TLV VAS User manual

172-65170MA-06 (VAS) 9 July 2015

Rapid Initial Air Vent

VAS

Copyright © 2015 by TLV CO., LTD.

All rights reserved

ISO 9001/ ISO 14001

Manufacturer

Kakogawa, Japan

is approved by LRQA LTD. to ISO 9001/14001

172-65170MA-06 (VAS) 9 Jul 2015

1

Contents

Introduction .......................................................................1

Safety Considerations.......................................................2

Features............................................................................4

Operation ..........................................................................4

Specifications....................................................................5

Configuration.....................................................................5

Installation.........................................................................6

Maintenance......................................................................7

Disassembly/Reassembly.................................................8

Troubleshooting ..............................................................10

Product Warranty ............................................................11

Introduction

Thank you for purchasing the Rapid Initial Air Vent.

This product has been thoroughly inspected before being shipped from the

factory. When the product is delivered, before doing anything else, check the

specifications and external appearance to make sure nothing is out of the

ordinary. Also be sure to read this manual carefully before use and follow the

instructions to be sure of using the product properly.

This Rapid Initial Air Vent is for use on water-bearing pipes, and should

therefore not be used on steam lines.

The Rapid Initial Air Vent operates by rapidly discharging the initial air when

supplying water to piping, then closing upon completion of discharge. During

operation, once it has closed, the air vent remains closed as long as there is

internal pressure. When draining piping, the Rapid Initial Air Vent automatically

opens to introduce air and remove water easily.

The Rapid Initial Air Vent ‘s simple, compact construction, with no hinges or

levers and only one moving part, the float, provides trouble-free operation and

long service life.

If detailed instructions for special order specifications or options not contained

in this manual are required, please contact for full details.

This instruction manual is intended for use with the model(s) listed on the

front cover. It is necessary not only for installation but for subsequent

maintenance, disassembly/reassembly and troubleshooting. Please keep it in

a safe place for future reference.

172-65170MA-06 (VAS) 9 Jul 2015

2

Safety Considerations

•Read this section carefully before use and be sure to follow the

instructions.

•Installation, inspection, maintenance, repairs, disassembly, adjustment

and valve opening/closing should be carried out only by trained

maintenance personnel.

•The precautions listed in this manual are designed to ensure safety and

prevent equipment damage and personal injury. For situations that may

occur as a result of erroneous handling, three different types of cautionary

items are used to indicate the degree of urgency and the scale of potential

damage and danger: DANGER, WARNING and CAUTION.

•The three types of cautionary items above are very important for safety: be

sure to observe all of them as they relate to installation, use, maintenance,

and repair. Furthermore, TLV accepts no responsibility for any accidents

or damage occurring as a result of failure to observe these precautions.

Symbols

Indicates a DANGER, WARNING or CAUTION item.

DANGER

Indicates an urgent situation which poses a threat of death or

serious injury

WARNING

Indicates that there is a potential threat of death or serious injury

CAUTION

Indicates that there is a possibility of injury or equipment /

product damage

WARNING

DO NOT use for toxic, flammable or otherwise hazardous

fluids.

This product is an air vent that discharges air from water piping

system. Use only for water and/or air. This product is for intended

use only. Improper use may result in such hazards as damage to

the product or malfunctions that may lead to serious accidents.

NEVER apply direct heat to the float.

The float may explode due to increased internal pressure,

causing accidents leading to serious injury or damage to property

and equipment.

CAUTION

Install properly and DO NOT use this product outside the

recommended operating pressure, temperature and other

specification ranges.

Improper use may result in such hazards as damage to the

product or malfunctions that may lead to serious accidents. Local

regulations may restrict the use of this product to below the

conditions quoted.

Safety considerations continued on next page.

172-65170MA-06 (VAS) 9 Jul 2015

3

CAUTION

Take measures to prevent people from coming into direct

contact with product outlets.

Failure to do so may result in burns or other injury from the

discharge of fluids.

When disassembling or removing the product, wait until the

internal pressure equals atmospheric pressure and the

surface of the product has cooled to room temperature.

Disassembling or removing the product when it is hot or under

pressure may lead to discharge of fluids, causing burns, other

injuries or damage.

Be sure to use only the recommended components when

repairing the product, and NEVER attempt to modify the

product in any way.

Failure to observe these precautions may result in damage to the

product and burns or other injury due to malfunction or the

discharge of fluids.

