Thisattachmentcontrolsthesprayfunctionsofaturf

sprayerbasedoncalculationfromuserinputandis

intendedtobeusedbyprofessional,hiredoperatorsin

commercialapplications.Itisprimarilydesignedfor

sprayinggolfcourseapplications,parks,sportselds,

andoncommercialgrounds.Itisdesignedtoonlybe

usedinconjunctionwithmachinesdesignatedbythe

manufacturer.

ThisproductcomplieswithallrelevantEuropean

directives,fordetailspleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

Introduction

Readthismanualcarefullytolearnhowtooperateand

maintainyourproductproperly.Theinformationinthis

manualcanhelpyouandothersavoidinjuryandproduct

damage.AlthoughTorodesignsandproducessafe

products,youareresponsibleforoperatingtheproduct

properlyandsafely.YoumaycontactTorodirectlyat

www.Toro.comforproductandaccessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

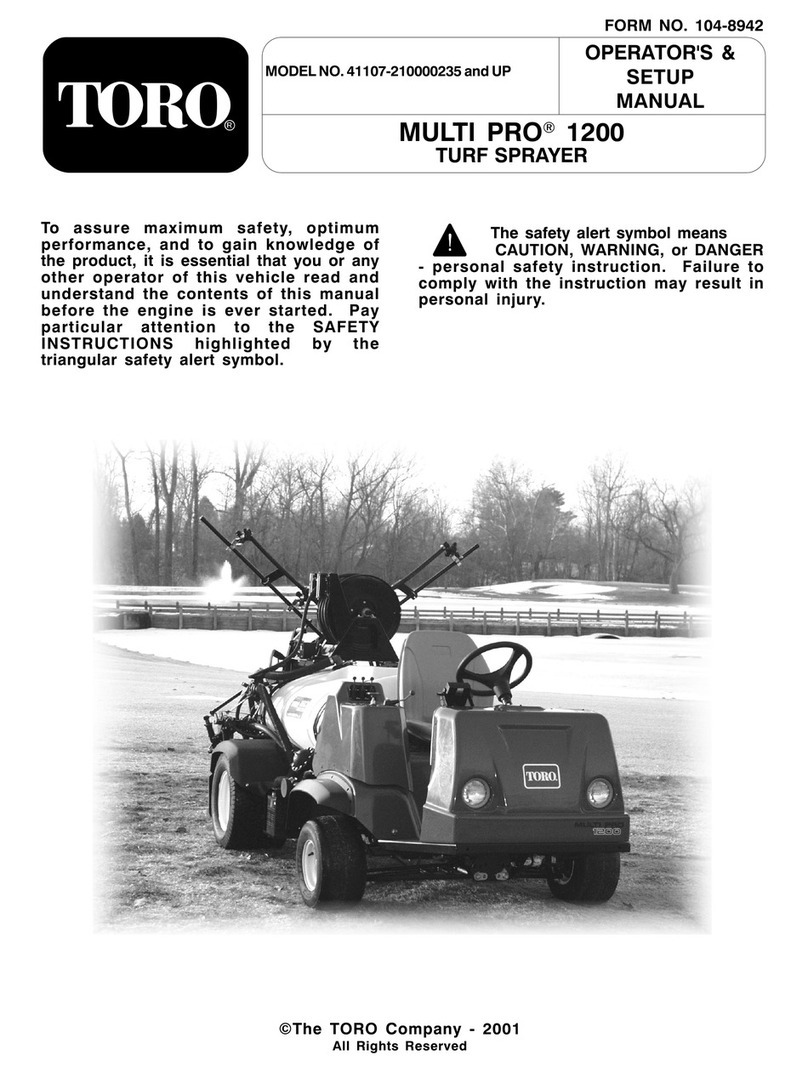

andserialnumbersofyourproductready.Figure1

illustratesthelocationofthemodelandserialnumbers

ontheproduct.

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizesgeneral

informationworthyofspecialattention.

Contents

Introduction.................................................................2

Safety...........................................................................3

Setup............................................................................4

InstallingtheProControlForModelYear2009

andOlderonly..................................................5

InstallingtheProControlForModelYear2010

andNeweronly.................................................6

ProductOverview........................................................9

Controls...............................................................9

Operation...................................................................11

InitiallyProgrammingtheConsole

Computer.......................................................11

ProgrammingtheConsoleComputer..................12

Self-TestingtheConsoleComputer.....................14

ActivatingtheDataLock....................................14

ChangingtheDataLock.....................................14

EnteringtheModeSequencewiththeData

LockActivated...............................................15

SettingthePowerDownDelayTime...................15

UsingtheConsoleComputerAlarm...................15

SettingtheLowLimitFlowSetPointandLow

LimitAlarm...................................................15

SettingUptheSystem.........................................15

InitiallyField-testingtheSystem..........................16

Maintenance...............................................................17

RecommendedMaintenanceSchedule(s)................17

CleaningtheFlowmeter......................................17

CalibratingtheFlowmeter..................................17

TestingtheFlowmeterCable...............................18

Troubleshooting.........................................................19

©2010—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA.

AllRightsReserved