Contents

Safety...........................................................................3

SafeOperatingPractices...........................................3

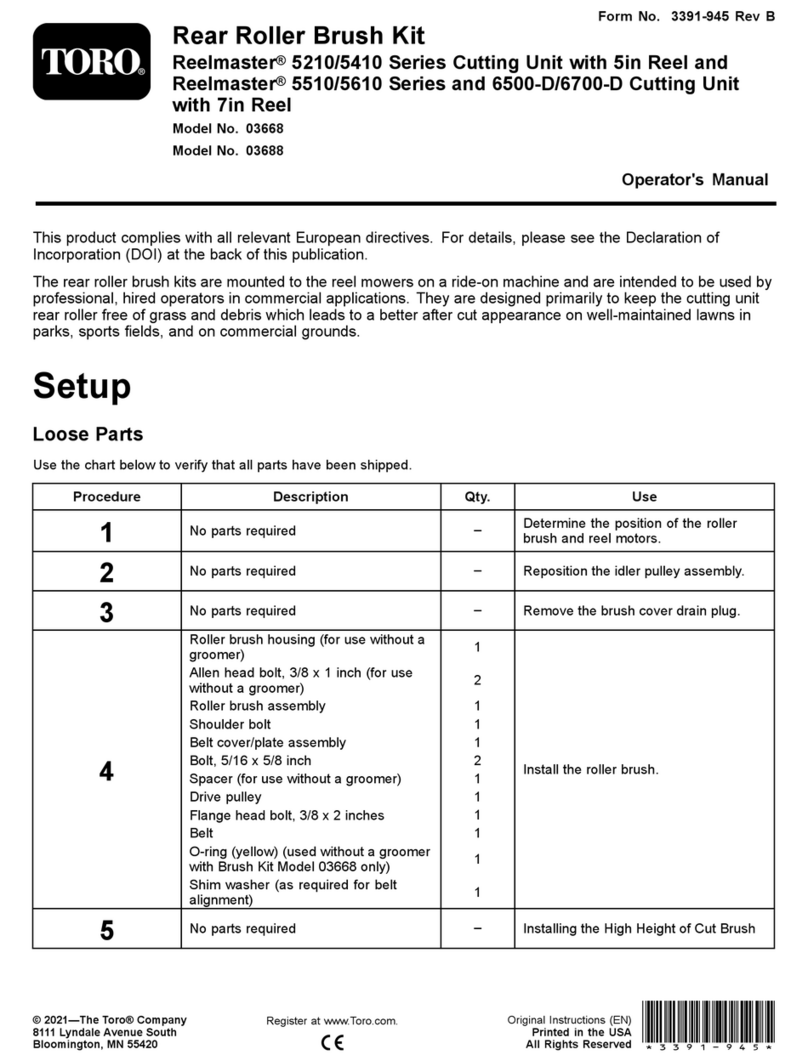

Setup............................................................................5

