B - 1Operating manual drying unit VX 5 EN

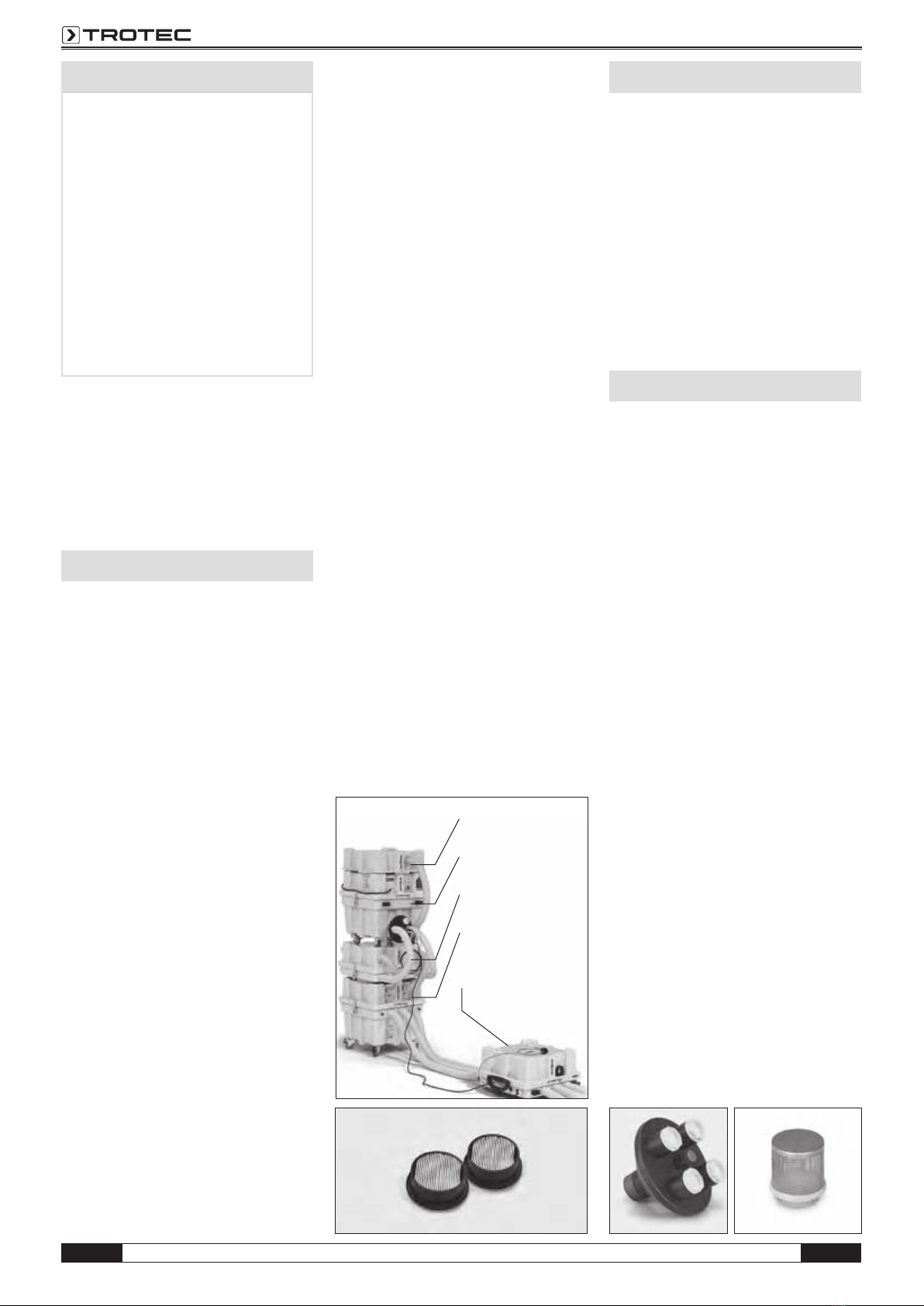

Fig. 4

Fig. 3

Fig. 1

1 silencer

NR 19

2 drying

unit VX 5

3 HEPA filter

HC

4 water separator

WA 4i with micro filter

system

5 drying unit

DA 4

Fig. 2

Table of contents

Safety .......................B - 1

Scope of delivery ..............B - 1

Device description .............B - 1

Start-up .....................B - 2

Shutdown ....................B - 2

Care and maintenance ..........B - 2

Warning .....................B - 2

Troubleshooting ...............B - 3

Technical data.................B - 3

Declaration of conformity ........B - 4

This release replaces all previous releases. No part of this publication may

be reproduced without written permission. The same applies for elec-

tronically processing, duplicating or spreading the publication. Subject to

technical changes. All rights reserved. Trademarks are used without guar-

antee that they may be used freely and primarily following the spelling of

the manufacturer. The product names used are registered and should be

treated appropriately. The right to make construction changes in the in-

terests of constant product improvement as well as changes to the shape

and colour is reserved. Scope of delivery may vary from product images.

