Safety

Thismachinehasbeendesignedinaccordancewith

ENISO5395:2013andANSIB71.4-2012.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepclearofanydischargeopening.Keep

bystandersandpetsasafedistanceawayfrom

themachine.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Parkthemachineonalevelsurface,lowerthe

cuttingunits,disengagethedrives,engagethe

parkingbrake(ifprovided),shutofftheengine,

andremovethekeybeforeleavingtheoperator's

positionforanyreason.

Improperlyusingormaintainingthismachinecan

resultininjury.T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol,whichmeans

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthisOperator’sManual.

SafeOperatingPractices

•ReadtheOperator’sManualforthetractionunit

andothertrainingmaterialcarefully.Befamiliar

withthecontrols,safetysigns,andtheproper

useoftheequipment.Iftheoperatorormechanic

cannotreadthelanguageofthismanual,itisthe

owner'sresponsibilitytoexplainthismaterialto

them.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includingeye

protection;substantial,slip-resistantfootwear;

longpants,andhearingprotection.Tiebacklong

hairanddonotwearloosejewelry.

•Inspecttheareawheretheequipmentistobe

usedandremoveallobjects,suchasrocks,toys,

andwire,thatthemachinecanthrow.

•Checkthatoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

•Stopthemachine,removethekey,andwaitfor

allmovingpartstostopbeforeinspectingthe

attachmentafterstrikinganobjectorifthereis

anabnormalvibrationinthemachine.Makeall

necessaryrepairsbeforeresumingoperation.

•Keepyourhandsandfeetawayfromthecutting

units.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Awornordamagedbladecanbreak,anda

pieceofthebladecouldbethrowntowardyouor

bystanders,resultinginseriouspersonalinjuryor

death.

•Inspectthebladeperiodicallyforwearordamage.

•Usecarewhencheckingtheblades.Wrapthe

bladesorweargloves,andusecautionwhen

servicingtheblades.Onlyreplaceorsharpenthe

blades;neverstraightenorweldthem.

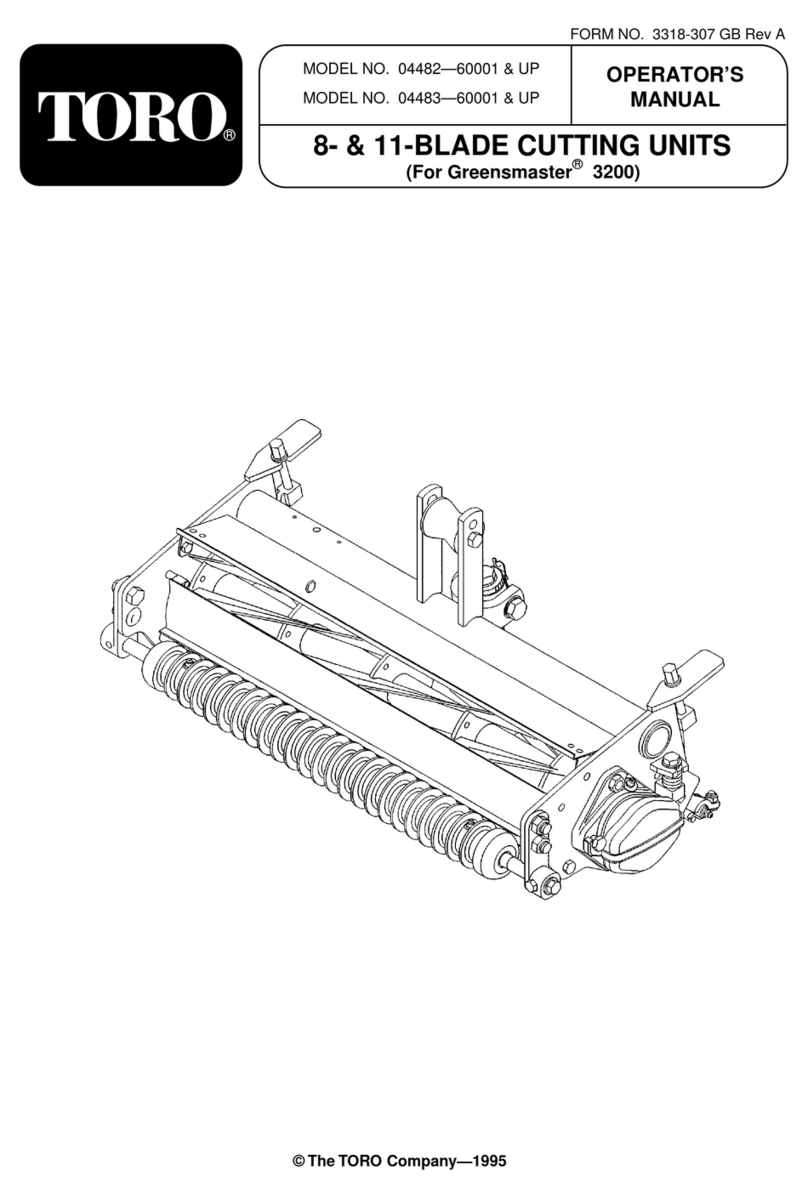

•Onmulti-bladedmachines,takecareasrotating1

bladecancauseotherbladestorotate.

3