WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

TheGeoLink®PrecisionSpraySystemautomatically

controlsthesprayapplicationrateandthespraying

area.Thesystemmonitorstheareasprayed,the

speedofthevehicle,andthetotalvolumeofmaterial

sprayed.Yousetthetargetvolumeperunitareato

sprayandthespraysystemautomaticallymaintains

theowwithintheproperrangeofthevehiclespeed

andcontinuallydisplaystheactualvolumeofmaterial

perareasprayed.

Readthismanualcarefullytolearnhowtooperate

andmaintainyourproductproperly.Theinformation

inthismanualcanhelpyouandothersavoidinjury

andproductdamage.AlthoughTorodesignsand

producessafeproducts,youareresponsiblefor

operatingtheproductproperlyandsafely.Youmay

contactTorodirectlyatwww.Toro.comforproduct

andaccessoryinformation,helpndingadealer,or

toregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorT oroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.

ModelNo.

SerialNo.

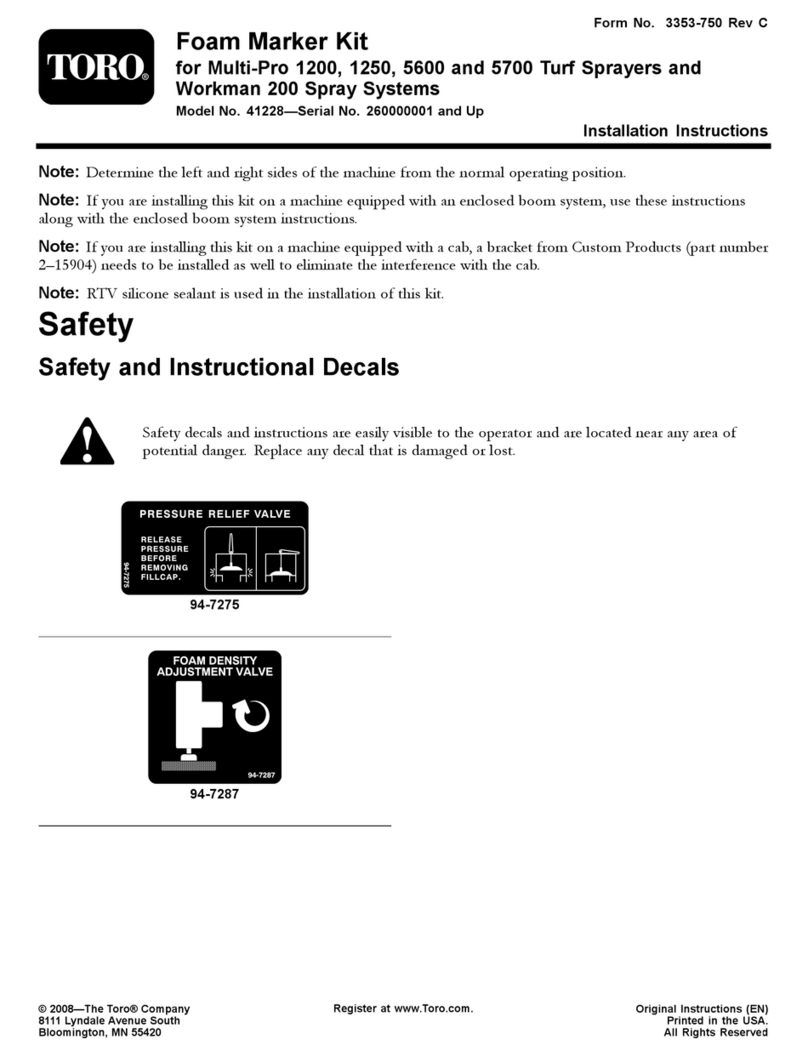

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure1),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure1

