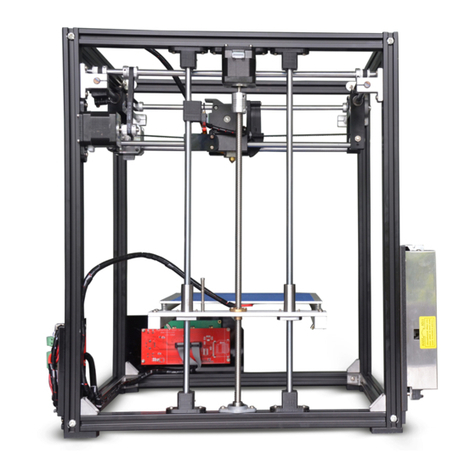

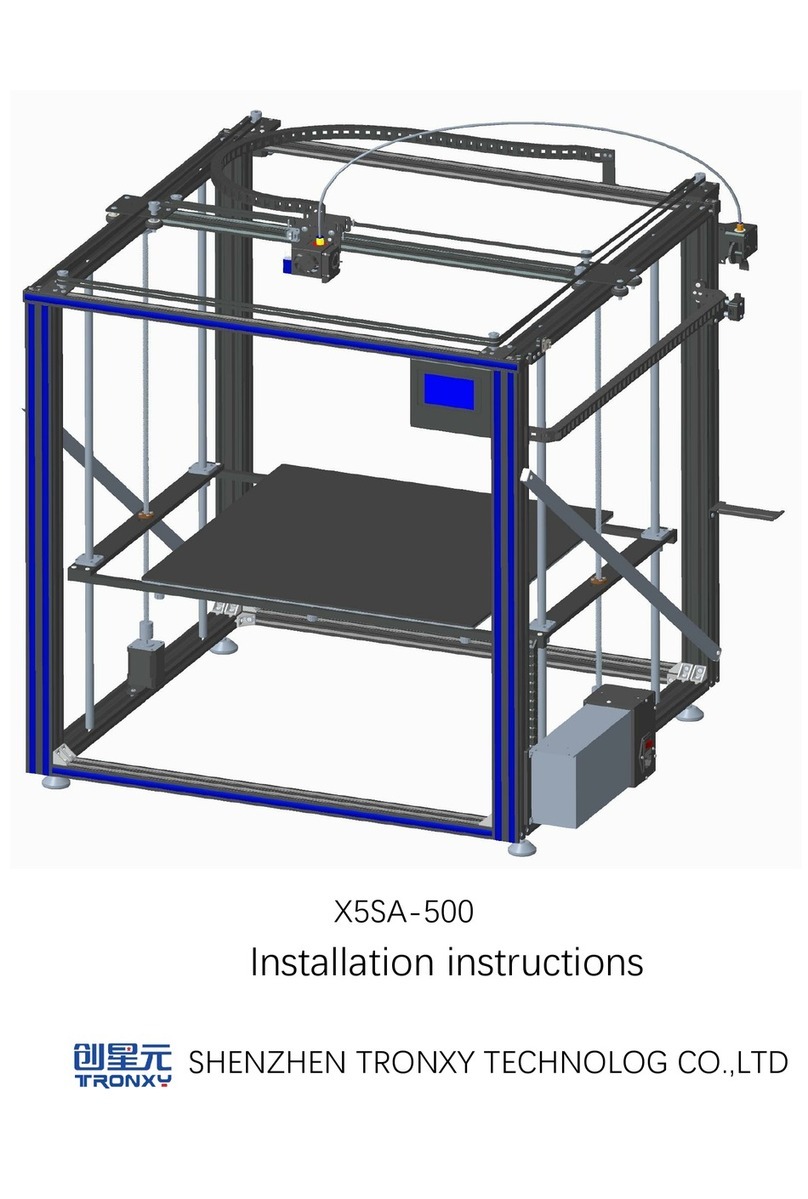

TRONXY X5SA-500-2E User manual

Table of contents

Other TRONXY 3D Printer manuals

TRONXY

TRONXY X5 User manual

TRONXY

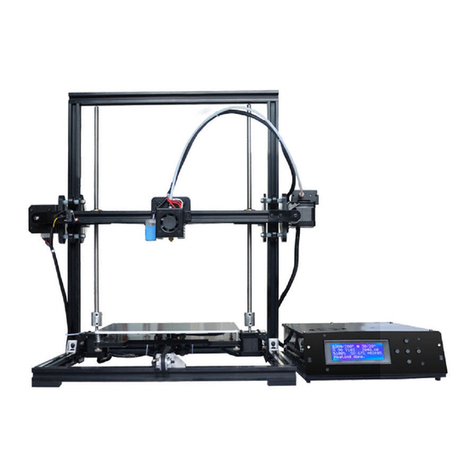

TRONXY X3A User manual

TRONXY

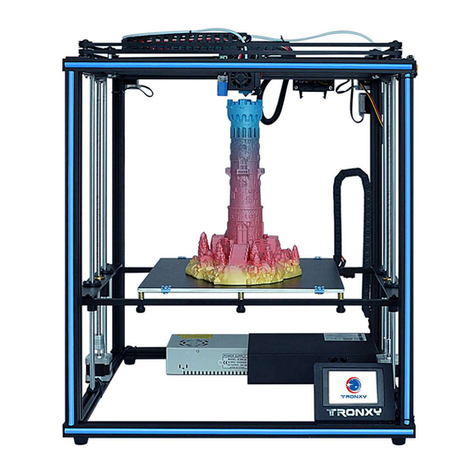

TRONXY X5SA User manual

TRONXY

TRONXY X5SA-400-PRO User manual

TRONXY

TRONXY X6-2E User manual

TRONXY

TRONXY XY-2 User manual

TRONXY

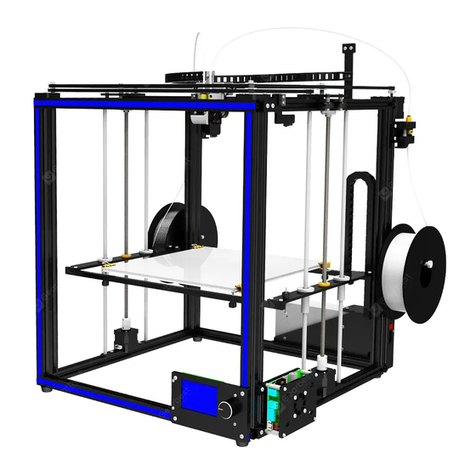