Do not use excessive force when connecting threaded pipes

to the product.

Over-tightening may cause breakage leading to fluid discharge,

which may cause burns or other injury.

Use only under conditions in which no freeze-up will occur.

Freezing may damage the product, leading to fluid discharge,

which may cause burns or other injury.

Use only under conditions in which no water hammer will

occur.

The impact of water hammer may damage the product, leading to

fluid discharge, which may cause burns or other injury.

172-65170MA-06 (VAS) 9 Jul 2015

4

Features

1. The air vent has no hinges or levers: the only moving part is the precision-ground

float, which eliminates concentrated wear and provides long service life.

2. Simple construction with few parts allows for easy maintenance.

3. The air vent is small and light.

Operation

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

1. When water is transported, air inside the piping is

forced into the air vent by the pressure of the flow.

The float inside the air vent is in the lower position,

thus the valve is fully open and allows the air that

enters the air vent and fills the area around the float

to then be discharged.

2. When discharge is completed, as water flows into the

air vent, the rising water level causes the float to rise

and to close the valve.

If there is a rapid rise in water level (caused by

rapidly opening a shut-off valve, etc.), a small amount

of water may leak with discharged air immediately

before the air vent closes.

3. Once it has closed, the air vent remains closed as

long as there is internal pressure.

4. When draining the piping, the air vent automatically

opens to introduce air and remove water more easily

(preventing a vacuum from forming in the piping).

Air

Water

172-65170MA-06 (VAS) 9 Jul 2015

5

Specifications

DO NOT use for toxic, flammable or otherwise hazardous fluids.

This product is an air vent that discharges air from water piping system.

Use only for water and/or air. This product is for intended use only.

Improper use may result in such hazards as damage to the product or

malfunctions that may lead to serious accident.

WARNING

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Use only under conditions in which no freeze-up will occur. Freezing

may damage the product, leading to fluid discharge, which may cause

burns or other injury.

