TRONXY XY-2 PRO User manual

Attention

After receiving the package, please check the

accessories according to the packing list. If

you have any questions, please contact

customer service.

Please use the machine in a ventilated, dry,

clean and flat environment

The machine contains high speed moving

parts and high temperature parts. Children

are not allowed to use the machine without

permission

Part of the accessories are consumable,

the warranty period is different

It is not recommended to use this machine

when unattended

Do not refit or disassemble the core parts

of the machine without permission

Relevant information is stored in

SD card, please check

Note: please make sure the voltage of the power supply is

consistent with the voltage in the area before printing.If

not, please turn the 110V-220V switch on the power

supply.

Directory

1. Machine parameters ………………………… 2

2. Packing list ………………………………… 3

3. Machine details ……………………………… 4

4. Installation ………………………………… 5

5. Wiring connection …………………………… 6

6. Structure debug ……………………………… 7

7. Operation & Print ………………………… 8

8. Failure cause analysis ………………………14

Tronxy FaceBookSupport

1

Service email :Support@tronxy.com

Print parameters:

Print size :255*255*260mm

Print accuracy :0.1-0.3mm

Print principle :FDM(fused deposition molding)

Nozzle size :0.4mm

Nozzle quantity :1

Print speed :20-150mm/s(advise 60mm/s)

Position accuracy :X/Y -0.0125mm,Z –0.000625mm

Filaments support :PLA、ABS

Temp parameters:

Print environment :8-40℃

Nozzle temp :275℃(MAX)

Software:

Slicer :Tronxy、Cura、Simplify3D

Input format :.stl、.obj

Output format :.gcode

Connection :SD card、USB cable

Power supply:AC 110/220V 50/60Hz DC 24V/360W

Machine parameters:

Machine size :478*455*520mm

Package size :510*480*230mm

Weight :≈12kg

1. Machine parameters

2

Upper bracket Base Filament

bracket

XY-2 PRO Specification

HM5*50 4PCS

Tools

Shovel Power line USB cable Stickers

Reader

(

with

SD card)

Filament

0.25KG Print head Clips(Color

random)

Quick

connection M6

Ties

2. Packing list

3

Notes :Please insure you received all items on the packing

list after receiving the printer.

If you have any questions , please contact the customer

service.

