408- 9875

3of 4Rev A

To avoid personal injury, make sure all guards are

installed on the arbor frame assembly or

the auto--cycle unit before terminating the

connector.

2. Place cable into the flutes of the fluted plate, as

shown in Figure 2.

Cable conductors must stay in the same flutes for

the entire length of the fluted plate.

3. Insert connector into the lower insert using the

instructions supplied with the connector--specific

kit.

4. Slide cable through the connector so that the

end of the cable is against the cable stop. The

cable must be positioned between the cable

guides. When cable is properly positioned, close

the cable clamp. See Figure 2.

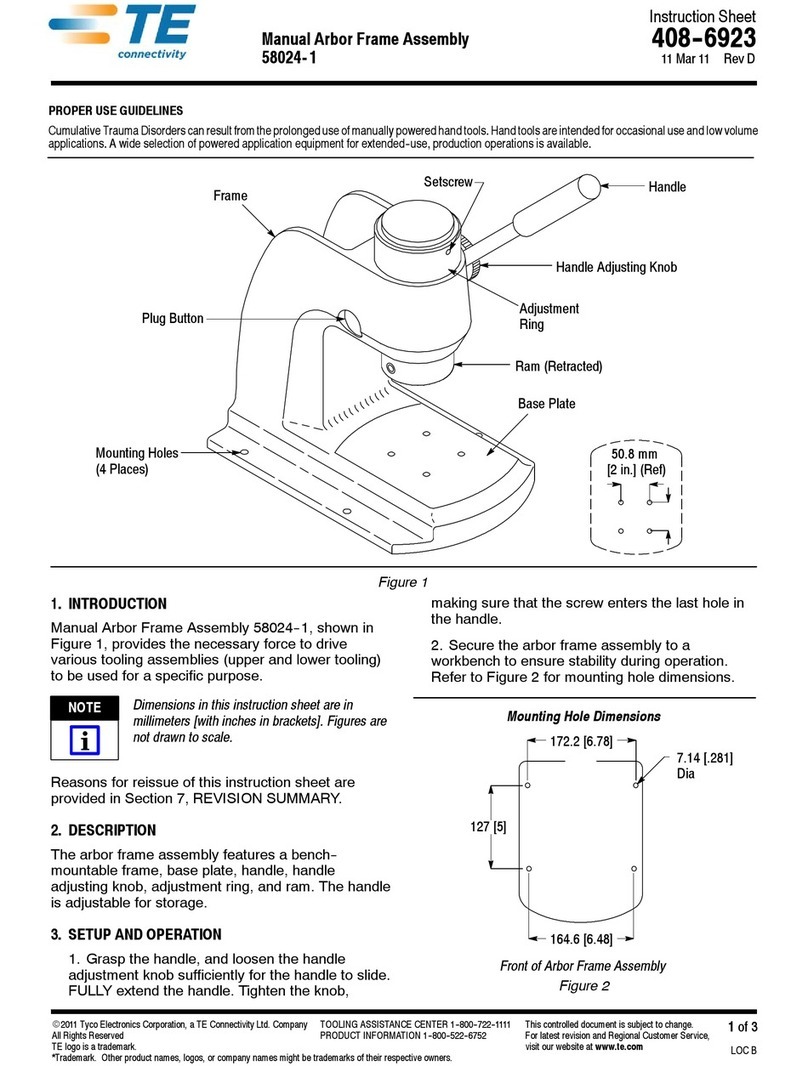

5. To actuate the ram for the arbor frame

assembly, slide lower tooling assembly toward rear

of base plate until it is positioned against the rear

tool stop. Pull down on the frame assembly handle

to terminate the cable to the connector.

To actuate the ram for the auto--cycle unit, slide

lower tooling assembly toward the rear of the

base plate until the sensing port closes. The

frame assembly will automatically cycle and

terminate the cable to the connector.

6. To retract the ram for the arbor frame assembly,

raise the tool handle. Slide tooling assembly out

from under the ram and remove the terminated

connector.

The ram will automatically retract when the

auto--cycle unit has completed the crimp cycle.

Slide the lower tooling out from under the ram to

remove the terminated connector.

