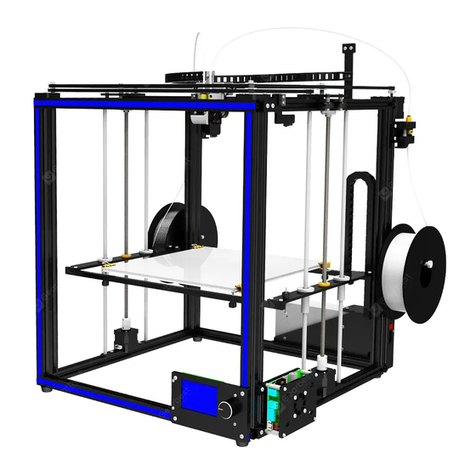

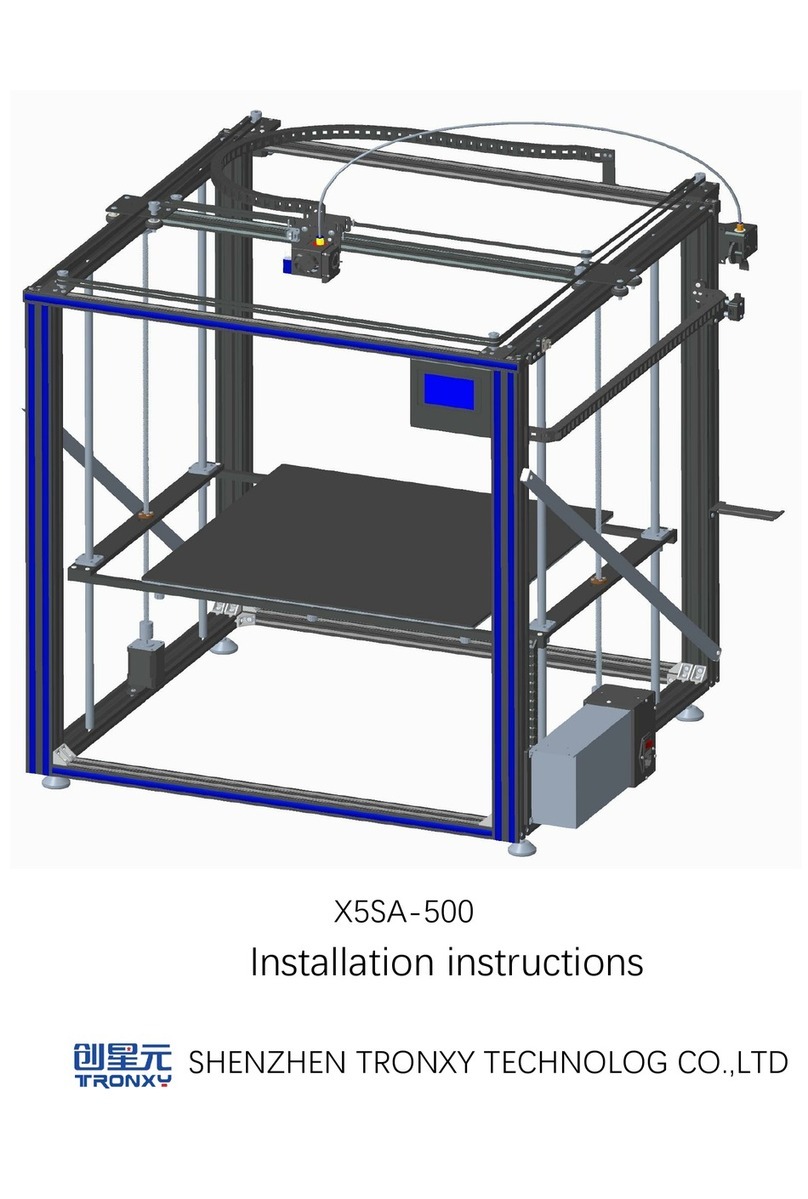

TRONXY X5SA-500-PRO User manual

Thank you for choosing TRONXY products!

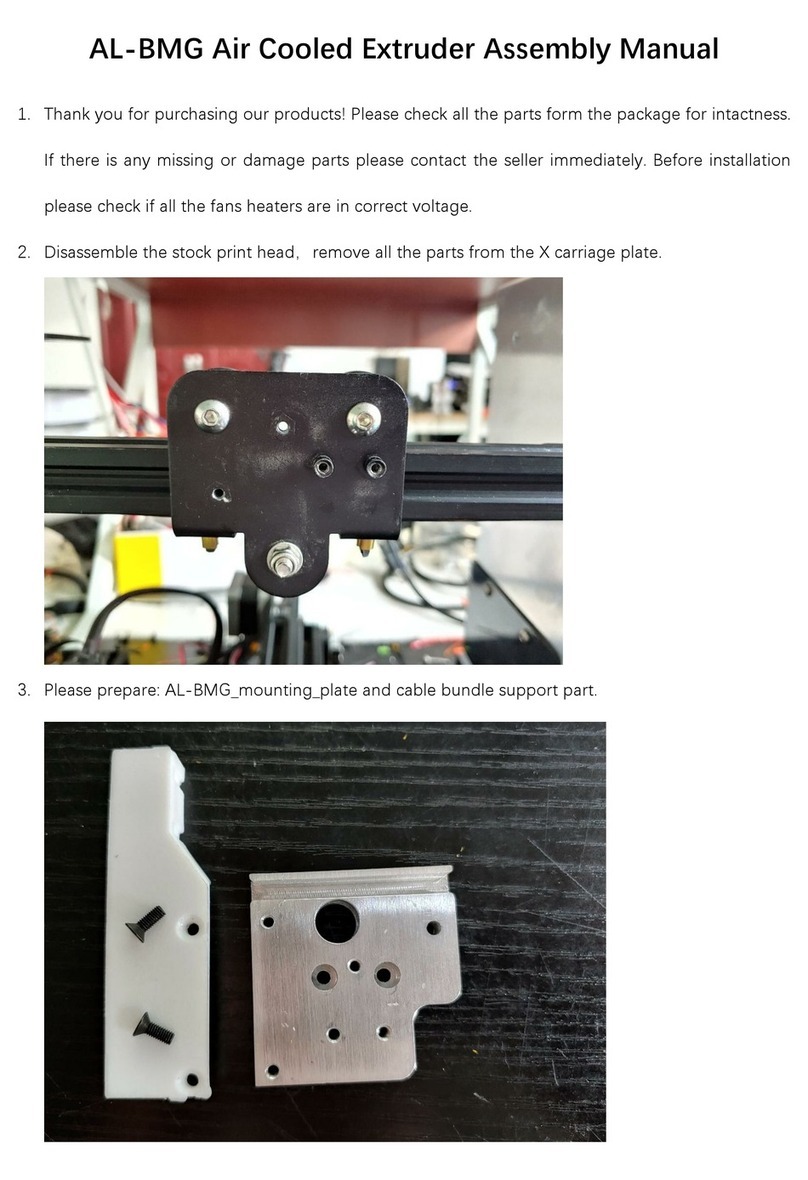

We will serve you whole heartedly!

