Semi-Auto Strapping Machine TP-201/202/203/202L

Q&A

Confidential TO: FROMM HOLDING AG

Page 1 of 7 8/19/2008

CONTENTS

I. After the strap has been inserted into the strap inlet (LS1 Switch is touched), the machine

does not start running...............................................................................................................2

II. Strapping cycle is completed but without tensioning ..............................................................2

III. After tensioning, the machine will not cut the strap. (The non-stop reversing may damage

the package.) ............................................................................................................................2

IV. While tensioning, there is a screeching sound and machine does not complete the strapping

cycle(pressure is too low) ........................................................................................................3

V. The machine has been activated but strap will not reverse (no tensioning) ............................3

VI. After completing one strapping cycle, strap is not refed. ........................................................3

VII. After completing one strapping cycle, the machine continues feeding strap ..........................4

VIII. Motor will not stop after the preset shut-off time....................................................................4

IX. Motor stops running.................................................................................................................4

X. Machine shuts off suddenly in the middle of a cycle ..............................................................4

XI. Jammed or split strap...............................................................................................................4

XII. Insufficient tension ..................................................................................................................5

XIII. The activating time is 2-3 seconds after the p.p. strap has been inserted into the strap inlet

(activation too slow) ................................................................................................................5

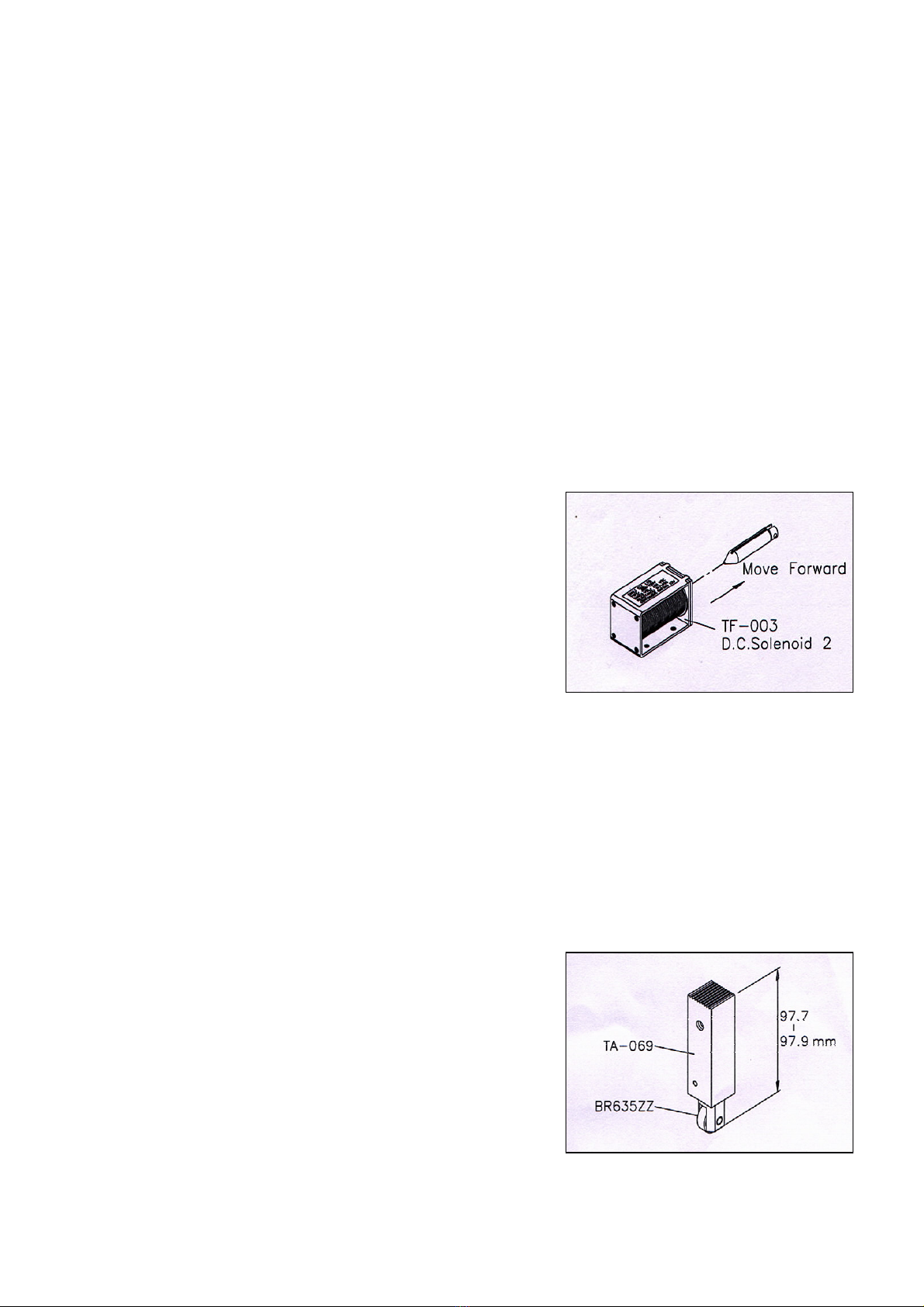

XIV. P. P. Strap will not seal.............................................................................................................5

