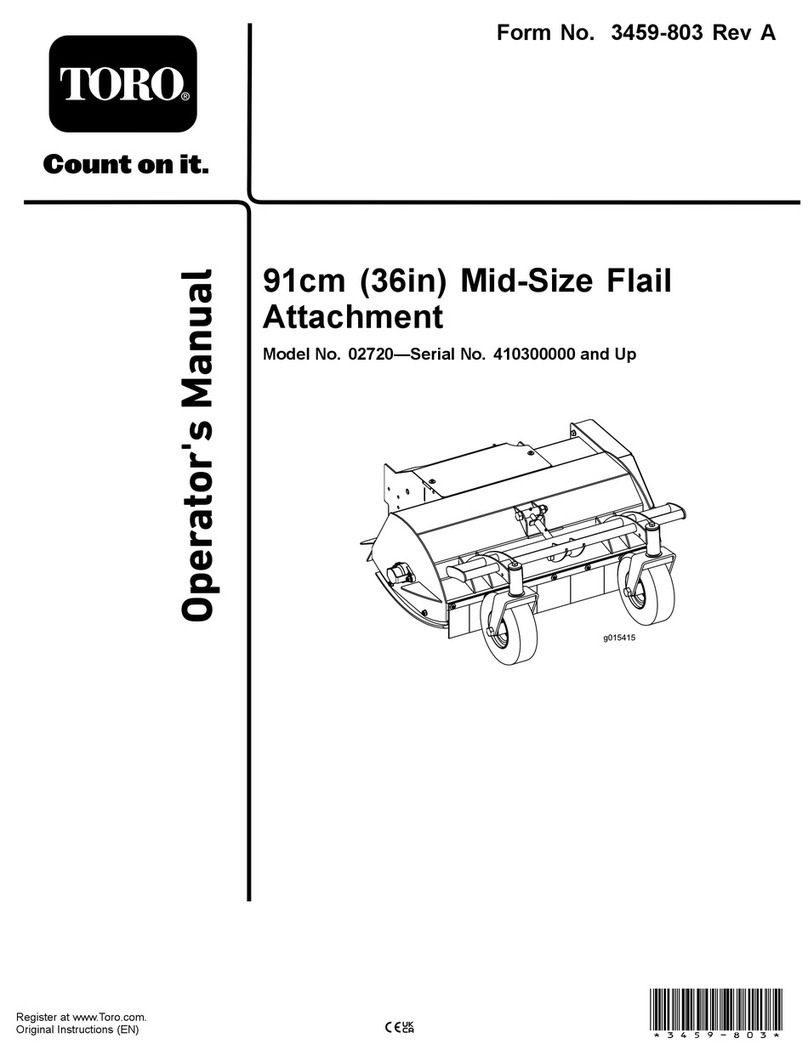

Type: Semi-mounted tow-behind, PTO-driven, deep coring

mechanical turf/fairway aerator.

Tractor Requirements: 18.6–33.6 KW (25–45 hp) @ 540

PTO rpm, category 1, three-point hitch with snubber chains

to restrain side movement and a hydraulic system with

“Lift” and “Float” control provisions. The tractor should

also have provisions for a hydraulic control valve and sys-

tem pressure relief valve to operate two remote single acting

hydraulic cylinders. System pressure should be between

6,895–13,790 kPA (1000 p.s.i. and 2000 p.s.i.)

The hydraulic cylinders, hoses and quick connection coupler

are supplied with aerator. The aerator attaches directly to

the tow tractor. Therefore, read your tractor operators manu-

al or contact the tractor service agency regarding installation

for power take-off driven, semi-mounted implements.

Tractor Attachment: Two pins are provided provided for

attaching the lower links of the tractor, and three-point

hitch to the aerator . Clamps are provided for rigid mount-

ing. The upper link of the hitch is not used or required. The

tractor hydraulic system provides the power to raise the aer-

ator for transport, and provides the “Float” control so the

aerator will follow the ground contour. A rack- and- pinion

gear, along with a screw-adjustable link maintain attitude

control for the aerator. Two caster wheels, out board from

the aerator, partially support the weight of the unit. The

remaining weight is transferred to the tractor.

Speed: 2.9–3.5 kmh (1.8 to 2.2 mph)—Aerating. 24 kmh

(15 mph) maximum—Transport. Transport speed should

vary with tractor and terrain.

Maximum PTO Speed: 540 rpm, 1-3⁄8” six-spline drive

shaft.

Maximum Top Crankshaft Speed: 400 rpm.

Frame Construction: Welded tubular and structural steel.

Coring Head Construction: Welded structural steel bar

and plate.

Tires: 16.5 x 6.5-8 ,6 ply, two wheels mounted on caster

forks, out board of frame.

7

Specifications

Tire Scrapers: Removes soil build up from each

wheel. Adjustable for desired clearance.

Drive Line: Ag-type, telescoping drive shaft with safe-

ty shields. Two cardan-type universal joints with ratch-

et type torque limiting clutch. Quick-lock, toolless cou-

pling, provided at both ends. Grease fittings for lubri-

cation.

Gear Power Train: Spur gear type gear box with pro-

visions for selecting the correct gear ratio to time the

aerator’s operating speed with the ground speed of the

tractor. Two timing gears are required (not included)

and must be selected for each individual application.

Drive line drivesare completely sealed. All compo-

nents operate in oil with anti-friction bearing provided.

Right angle gear box with two output shafts, coupled

and driven from the gear box. Gear box is fully sealed

with all components operating in oil. Hardened and

tempered bevel gears with anti-friction bearings.

Two integral gear boxes within the aerator frame drive

the flywheel and plungers for the coring tines. Gear

boxes are fully sealed with anti-friction bearings and

hardened and tempered spur gears operating in oil.

These gear boxes are coupled and driven from the right

angle gear box previously listed.

Lubrication: All gear boxes are filled at the factory

with SAE 80w/90 multi-viscosity gear oil. Each gear

case has provisions for checking oil level and drain

plugs for servicing its components. A breather is pro-

vided to prevent excess pressure for each gear case.

Grease fitting are provided to lubricate bearings and

suspension components.

Hydraulic System: Two, single-acting hydraulic

cylinders provide operation for raising and lowering the

aerator. Hydraulic hoses with quick coupler fittings

attach to the tractor hydraulic system.

Plungers: Fabricated structural steel tubing, coupled to

two flywheel crankshafts to provide controlled entrance

and exit of the coring tines into the turf grass. Anti-

friction bearings provided. The standard tine holder

has provisions for six tines and a optional tine holder