Please read the instruction carefully

Please visit tronxy.com for more information

TEL:+86-755-89968500

Relevant information is stored in

SD card,please check

After- sale service:support@tronxy.com

Service nach dem Verkauf: support@tronxy.com

アフターサービス:support@tronxy.com

Послепродажное обслуживание: support@tronxy.com

Facebook QR CodeX5SA-500Pro Install

video QR Code

Aftersale contact

QR Code

Servicio postventa: support@tronxy.com

Serviço pós-venda: support@tronxy.com

판매 후 서비스 : support@tronxy.com

بع دعيبلا :support@tronxy.com

Pay attention

Please read this instruction carefully and follow the

safety instruction.

When the 3D printer is working, it will produce high temperature.Do not

touch working parts or extruder directly.After printing, the working part

may still be in the high temperature state.Please wait patiently for the

working parts and the print model to cool down before removing the model

from the print platform.

Please use the 3D printer in a spacious and well-ventilated

environment.

The recommended ambient temperature for 3D printers is

8°C-40°C, and the humidity is 20%-80%. Using outside this

range may bring bad printing effects.

In case of emergency, could turn off the power of the

3D printer directly.

3D printers contain working parts that move at high

speeds, so be wary of pinching your hands.

When removing the model from the print platform, be careful

not to swipe sharp objects at your finger.

Assemble the 3D printer or polish the model. suggest Wear

goggles.

Please pay attention to the protection of 3D printer

against rain and moisture.

Keep children away from the machine when it running

It is not recommended to run a 3D printer when left

unattended.

Use wires must be connected to the earth

Catalogue

1. Machine parameter ………………………………………1

2. Introduction to machine structure …………………2

3. Packing list ……………………………………………………3

4. Installation instructions …………………………………4

5. Interface operation and printing …………………17

6. Slice software ………………………………………………20

7. Fault cause analysis ………………………………………23

Print parameters

Print principle

: FDM (Fused deposition molding)

Print size

: 500×500×600 (mm3)

Print accuracy

: 0.1-0.4 mm

Positioning accuracy

:X/Y0.00625mm,Z 0.0125mm

Nozzle quantity

: 1

Nozzle size

: 0.4 mm

Print speed

: 20~100mm/s (suggest 60mm/s)

Moving speed

: 100mm/s

Filament

: PLA, TPU, ABS, wood etc.

Temperature parameters

Environmental temp:

8°C - 40°C

Nozzle temp:

Max260℃

Heat bed temp:

support

Software

Slice software:

Cura

Input format:

.STL .OBJ

Output format:

GCode

Connection:

TF card, USB cable(Suitable for skilled users

)

Power supply

Power input:

110V/220V AC, 50/60Hz

Power output

:24V/21A DC

Physical parameter

Machine size:

810mm×812mm×915mm

Machine weight:

~28.5kg

1. Machine parameter

1

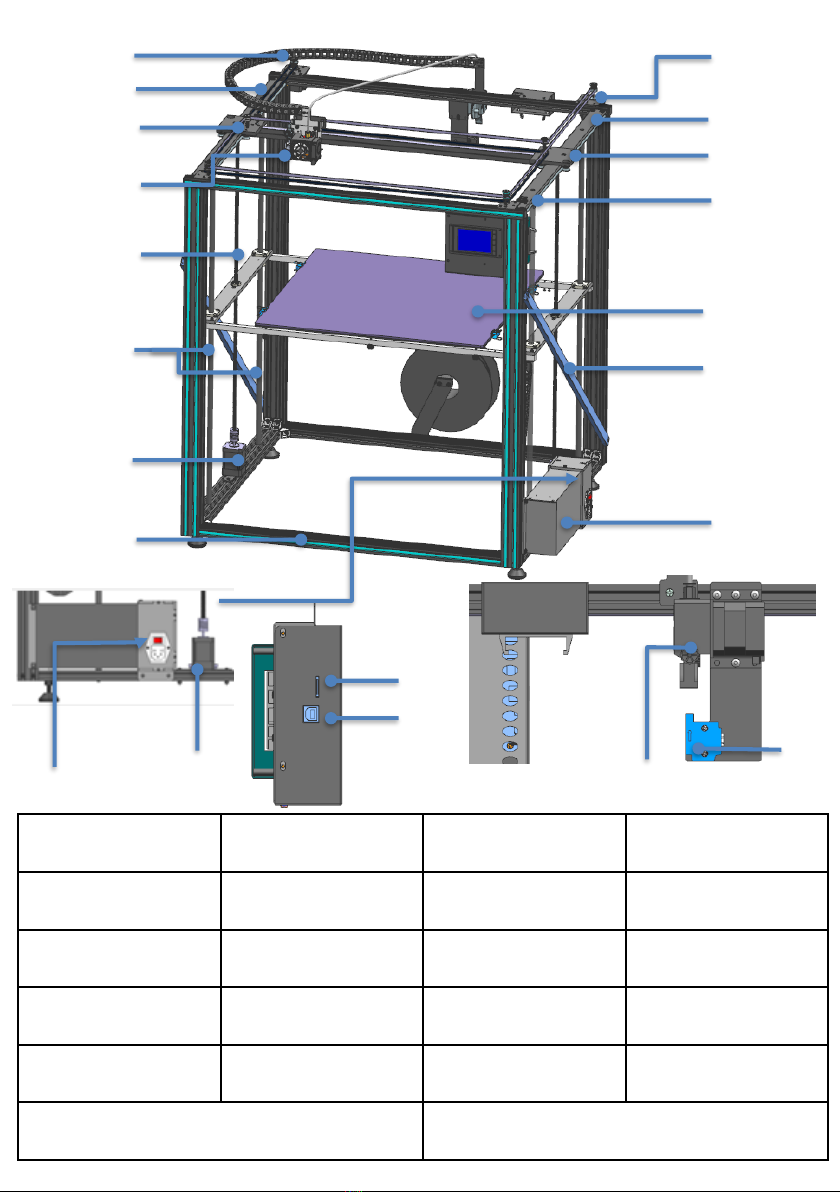

2. Introduction to machine structure

④

⑤

①

②

③

⑥

⑦

⑧

⑨

⑩

⑪

⑫

⑬

⑮

⑭

⑯⑰

⑱

⑲

⑳㉑

2

1.Power Supply 2.Stainless steel pipe 3.Heatbed 4.Y axis switch

6.Y-right guide rail

5.Y- right skateboard 7.Xmotor

9. Y-left guide rail 10.Y- right skateboard 11. extruder head

13.lead screw

12.polish rod

14.Z2motor 16.power switch

17.Z1motor 18.TF interface 19.USB interface

15.aluminum frame

20.Titan extruder

21.filament run-out detection

8.Ymotor

3. Packing list

2

040

aluminum

profile

630mm 2PCS

660mm 2PCS

2020aluminum

profile

740mm 2PCS

4040aluminum profile

780mm 4PCS

Stainless steel pole

2PCS

OSG External double

axis guide rail

-Y

axis

670mm 2PCS

OSG External double

axis guide rail

-X

axis

650mm 1PCS

beams/footlock

2pcs

left and right

sliding parts

polished rod

760MM 4PCS

lead screws

665MM 2PCS

left /right belt pulley

parts X/Y axis motors

Zaxis motor

parts

Titan extruder

component bag

controller + touch

screen belt bag

filament

+seal

(

Color random

)

Power Supply

print head

aluminum plate with

balck sticker heat bed

screws bag 4PCS

Corner code bag

1PCS

shovel

(

Color

random)

USB cable+ power line

Tools bag reader+TFcard

Yswitch parts

1PCS

filament run out

detection parts

1PCS

Double limit plate

2pcs

3

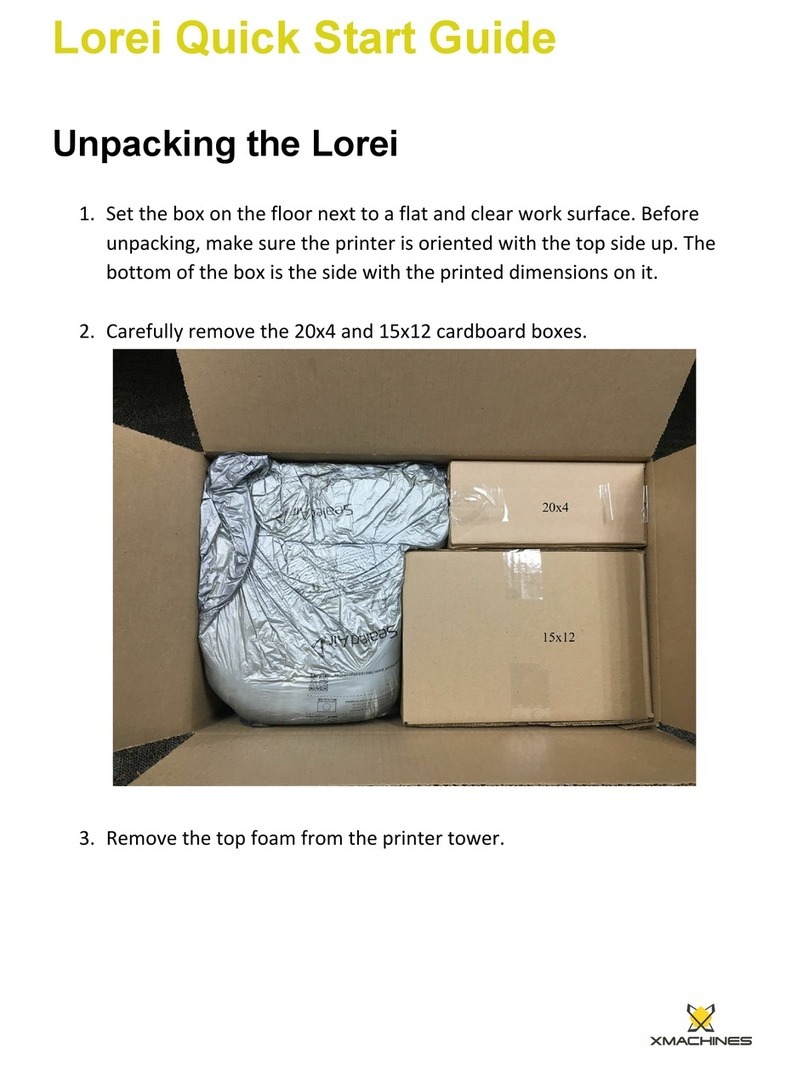

After receiving the goods, please

check the accessories according to

the packing list. If you have any

questions, please contact customer

service.

4. Installation instructions

Step 1:base frame assembly

Assembly material specification and quantity

:

aluminum1

40*40*780 4PCS

aluminum2

40*20*660 2PCS

aluminum3

40*20*630 2PCS

Corner code

20PCS

screws M4*8

40PCS

gasket M4

40PCS

boat nuts M4

40PCS

screws M5*45

8PCS

12-aluminum1

4

1-aluminum2

M5*45

M5*45

2-aluminum3

Four countersunk

holes facing upward

on the surface

M4*8 M4 gasket boat nuts

Corner codes can be installed with

20 standby codes at a time

32-aluminum1

M5*45

M5*45

2

Note:

Installation

corner codes

should be kept

parallel and

vertical between

each aluminium

profile without

clearance.

Adjustment of

M5*45 can be

loosened slightly

before locking.

Slightly lock M5*45 screw for

easy follow-up adjustment

M6 threaded

hole Upward

M6 threaded hole

Upward

M6 threaded

hole Upward

M6 threaded hole

Upward

Installation corner codes in the connection of aluminium

profiles, it is necessary to keep the vertical and parallel

locking angle codes between the various aluminium

profiles.