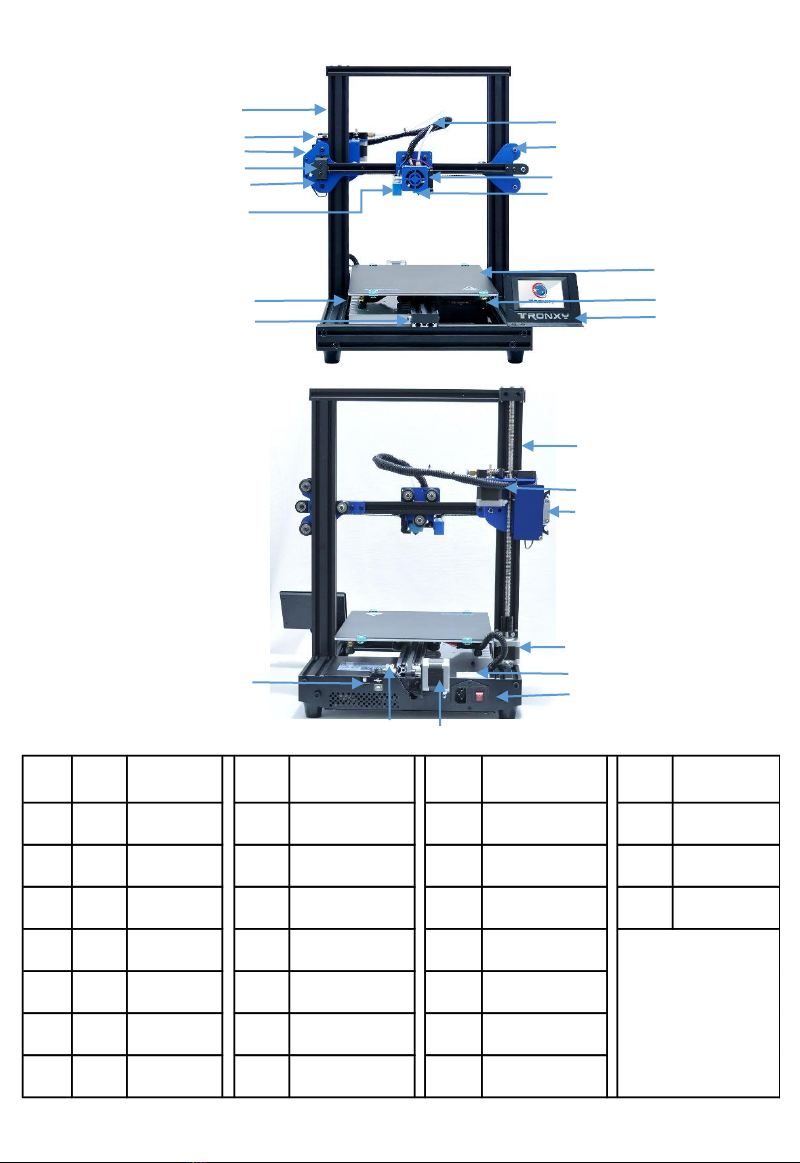

3. Machine details

2

22

23

序号 NO. Commodity NO. Commodity NO. Commodity NO. Commodity

1 1

Upper

bracket

8 Y axis wheels 15 Touch screen 22 Y axis motor

2 2

Filament

run-out

9 Feeding tube 16 Lead screws 23

Y limited

switch

3 3 X axis motor 10 Right slicer 17 Extruder motor 24

USB/SD card

interface

4 4

X limited

switch

11

Print head

component

18 30P single cable

5 5 Left slicer 12 Extruder 19 Z axis motor

6 6

Auto level

sensor

13 Heatbed 20 Control box

7 7 Power 14 Adjustment nuts 21 Power switch

1

3

4

5

6

7

8

9

11

12

10

16

17

18

14

15

13

20

21

19

4

24

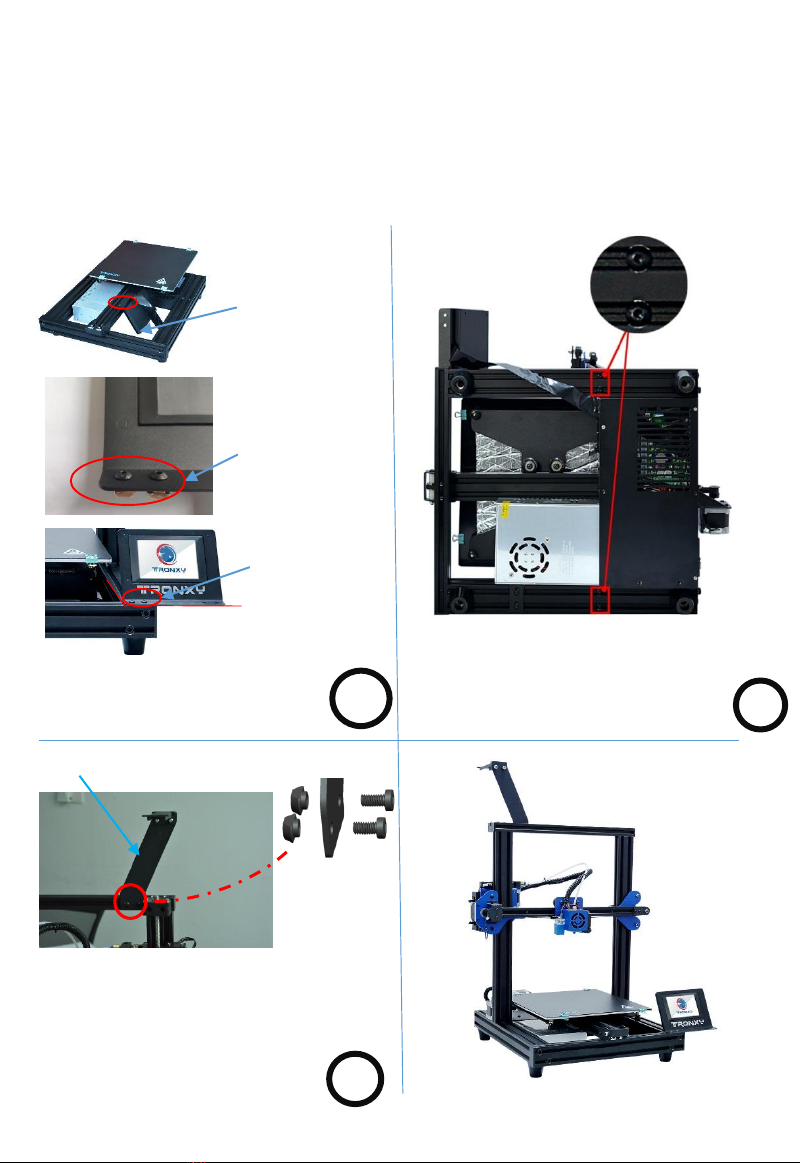

4. Installation

1

Loosen the screws

with the socket

wrench and remove

the touch screen

from the beam.

Remove the screws

and nuts.

Filament

bracket

Take the upper bracket and match the

four holes to the four holes of the

base. Use four M5*50 screws to lock

the upper bracket to the base.

Lock the ship nut

with socket wrench

and fix the touch

screen on the front

beam profile of the

base.

Note: the controller must be locked

on the front beam, otherwise it will

collide with the hot bed.

Take out the filament bracket, lock

the ship nut with hexagon wrench,

and fix the bracket on the upper

beam.

5

2

3

done

Pass the removed

screw through the

touch acreen

bracket and carry

the ship nut.

Note: please make sure the voltage of the power supply is

consistent with the voltage in the area before printing.If

not, please turn the 110v-220v switch on the power supply.

5. Wiring connection

Z motor line

Z motor line

6

Switch line

Switch board

Switch board

Switch line installation

method:

Remove the buckle, and

put it on the notch side

of the quasi-adapter

plate on the raised side

of the adapter, and

insert it firmly until the

buckle bounces back.

Power 110v-220v switch

If the machine structure is loose during transportation, it can be

solved by adjusting the eccentric nut.As shown in the figure below

(eccentric nut in red circle), turn the nut with a wrench to adjust the

tightness of the pulley (the pulley should not be adjusted too tight

to avoid smooth operation).

6. Structure debug

Wrench

Left slicer Right slicer Print Head HeatBed

If the structure is loose in other places, you can tighten the screws

directly.Before debugging, make sure the machine structure is in a

stable and smooth state. You can slide the print head and platform

module by hand to ensure smooth and stable sliding before leveling

printing.