TRONXY X5S 2E User manual

TRONXY

TRONXY XY-2 PRO User manual

TRONXY

TRONXY X5S User manual

TRONXY

TRONXY VEHO 600-2E User manual

TRONXY

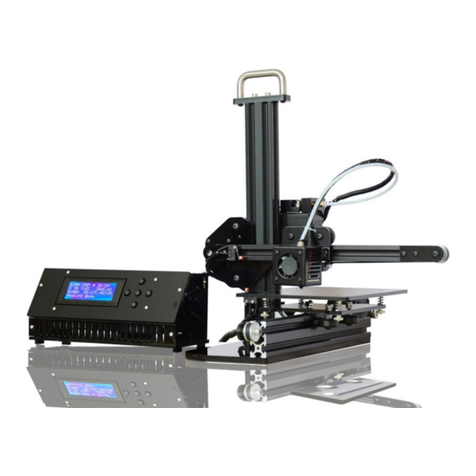

TRONXY X1 User manual

TRONXY

TRONXY X5SA-400-2E User manual

TRONXY

TRONXY X5SA-500-PRO User manual

TRONXY

TRONXY X3A User manual

TRONXY

TRONXY X3A User manual

TRONXY

TRONXY Ultrabot User manual

TRONXY

TRONXY VEHO600 User manual

TRONXY

TRONXY XY-3 PRO V2 User manual

TRONXY

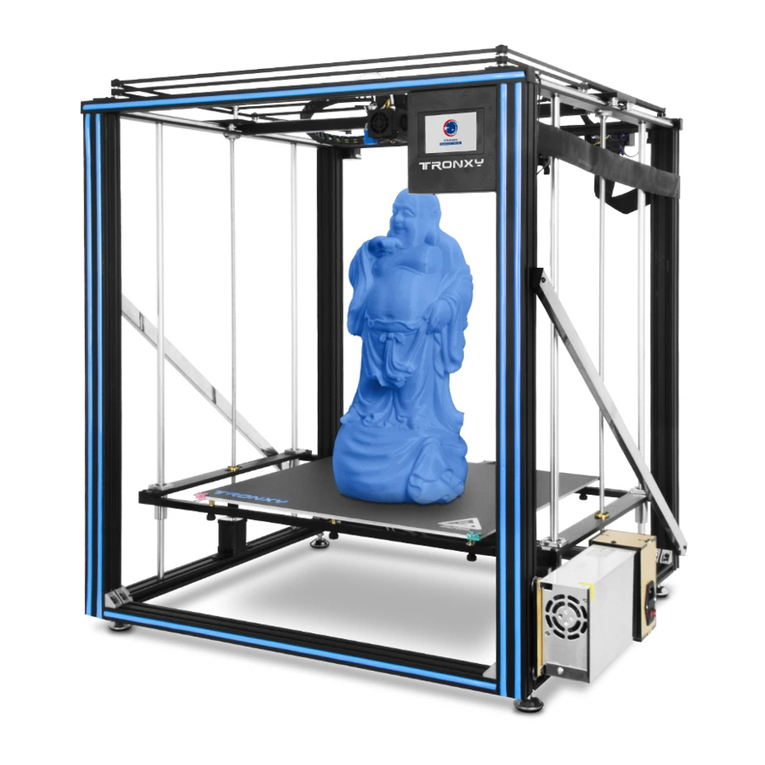