ToolsRequiredforSetup..........................................5

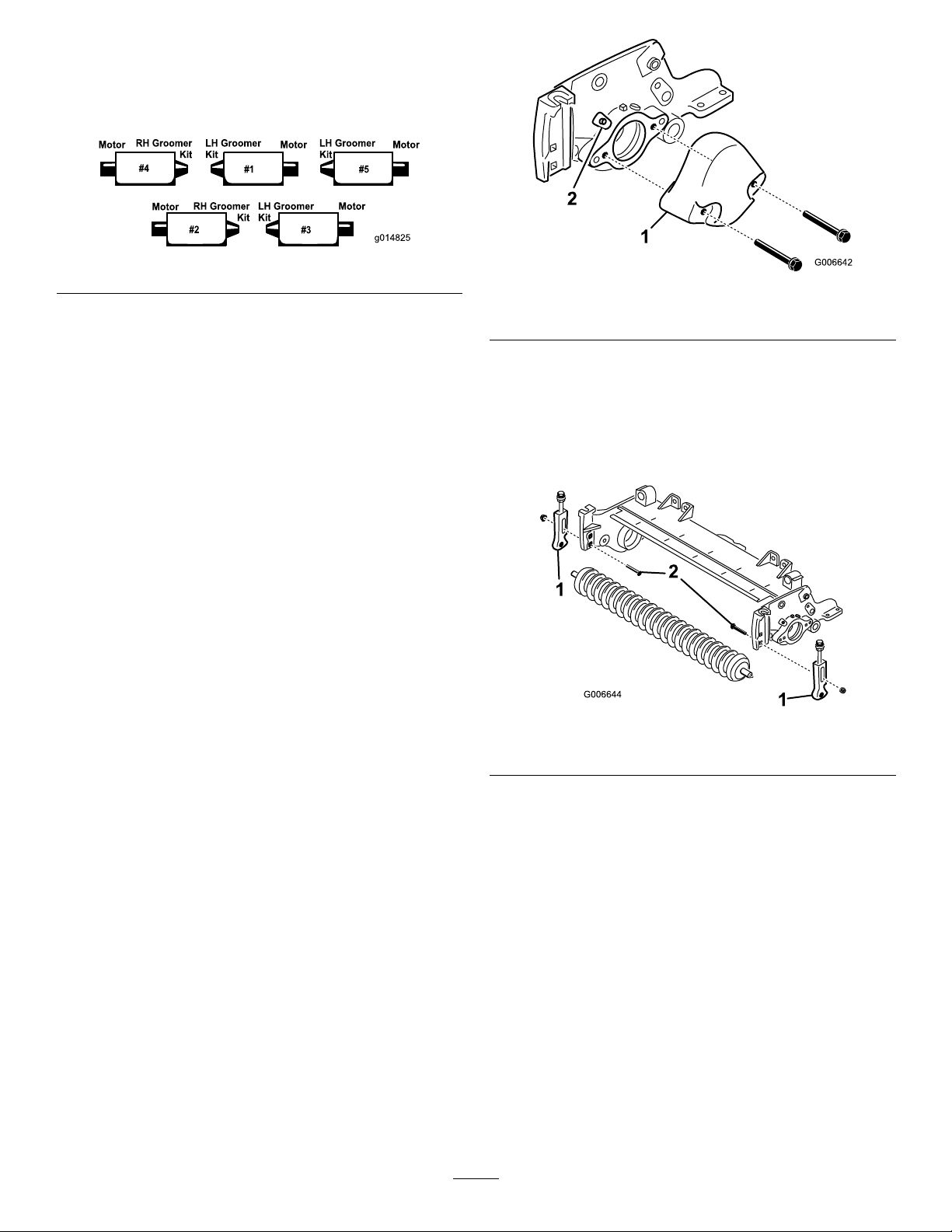

InstallingtheGroomer.............................................6

InstallingtheBroomerKit(optional).........................17

Operation....................................................................18

AdjustingtheGroomerHeight.................................18

TestingtheGroomerPerformance............................20

Maintenance.................................................................21

Cleaning................................................................21

Lubrication............................................................21

InspectingtheBlades..............................................21

GroomerPulley/BeltAlignment..............................21

GroomerBindingTroubleshooting...........................22

Safety

ThismachinehasbeendesignedinaccordancewithENISO

5395:2013.

SafeOperatingPractices

•Read,understand,andfollowallinstructionsinthe

tractionunitandcuttingunitoperatormanualsbefore

operatingthegroomer.

•Read,understand,andfollowallinstructionsinthis

operator’smanualbeforeoperatingthegroomer.

•Neverallowchildrentooperatethecuttingunits.Do

notallowadultstooperatetractionunitorcuttingunits

withoutproperinstruction.Onlytrainedoperatorswho

havereadthismanualshouldoperatethecuttingunits.

•Neveroperatethecuttingunitswhenundertheinuence

ofdrugsoralcohol.