The first step is to install the frame. After the

installation, the frame is assembled with the

second step, as shown in the figure.

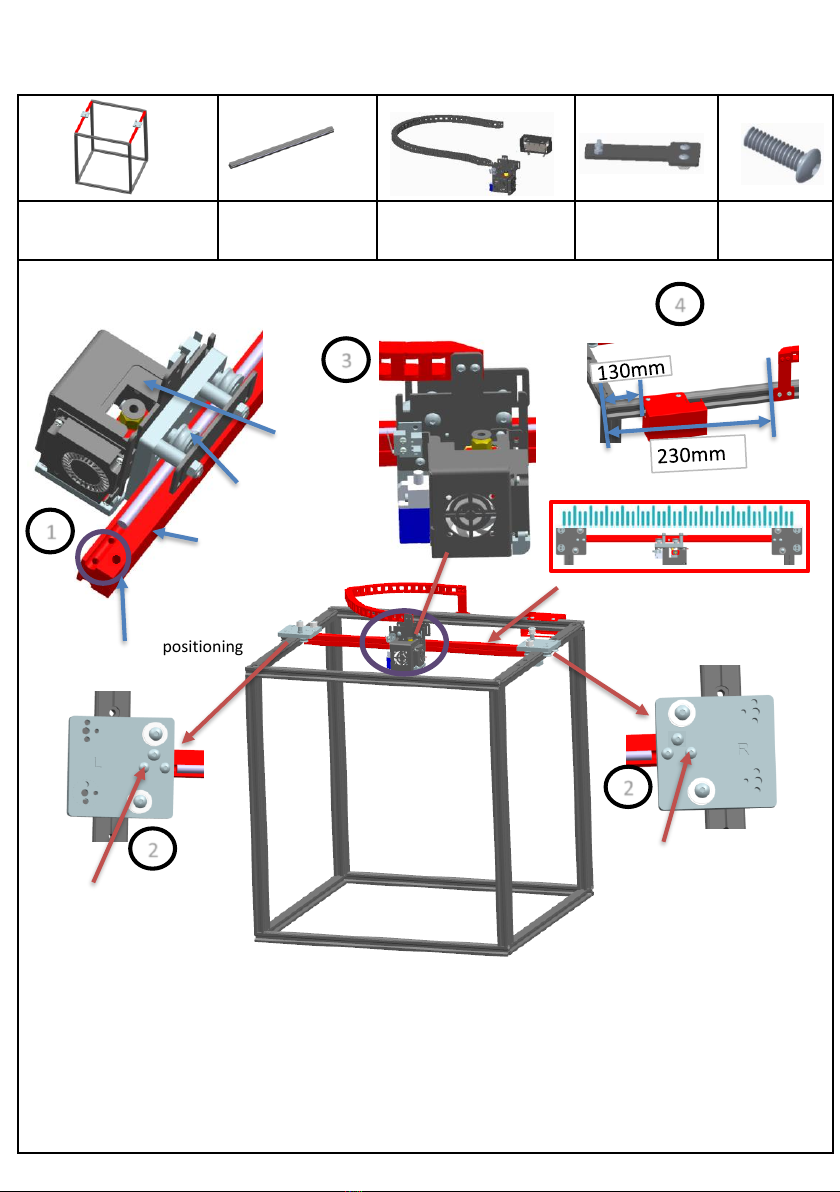

Assembly material specification and quantity

:

base frame

1pcs

aluminum4

20*20*740 2PCS

L skateboard 1PCS

Y left guide 1PCS

R

skateboard

1PCS

Y right guide 1PCS

screwsM6*25

16PCS

Step 2: Sliding plate assembly

Take out the Y-axis guide rail and penetrate into

the left component and the right component of

the slide, respectively, as shown in the figure.

1The screw M6*25 is slightly locked on the Y-axis

guide rail to facilitate subsequent adjustment.

Direction Reference

Point for Installation

of Guideway

5

2aluminum

4

8-M6*25

Note: The installation position of Aluminum

Profile 4 and the bottom Aluminum Profile 3 (with

countersunk head holes) are in the vertical

direction. Do not misfit them.

2

Note: The left and right skateboards

penetrate the guide rail.

Please install in the right direction

according to the drawing.

(Refer to Y-axis guideway bag

Letters, L to L, R to R)

38-M6*25

When installing Y-axis guide to the frame, please

note that M4 screw holes are in the same direction,

and use this to determine the front of the 3D printer.

M4 screw

hole

Aluminum profile 4 aligns bottom frame, slightly

locking M6*25 screw, no locking is needed to

facilitate subsequent adjustment and installation.

Assembly material specification and quantity

:

basic frame 1pcs

X axis guide rail parts

20*18*650 1PCS

Print head parts

1pcs

drag chain plate

1pcs

screws

M4*20 6PCS

Step 3: Sliding plate assembly

1

pulley

X axis guide rail

M4 screws holes positioning

print head

3-M4*20

3-M4*20

2

2

3

4

6

1.Insert the print head into the X-axis guide rail, pay attention to the direction of the M4 screw hole, as

shown in Figure 1.

2. Insert the X-axis rail assembly into the alignment hole of the chassis, and tighten the screw

RM4*20 without locking it, as shown in Figure 2.

3. Move the left and right sliders to confirm that the X-axis rail assembly moves flexibly after locking

the RM4*20 screw.

4. After adjustment, lock the screw of RM5*25 on the Y-axis guide and move the X-axis guide assembly

again. Repeat the adjustment to ensure that the slide is flexible and has no gap after the locking screw.

