assembly, until the

seating tool bottoms on the top of the cage

assembly.

3. Place the cage assembly on the pc board so

that the contacts and alignment posts are

aligned and started into the matching holes in

the pc board.

Figure 2

PCBoardSupportFixture

Customer Supplied)

PrintedCircuit(PC) Board

Ram of Application

Tool (Fully Down)

Seating Tool

Compliant Pin Contacts (and

Any Protruding Components)

InsertedIntoHolesinPCBoard

and PC Board Support Fixture

Tool Seating Height

“A” (With Cage

Assembly Seated)

0.10 (Max)

Gap Allowed

Application Tool

Shut Height (Ram

Fully Down) See

Section 4, Step 1

CONNECTOR TYPE “A”

Standard (Without Cover) 42.15

Standard (With Cover) 42.37

Belly-Belly (Without Cover) 41.80

Belly-Belly (With Cover) 42.05