CAUTION

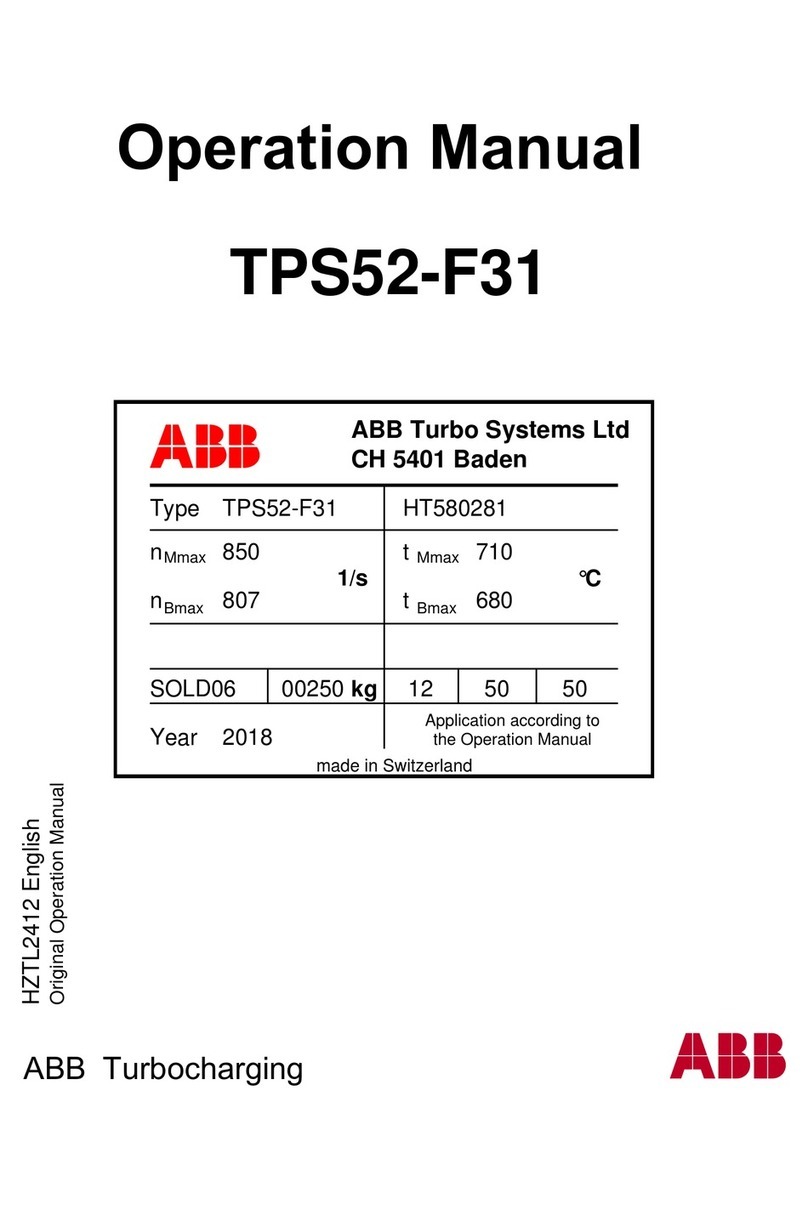

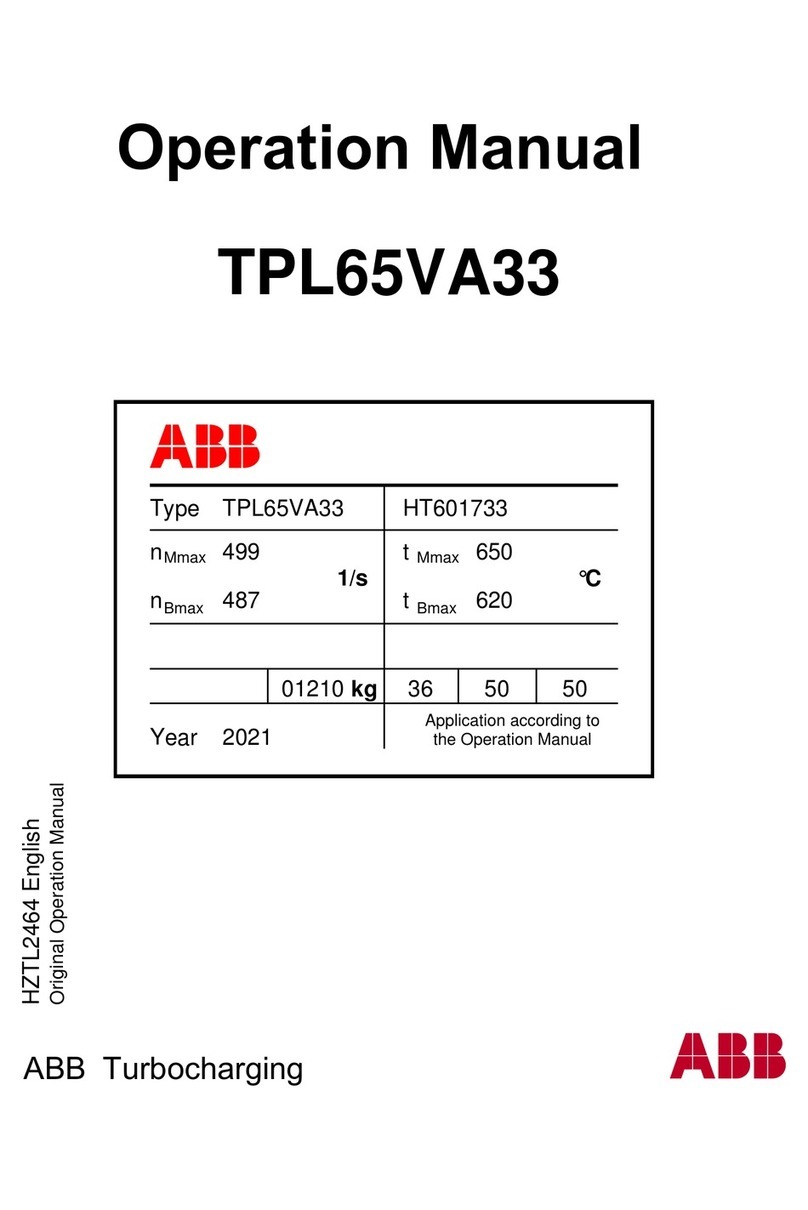

Refer to the product nameplate for detailed specifications.