Left

slicer

Right

slicer

Print Head

HotBed

7

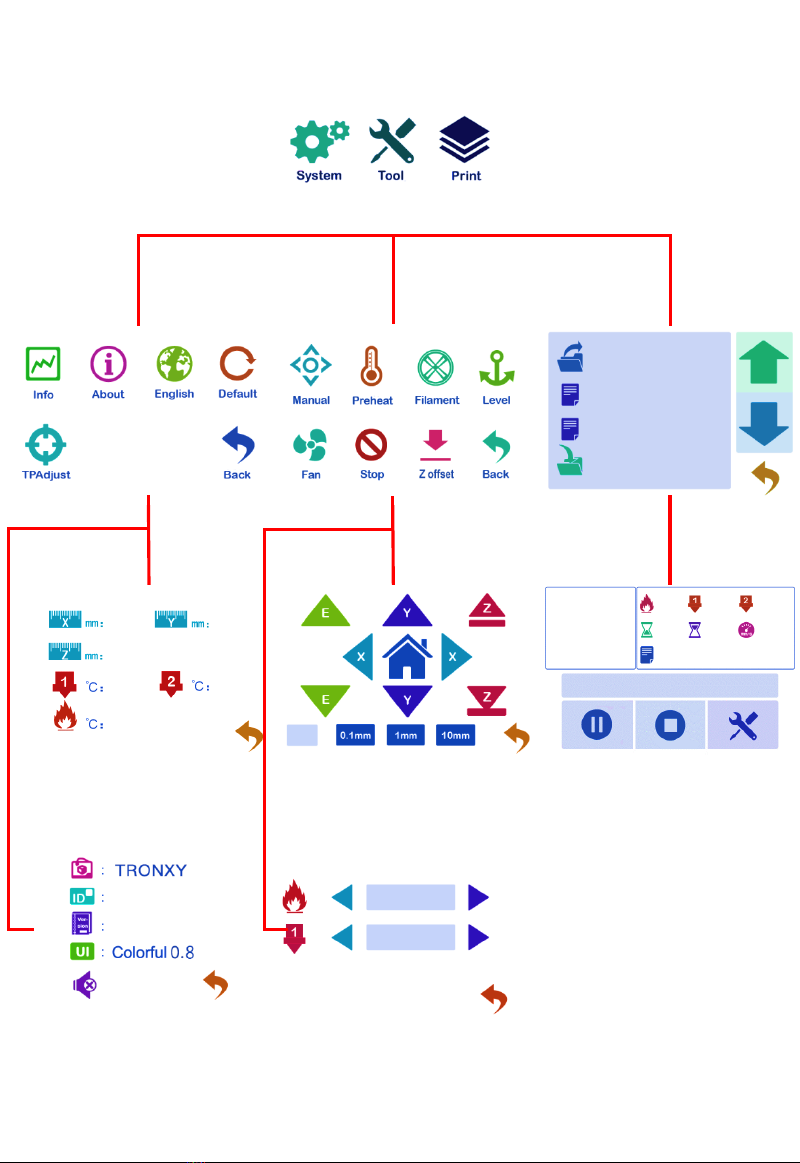

7. Operation & Print

8

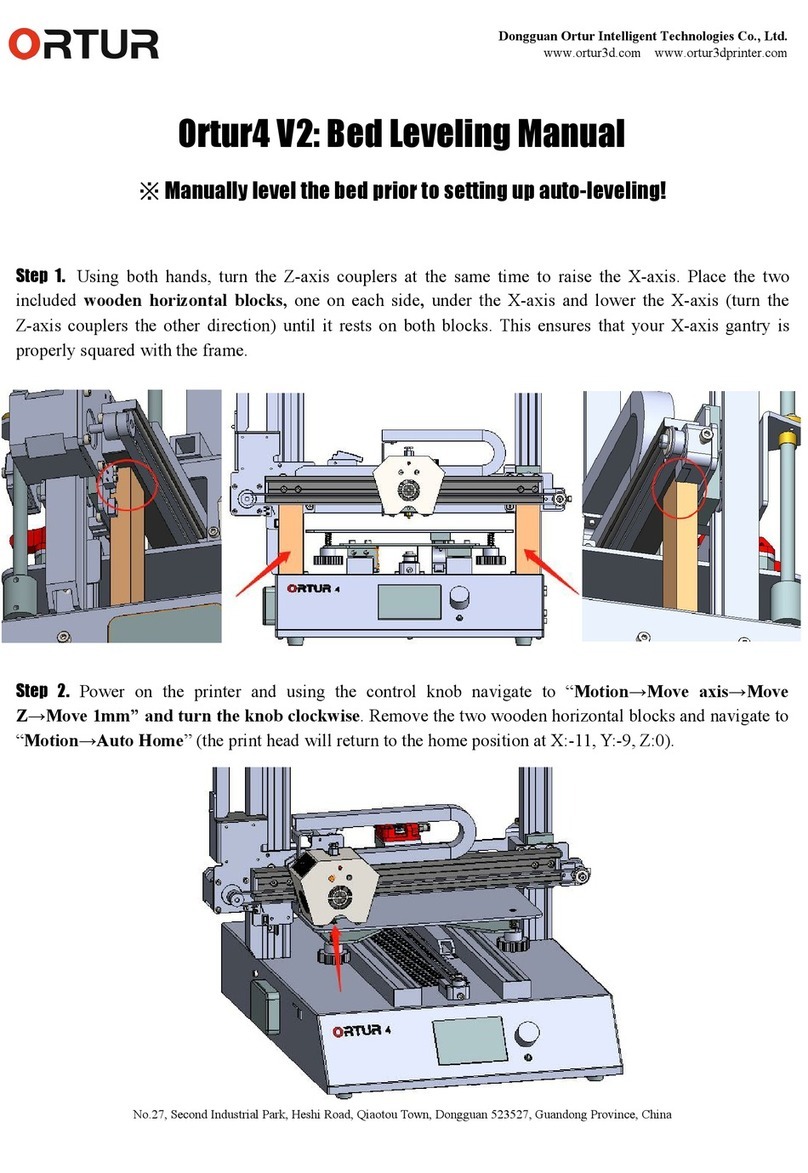

Manual leveling:

Click the four points of ABCD in the figure below, the print head will move

to the corresponding position, and then adjust the leveling nut M, so that

the interval between the nozzle and the platform is a piece of A4 paper.

