g000502

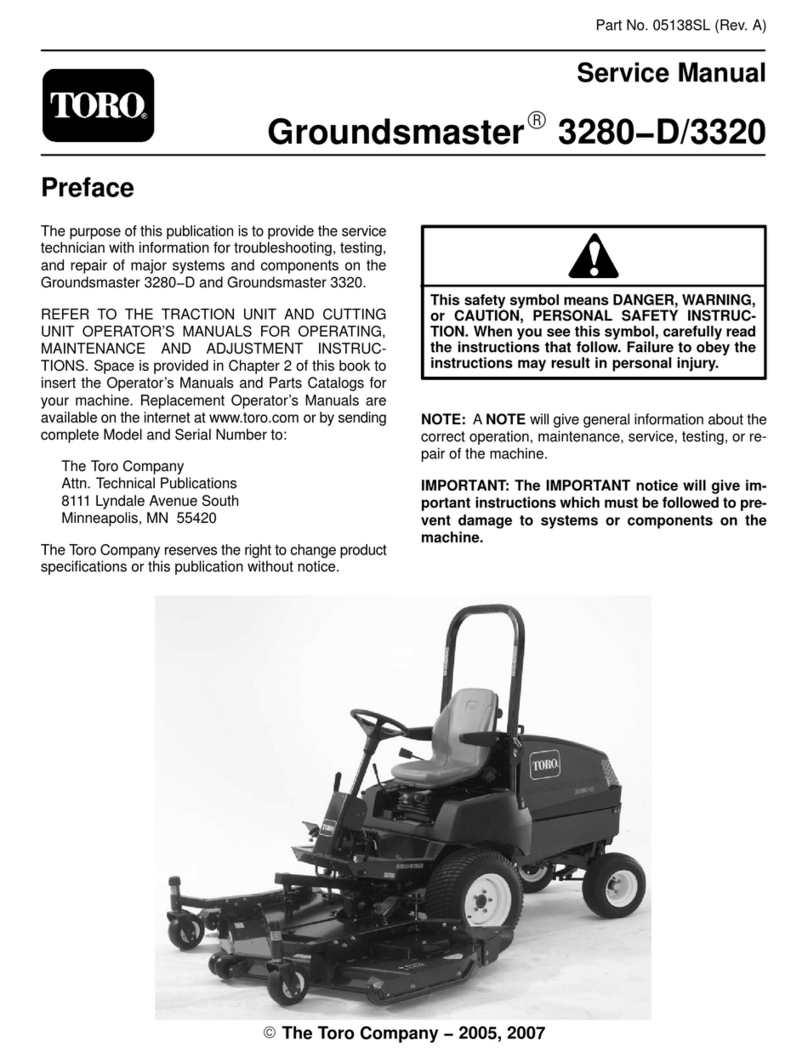

Figure3

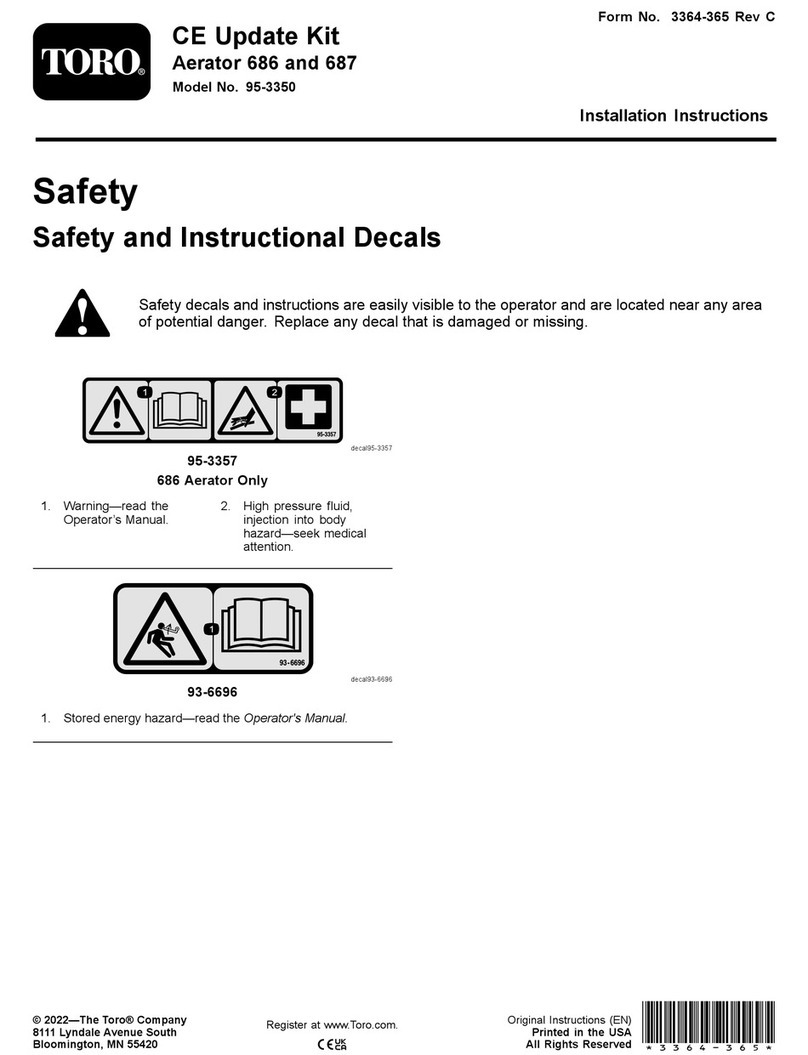

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................4

GeneralSafety...................................................4

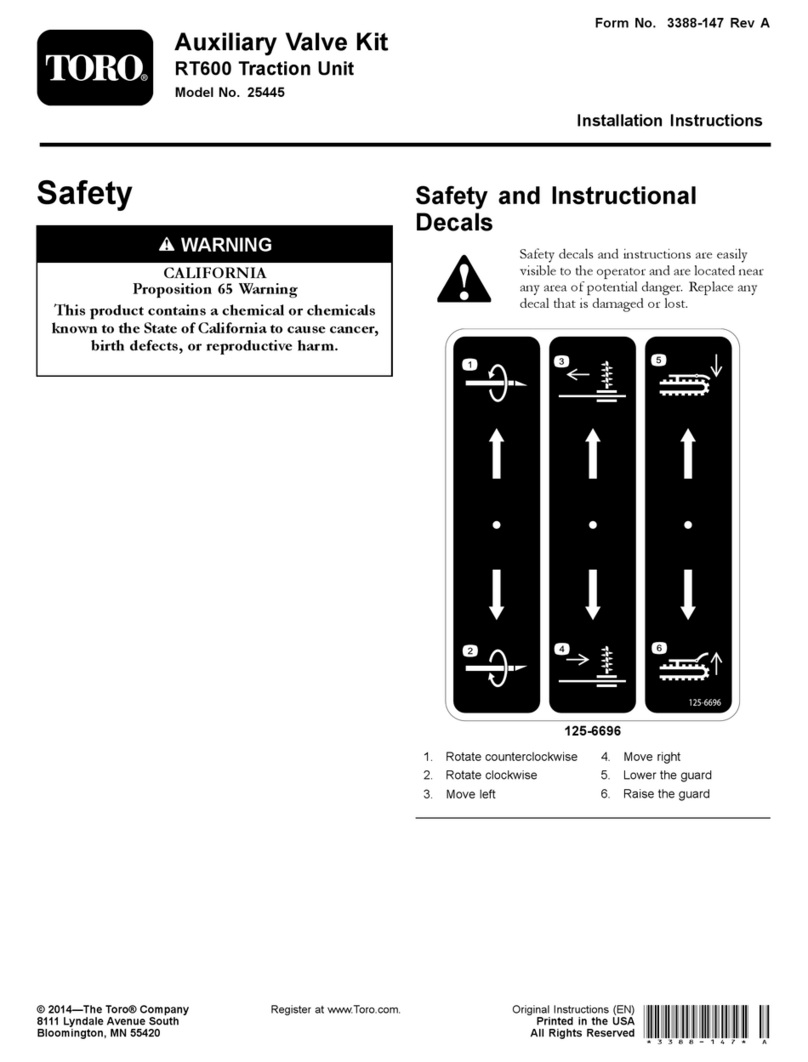

SafetyandInstructionalDecals..........................4

Setup........................................................................8

1InspectingtheMachine....................................9

2ConnectingtheLowerLinkArms......................9

3ConnectingtheUpperLink.............................10

4ConnectingthePTOShaft..............................11

5AdjustingtheSwayLinks...............................12

6LevelingtheAeratorSide-to-Side...................13

7AdjustingtheRollerScraper...........................13

8InstallingtheTineHeadsandthe

Tines.............................................................14

9InstallingtheTurfGuards...............................14

10SecuringtheHoodLatches(CE

only)..............................................................14

11RemovingtheStorageStands......................15

ProductOverview...................................................16

Controls...........................................................16

Specications..................................................16

Attachments/Accessories.................................16

BeforeOperation.................................................19

BeforeOperationSafety...................................19

OutCrossTractionUnitControls.......................19

AdjustingtheAerationDepth............................19

UnderstandingtheTractorControls..................20

UnderstandingthePrinciplesof

Operation......................................................20

PracticingtheOperatingProcedures................20

PreparingtoAerate..........................................21

DuringOperation.................................................21

DuringOperationSafety...................................21

OperatingtheMachine.....................................22

AdjustingtheHoleSpacing...............................23

AeratingHardGround.......................................24

UsingNeedleTines..........................................24

AvoidingRootZoneLifting................................24

AdjustingtheRotalinkAssembly.......................24

OperatingTips.................................................25

AfterOperation....................................................25

AfterOperationSafety......................................25

TransportingtheMachine.................................25

CleaningtheMachineafterUse........................25

Maintenance...........................................................26

RecommendedMaintenanceSchedule(s)...........26

MaintenanceSafety..........................................26

JackingtheMachine.........................................27

GreasingtheBearingsandBushings................27

CheckingtheGearboxLubrication....................28

ChangingtheGearboxLubrication...................28

CheckingtheCoringHeadFastener

Torque...........................................................29

InspectingtheBelts..........................................29

AdjustingtheBeltTension.................................29

ReplacingtheDriveBelt...................................30

AdjustingtheSideShield..................................31

ReplacingtheTurfGuards................................31

CoringHeadTiming..........................................32

RemovingtheAeratorfromtheTractor.............32

Storage...................................................................34

StorageSafety..................................................34

StoringtheMachine..........................................34

3