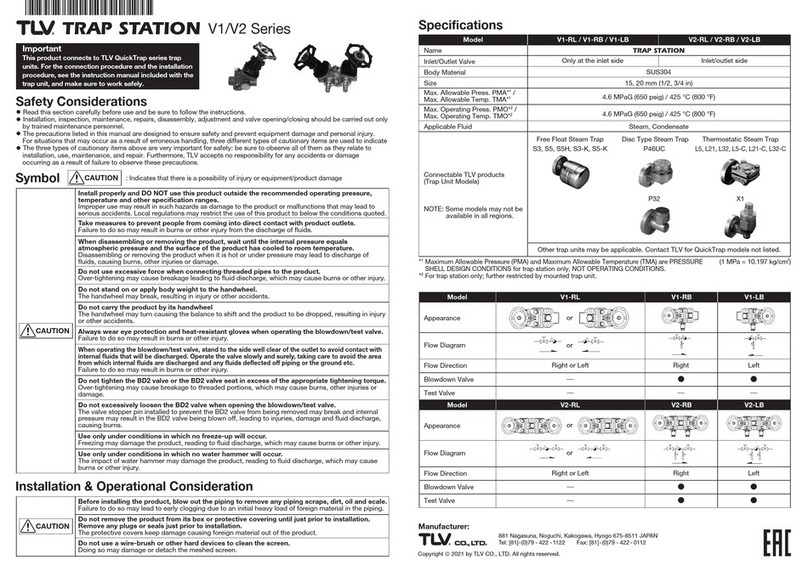

Model

Production Lot No.

X-element Type

Maximum Allowable

Temperature (TMA)*

Maximum Operating

Temperature (TMO)

Nominal Diameter

Maximum Allowable

Pressure*

Maximum Operating

Pressure

Valve No.**

* Maximum allowable pressure (PMA) and maximum allowable temperature (TMA) are

PRESSURE SHELL DESIGN CONDITIONS, NOT OPERATING CONDITIONS.

** Valve No. is displayed for products with options. This item is omitted from the nameplate

when there are no options.

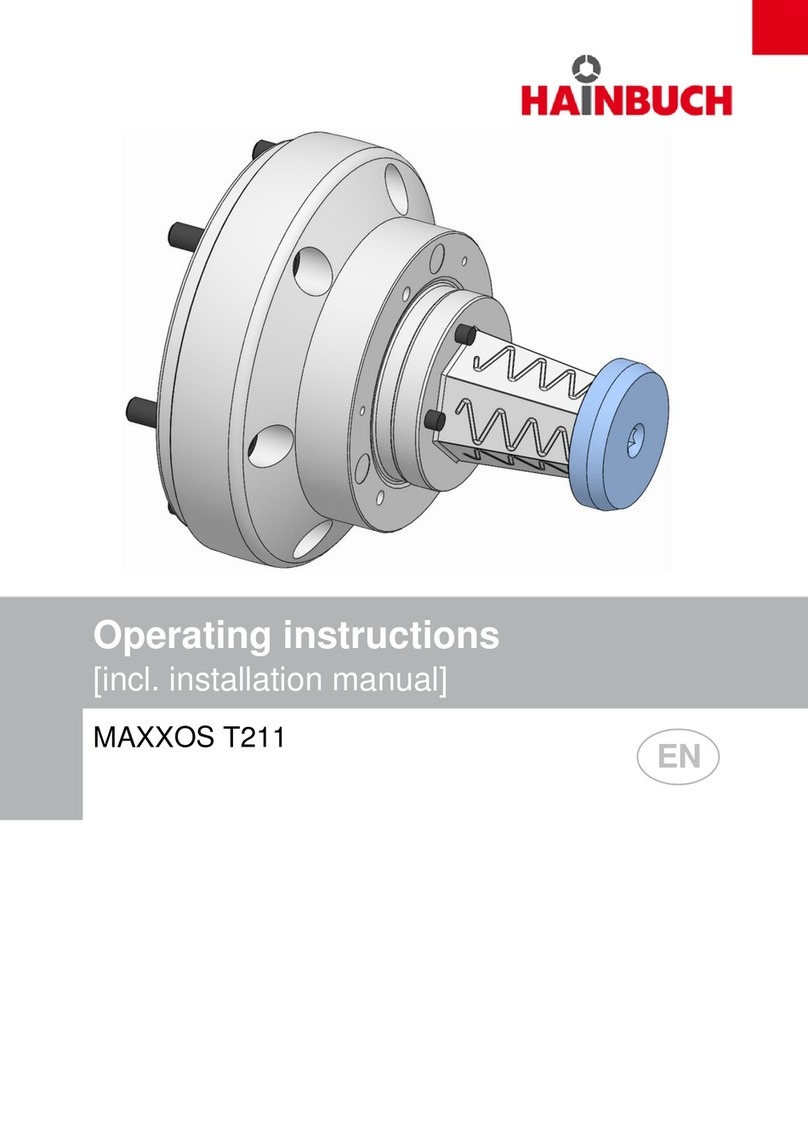

Configuration

No.

