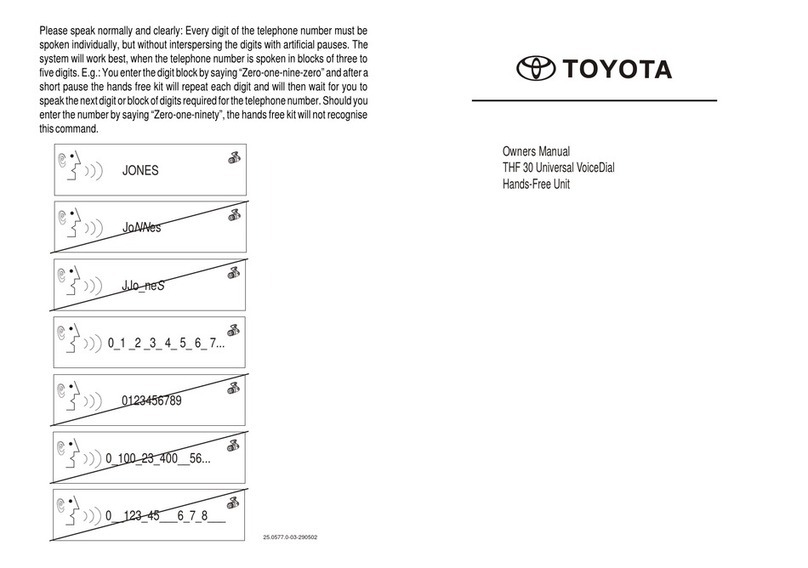

Toyota PZQ44-89100 User manual

Other Toyota Automobile Accessories manuals

Toyota

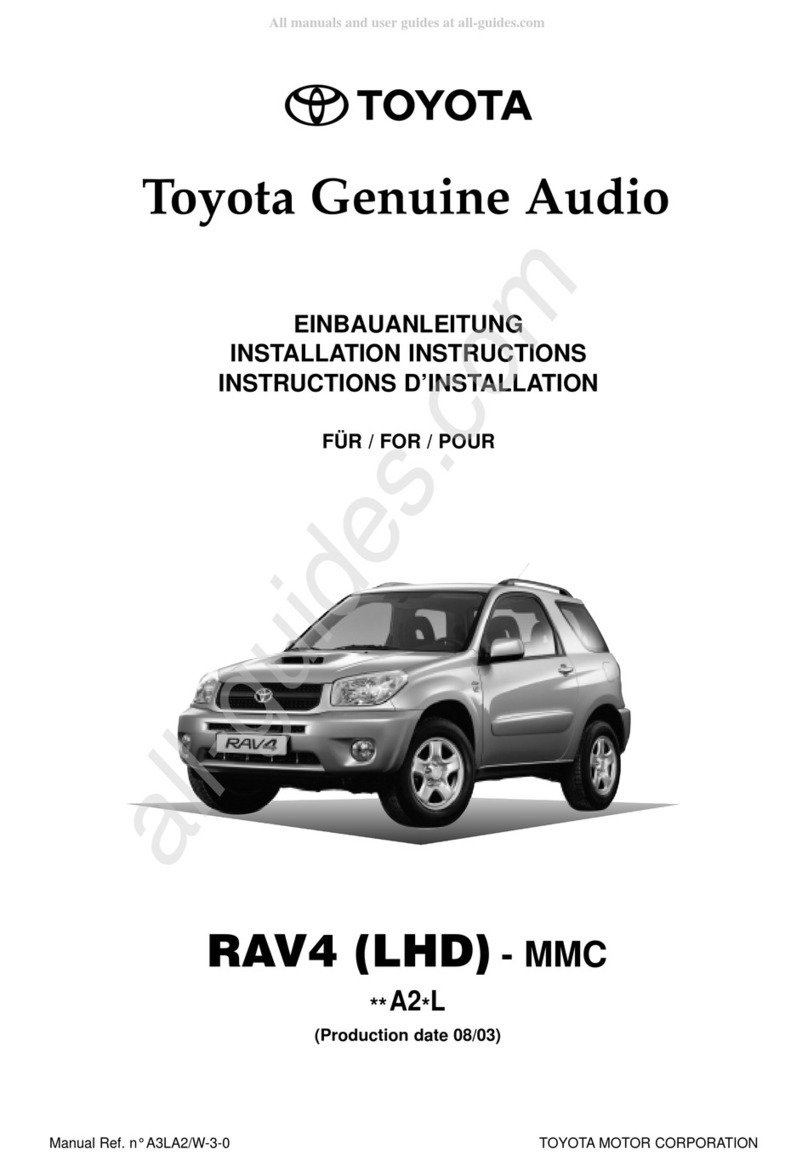

Toyota A2 L Series User manual

Toyota

Toyota CLA20L User manual

Toyota

