408- 6923

Rev D2 of 3

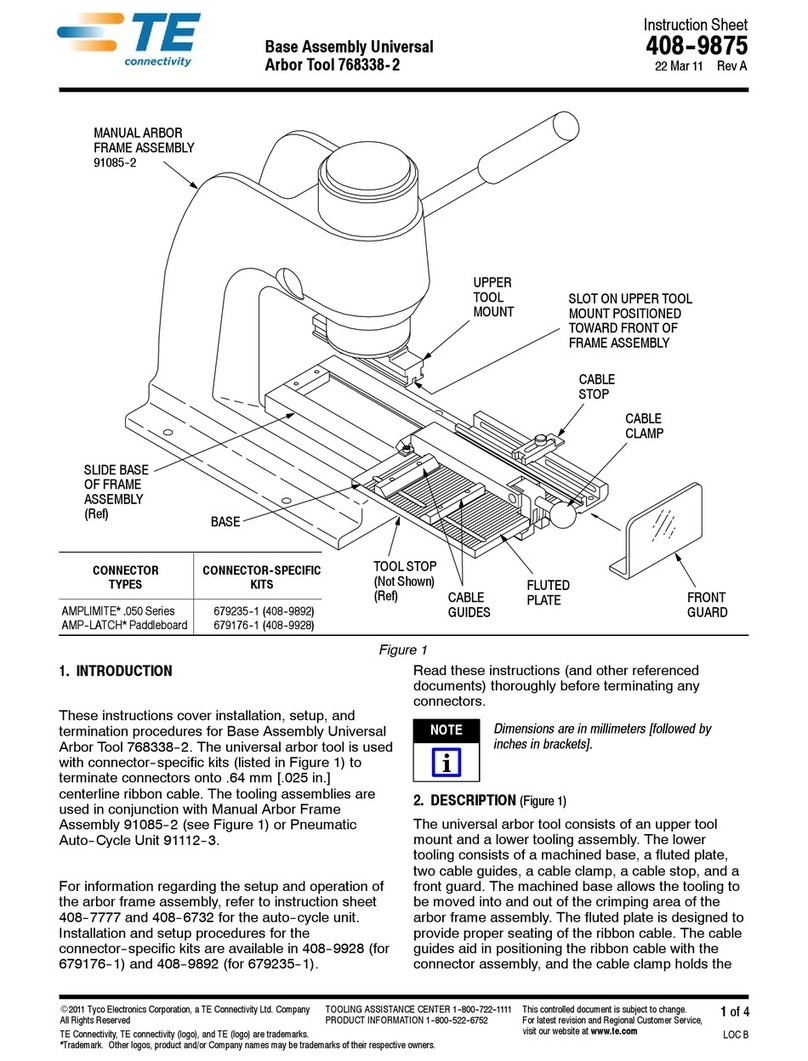

3. Secure the appropriate upper tooling to the ram

according to the instructions packaged with the

upper tooling.

4. Secure the appropriate lower tooling to the base

plate according to the instructions packaged with

the lower tooling.

5. To actuate the ram, pull down on the handle

until the upper tooling bottoms on the lower tooling.

To retract the ram, raise the handle.

Before beginning production, make sure that the

ram height is properly set according to Paragraph

4.1 and, if desired, adjust the handle according to

Paragraph 4.2.

4. ADJUSTMENTS

IMPORTANT: The ram height should be set before

adjusting the handle.

4.1. Ram Height Adjustment

After installing the tooling assembly, it might be

necessary to adjust the height of the ram. Adjust the

ram height as follows:

1. Determine the closed ram height dimension

required for the application.

2. Measure the distance between the bottom

surface of the upper tooling and the upper surface

of the lower tooling. Determine the direction (UP or

DOWN) that the ram must be moved.

3. Loosen the setscrew on the adjustment ring,

rotate the adjustment ring clockwise to increase

ram height, or counterclockwise to decrease ram

height, then tighten the setscrew. Continue making

adjustments until the proper closed ram height

dimension is attained.

4.2. Adjusting the Handle

To avoid personal injury when adjusting the

handle, STAY CLEAR OF THE HANDLE.

Depending on position, the weight of the ram

could force the handle to rotate quickly.

1. Using the tip of a small flat--blade screwdriver,

remove the plug button. Remove the socket head

cap screw and washer from the bore of the frame.

2. Grasp the adjustment ring, and pull the pinion

(small diameter gear in bore of frame) out of the

frame just enough to disengage it from the gear

teeth in the ram. Allow the ram to drop slowly until

the adjustment ring rests on the frame.

If the adjustment ring is NOT held in place when

the pinion is removed, the ram will drop and the

adjustment ring will slam onto the frame.

