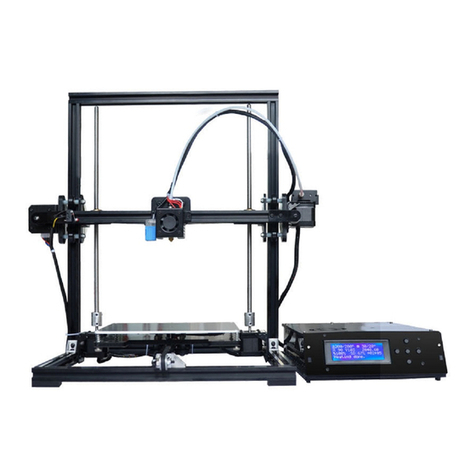

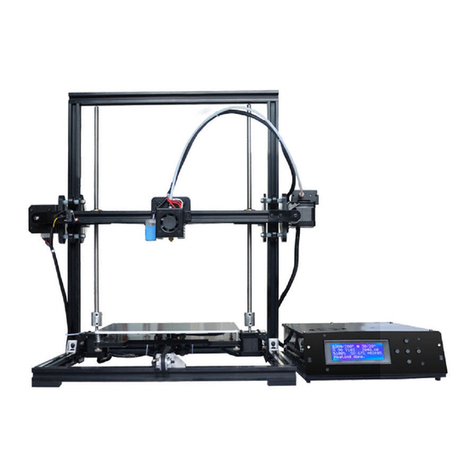

TRONXY D01 User manual

Table of contents

Other TRONXY 3D Printer manuals

TRONXY

TRONXY X5SA-400-2E User manual

TRONXY

TRONXY P802M User manual

TRONXY

TRONXY XY-3 User manual

TRONXY

TRONXY VEHO 600-2E User manual

TRONXY

TRONXY X5SA-500-PRO User manual

TRONXY

TRONXY X5SA User manual

TRONXY

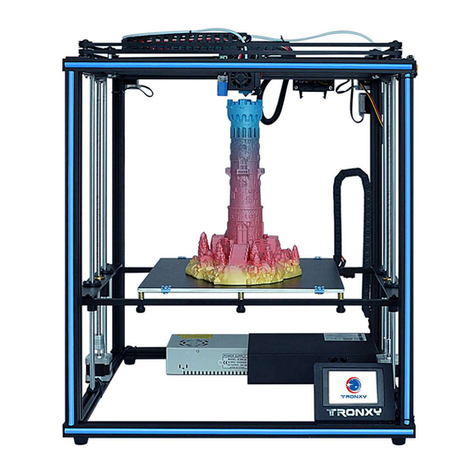

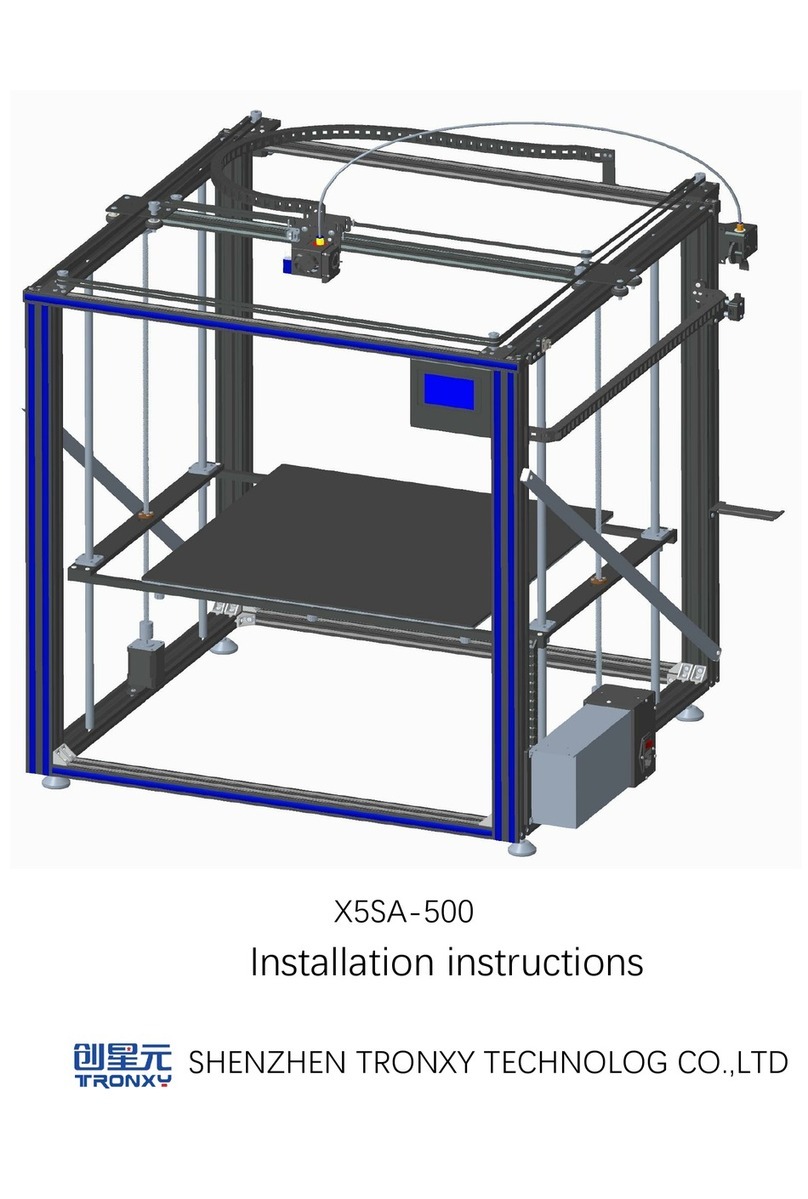

TRONXY X5SA-500 User manual

TRONXY

TRONXY X5S 2E User manual

TRONXY

TRONXY X6D User manual

TRONXY

TRONXY XY-2 User manual

TRONXY

TRONXY XY-2 PRO User manual

TRONXY

TRONXY X1 User manual

TRONXY