Toyota 4RunneR 2014 User manual

Toyota

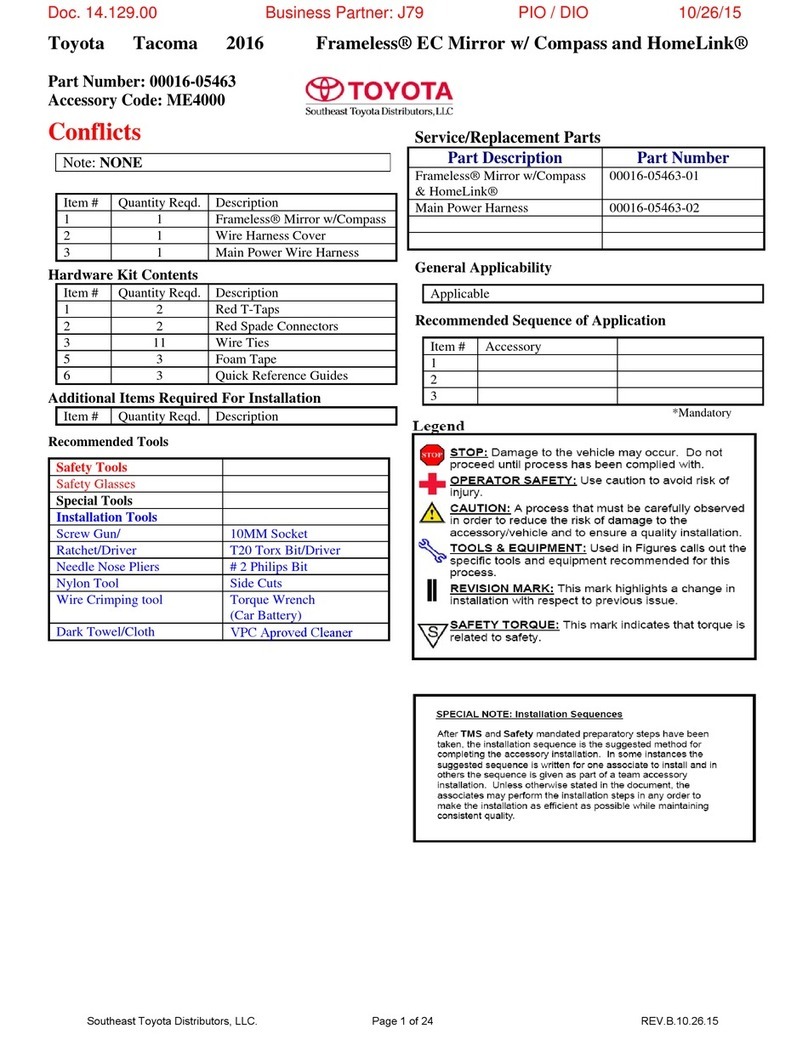

Toyota Frameless Mirror w/Compass& HomeLink User manual

Toyota

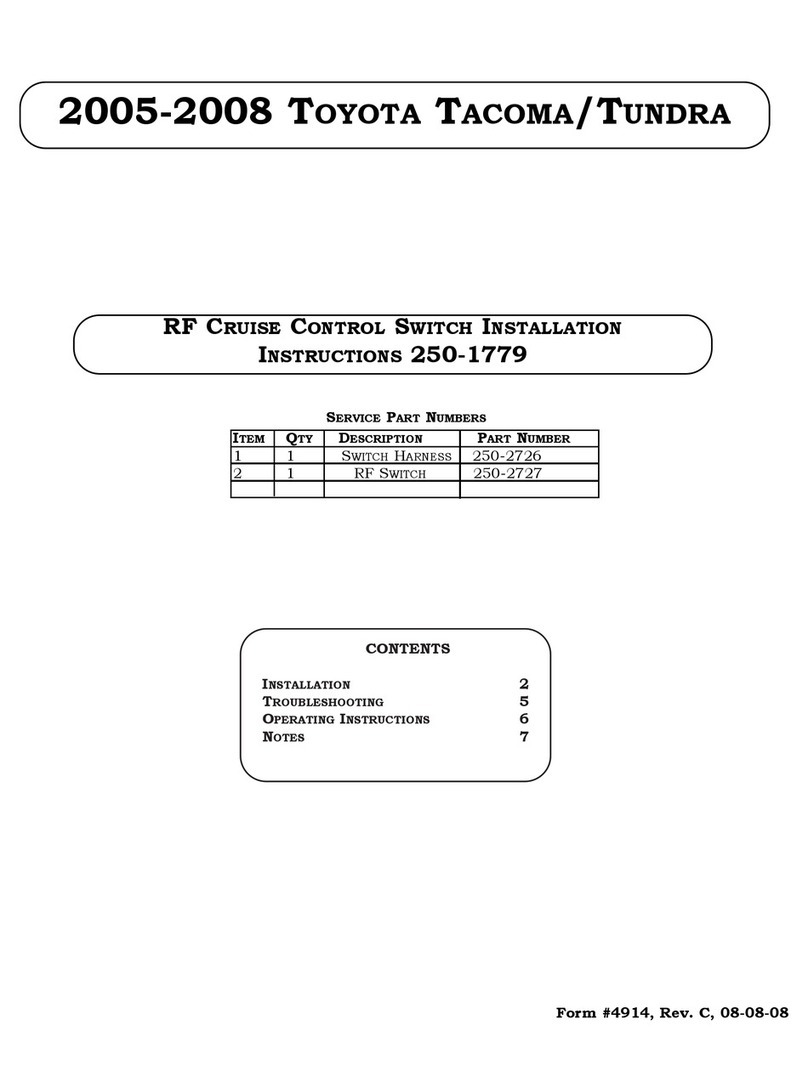

Toyota 2005-2008 TACOMA User manual

Toyota

Toyota I Site DHU4 User manual

