Teledyne FST-040 User manual

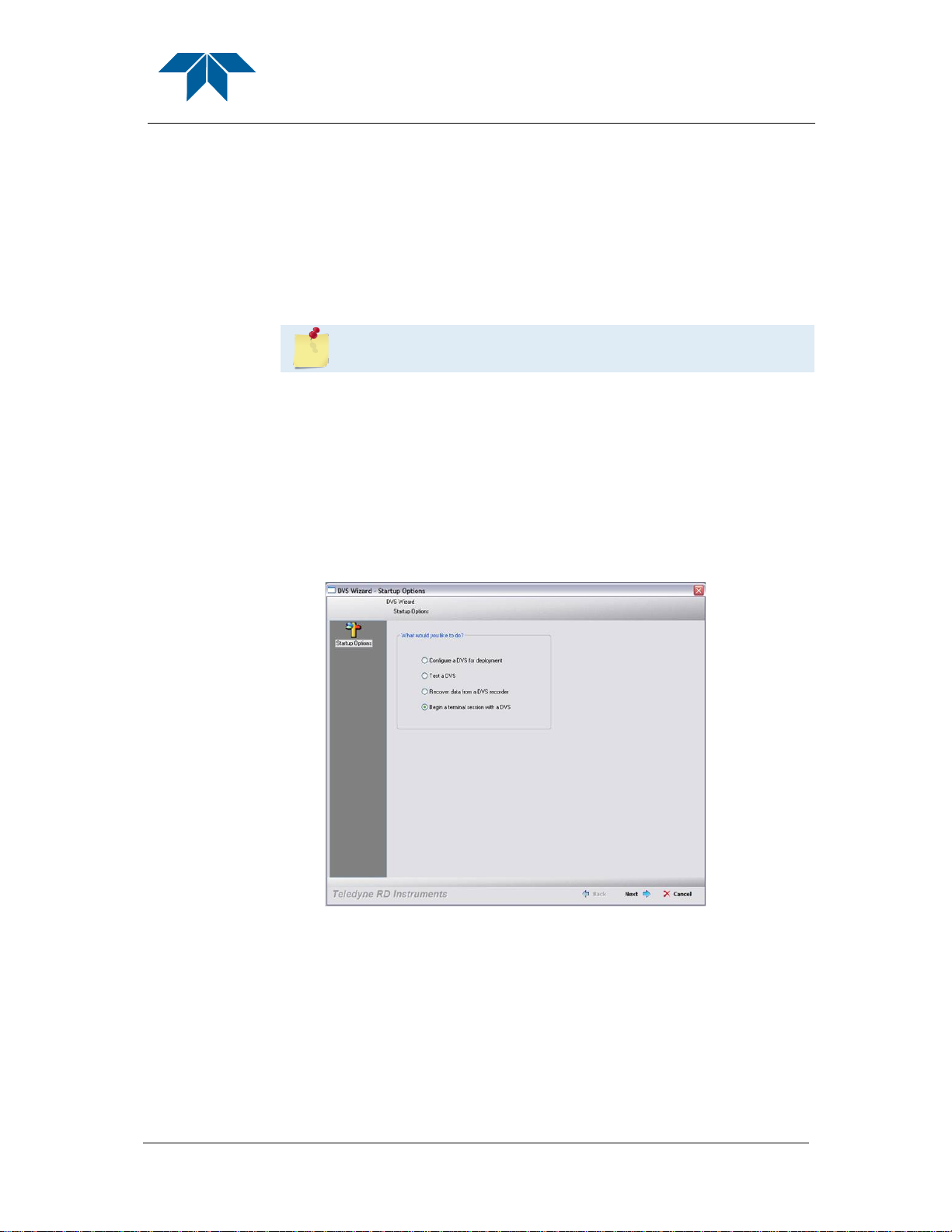

Other Teledyne Test Equipment manuals

Teledyne

Teledyne T750 User manual

Teledyne

Teledyne ZD200 Parts list manual

Teledyne

Teledyne HPM 4 User manual

Teledyne

Teledyne HDO8000A User manual

Teledyne

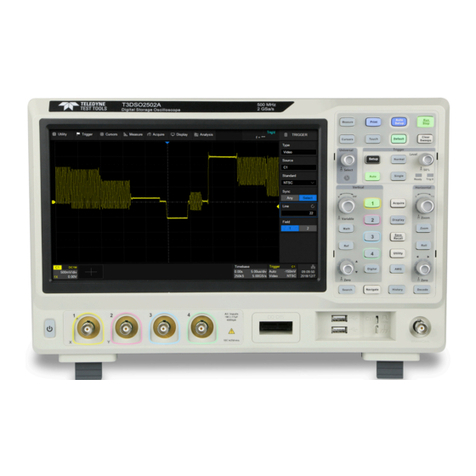

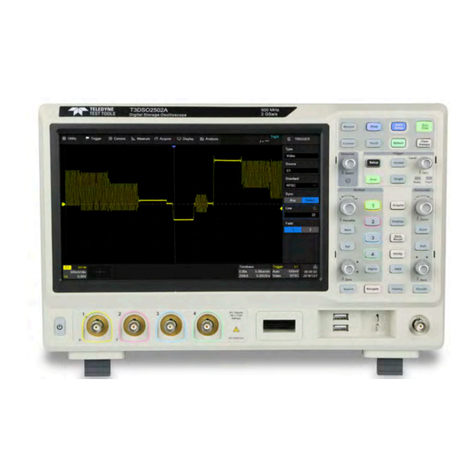

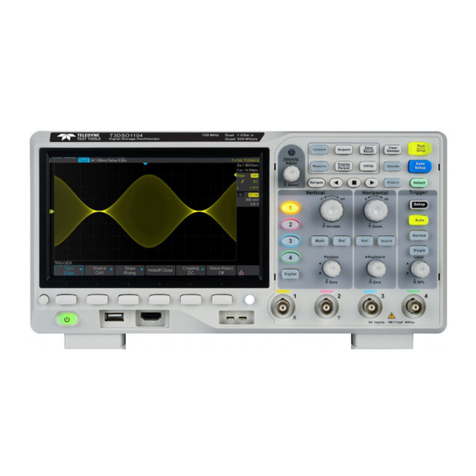

Teledyne LeCroy T3DSO2000A Series User manual

Teledyne

Teledyne LeCroy Waverunner LT Series Instruction sheet

Teledyne

Teledyne 804A User manual

Teledyne

Teledyne T700 User manual

Teledyne

