CONTENT

Introductions ����������������������������������������������������������������������������� 1

Features ������������������������������������������������������������������������������������ 1

Applications ������������������������������������������������������������������������������� 1

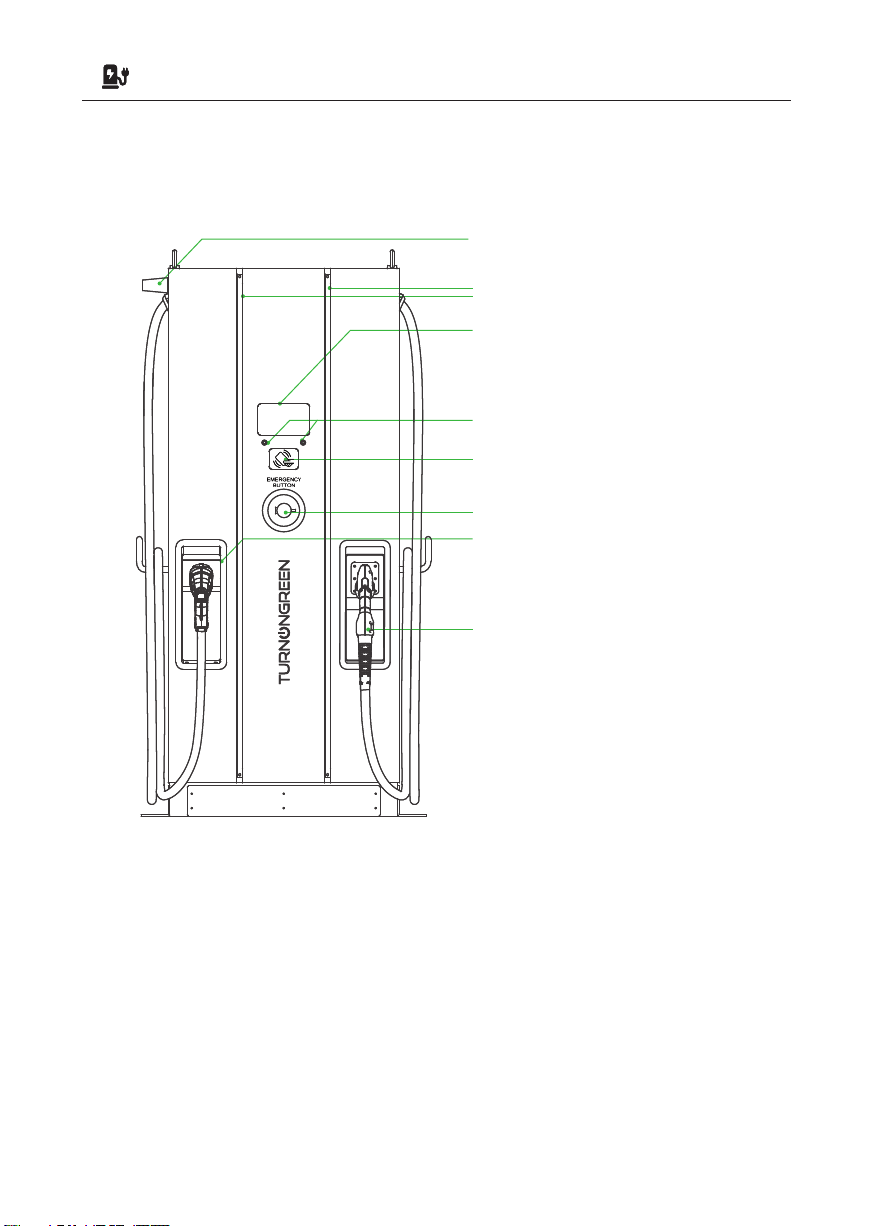

1� Basic User Interface ��������������������������������������������������������������� 2