After adjusting the four points in turn, it needs to be verified again. If the

interval is appropriate, the leveling is completed.

AB

C

D

M

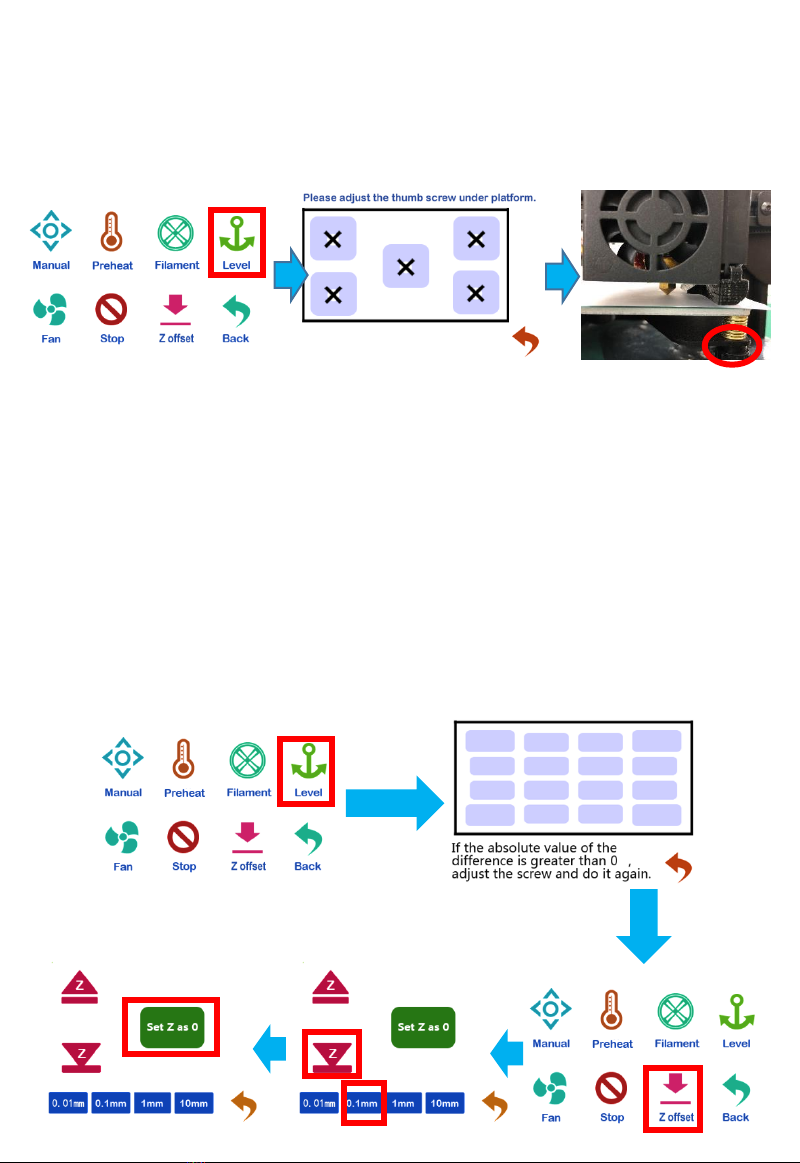

Auto leveling:

①Automatic leveling for automatic leveling version of the machine, the

manual version can not be use. Click the leveling function in the figure to

automatically pop up the interface, select "automatic leveling",jump out of

the figure (1) interface, and start leveling. After the Detection is completed,

the error value of each point will be displayed. If the value is greater than

0.8, adjust the leveling nut in the corresponding area, and then reset until

all values are less than 0.8, then the automatic leveling is completed

②Then click “Z offset”, the print head will move to the middle of the platform,

observe the height of the nozzle and platform, and then click ①②,make

the distance between the nozzle and platform for a piece of A4 paper

height, then click ③, reset the zero, so that the end of leveling.

Auto level

③

①

②

9

8

Figure (1)

Load and unload filaments:

After waiting for temperature up to 180 ℃, consumables through the

run out detection, extruder and feed pipe until the nozzle has

consumable extrusion, as shown in the figure below:

Straighten

Filament

Print test:

Click →“TEST FILE”→ ,Start printing

If the filaments cannot stick to the first layer when printing, the

nozzle will be on the high side. The Z offset value can be

appropriately increased when setting the Z offset value, or a lower

first layer height can be set when setting the slice.If the feeding of

nozzle filament is very small, the nozzle is too low. The z-offset

value can be appropriately reduced when setting Z offset or the

first layer height can be set higher when setting slice.