Toyota

Toyota BSM User manual

Toyota

Toyota PVM User manual

Toyota

Toyota PW960-0R000 User manual

Toyota

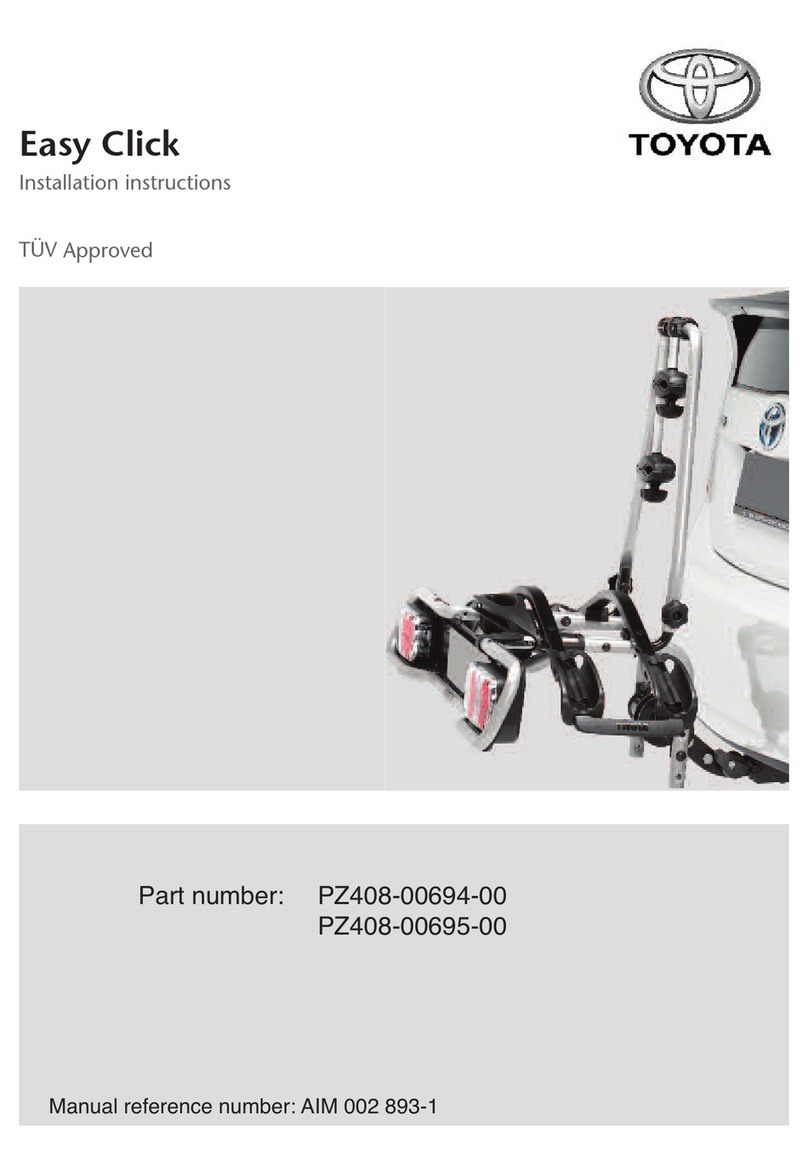

Toyota PZ408-00694-00 User manual

Toyota

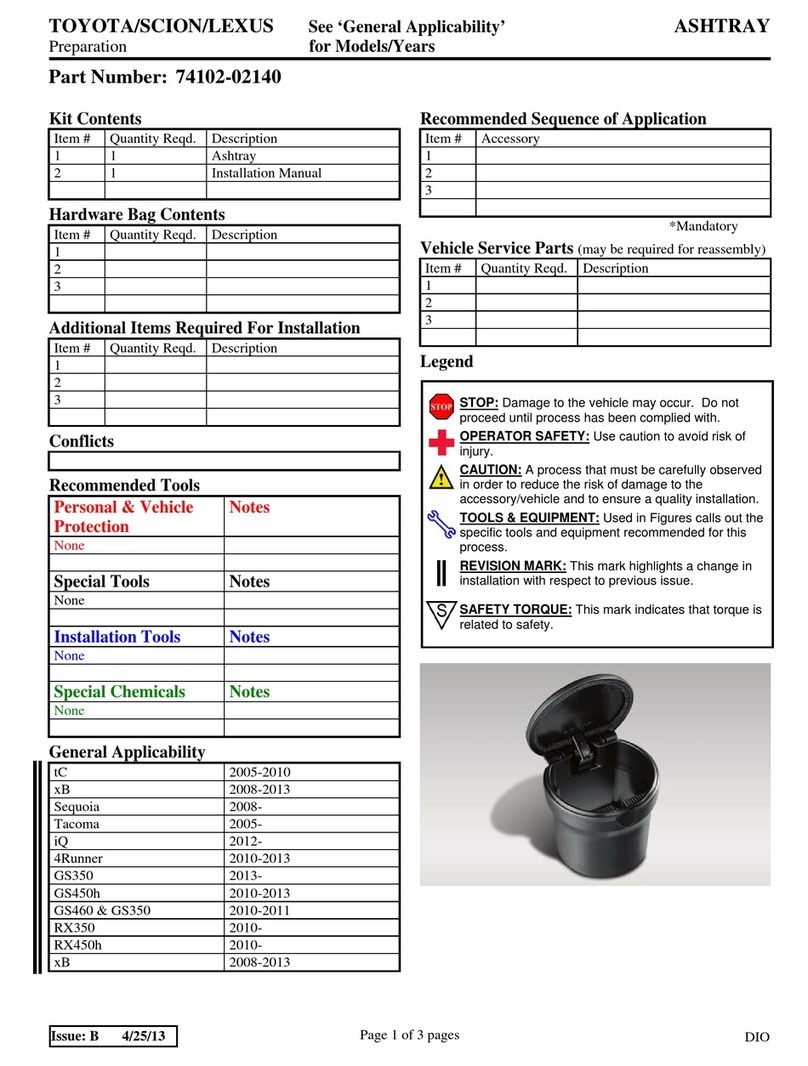