Part Name

1

Body

2

Union

3

Cap Nut

4

Valve Seat

5

Valve Seat Holder

6

Float

7

Float Guide

8

Snap Ring

9

Valve Seat Gasket

10

Union Gasket

11

Nameplate

172-65170MA-06 (VAS) 9 Jul 2015

6

Installation

DO NOT use for toxic, flammable or otherwise hazardous fluids.

This product is an air vent that discharges air from water piping system.

Use only for water and/or air. This product is for intended use only.

Improper use may result in such hazards as damage to the product or

malfunctions that may lead to serious accident.

WARNING

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Do not use excessive force when connecting threaded pipes to the

product. Over-tightening may cause breakage leading to fluid

discharge, which may cause burns or other injury.

CAUTION

Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

1. Before installation, be sure to remove all protective seals.

2. Before installing the product, open the inlet valve and blow out the piping to

remove any piping scraps, dirt and oil. Close the inlet valve after blowdown.

3. This product must be installed vertically, with the inlet at the bottom and the outlet

at the top, and should be inclined no more than 5° horizontally and front-to-back

(Figure 2).

4. Install the product in a location where air is likely to collect, such as a bend in the

piping.

5. Install the product so that the outlet pipe reaches a drainage vessel or ditch. Make

sure the end of the pipe is above the waterline, so that dirt and water can not be

sucked up by vacuum when the system shuts down (Figure 1).

6. Inlet piping with no horizontal portion is recommended for water/air displacement.

If there is a horizontal portion, make the pipe diameter of the horizontal portion

larger than the vertical portion or make the horizontal portion as short as possible.

7. Make sure the inlet piping diameter is at least as large as the product’s inlet diameter.

8. Installation of an isolation valve just before the product’s main connection is

recommended as it enables maintenance during operation. A full-bore ball valve is

recommended.

9. Make sure to take measures to prevent foreign matter from flowing into the product.

10.This is a rapid initial air vent for quickly venting large amounts of air at startup

only. If air venting is necessary during system operation, install an automatic air

vent as well.

If there is a problem, determine the cause using the “Troubleshooting” section in this manual.

Figure 1

Make sure the end

of the pipe is above

the waterline

Figure 2

Tolerance Angle for

Installation: - 5

172-65170MA-06 (VAS) 9 Jul 2015

7

Maintenance

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Be sure to use only the recommended components when repairing the

product, and NEVER attempt to modify the product in any way. Failure to

observe these precautions may result in damage to the product or burns

or other injury due to malfunction or the discharge of fluids.

CAUTION

Operational Check

A visual inspection of the following items should be done on a daily basis to

determine whether the air vent is operating properly or has failed.

If the air vent should fail, it may cause water leakage or hindrance to water flow.

Normal

:

Air is discharged as it accumulates, with the air vent

closing (with no leakage) when no air is present in the

piping.

B

locked

(Discharge Impossible) :

No air is discharged though air accumulates in the air

vent.

NOTE: Once the air vent closes, it will remain closed until internal pressure

drops to near or below atmospheric pressure. This condition may be

confused with a malfunction (blocked). If air is expected to accumulate

in the piping during operation, use together with an automatic air vent.

Leakage :

Water is discharged or leaks through the air vent outlet

during closed position.

Parts Inspection

When parts have been removed, or during periodic inspections, use the following

table to inspect the parts and replace any that are found to be defective.

Procedure

Gaskets: check for warping or scratches

Valve Seat Surface: check for scratches or wear

Float: check for scratches or dents

Float Guide: check for deformation

172-65170MA-06 (VAS) 9 Jul 2015

8

Disassembly/Reassembly

NEVER apply direct heat to the float. The float may explode due to

increased internal pressure, causing accidents leading to serious injury

or damage to property and equipment.