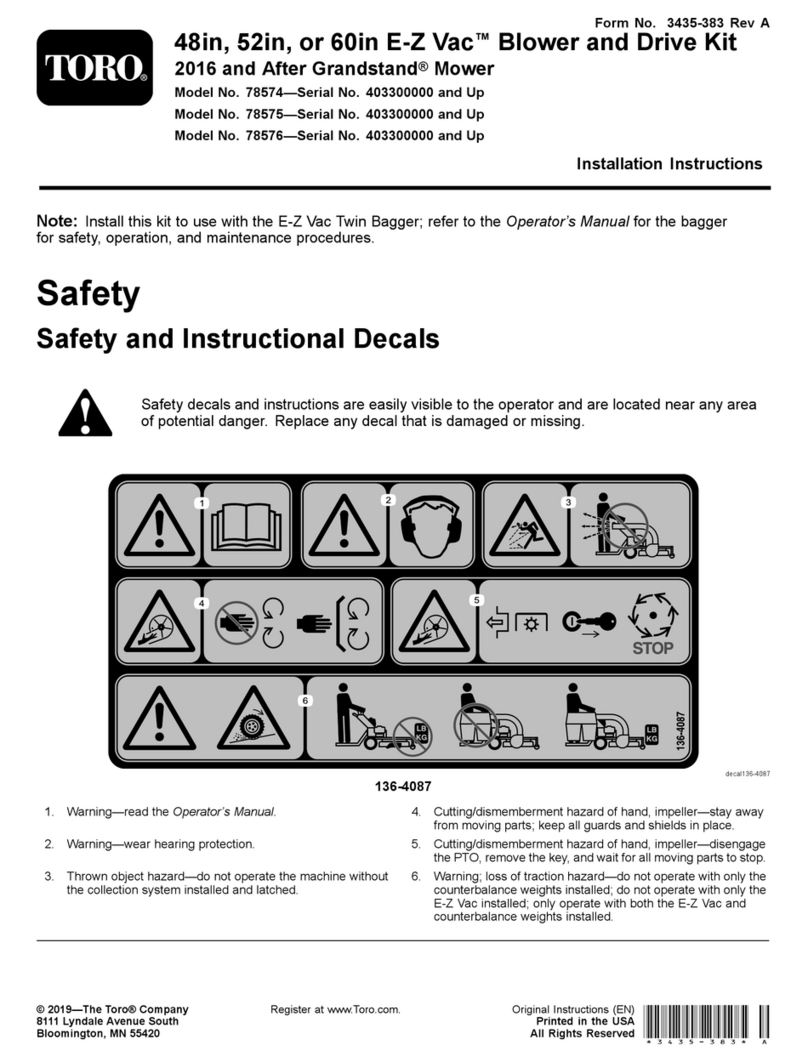

•Keepallshieldsandsafetydevicesinplace.Ifashield,

safetydeviceordecalisillegibleordamaged,repairor

replaceitbeforeoperationiscommenced.Alsotighten

anyloosenuts,bolts,andscrewstoensurecuttingunitis

insafeoperatingcondition.

•Alwayswearsubstantial,slip-resistantfootwear.Donot

operatecuttingunitwhilewearingsandals,tennisshoes,

sneakersorshorts.Also,donotwearloosettingclothing

whichcouldgetcaughtinmovingparts.Alwayswear

longpantsandsubstantialshoes.Wearingsafetyglasses,

safetyshoesandahelmetisadvisableandrequiredby

somelocalordinancesandinsuranceregulations.

•Removealldebrisorotherobjectsthatmightbepicked

upandthrownbythecuttingunitblades.Keepall

bystandersawayfromthemowingarea.

•Ifthebladesstrikeasolidobjectorthecuttingunit

vibratesabnormally,stopandshuttheengineoff.Check

cuttingunitfordamagedparts.Repairanydamagebefore

restartingandoperatingthecuttingunit.

•Lowerthecuttingunitstothegroundandremovekey

fromignitionswitchwhenevermachineisleftunattended.

•Besurecuttingunitsandgroomersareinsafeoperating

conditionbykeepingnuts,boltsandscrewstight.

•Removekeyfromignitionswitchtopreventaccidental

startingoftheenginewhenservicing,adjustingorstoring

themachine.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Performonlythosemaintenanceinstructionsdescribedin

thismanual.Ifmajorrepairsareeverneededorassistance

isdesired,contactanAuthorizedToroDistributor.

•Toensureoptimumperformanceandsafety,always

purchasegenuineTororeplacementpartsandaccessories

tokeeptheToroallToro.Neveruse“will-t”

replacementpartsandaccessoriesmadebyother

manufacturers.LookfortheTorologotoassure

3