10

Filament run

out detection

Extrusion

Feed pipe

Click 23/0 23/199

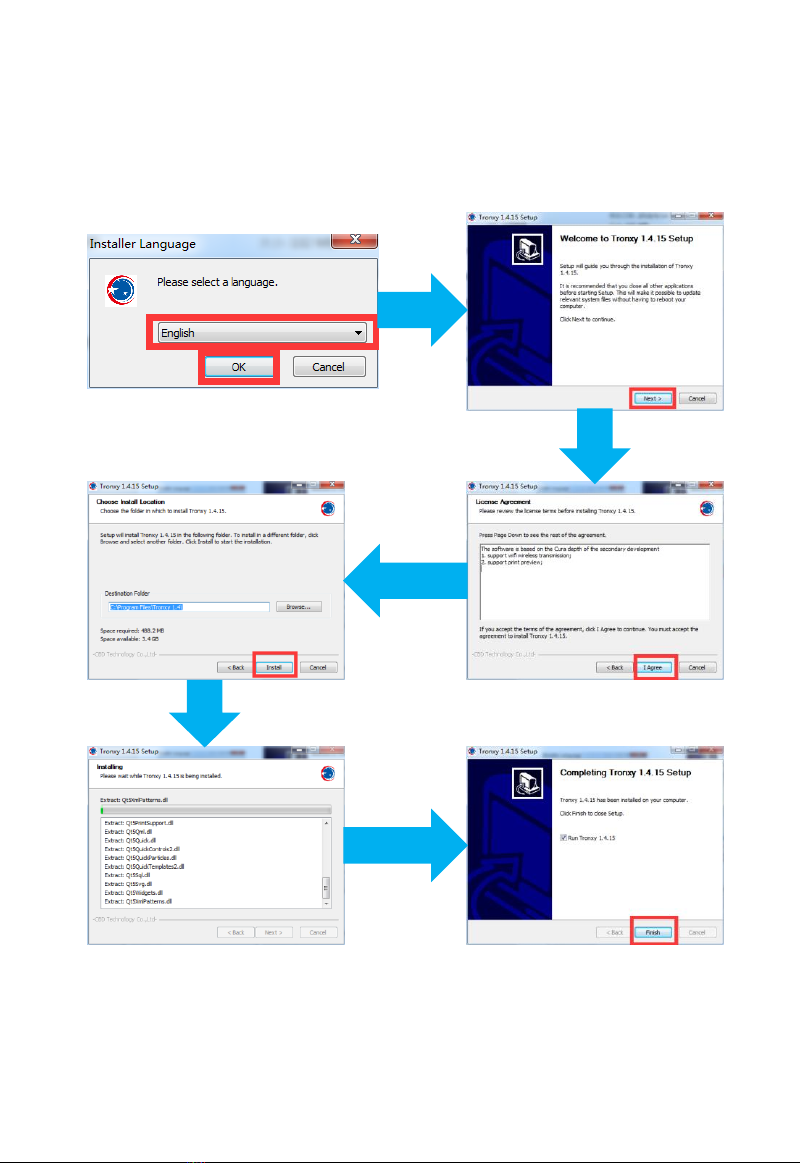

1. Installation

Find out slice software in SD card“TronxyInstall.exe ”double click,

Then follow these steps to complete the installation.

11

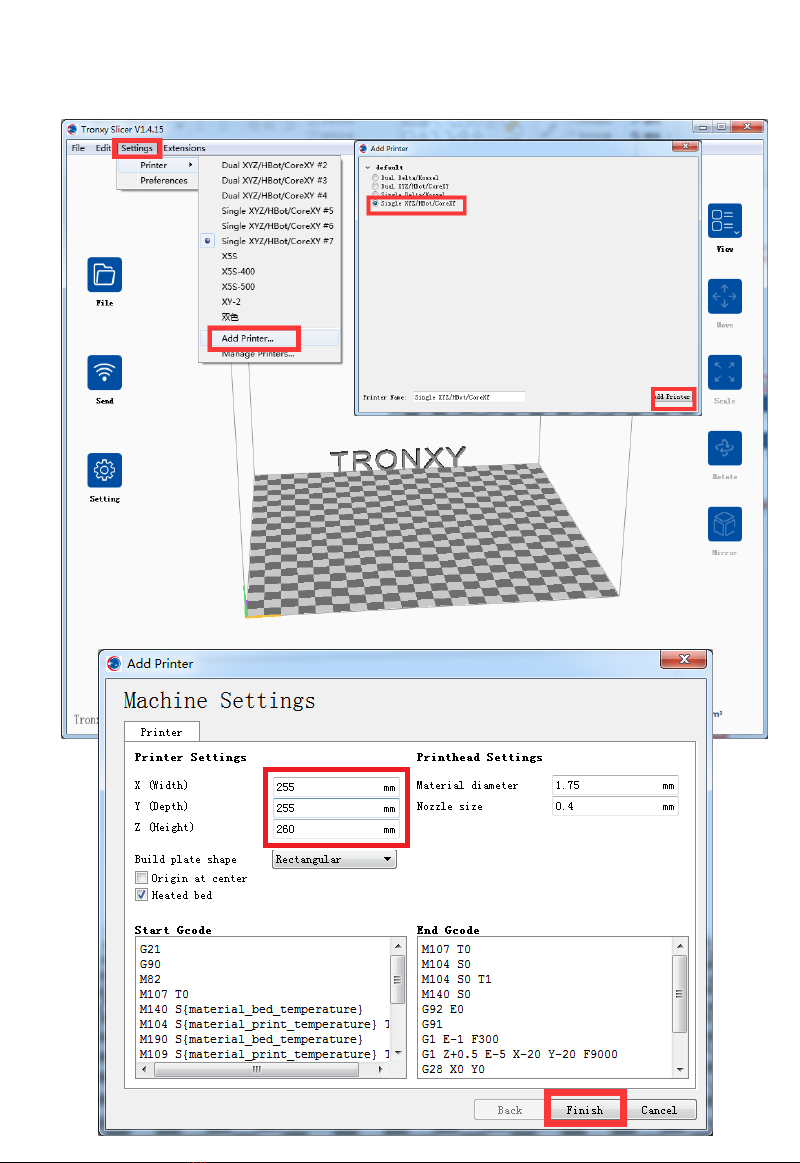

2. How to use slice software

① 、Type setting: follow the steps below to complete the setting.