WARNING

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

Be sure to use only the recommended components when repairing the

product, and NEVER attempt to modify the product in any way. Failure to

observe these precautions may result in damage to the product or burns

or other injury due to malfunction or the discharge of fluids.

CAUTION

Disassembly/Reassembly

Use the following procedures to remove components. Use the same procedures in

reverse to reassemble. (Installation, inspection, maintenance, repairs, disassembly,

adjustment and valve opening/closing should be carried out only by trained

maintenance personnel.)

Part

During Disassembly

During Reassembly

Cap Nut

Remove with a wrench

Consult the table of tightening torques

and tighten to the proper torque

Union

Remove, being careful not to scratch

the gasket sealing surface

Make sure there are no pieces of the

old gasket left on the sealing surfaces

and reattach

Union

Gasket

Remove carefully, being careful not to

scratch the sealing surfaces

Replace with a new gasket if damaged;

make sure there are no pieces of the

old gasket left on the sealing surfaces

of the body

Valve Seat/

Valve Seat

Holder

Remove with a socket wrench

Replace with a new valve seat / valve

seat holder if misshapen or damaged

Consult the table of tightening torques

and tighten to the proper torque

Valve Seat

Gasket

Remove if damaged

Replace with a new gasket if damaged

Float

Remove, being careful not to scratch

the polished surface

Insert, being careful not to scratch or

misshape

Snap Ring

Remove with appropriate pliers

Insert securely into the groove

Float Guide

Remove without misshaping

Insert, being careful not to misshape

172-65170MA-06 (VAS) 9 Jul 2015

9

Table of Tightening Torques

VAS Size

Inlet / Outlet

mm (in)

Part Name Torque Distance Across Flats

N⋅m

(lbf·ft)

mm

(in)

20 (3/4) / 15 (1/2)

Cap Nut

50

(37)

55

(25/32)

Valve Seat Holder

20

(15)

17

(21/32)

40 (11/2) / 25 (1)

Cap Nut

80

(59)

75

(215/16)

Valve Seat Holder

35

(26)

27

(11/16)

(1 N⋅m ≈10 kg⋅cm)

NOTE: - Coat all threaded portions with anti-seize.

- If drawings or other special documentation were supplied for the product, any torque

given there takes precedence over values shown here.

Exploded View

Cap Nut

Union

Valve Seat Gasket

Valve Seat

(Valve Seat Holder)

Float

Snap Ring

Float Guide

Union Gasket

Body

172-65170MA-06 (VAS) 9 Jul 2015

10

Troubleshooting

NEVER apply direct heat to the float. The float may explode due to

increased internal pressure, causing accidents leading to serious injury

or damage to property and equipment.

WARNING

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

When the product fails to operate properly, use the following table to locate and

remedy the cause.

Problem

Cause

Remedy

No initial air is

discharged

(blocked)* or

discharge is

poor

The trapped air cannot displace the

water in the piping

Correct the inlet piping

The valve seat is clogged with dirt or

foreign matter

Clean the valve seat

The inlet or outlet piping is clogged

Clean the piping

Water leaks

when the vent is

closed

There is a build-up of rust or scale on

the valve seat or the valve seat is

damaged

Clean the valve seat or replace with a

new valve seat

The float is misshapen, dirty or has a

film build-up

Clean the float or replace with a

new float

The installation angle of inclination is

incorrect

Correct the installation

The vent does

not close, and

water is blowing

The float is damaged or filled with

water

Replace with a new float

The specific gravity of the liquid is

outside the specifications for this

product

(This product is for water system)

Select a product with suitable

specifications for the operating

conditions

* NOTE: Once the air vent closes, it will remain closed until internal pressure drops to near or

below atmospheric pressure. This condition may be confused with a malfunction

(blocked). If air is expected to accumulate in the piping during operation, use

together with an automatic air vent.

172-65170MA-06 (VAS) 9 Jul 2015

11

Product Warranty

1. Warranty Period

One year following product delivery.

2. Warranty Coverage

TLV CO., LTD. warrants this product to the original purchaser to be free

from defective materials and workmanship. Under this warranty, the

product will be repaired or replaced at our option, without charge for parts

or labor.

3. This product warranty will not apply to cosmetic defects, nor to any

product whose exterior has been damaged or defaced; nor does it apply in

the following cases:

1) Malfunctions due to improper installation, use, handling, etc., by other

than TLV CO., LTD. authorized service representatives.