TRONXY XY-3 PRO V2 User manual

TRONXY

TRONXY X5S User manual

TRONXY

TRONXY XY-2 PRO User manual

TRONXY

TRONXY X5SA-400-PRO User manual

TRONXY

TRONXY X5 User manual

TRONXY

TRONXY VEHO600 User manual

TRONXY

TRONXY Ultrabot User manual

TRONXY

TRONXY X3A User manual

Popular 3D Printer manuals by other brands

3D Systems

3D Systems ProX user guide

FLASHFORGE 3D PRINTER

FLASHFORGE 3D PRINTER inventor quick start guide

Dolomite

Dolomite fluidic factory quick start guide

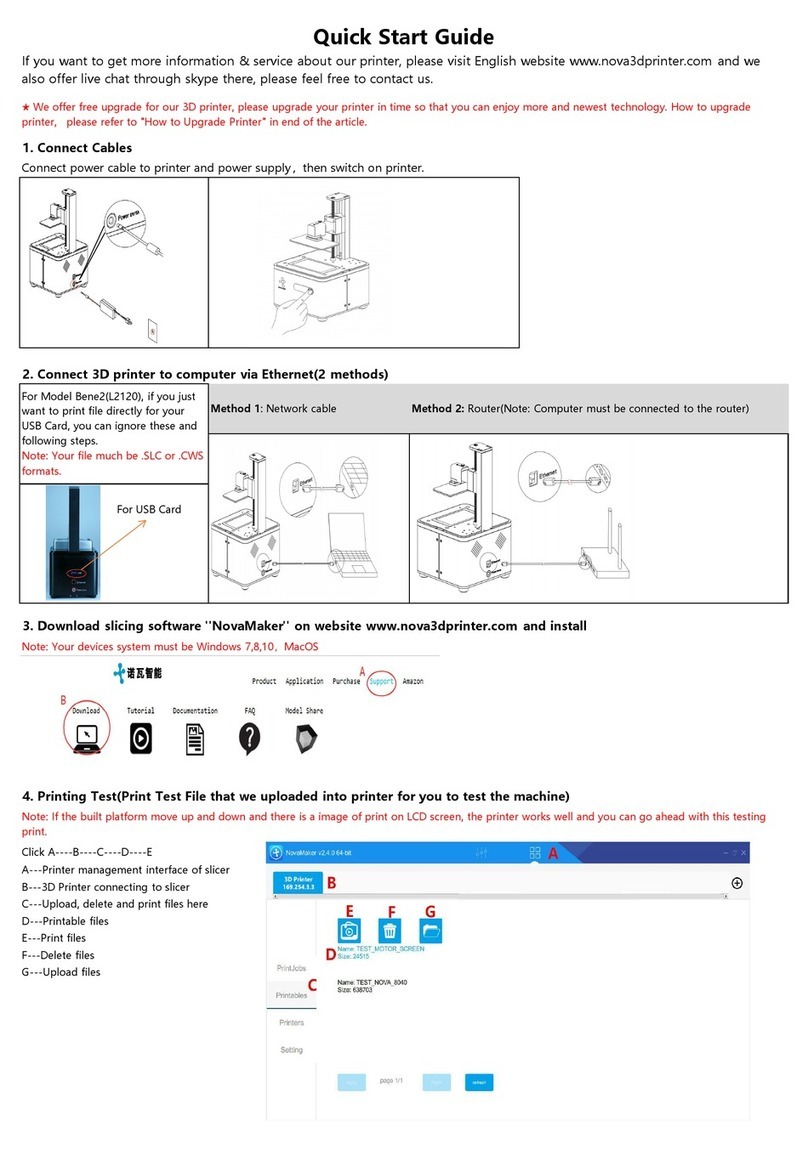

Nova

Nova Bene2 L2120 quick start guide

zortrax

zortrax M200 Maintenance Guide

3D Upfitters

3D Upfitters BlazeCut Fire Extinguisher installation manual