capturedinthelanyardsonthedrivepulleyguard

(Figure8).

18.Adjustthecasterpositionandthebladeheightto

thecorrectheightofcutreferringtotheAdjusting

theHeightofCutsectionintheOperator’sManual.

Installthedeckcoverandsecureitwiththeremoved

fasteners.

19.Ifthehydraulicpumpby-passvalvewasopenedso

thepowerunitcouldbepushed,closetheby-pass

valves,butdonotovertighten.Checkallfasteners

arecorrectlytightenedandalluidlevelsareat

thecorrectlevel.Starttheenginereferringtothe

StartingandStoppingsectionintheOperator’sManual

andchecktheoperationofallcontrols,referringto

theOperator’sManual.

20.Collectallpartsanddocumentationbacktogetherfor

thecustomer.Filloutthewarrantyandpre-delivery

inspectiondocumentation.

Note:Awarrantyregistrationcardneedstobe

completed,bothforthepowerunitandthedeck.

2

SettingtheIdleSpeed

NoPartsRequired

Procedure

InordertoensurecompliancewiththeEUNoise

Directive,thedealerisrequiredtoverifythecorrect

enginespeed2900RPMwhenthepowerunitis

connectedtomodels02710and02711and3500RPM

whenthepowerunitisconnectedtomodel02712.

2900/3500RPMistheunloadedenginerpm,adjust

withthePTOOff(Disengaged).Toleranceisplus0

rpm,minus50rpm.Theengineshouldbewarm;run

theenginefor15minutesbeforeadjusting.Double

checkthenalenginespeedaftersettingsaremadeand

tightened.