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

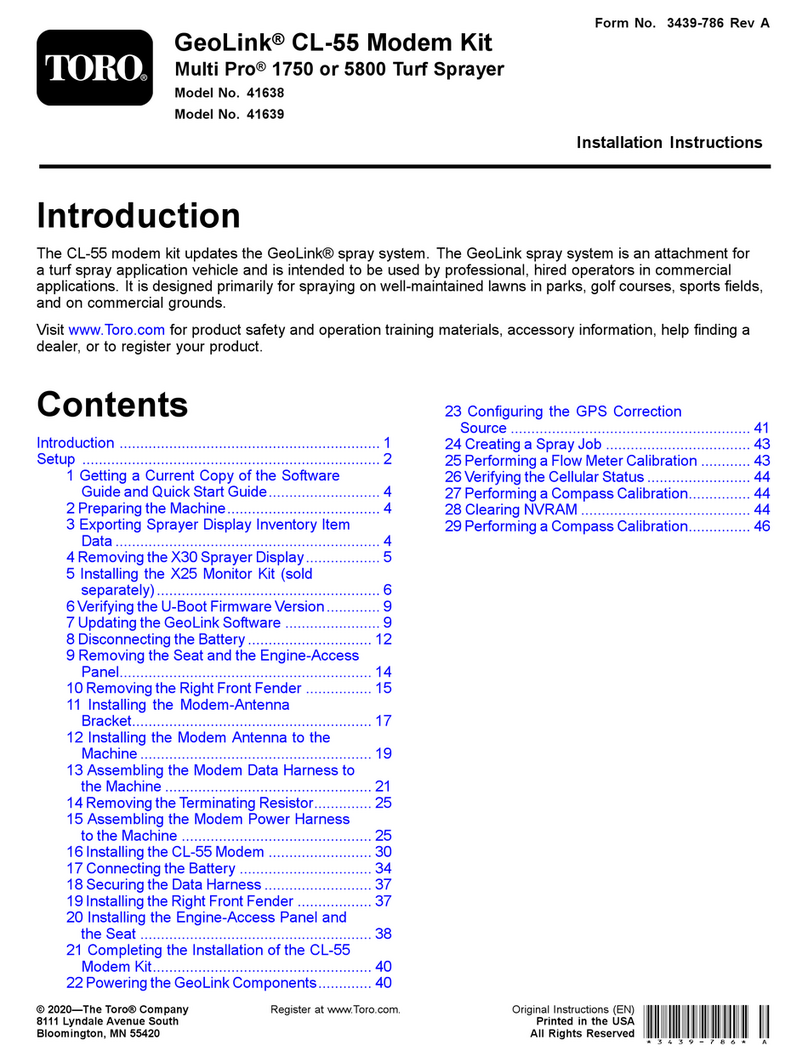

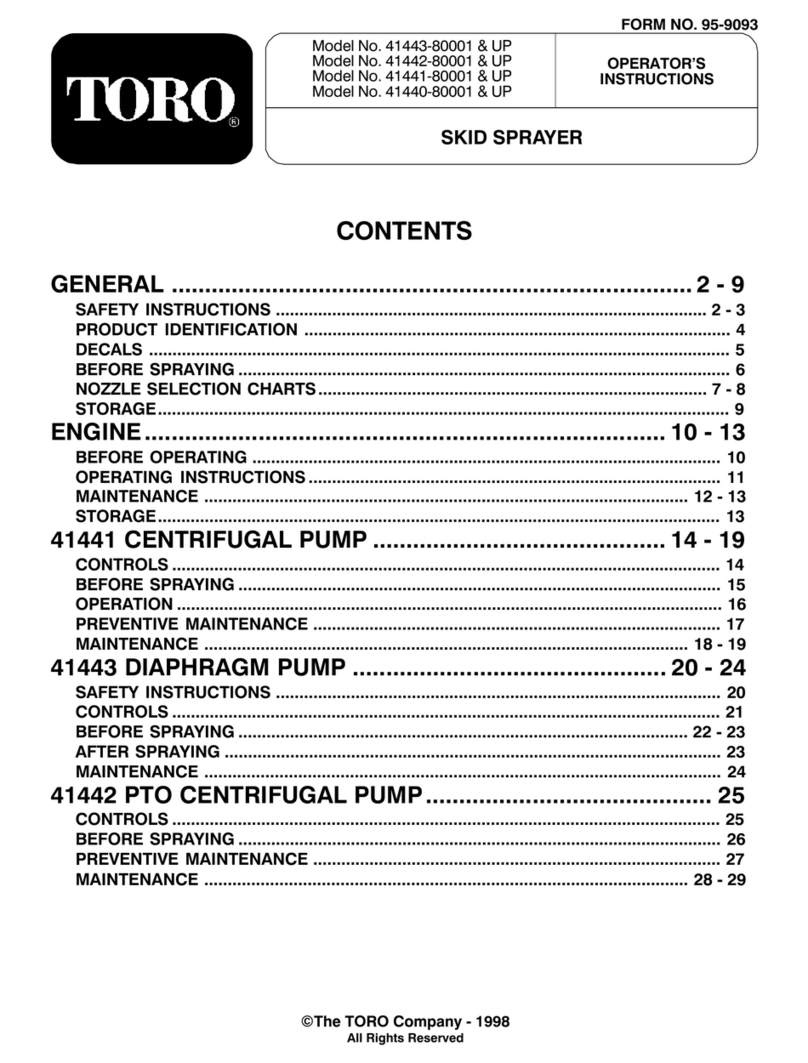

Contents

Safety.......................................................................3

ProductOverview.....................................................4

Controls.............................................................4

Operation..................................................................6

UnderstandingtheDifferentDisplay

Modes.............................................................6

StartingtheDisplay............................................6

UnderstandingtheLEDLights............................6

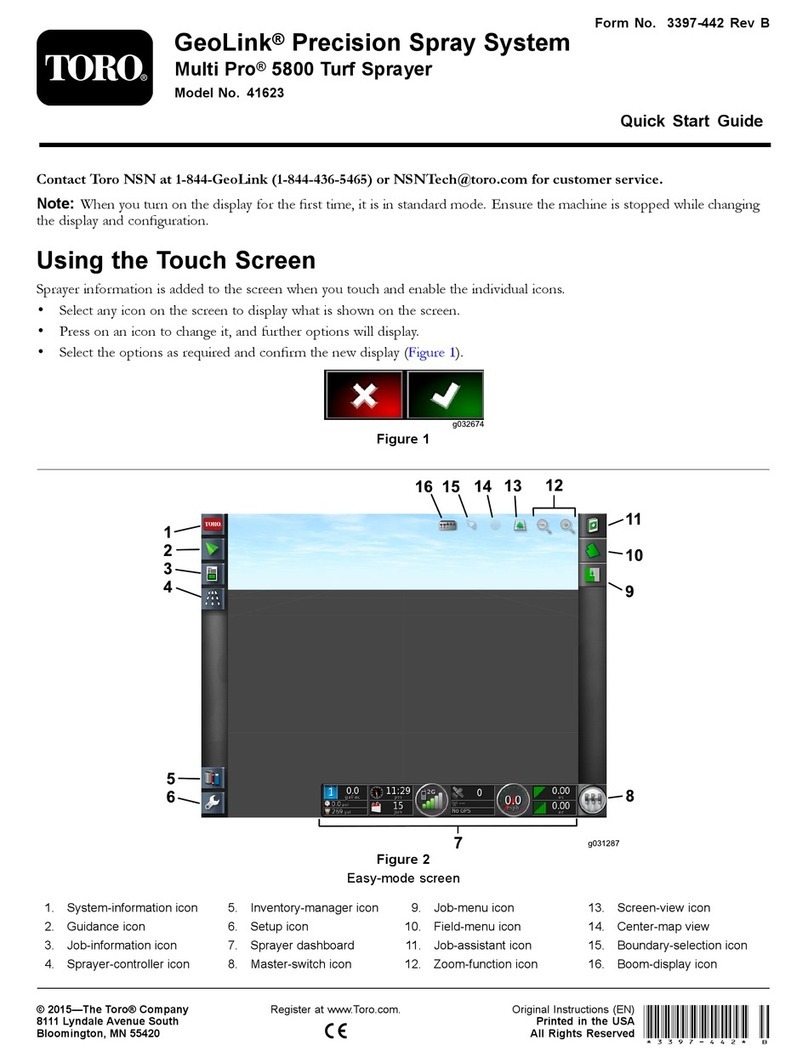

UsingtheT ouchScreen......................................7

UsingtheMasterSwitch....................................7

SelectingtheCorrectUnitsofMeasure...............7

UsingtheEasyMode..........................................8

RecordingJobDetails........................................11

ExportingJobInformation.................................12

SettinguptheSystem.......................................13

InitiallyT estingtheSystem................................13

OperatingTips.................................................14

Maintenance...........................................................15

RecommendedMaintenanceSchedule(s)...........15

CleaningtheFlowmeter....................................15

CleaningtheDisplayScreen.............................15

Troubleshooting......................................................16

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved