FormNo.3403-794RevB

PivotingHoseReelKit

2015andAfterMulti-Pro5800TurfSprayer

ModelNo.41621—SerialNo.316000001andUp

Operator'sManual

Introduction

Readthismanualcarefullytolearnhowtooperate

andmaintainyourproductproperly.Theinformation

inthismanualcanhelpyouandothersavoidinjury

andproductdamage.AlthoughTorodesignsand

producessafeproducts,youareresponsiblefor

operatingtheproductproperlyandsafely.

YoumaycontactT orodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

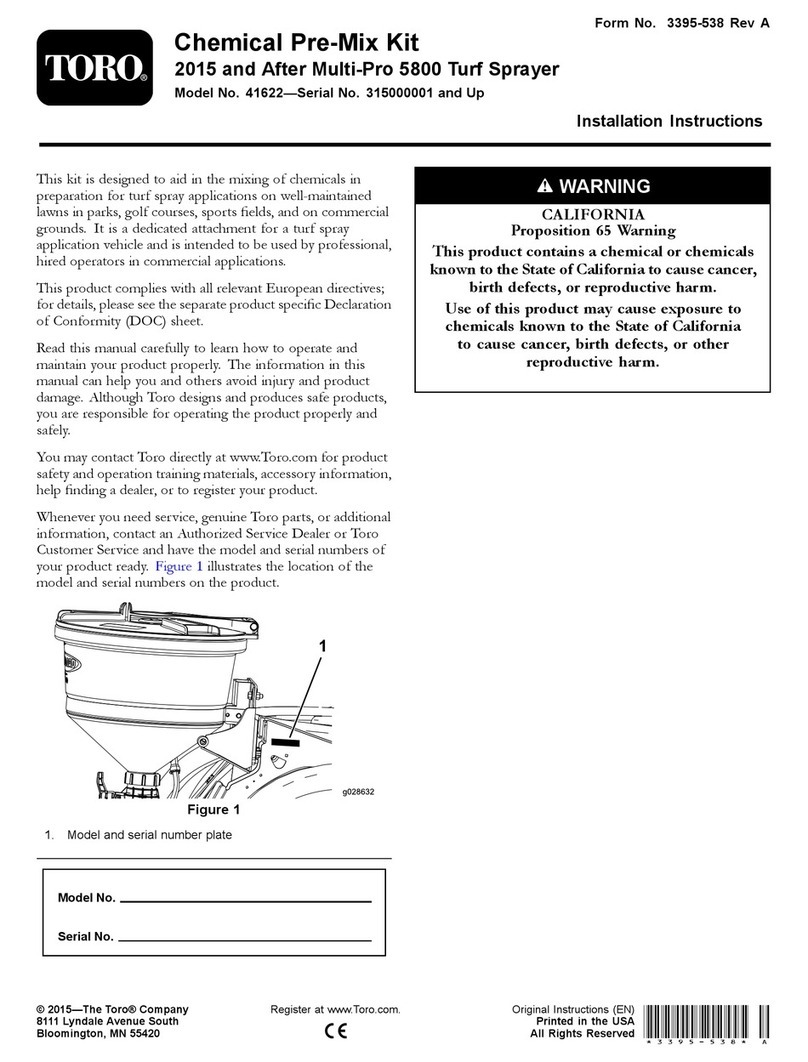

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

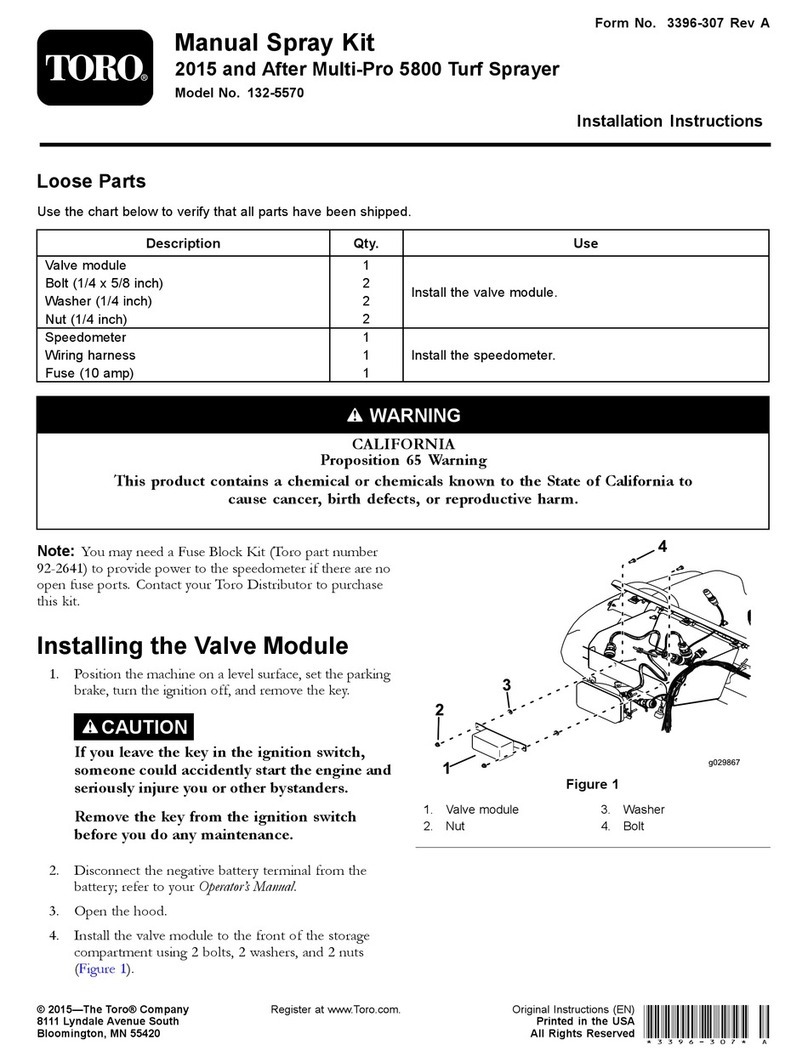

andserialnumbersofyourproductready.Figure1

illustratesthelocationofthemodelandserialnumbers

ontheproduct.

g028037

Figure1

1.Modelandserialnumberplate

ModelNo.

SerialNo.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Note:Thisproductcomplieswithallrelevant

Europeandirectives.Fordetails,pleaseseethe

DeclarationofIncorporation(DOI)atthebackofthis

publication.

Determinetheleftandrightsidesofthemachinefrom

thenormaloperatingposition.

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructions

andalwayspayattentiontothesafety-alert

symbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

Readalsothesafetyandoperationinstructionsinthe

vehicleOperator'sManual.

•Donotaimthehandsprayeratanypersonor

animal.Fluidsunderhighpressurecanpenetrate

skinandcausesevereinjury,possiblyresultingin

amputationordeath.Hotliquidsandchemicals

canalsocauseburnsorinjury.Ifanypartofthe

bodycomesincontactwiththespraystream,

immediatelyconsultaphysicianfamiliarwith

injecteduidinjuries.

•Donotplaceyourhandoranyotherpartofyour

bodyinfrontofthespraynozzle.

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved*3403-794*B