TRONXY X5SA-500 User manual

TRONXY

TRONXY XY-2 PRO User manual

Popular 3D Printer manuals by other brands

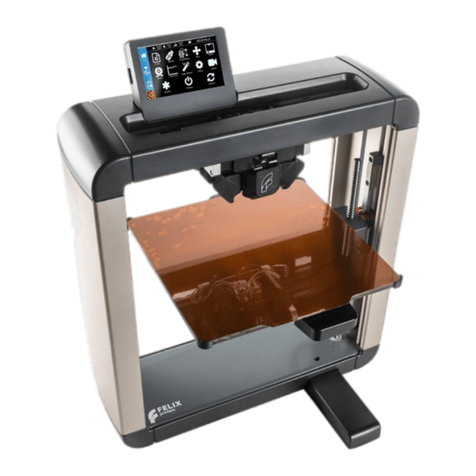

FELIXprinters

FELIXprinters Pro Series How-to

3D Upfitters

3D Upfitters 3D Printer Carbon Air Filter installation manual

Shining 3D

Shining 3D AccuFab L4D installation guide

FELIXprinters

FELIXprinters Pro Series troubleshooting guide

Airwolf 3D

Airwolf 3D HD2x user manual

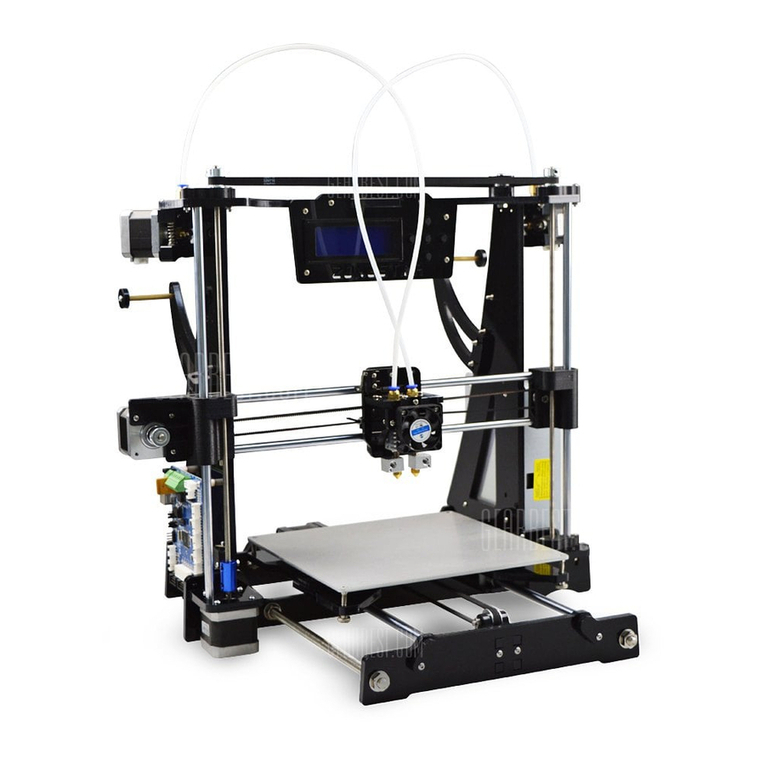

Zonestar

Zonestar P802CR2 installation guide