As shown in the figure, the pulley on the print head

runs through the X axis guide rail and the slide

block moves smoothly without any clearance

The skateboard is in line with

the X-axis guide

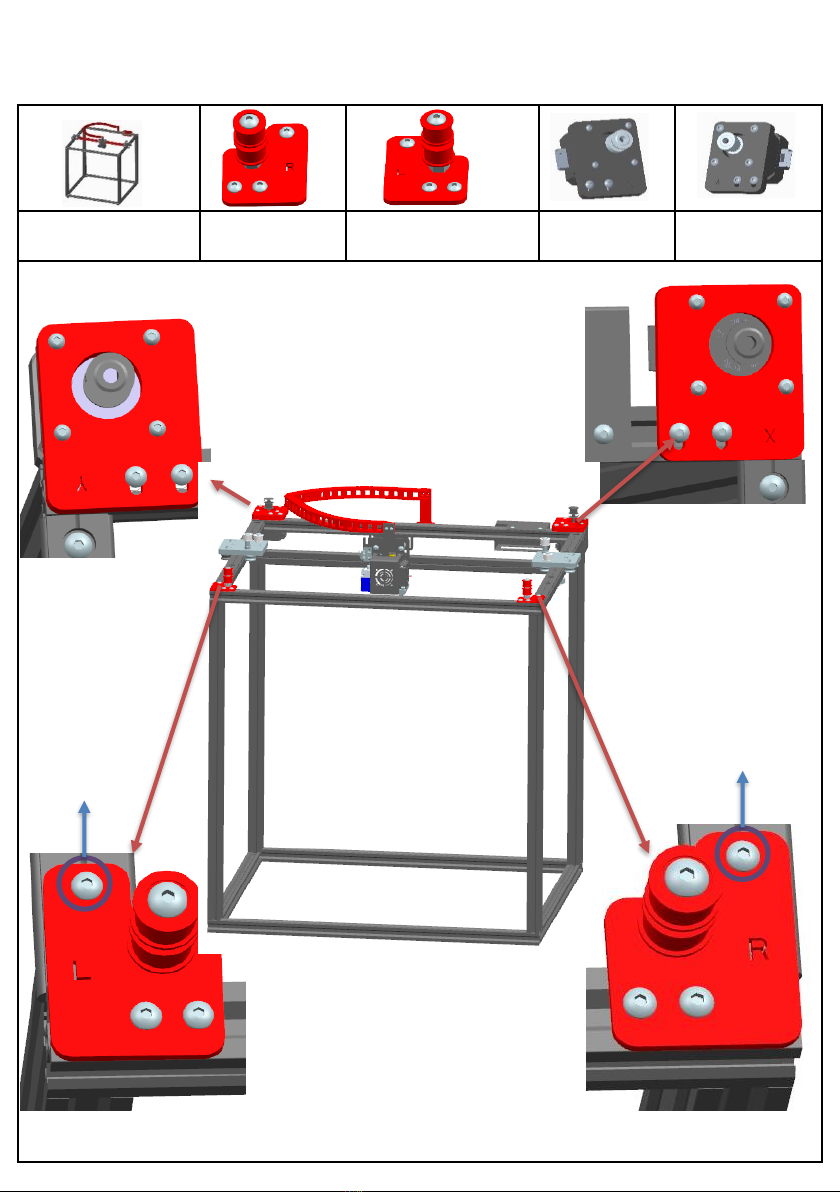

Assembly material specification and quantity

:

basic frame parts

1pcs

right wheel parts

1pcs

left wheel parts

1pcs

X motor

1pcs

Y motor

1pcs

Step 4:XY axis motors and wheels assembly

7

This screw

positioning

Don't need to

tighten M4*16

This screw

positioning

Don't need

to tighten

M4*16

1. Lock and fix the assembled parts in the

position as shown in the figure

Assembly tips for M4 ship nut: first

align the M4 nut with the aluminum

profile slot, put it into the aluminum

profile slot, use a screwdriver to

reverse loosen, release the M4 ship

nut over the aluminum profile slot,

and then tighten it forward

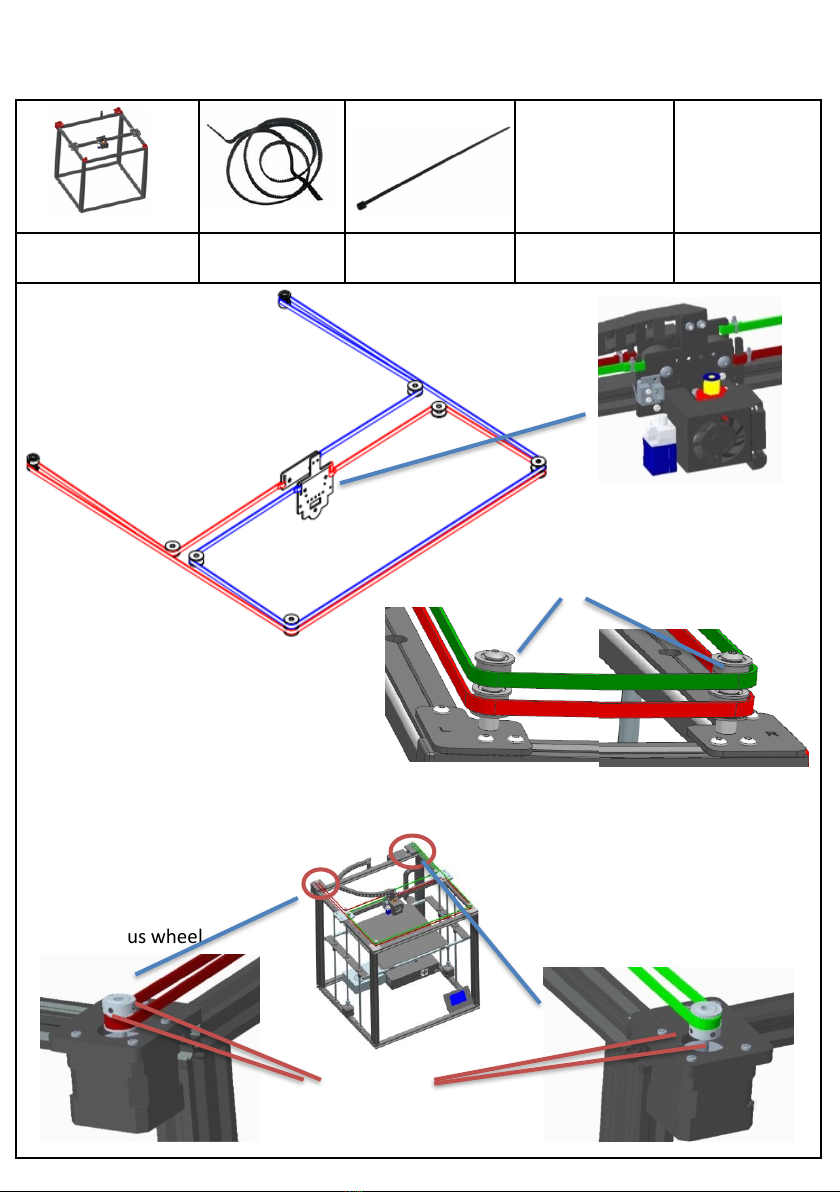

Assembly material specification and quantity

:

basic frame

1pcs

Belt

2pcs Ties

Step 5:Belts assembly

4-M3*3

8

Synchronous wheel

Synchronous wheel

Note: When the machine prints normally

after assembly.If the belt is too loud when

moving,The height of the left and right

wheel assembly can be adjusted by

increasing and reducing the gaskets.