This document was produced with all due care. We accept no liability

whatsoever for mistakes or omissions. © TROTEC®

Safety

Read this manual carefully before starting or us-

ing the device. Store the manual near the device

or its site of use!

Observe the following instructions:

• Do not use the device in potentially explosive

rooms.

• Do not use the device in atmospheres contain-

ing oil, sulphur, chlorine or salt.

• Set the device up in an upright and stable po-

sition.

• The device is designed for indoor use. Do not

use the device at a humidity level of more than

90% or in the rain.

• Ensure that the air inlet and outlet are not ob-

structed.

• Ensure that the suction side is kept free of dirt

and loose objects.

• Do not cover or transport the device during

operation.

• When using cable drums, always unroll the

cable completely.

m During damage restoration, provide a

sufficient fresh air supply! The room tem-

perature must not exceed 35°C. Ventilate

several times a day. If necessary, direct

the exhaust air produced by the VX out of

the room. You can also set up the VX in

another room (not outdoors!) and direct

the air current needed for drying to the

inside.

• Make sure to keep the dust exposure as low

as possible in low pressure operation by using

suitable micro filters (fig. 2).

• Make sure that the suction strainer (fig. 4) is

used when the device is operated with excess

pressure.

• Repair and maintenance work on electrical

equipment may only be carried out by an elec-

trically skilled person.

• On construction sites, the compressors must

only be operated with an upstream residual

current device (RCD) 30mA.

• Do not operate the device in a heavily

dust-loaded environment (e.g. during grinding

work).

Intended use

The turbines are to be used in low and excess

pressure mode for insulation drying of floating

screeds, flat roofs (warm roof constructions) and

hollow floorings. They are intended to transport

non-aggressive and non-explosive gaseous me-

dia. Any other use is regarded as non-intended

use.

Improper use

The devices are not suitable for the inflation of

bouncy castles or similar objects. Media other

than those listed as intended use must not be

transported.

Personnel qualifications

The compressors may only be operated by ex-

pert persons who have been instructed in the

operation of the devices and trained in insulation

drying techniques. The operating manual is to be

consulted for this purpose. Instructed persons

have been informed of and, if necessary, trained

for the tasks they were entrusted with as well as

of potential hazards resulting from inappropriate

behaviour.

Scope of delivery

Standard scope of delivery:

• 1 x compressor

• 1 x suction strainer fig. 4

• 2 x connectors 50/38 mm

• 1 x operating manual

Optionally available accessories:

• door gap nozzle PlanoPro

(Art. no. 6.100.000.160)

• MultiQube silencer NR 19

(fig. 1; no. 1);

Art. no. 6.100.000.120

• Quad distributor Pro (fig.3);

Art. no. 6.100.000.142

Description of the device

The compressors of the VX series are used for

drying insulation layers. In case of excess pres-

sure drying, the roomair is blown into the humid

insulation layer via bore holes, the insulation

layer absorbs the humidity and returns it to the

environment via the expansion joints.

In case of low pressure drying, a drying chain

(fig. 1) consisting of water separator, air filter

and compressor is used to suck the air out of the

insulation layer. The air sucked out of the bore

holes is separated from solid particles and water

drops inside the water separator. Particles and

mould spores are filtered out by the HEPA and

F7 filters.

Should there be any concerns relating to air pol-

lution due to fibres or spores from inside the in-

sulation layer (GefStoffV: Ordinance on Hazardous

Substances), the use of the low pressure proce-

dure is compulsory in order to filter the polluted

air. The silencer allows to effectively decrease the

volume in occupied buildings.

The humid air has to be dried additionally by ade-

quately powerful mobile dehumidifiers.

• To be able to use the high performance of the

VX compressors, it is necessary to operate the

optional quad distributor Pro (fig. 3) with at

least two 38mm hoses. If no quad distributor

can be used, the hose diameter should be at

least 50mm, for otherwise there might be per-

formance losses of up to 10%.

• This VX distributor is equipped with self-regu-

latory step switches.

• The device comes with 4 power stages:

stage 1 with 100 m³/h; stage 2 with 150 m³/h

and stage 3 with 180 m³/h as well as the boost

stage with up to 245 m³/h. In addition, there

is a "whisper mode" with 100 m³/h as well.

For each of these steps, the VX tries to achieve

the target air volume, regardless of the con-

struction.