www.tmgindustrial.com 2 / 22 TOLL FREE: 1-877-761-2819

CONTENTS

IMPORTANT SAFETY INFORMATION ............................................................................................................... 3

Safety always .............................................................................................................................................................................................3

Transport machinery safely.......................................................................................................................................................................4

Safety Labels..............................................................................................................................................................................................4

INTRODUCTION.................................................................................................................................................. 5

Using This Manual......................................................................................................................................................................................5

Terminology................................................................................................................................................................................................5

Owner Assistance ......................................................................................................................................................................................5

SECTION 1: ASSEMBLY AND SET-UP ............................................................................................................... 6

Tractor Requirements ................................................................................................................................................................................6

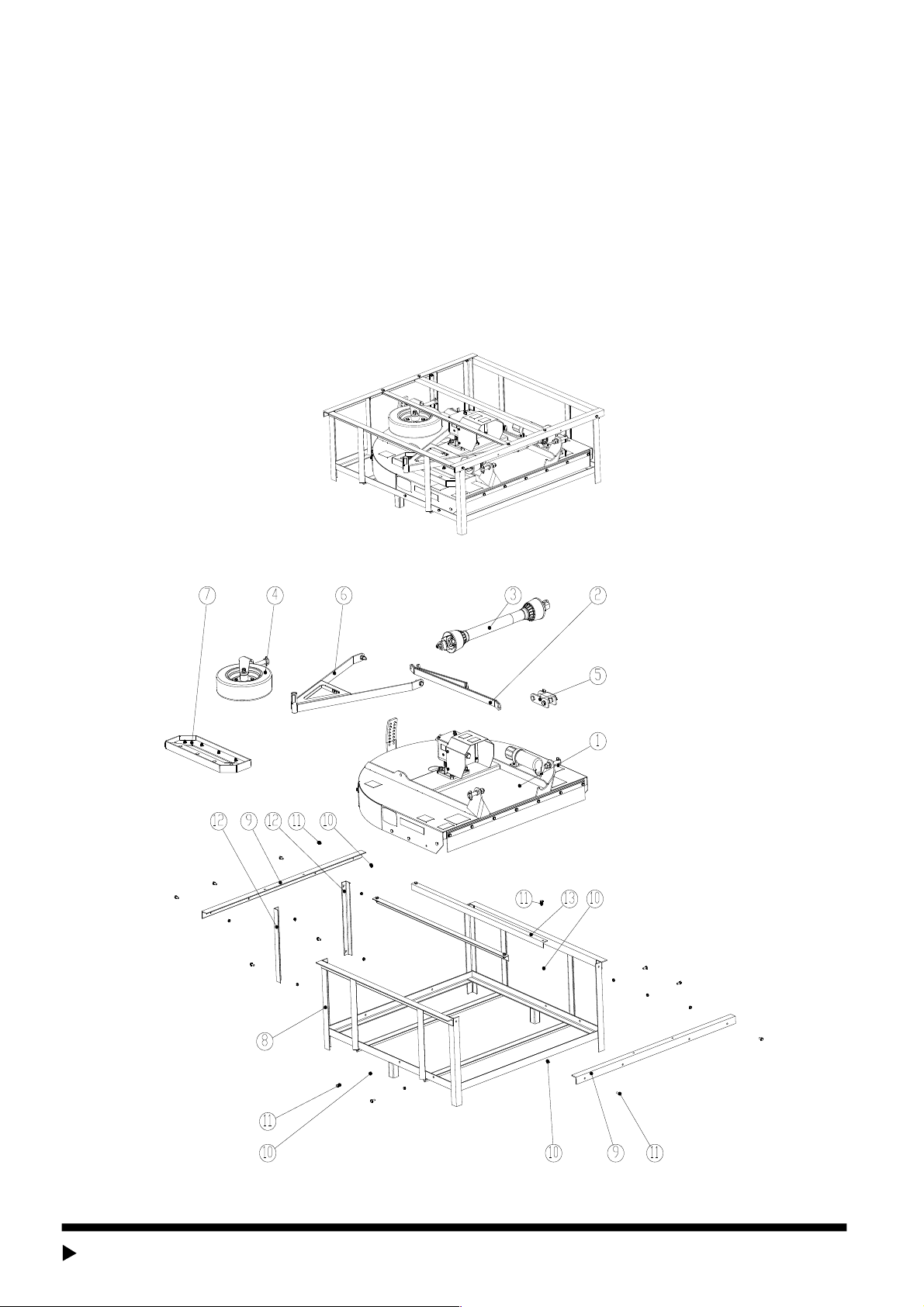

Packing Description...................................................................................................................................................................................6

Packing List ................................................................................................................................................................................................7

Installation Wizard .....................................................................................................................................................................................9

Tractor Hook-Up.......................................................................................................................................................................................12

Driveline Installation.................................................................................................................................................................................12

SECTION 2: OPERATING INSTRUCTIONS.......................................................................................................13

Transporting .............................................................................................................................................................................................13

Mowing Instructions ................................................................................................................................................................................13

Operating Instructions .............................................................................................................................................................................13

SECTION 3: ADJUSTMENTS............................................................................................................................14

Leveling the Rotary cutter........................................................................................................................................................................14

Cutting Height Adjustment......................................................................................................................................................................14

3-Point Hitch Adjustments ......................................................................................................................................................................14

Belt Tension..............................................................................................................................................................................................14

SECTION 4: MAINTENANCE AND LUBRICATION...........................................................................................14

Maintenance.............................................................................................................................................................................................14

Knife Replacement...................................................................................................................................................................................14

Storage......................................................................................................................................................................................................15

Lubrication................................................................................................................................................................................................15

SECTION 5: SPECIFICATIONS & CAPACITIES ................................................................................................15

SECTION 6: TROUBLESHOOTING....................................................................................................................16

SECTION 7: APPENDIX.....................................................................................................................................17

Warranty....................................................................................................................................................................................................17

Bolt Torque ...............................................................................................................................................................................................17

PART BREAKDOWN LIST .................................................................................................................................19