2) Malfunctions due to dirt, scale, rust, etc.

3) Malfunctions due to improper disassembly and reassembly, or

inadequate inspection and maintenance by other than TLV CO., LTD.

authorized service representatives.

4) Malfunctions due to disasters or forces of nature.

5) Accidents or malfunctions due to any other cause beyond the control of

TLV CO., LTD.

4. Under no circumstances will TLV CO., LTD. be liable for consequential

economic loss damage or consequential damage to property.

* * * * * * *

For Service or Technical Assistance:

Contact your representative or your regional office.

Manufacturer

CO., LTD.

881 Nagasuna, Noguchi

Kakogawa, Hyogo 675-8511 JAPAN

Tel: 81-(0)79 - 427 - 1800

Table of contents

Other TLV Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

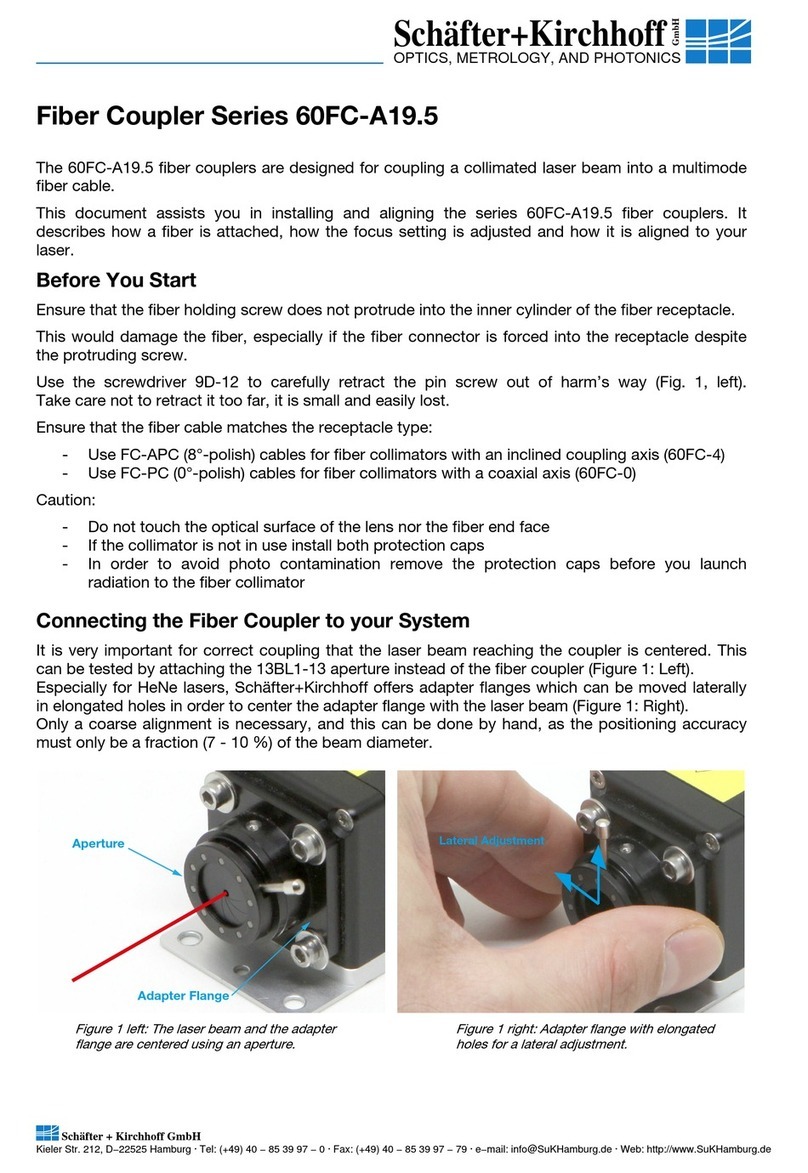

Schäfter+Kirchhoff

Schäfter+Kirchhoff 60FC-A19.5 Series quick start guide

SCHUNK

SCHUNK PFH 150 Assembly and operating manual

IBM

IBM BladeCenter HT 8740 Problem determination and service guide

Pilz

Pilz PSSu E S PD-D operating manual

Pilz

Pilz PSSu E F 2DOR 8 operating manual

ASCO Numatics

ASCO Numatics 453 Installation and maintenance instructions