Contents

Hans Turck GmbH & Co. KG | T +49 208 4952-0 |

[email protected] | www.turck.com

V01.00 | 2023/03 | 2Contents

1 About these Instructions ...................................................................................................................4

1.1 Target groups ...................................................................................................................4

1.2 Explanation of symbols used.........................................................................................4

1.3 Other documents.............................................................................................................4

1.4 Feedback about these instructions ..............................................................................4

2 Notes on the product .........................................................................................................................5

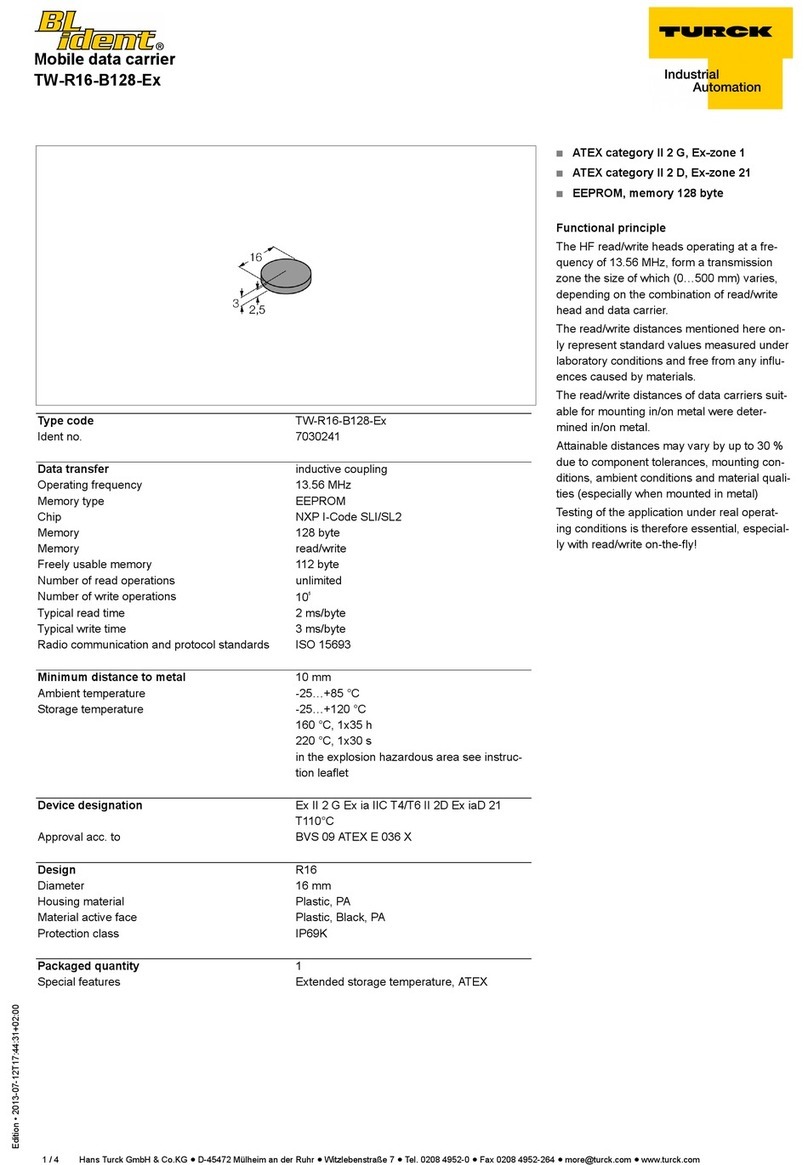

2.1 Product identification .....................................................................................................5

2.2 Scope of delivery..............................................................................................................5

2.3 Turck service .....................................................................................................................5

3 For your safety.....................................................................................................................................6

3.1 Intended use .....................................................................................................................6

3.2 General safety instructions ............................................................................................6