①

②

③

④

⑤

⑥

12

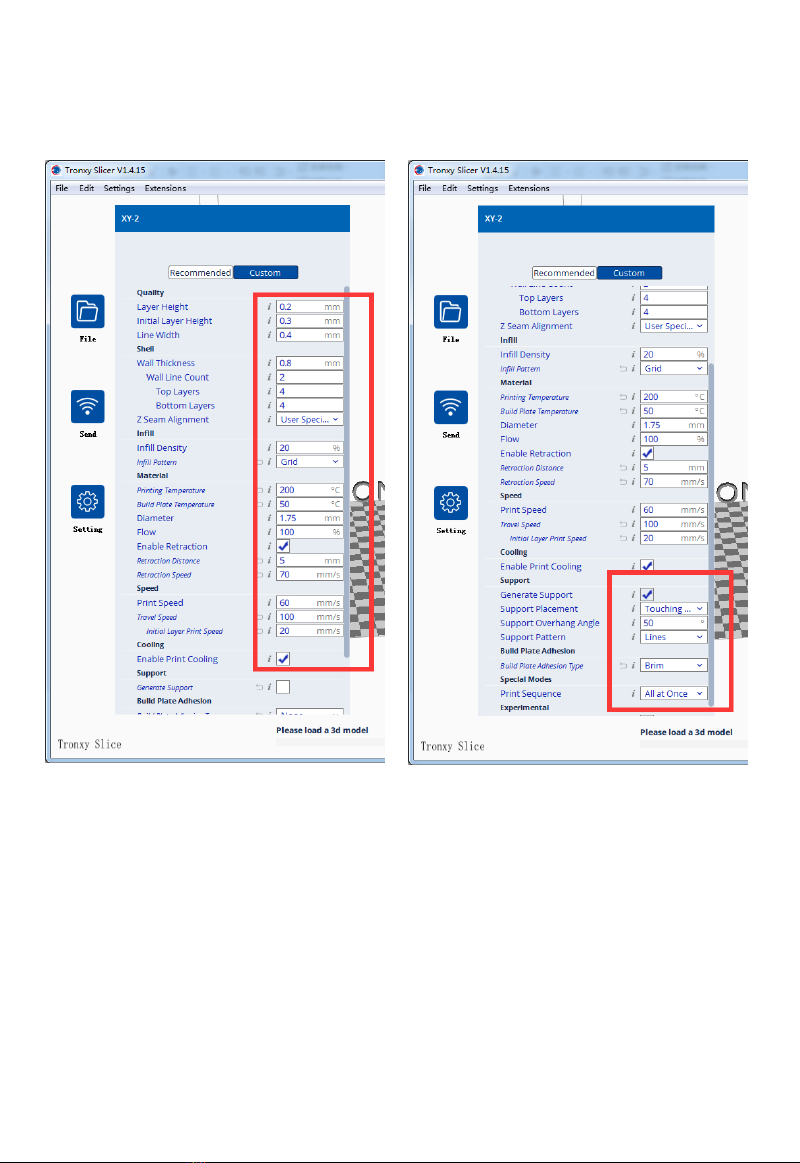

② 、Parameter setting:(The following figure gives the reference

value, according to their own needs can be modified)

Layer thickness :0.1-0.3mm

Print temp :PLA - 200 ℃ABS - 240 ℃

Heatbed temp :PLA - 50℃ABS - 80 ℃

Print speed :20-150mm/s (suggest 60mm/s)

Support :Choose according to the model

structure

Platform support:It is recommended to use the

model when the bottom contact is small

Some parameters are set for reference:

13

2. The contents of the SD card cannot be read

1)Check the card reader if damage.

2)If the connect computer show empty, please format the SD

card and try again.

3)Check whether the SD card is inserted into the socket correctly.

4)The filename has an illegal character, please rename it.

5)Please replace the damaged SD card and try again.

3. if the print head does not produce enough material

or does not produce enough material

1)Check whether the print head temperature have not reached

200 ℃above (PLA), led to consumable cannot squeeze,

waiting for the temperature rises to the set target.

2)Check whether the filaments are knotted, which leads to

unsmooth feeding.

3)Check whether the filaments or pipes are not inserted in place,

resulting in the failure of feeding.

4)Check whether the temperature of the print head is too high,

which leads to excessive softening of filaments and can't be

extruded normally.

5)Check whether the diameter of filaments is inconsistent with

the diameter set in the slicing software, so that the amount of

extrusion filaments is not enough.

6)Check whether the consumables are blocked by dirt or nozzle

blocked during extrusion.

7)Replace with better quality filaments.

1. Machine cannot start

1)Check the power line and other wires connect correct or not.

2)Check whether the supply voltage matches the local standard.

3)Check whether the screen or power supply is damaged and

replace in time.

4)Check the wires if damage or breakage.

5)Check whether the power fuse is burnt out.

8. Failure cause analysis

14

4. If the first layer upwarp

1)Check that the hot bed has been leveled.

2)Check the surface of the hot bed for dirt.

3)Check whether the distance between the nozzle and the platform is

too high, resulting in insufficient adhesive force.

4)Check the hot bed for adequate temperature.

5)Check the first layer of the slicing software to see if it is printing too

fast.

5. The model is not easy to take off

1)Heating the hot bed to 50-70 ℃, and after cooling to try again, or

use the shovel.

2) It is recommended to buy TRONXY magnetic stickers.