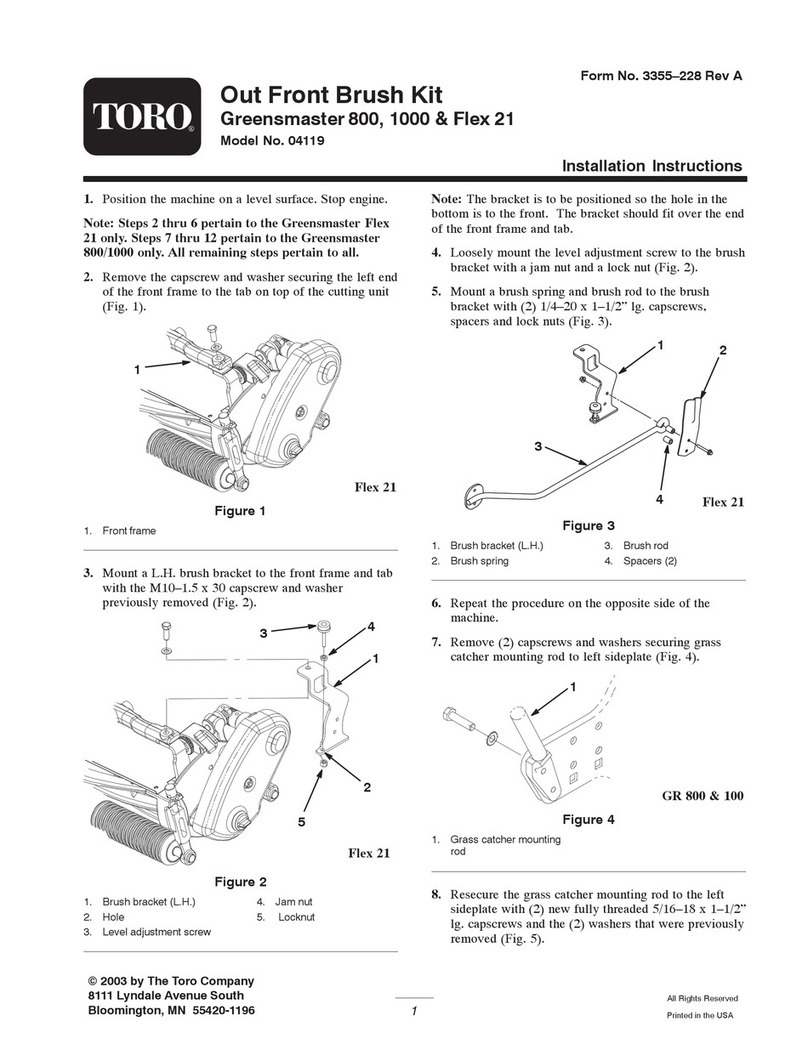

1.1.Loosenthelocknutandunscrewthehighidle

screwafewturns.Whensettingtheenginerpmon

powerunitsconnectedtomodels02710and02711,

replacethehighidlescrewwiththehighidleM5x

50screwsuppliedwith02710and02711(Figure9).