3. Rotate the handle to the desired position.

Ensure that the pinion rotates with the handle.

4. Push the pinion into the bore of the frame until it

engages the gear teeth in the ram.

5. Re--install the socket head cap screw and

washer. Re--install the plug button.

5. MAINTENANCE AND INSPECTION

5.1. Inspection

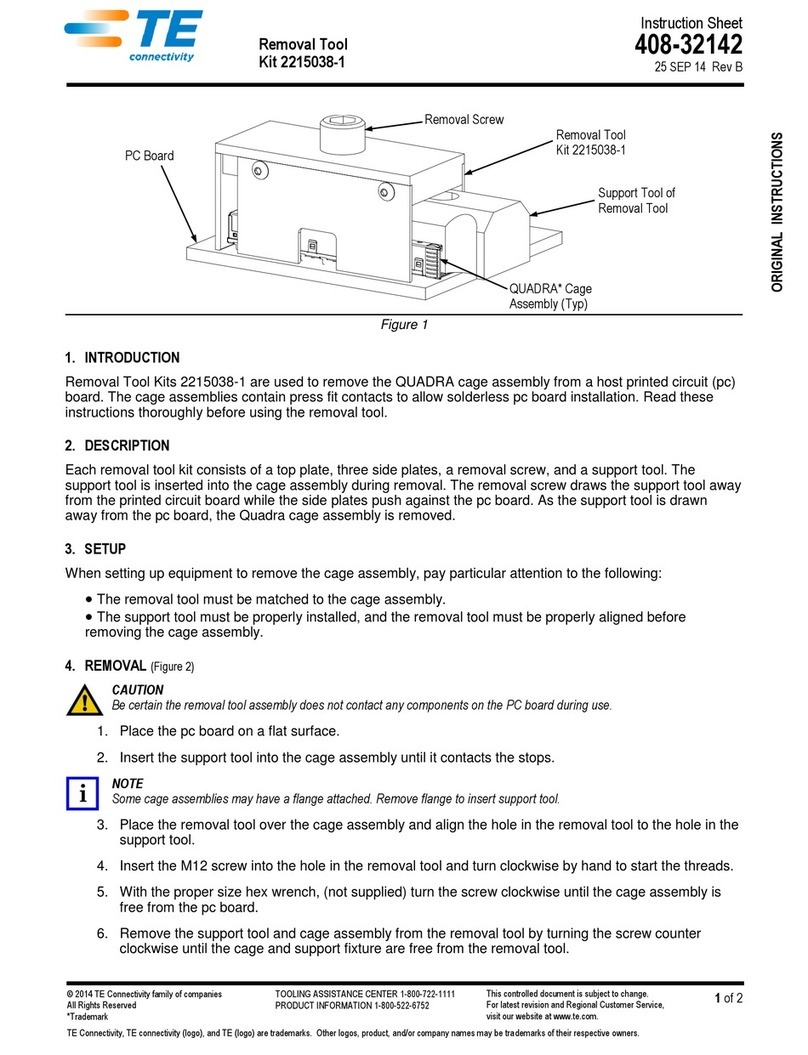

It is recommended that the arbor frame assembly be

inspected according to Figure 3 immediately upon

arrival at your facility (and at regularly scheduled

intervals thereafter) to ensure that it has not been

damaged during handling.

5.2. Lubrication

To prolong the useful life of the arbor frame assembly,

and to provide the smoothest operation, lubricate

monthly as follows:

Though recommendations call for lubrication at

least once a month, the frequency should be

based on amount of use, working conditions, and

established company policies.

1. Remove the upper tooling and lower tooling.

2. Move the ram to the bottom of its stroke (the

adjustment ring should bottom on the base plate).

Note the position of the handle. Loosen the handle

adjustment knob sufficiently for the handle to slide

from its mounting hole. Remove the handle.

3. Using a small flat--blade screwdriver, turn the

spring plunger (refer to Figure 3 for location)

counterclockwise until it no longer contacts the

ram.

4. Grip the adjustment ring, and pull it upward,

then remove the ram.

5. Apply ANDEROL 757 grease, or equivalent, to

the gear teeth on the ram and to the bore of the

frame.

6. Re--assemble the ram into the bore with the

grooved side of the ram aligned with the spring

plunger. Ensure that the gear teeth in the ram

engage the teeth of the pinion (small diameter gear

in bore of frame) so that the handle position will be

the same as noted in Step 2 when the adjustment

ring bottoms.

7. Turn the spring plunger clockwise until it

bottoms lightly on the ram, then back off one--half

of a turn.

NOTE

i

DANGER

CAUTION

!

NOTE

i