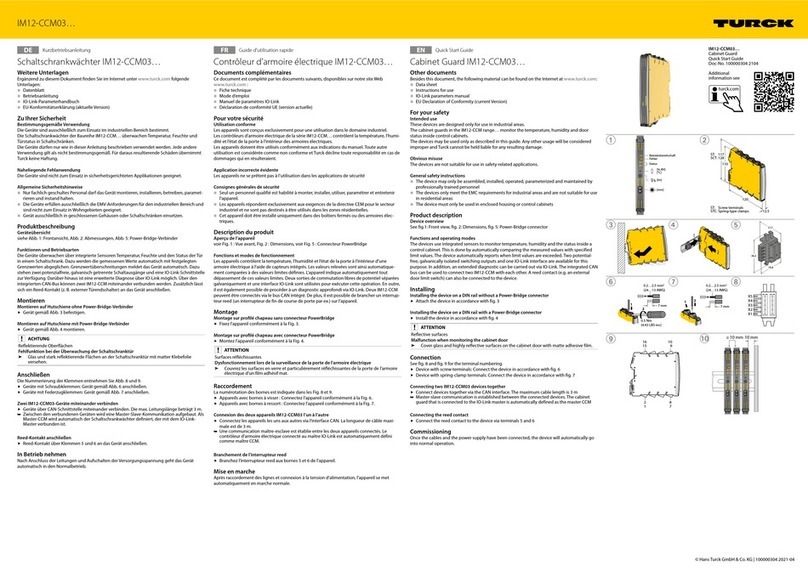

4 Product description ............................................................................................................................7

4.1 Device overview...............................................................................................................7

4.2 Properties and features ..................................................................................................7

4.3 Operating principle .........................................................................................................8

4.4 Functions and operating modes...................................................................................8

4.4.1 IO-Link mode......................................................................................................................................8

4.4.2 SIO mode.............................................................................................................................................8

4.4.3 Configuration mode........................................................................................................................8

4.4.4 Foreign object detection (FOD) ..................................................................................................9

4.5 Technical accessories ................................................................................................... 10

5 Installing ............................................................................................................................................ 12

5.1 Angle offset.................................................................................................................... 13

5.2 Lateral offset.................................................................................................................. 13

6 Connection ........................................................................................................................................ 14

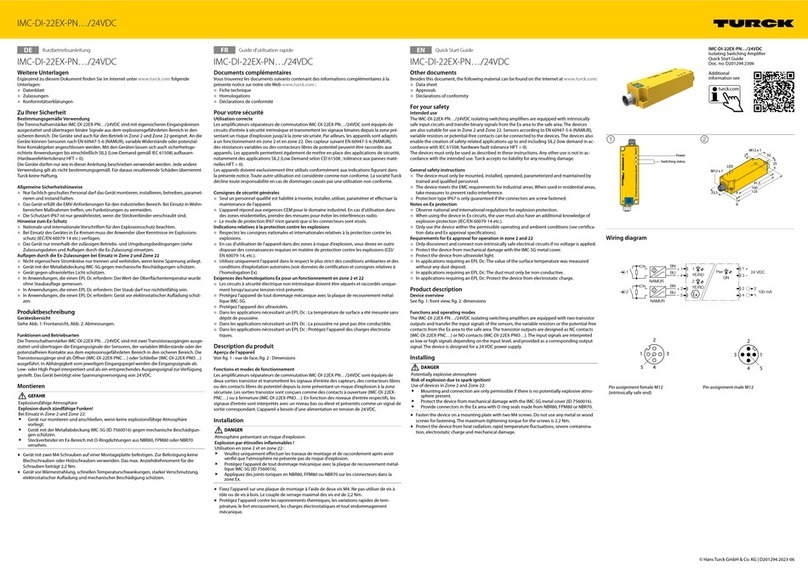

6.1 Wiring diagrams............................................................................................................ 14

6.2 IO-Link mode ................................................................................................................. 14

6.3 SIO mode ........................................................................................................................ 14

6.3.1 Digital input..................................................................................................................................... 14

6.3.2 Digital output.................................................................................................................................. 14

7 Commissioning................................................................................................................................. 15

7.1 IO-Link mode ................................................................................................................. 15

8 Operation........................................................................................................................................... 16

8.1 LEDs ................................................................................................................................. 16

8.2 Temperature derating.................................................................................................. 17

8.3 Resetting to factory settings....................................................................................... 17

9 Setting................................................................................................................................................ 18

10 Troubleshooting............................................................................................................................... 19

11 Maintenance ..................................................................................................................................... 20

12 Repair ................................................................................................................................................. 20

12.1 Returning devices ......................................................................................................... 20