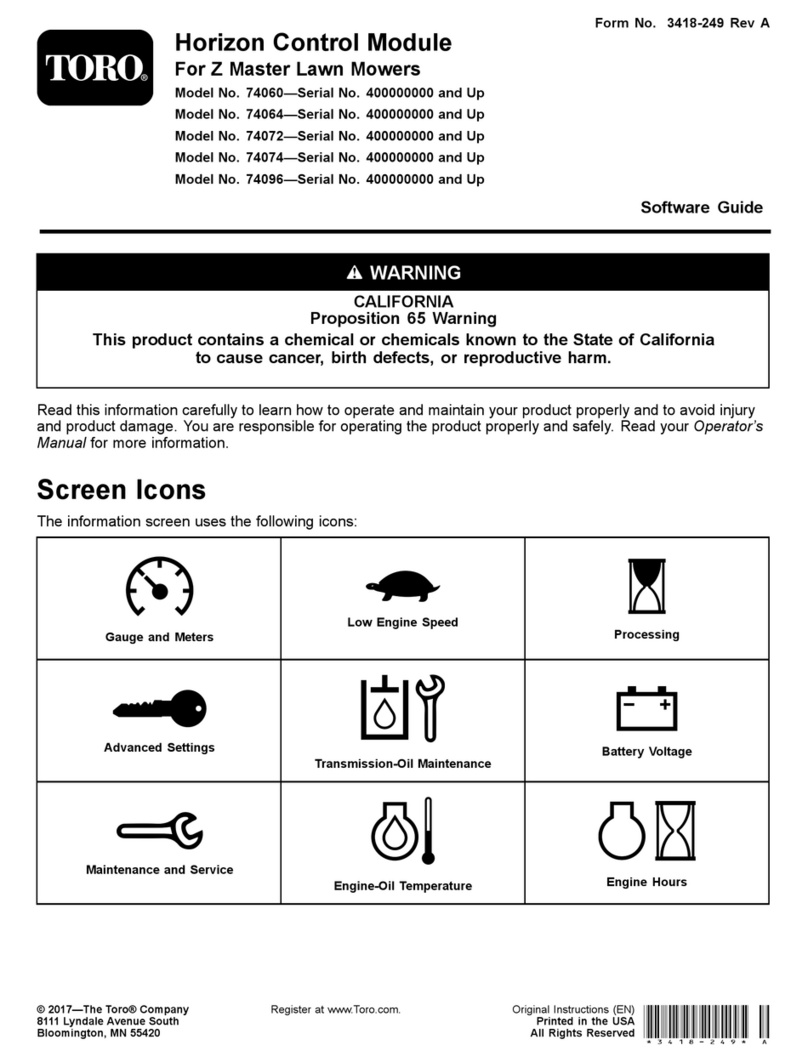

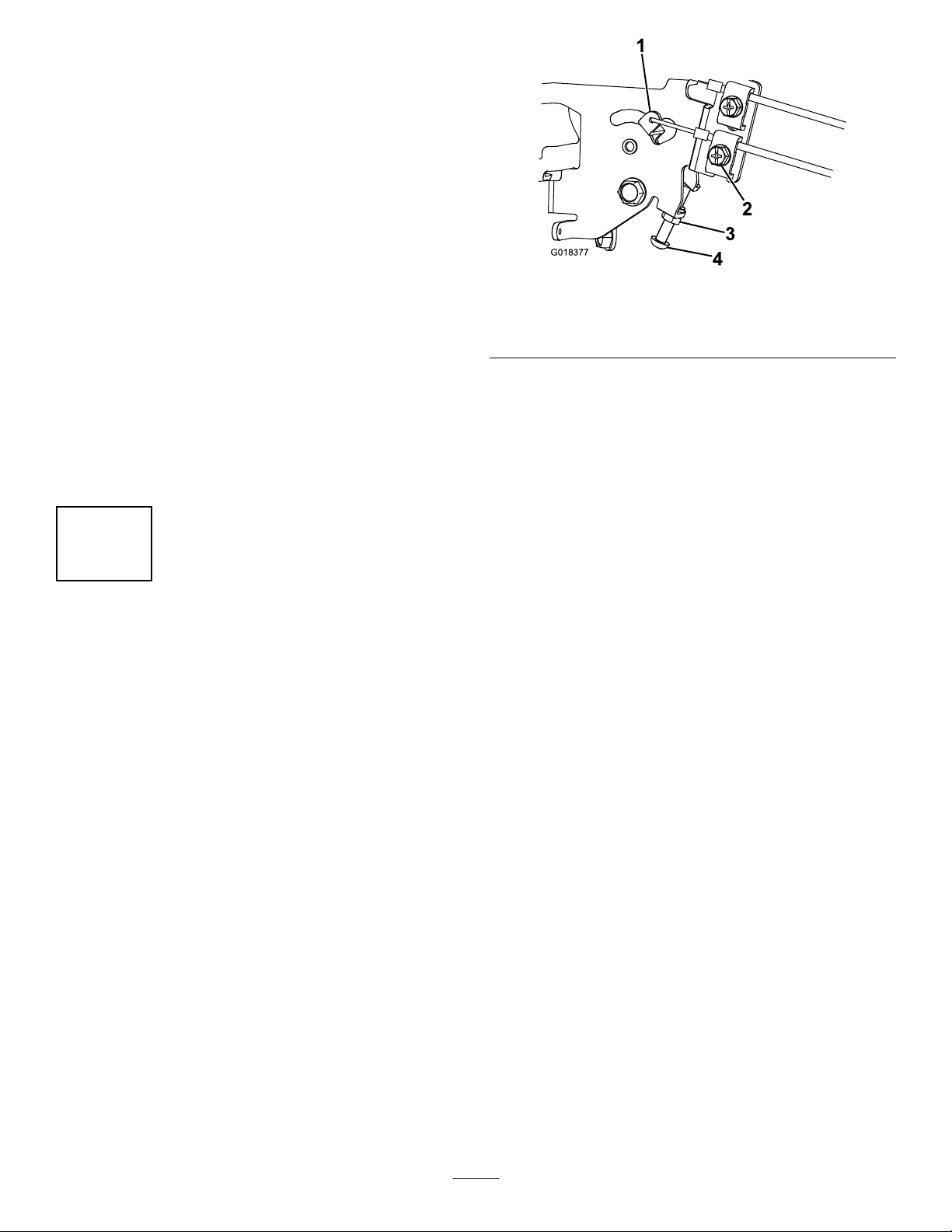

Figure9

1.Speedcontrollever3.Locknut

2.Cablescrew4.Highidlescrew

2.Movethethrottlelever,ontheoperatorcontrol

panel,toobtainthedesiredenginerpm.

3.Turnthehighidlescrewsothattheendofitjust

touchesthespeedcontrollever,andtightenthelock

nut(Figure9).

4.Checkthehighidlespeedandrepeatthisprocedure

ifnecessary.

5.Loosenthecablescrewandadjustthecablelength

sothatthethrottleleverontheoperatorcontrol

panelissettofullthrottlewhenthespeedcontrol

levertouchesthepreviouslysethighidlescrew .

6.Tightenthecablescrew .

4