Teledyne LabMaster 10 Zi Series Parts list manual

Teledyne

Teledyne HDO9000 User manual

Teledyne

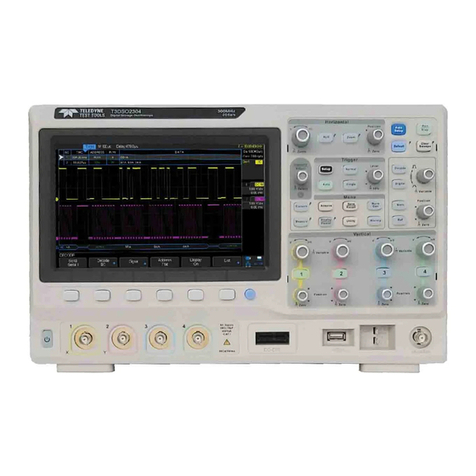

Teledyne T3DSO1000 Operating instructions

Teledyne

Teledyne T700 User manual

Teledyne

Teledyne GT Series Quick start guide

Teledyne

Teledyne T3HVD User manual

Teledyne

Teledyne T703 User manual

Teledyne

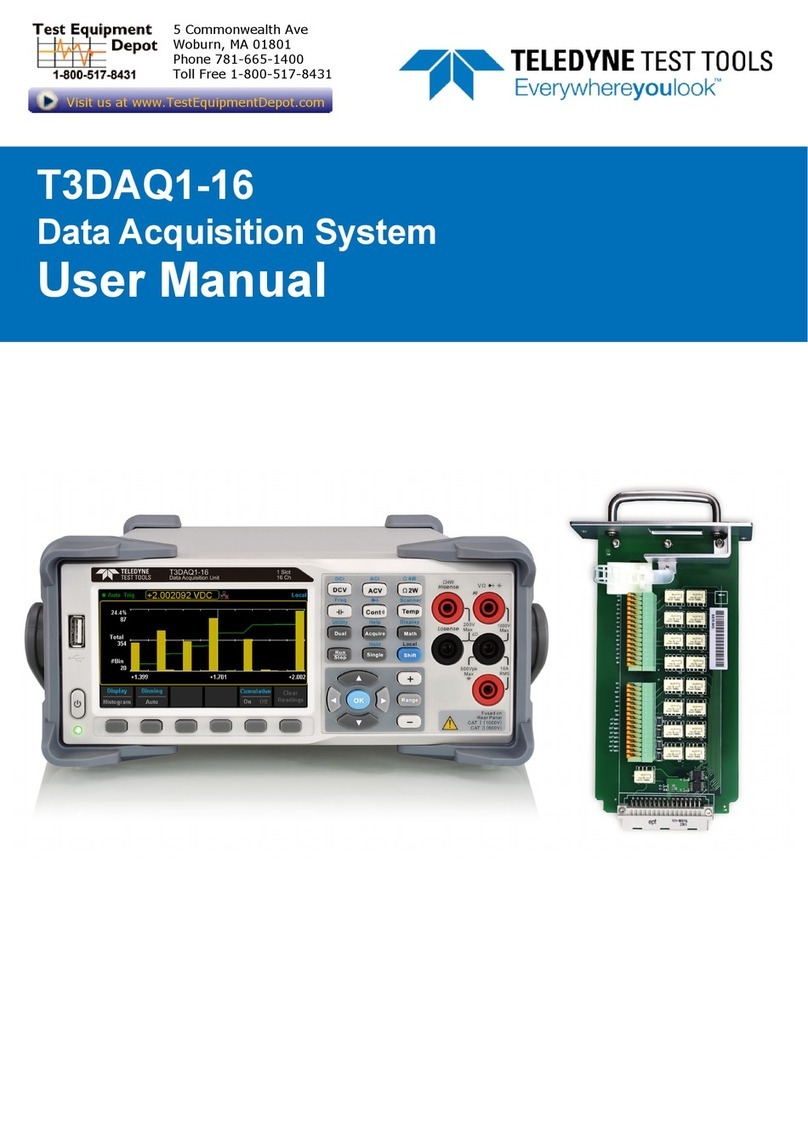

Teledyne T3DAQ1-16 User manual

Teledyne

Teledyne CP030A User manual

Teledyne

Teledyne T3NFP3 User manual

Teledyne

Teledyne T3DSO1000A Series User manual

Teledyne

Teledyne LabMaster 10 Zi Series User manual