XV. Incomplete cutting ...................................................................................................................6

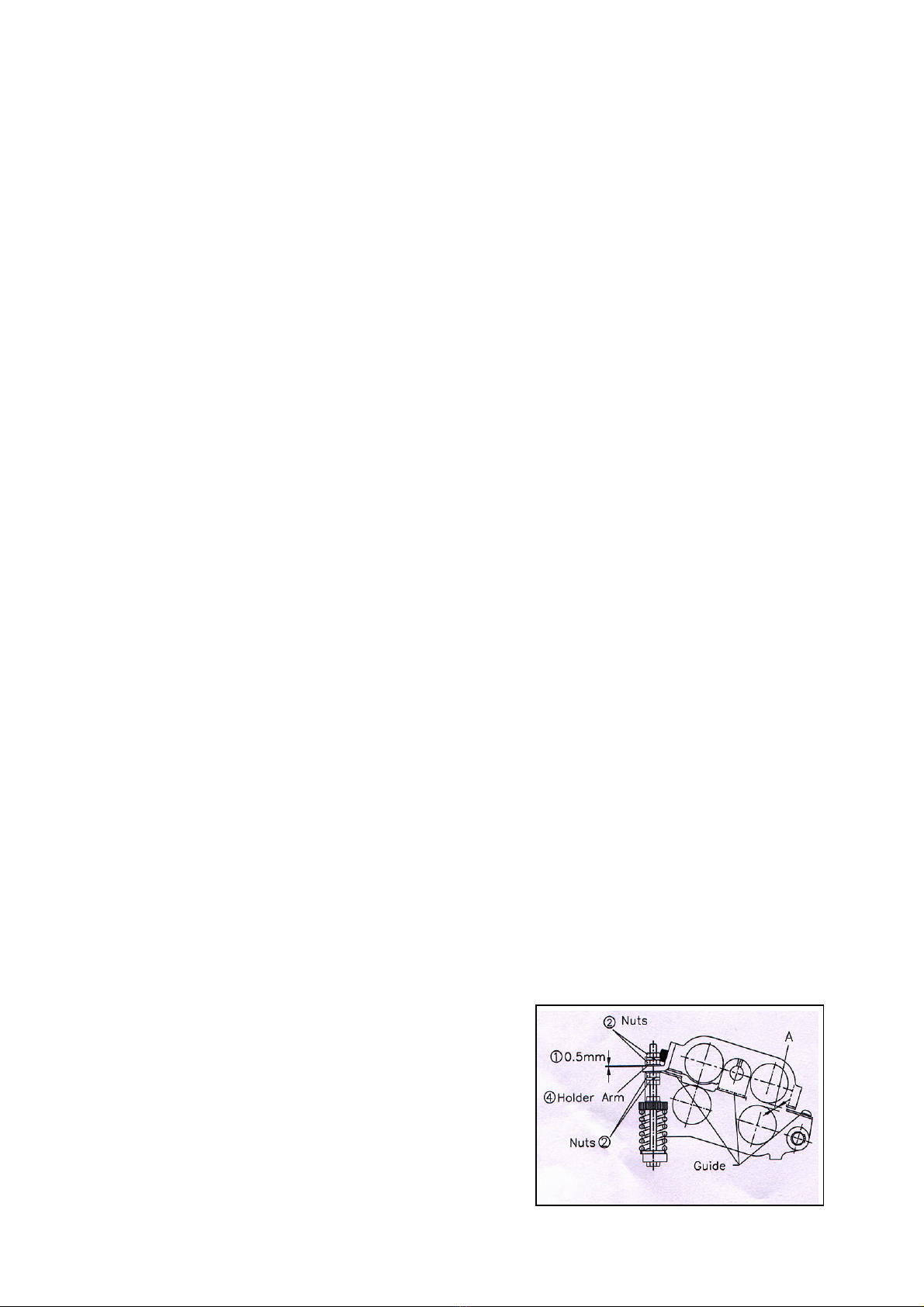

XVI. Misaligned strap joint or insufficient strap joint......................................................................6

XVII. After one complete cycle, the machine continues feeding or reverses a little bit ...................6

XVIII. TA-080 Slide does not return to its home position ..................................................................7

XIX. Reel unit does not brake and strap becomes loose on the reel.................................................7

XX. The TG-007 P.C.Board is burnt ...............................................................................................7