6. Can‘t heat it up

1)Check the heating rod and thermistor for poor contact or damage.

2) Check that the slice software has set the target temperature.

3) Check whether the thermistor wire falls off.

7. Motor out of step

1)Check the tightness of the belt, whether the pulley is not locked.

2)Check the current voltage.

3)Check X/Y/Z axis motion is smooth.

4)Print speed too fast.

5)Environment temp too high.

6)Need flash the firmware.

8. Abnormal motor noise or vibration

1)Check whether the motor line is in bad contact, loose or wrong

connection.

2)Motor temperature is too high.

3)Check whether the motor is damaged.

4)Flash the firmware.

5)The printing load is too heavy.

15

9. Model dislocation and fault

1)Nozzle feeding not smoothly, please clean the nozzle or

replace the nozzle

2)Check that if the printing speed is too fast

3)The quality of filaments is poor, please replace with new

filaments

10. Abnormal sound and vibration of filaments

feeding motor

1)Please check whether the nozzle is blocked

2)The nozzle feeding is not smooth, please clean the nozzle

3)Whether the software Settings are incorrect

4)Check whether the motor does not work

5)Check the motor working or not or feeding gear is not working

11. Screen related questions

1)No screen/blue screen, please restart or check whether the

cable is plugged in

2)Touch screen malfunction, check whether the screws are

installed too tight

3)Garbled/splash screen, static, ground connection or restart

12. Motherboard related issues

1)The wiring is not responding. Please check the wiring installation

