Hans Turck GmbH & Co. KG •

6

Instructions for use – Inductive Coupler NIC…-M30

2.4 Manufacturer and service

With almost 50 years of experience and an extensive know-how, we can support you in every project phase – from

the initial analysis right through to the tailored implementation and commissioning of your application. In the

TURCK product database you will find the right solution, whether this involves software tools for programming,

configuration or commissioning support, detailed data sheets or CAD data in almost 80 export formats – acces-

sible worldwide, in nine different languages, free of charge and without registration. You can access the Product

Database via the following address: www.turck.de/en

For further inquiries contact Application Suport:

■800.544.7769

■appsupport@turck.com

Or contact your local TURCK representative via the below link:

http://turck.us/Support/North_American_Sales_Channel/

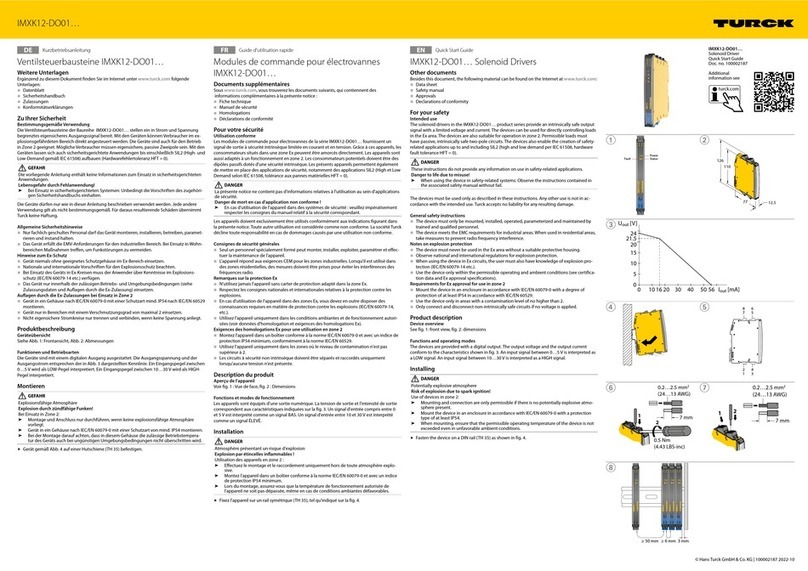

3 For Your Safety

The product is designed according to the latest state of the art technology. Residual hazards, however, still exist.

Observe the following safety instructions in order to avoid hazards. TURCK accepts no liability for damage caused

by failure to observe these safety instructions.

3.1 Intended use

Inductive couplers consist of a primary side and a secondary side. The devices are used for the contactless and

bidirectional transfer of power and data between an air interface (max. 7mm) in industrial environments. The pri-

mary side supplies power to the secondary side through the air interface. The secondary side supplies in turn data

from the connected sensors as well as sensors and actuators connected in IO-Link mode.

The product must only be fitted, installed, operated and maintained by trained and qualified personnel. The ma-

chine designer, supervising engineer, machine builder and/or the maintenance electrician are responsible for en-

suring that the product is used in full compliance with all applicable regulations and standards.

3.2 Safety instructions for inductive couplers

WARNING

Possible risk of heating the devices

Risk of burns through contact with hot surfaces of the device!

Do not place any metal objects such as screw drivers in the electrical field between the primary and secondary

side.

3.3 General safety notes

Observe the following safety instructions in order to prevent danger to persons and property:

WARNING

The devices are not safety devices and must not be used for people or machine protection.