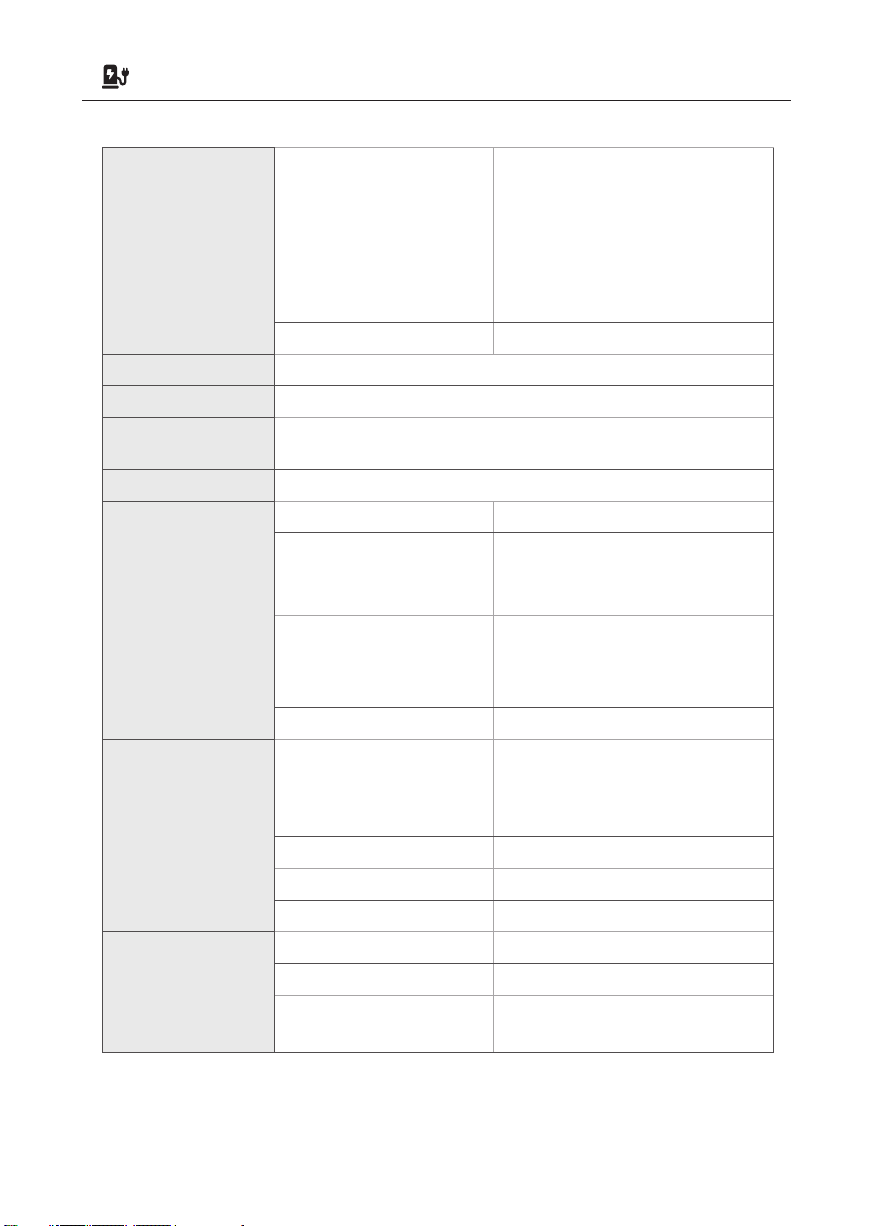

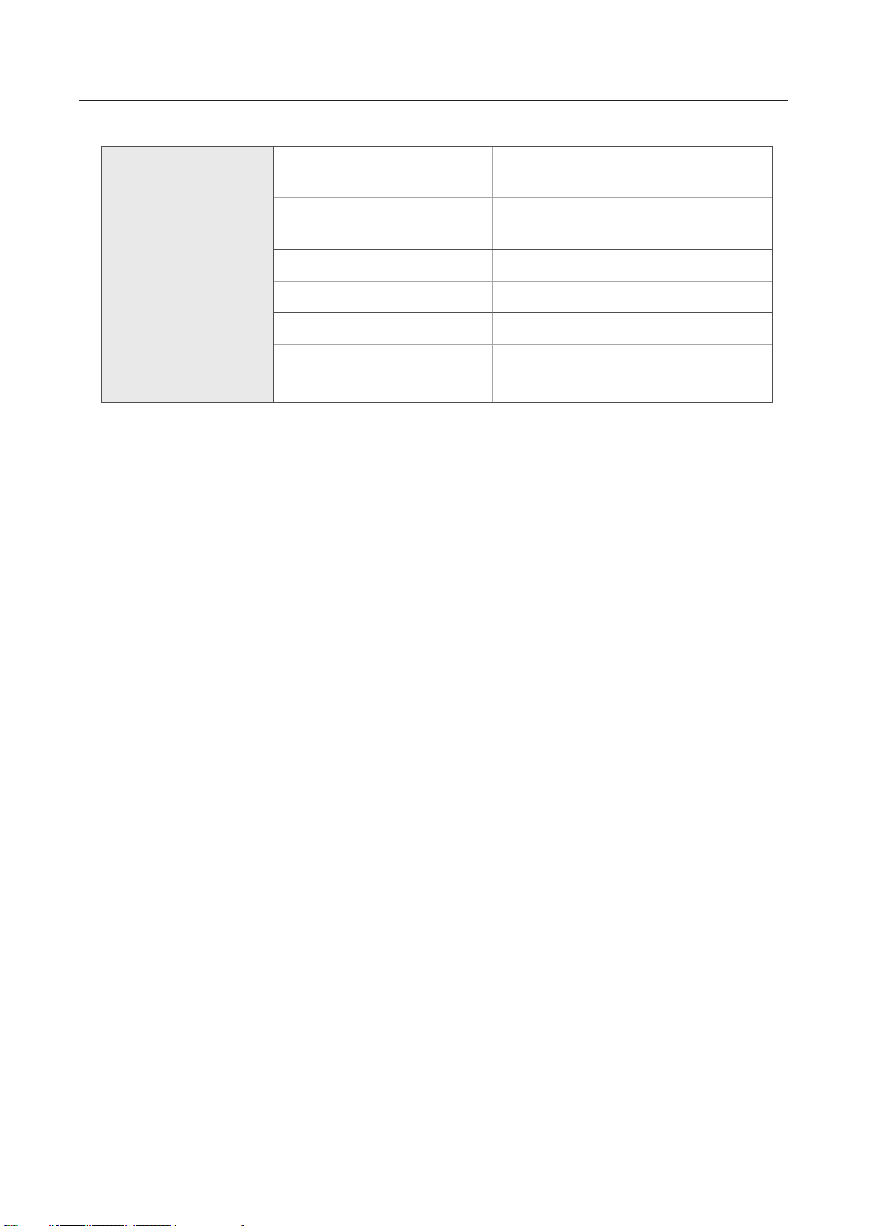

2. Specication �������������������������������������������������������������������������� 3

2.1 Product Specication ������������������������������������������������������ 3

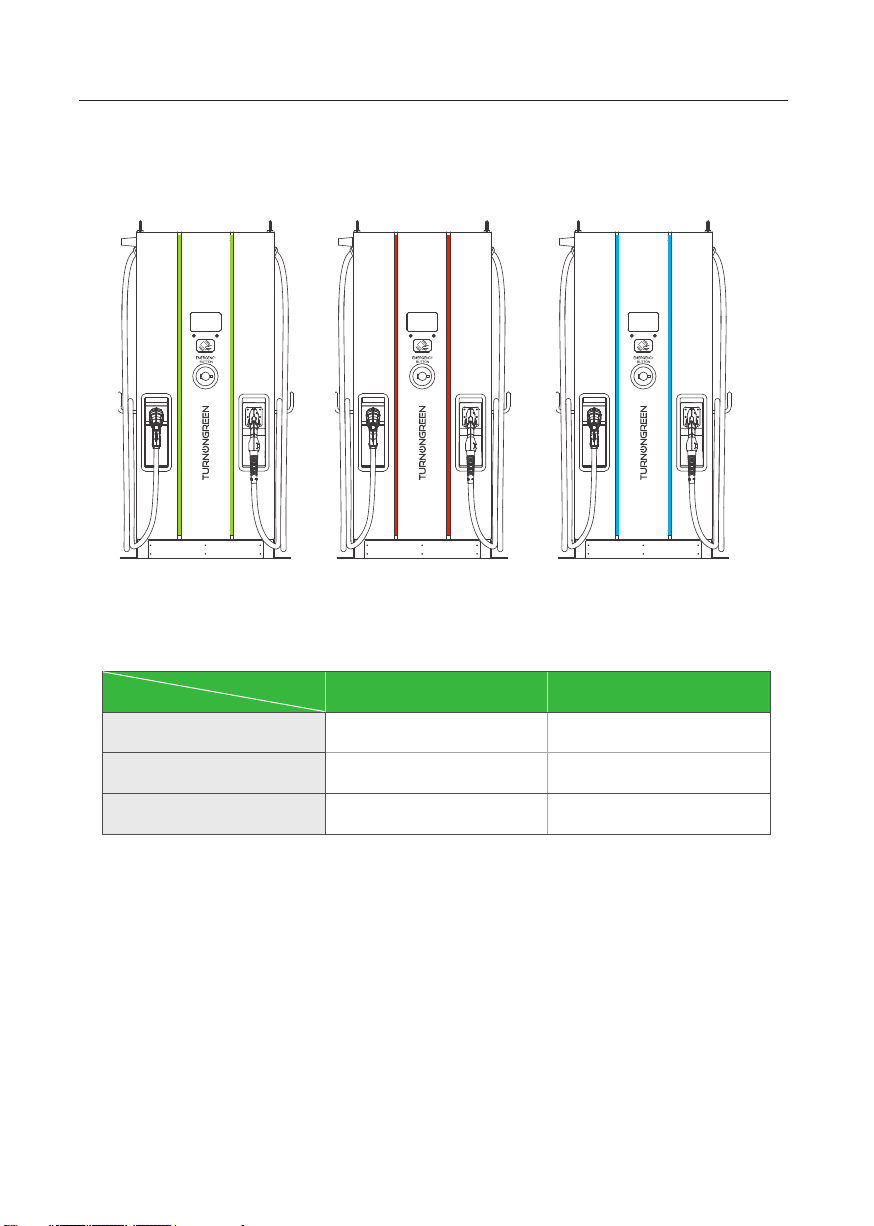

2�2 FPS 1200 Version Description ����������������������������������������� 6

2�3 LED Indication and Operation Status �������������������������������� 7

2�4 Dimensions ��������������������������������������������������������������������� 8

2�5 Direction of cooling Airflow ���������������������������������������������� 8

3� Installation Instruction ����������������������������������������������������������� 9

3�1 Before Installation ����������������������������������������������������������� 9

3�2 Grounding and Safety Requirement �������������������������������� 10

3�3 Unpack the charger �������������������������������������������������������� 12

3�4 Recommended Tools for Installation and Inspection ������� 15

3�5 Installation Procedure ���������������������������������������������������� 16

3�6 Installation Inspection & Commissioning ����������������������� 21

4� Network Setting ������������������������������������������������������������������� 24

4�1 Wi-Fi Network Setting ���������������������������������������������������� 24

4�2 3G/4G Setting ���������������������������������������������������������������� 26

4�3 Time setting ������������������������������������������������������������������ 28

5� Operation Process ���������������������������������������������������������������� 30

5�1 Operating Sequence ������������������������������������������������������� 30

5�2 Operating Procedure ������������������������������������������������������ 30

5�3 Troubleshooting ������������������������������������������������������������ 35

5�4 Status Codes ����������������������������������������������������������������� 35

6� Maintenance ������������������������������������������������������������������������ 56

6�1 General Maintenance ����������������������������������������������������� 56

6�2 Replacement Kits and Accessories ��������������������������������� 59

7� Limited Product Warranty ����������������������������������������������������� 60

Appendix - Package list ������������������������������������������������������������ 61