Toyota 74102-02140 User manual

Toyota

Toyota handsfree communication User manual

Toyota

Toyota PZ420 I0291 ME User manual

Toyota

Toyota PT427-48080 User manual

Toyota

Toyota Bluetooth hands-free system User manual

Toyota

Toyota TOYOTA COMPUTER-CONTROLLED SYSTEM Installation guide

Toyota

Toyota PT278-48140 User manual

Toyota

Toyota PZ403-99646-00 User manual

Toyota

Toyota Avensis 2006 TNS600 User manual

Toyota

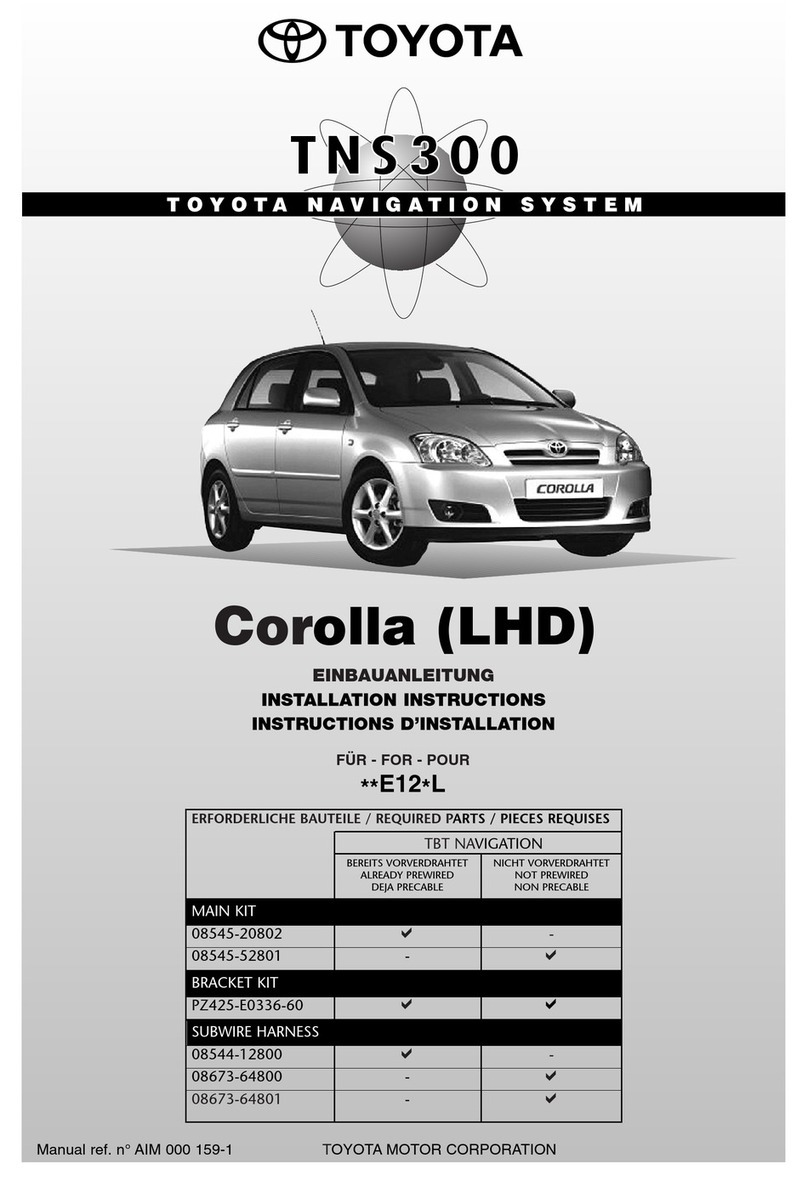

Toyota TSN 300 Corolla E12 L Series User manual