During the printing process, the leather belt

has a slight sound, which is normal.

Left and right wheels

Belt tying diagram

X motor

Y motor

1.As shown in the figure, after

adjusting the distance between

the motor gear and the belt, lock

the 2 rice screws on the gear.

2. Also assemble the second belt,

the tension of the second belt

should be equal.

Note: Synchronization wheels on X, Y axis motors

Height should be adjusted by itself.

Be sure to install the belt

Each belt is on the same planeUp.

Location of Print Head Band

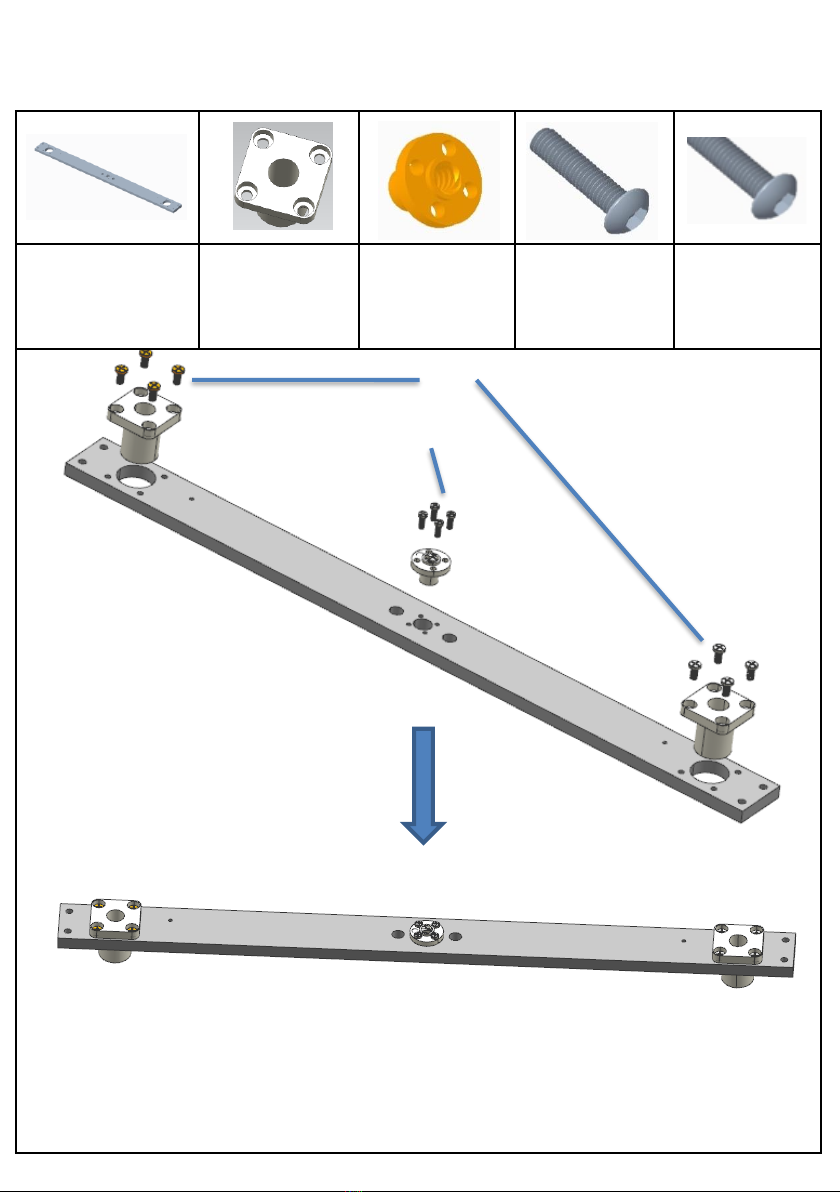

Assembly material specification and quantity

:

beams

2pcs

Linear bearing

4pcs

copper linear

bearing

2pcs

screws M4*12

16pcs

screws M3*8

8pcs

Step 6:Linear bearing assembly

16-M4*12

9

8-M3*8

Assembly material specification and quantity

:

basic frame

1pcs

Z axis motor parts

2pcs

foot lock parts

2pcs

bearing base parts

2pcs

polish rod

Φ8*760 4PCS

lead screwT8*665

2PCS

screws M4*30

8PCS

screws M4*8

4PCS

screws M4*16

4PCS

Step 7:Z axis parts assembly

4-M4*8

2-M3*3

4-M4*4

4-M4*30

M3 hole is inside.

1

2

3

10

polish

rod

polish

rod

lead screw

bearing base parts

As shown in Figure 1, assemble the assembly, put

the assembly into the frame as shown in Figure 2,

and align the holes to lock the screws.