7. Measure the termination height of the connector.

The dimension should conform to the termination

height dimensions provided in Application

Specification 114--40049. If the termination height

is incorrect, an adjustment to the ram height is

required. Refer to the instruction sheet supplied

with the appropriate frame assembly for ram height

adjustment procedures.

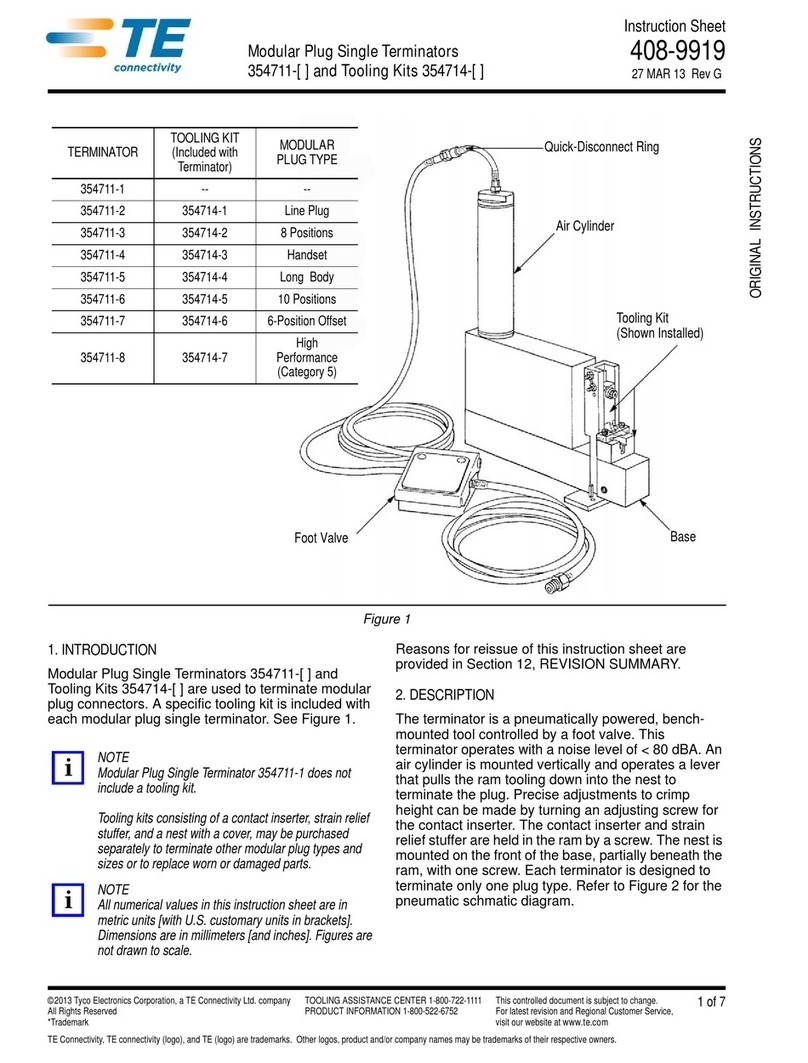

5. MAINTENANCE AND INSPECTION

5.1. Maintenance

Base Assembly Universal Arbor Tool 768338--2

requires little maintenance other than to keep it clean.

Remove debris and contaminants from the tooling

with a clean, soft, lint--free cloth or a clean, soft brush.

Do not use objects that could damage the tooling and

do not use any solvents that could harm paint or

plastic material. When not in use, store the tooling in

a clean, dry area.

5.2. Inspection

The tooling should be inspected immediately upon

arrival at your facility and at regularly--scheduled

intervals thereafter to ensure that it has not been

damaged. Examine the tooling for any signs of

damage or excessive wear during inspections. If

replacement of parts is necessary, refer to Figure 3

for the list of customer--replaceable parts.

6. REPLACEMENT AND REPAIR

Figure 3 provides a list of customer--replaceable parts

for the Base Assembly Universal Arbor Tool

768338--2. Replacement parts can be ordered

through your local TE Connectivity representative.

Parts replacement and tooling repair may also be

secured by calling the Product Information or the

Tooling Assistance Center at the numbers shown on

the bottom of the first page of this document.

7. REVISION HISTORY

Since the previous version of this document, the

following has been changed:

SUpdated document to corporate requirements.

DANGER

NOTE

i

NOTE

i

NOTE

i