2)Automatic shutdown restart, may be abnormal firmware or

module of “resume print after power failure” damaged

3)Lack of heat dissipation, please lower the ambient temperature

4)No response due to motherboard damage

13. Unable to connect to printer

1)Check that the driver is not installed or properly installed

2)The serial port was not selected correctly

3)The software parameters do not match

16

ONLY NEEDS 3 STEP TO FINISH

THE REST INSTALLATION

FILAMENT RUN-OUT DETECTION

RESUME PRINTAFTER POWER-OFF

AUTO LEVEL

ALL METAL

Other manuals for XY-2 PRO

2

Table of contents

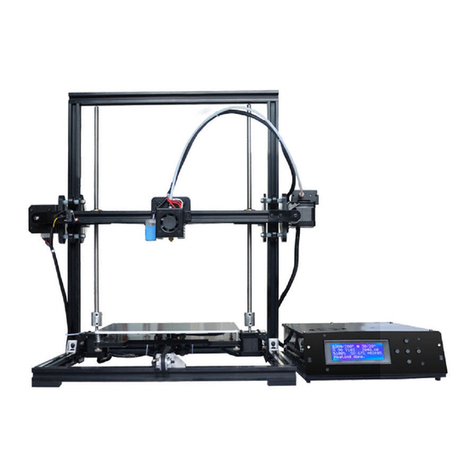

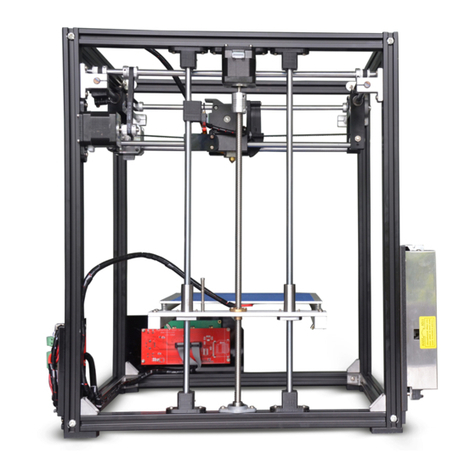

Other TRONXY 3D Printer manuals

TRONXY

TRONXY X6-2E User manual

TRONXY

TRONXY X3A User manual

TRONXY

TRONXY D01 User manual

TRONXY

TRONXY VEHO 600-2E User manual

TRONXY

TRONXY XY-3 User manual

TRONXY

TRONXY X5SA-500-2E User manual

TRONXY

TRONXY VEHO600 User manual

TRONXY

TRONXY X1 User manual

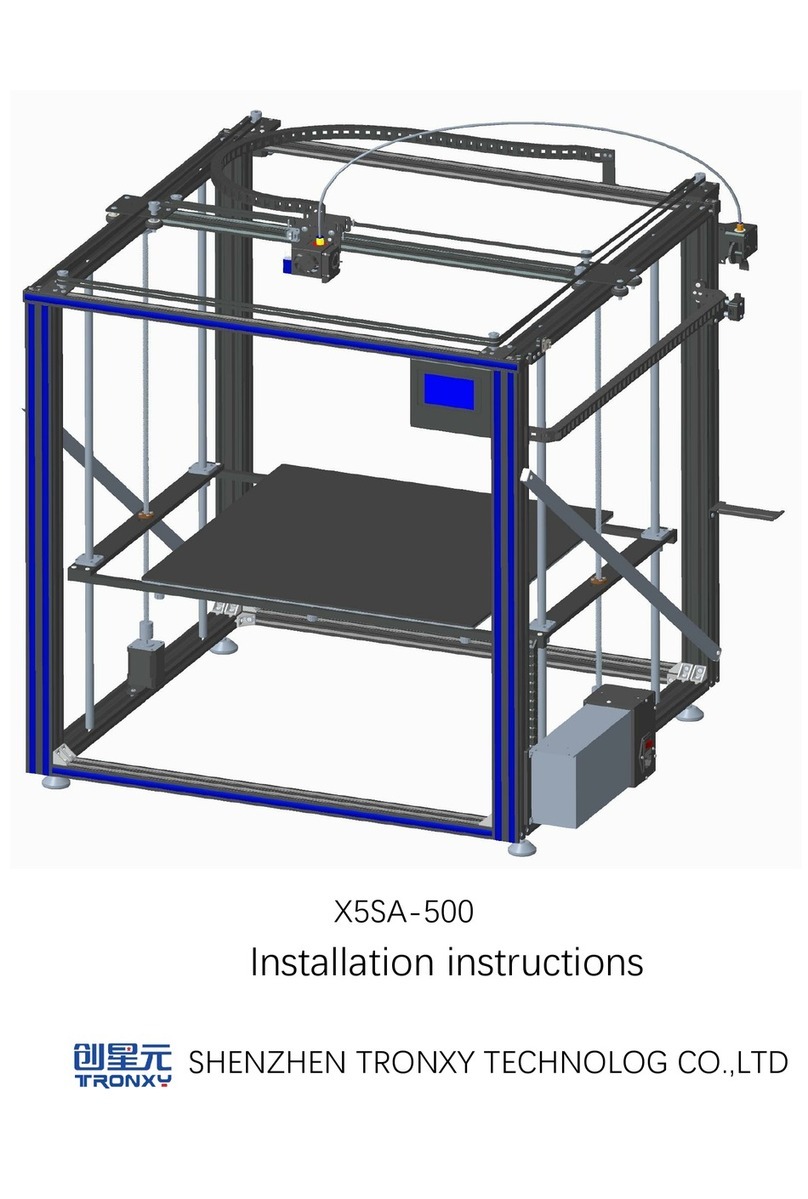

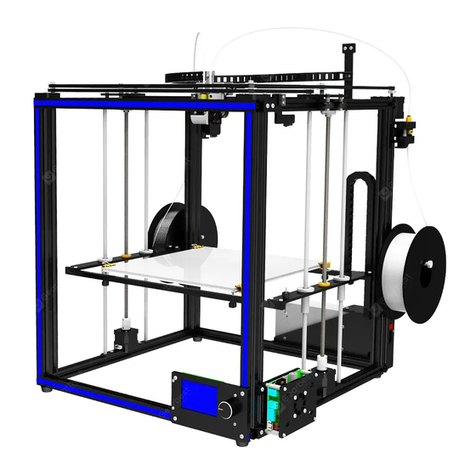

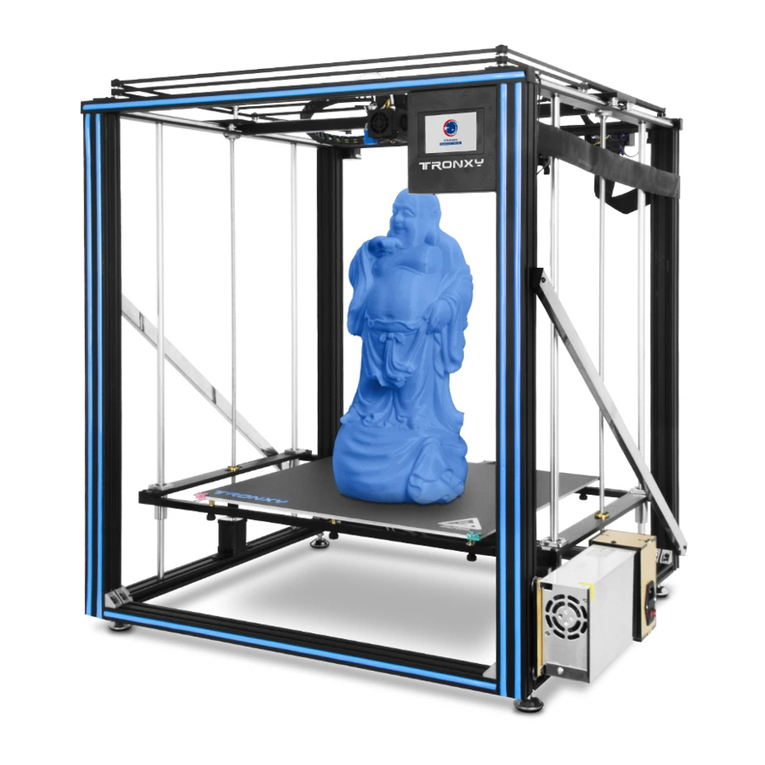

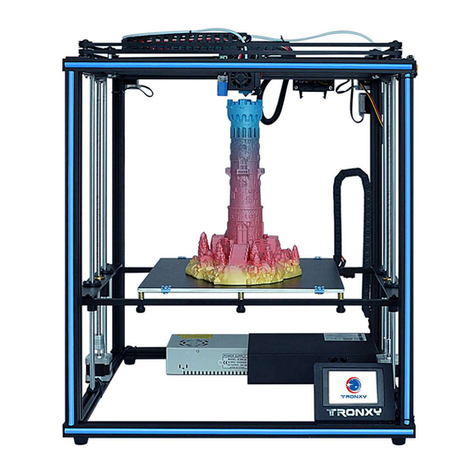

TRONXY

TRONXY X5SA-500 User manual

TRONXY

TRONXY XY-2 PRO User manual

TRONXY

TRONXY X5S 2E User manual

TRONXY

TRONXY X3A User manual

TRONXY

TRONXY X5SA-400-PRO User manual

TRONXY

TRONXY X5SA-500-PRO User manual

TRONXY

TRONXY X5SA User manual

TRONXY

TRONXY XY-3 PRO V2 User manual

TRONXY

TRONXY X5SA-400-2E User manual

TRONXY

TRONXY X6D User manual

TRONXY

TRONXY X5 User manual

TRONXY

TRONXY Ultrabot User manual