Adjust the verticality of the polished

rod and tighten the screws

Shim

4-M4*30

M4 nut

4-M4*16

Assembly material specification and quantity

:

basic frame

1PCS

Power Supply

1PCS

controller box

1PCS

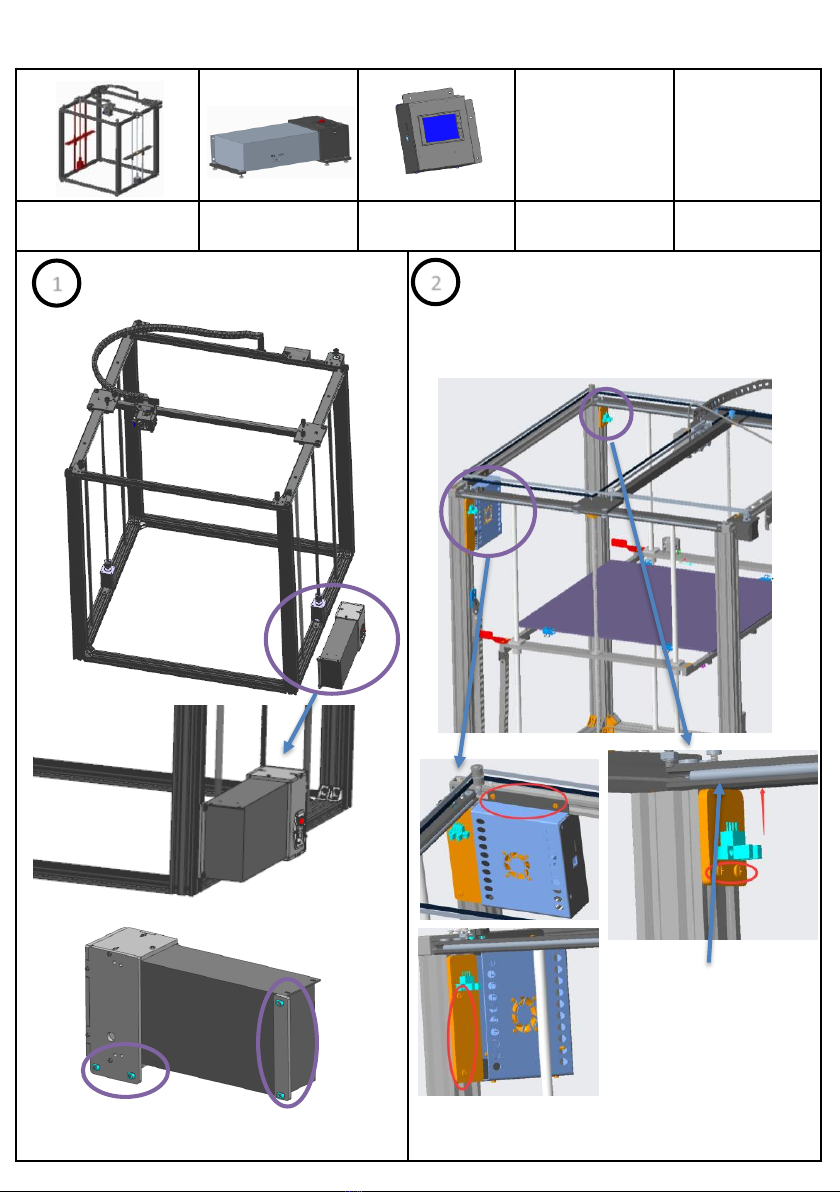

Step 8:Controller box assembly

1Install the power supply in the

lower right corner of the front of

the printer

2

boat nuts

11

boat nuts

Align

Install the main control box on the right

(facing the machine) profile (including a

photoelectric switch), and the other

photoelectric switch is fixed on the left

profile

Assembly material specification and quantity

:

basic frame

1pcs

heat bed parts

1pcs

beams

2pcs

plastic nuts M3

6pcs

screws M4*12

8pcs

spring

6pcs

nuts M3

6pcs

screws KM3*30

6pcs

Double limit

plate 2pcs

Step 9:Print plate assembly

1

4pcs hole position

6-KM3*30

6-spring

6-M3nuts

≈10mm

Move the left and right transverse plates on the

same plane. Lock the hot bed assembly on the

transverse plate according to Figure 2, and fix the

tow chain bracket according to Figure 3.

Rotate the screw, synchronize the moving platform

up and down, confirm the flexible movement,

need to adjust the screw PM4*12 and light rod and

motor screw.

beams

12

2-boat nuts+2-M4*8

2-M4*8

Hot bed drag chain

8-M4*12

3

2

Double

limit

plate

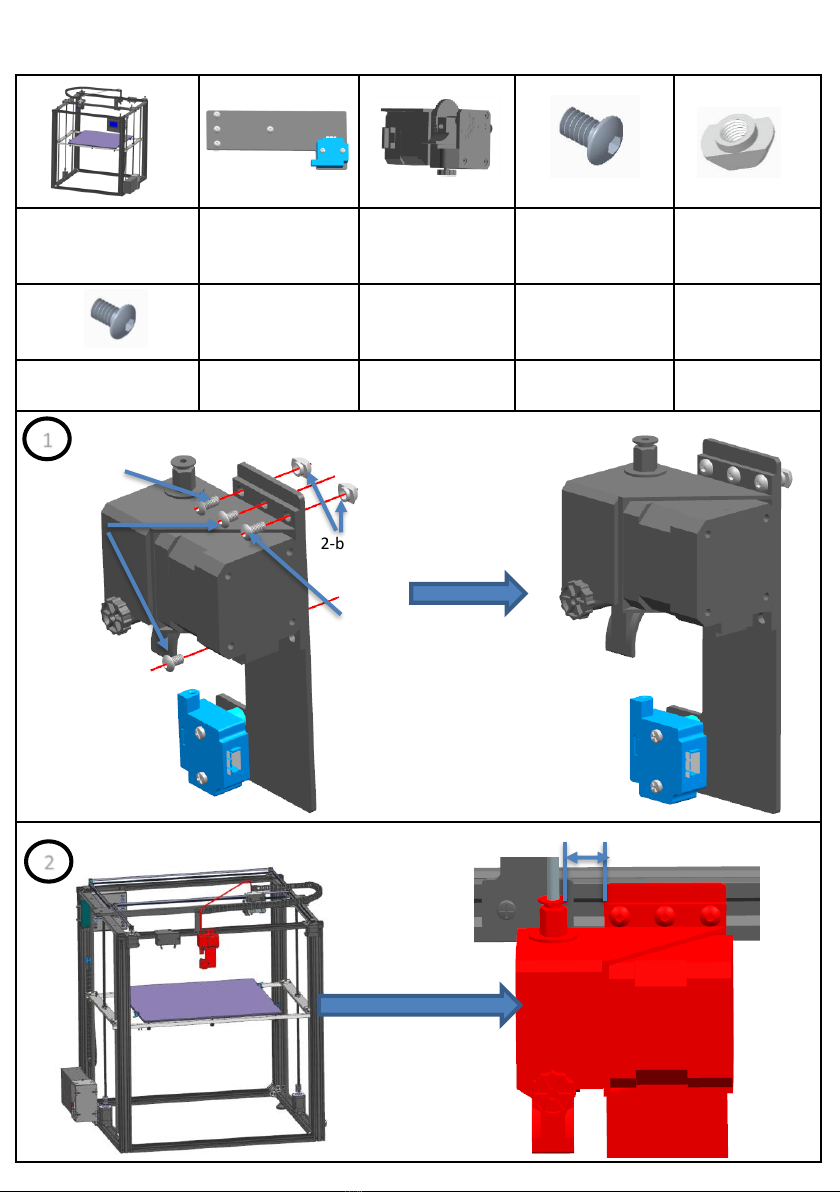

Assembly material specification and quantity

:

basic frame

1pcs

filament run out

detection parts

1pcs

Titan extruder

1pcs

screw RM4*8

2pcs

boat nuts

M4

2pcs

screw RM4*6

2pcs

Step 10:Feeding motor assembly

1

2-RM4*6 2-boat nuts

2

13

RM4*8

RM4*8

10MM

Assemble Titan extruder to filament runout detection parts

As shown, lock the Titan extruder assembly to the basic frame

Assembly material specification and quantity

:

printer

1PCS

Y switch parts

1PCS

bracket part

1PCS

screw

PM5*10

screwRM4*6

4PCS

boat nuts M4

2PCS

Step 11:Switch and filament bracket assembly

feeding tube

Note: the feed tube of the print head is not inserted at the bottom, which may lead to

blockage.

2-RM4*6 2-boat nuts M4 2-M5*10

14

Limit switch installed above Y-axis R Guide

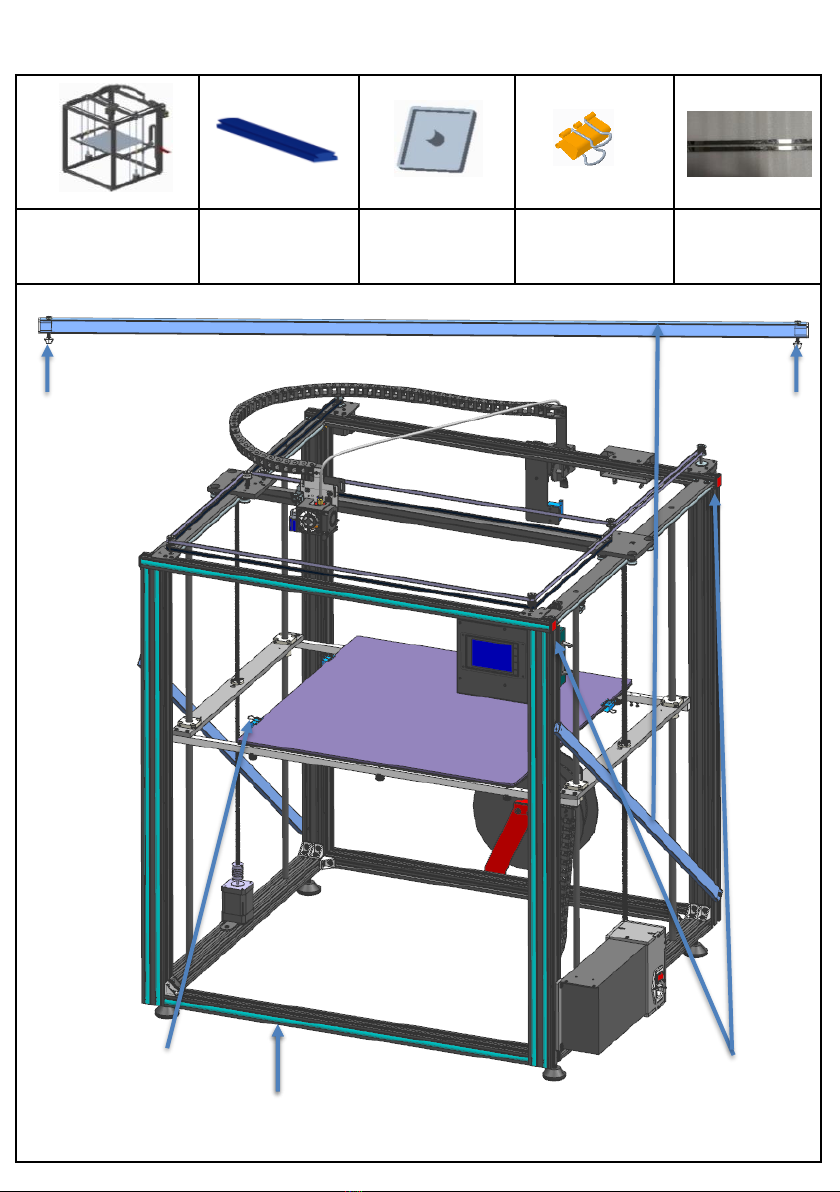

Assembly material specification and quantity

:

printer

1PCS seal end cap

4PCS

clips

4PCS

Stainless

steel pole

2PCS

Step 12:Black sticker and seal assembly

15

seal

4-end cap

4-clips

boat nuts M4 boat nuts M4

Fix stainless steel rod to both sides of printer

Table of contents

Other TRONXY 3D Printer manuals

TRONXY

TRONXY X5S 2E User manual

TRONXY

TRONXY X5 User manual

TRONXY

TRONXY P802M User manual

TRONXY

TRONXY X1 User manual

TRONXY

TRONXY XY-2 PRO User manual

TRONXY

TRONXY X5SA-400-2E User manual

TRONXY

TRONXY X5SA-500 User manual

TRONXY

TRONXY X3A User manual

TRONXY

TRONXY Ultrabot User manual

TRONXY

TRONXY X5SA User manual

TRONXY

TRONXY X6-2E User manual

TRONXY

TRONXY VEHO 600-2E User manual

TRONXY

TRONXY X5SA-500-2E User manual

TRONXY

TRONXY X5S User manual

TRONXY

TRONXY X3A User manual

TRONXY

TRONXY D01 User manual

TRONXY

TRONXY X3A User manual

TRONXY

TRONXY XY-3 User manual

TRONXY

TRONXY XY-2 User manual

TRONXY

TRONXY X5SA-400-PRO User manual