Parts List

COVERING:--

TOUGHLON STL 100 WHITE

TOUGHLON STL 201 BLACK

TOUGHLON STL 241 TURQUOISE

TOUGHLON STL 360 VIOLET

TOUGHLON STL 311 FERRARIRED

TOUGHLON STL 351 DARK BLUE

P.2

1. MAIN WING -- 1 pair

2. SCREW PB2x25mm -- 6 pcs

SCREW PWA2x8mm -- 8 pcs

FUEL TUBE Ø6x5mm -- 4 pcs

STRAPER PL4112102 -- 2 pcs

CLEVIS PL4112103 -- 2 pcs

TRI-HORN M3x14mm PL4111185 -- 2 sets

PUSHROD Ø1.8x120mm w/ Threads (For Aileron) -- 2 pcs

SERVO MOUNTING PANEL PL5310000-- 1 pair

3. STABILIZER & ELEVATOR -- 1 set

FUSELAGE -- 1 pc.

4. VERTICAL FIN & RUDDER -- 1 set

5. TAIL LANDING GEAR PL7100001 -- 1 set

TAIL WHEEL Ø30mm -- 1 pc.

COLLAR Ø2.1mm w/ set screw -- 1 set

SCREW PA3x12mm -- 2 pcs

6. SCREW PM2x25mm -- 3 pcs

M2 NUT -- 3 pcs

FUEL TUBE Ø6x5mm -- 2 pcs

CLEVIS PL4112103 -- 2 pcs

TRI-HORN M3x14mm (w/ o-Base For Rudder) PL4111185 -- 2 sets

RIGGING COUPLER Ø1.8x27mm w/ Threads HW4201304 -- 2 pcs

COPPER TUBE d2.5xD3.2x8mm --2 pcs

WIRE Ø1x700mm (For Rudder) -- 2 pcs

7. SCREW PB2x25mm -- 6 pcs

FUEL TUBE Ø6x5mm -- 2 pcs

CLEVIS PL4112103 -- 2 pcs

TRI-HORN M3x14mm (For Elevator) PL4111185 -- 2 sets

PUSHROD Ø1.8x600mm w/ Threads (For Elevator) -- 2 pcs

8. MAIN LANDING GEAR HW2404045 -- 1 set

MAIN LANDING GEAR COVER -- 1 pair

WHEEL Ø76mm PL3111760 -- 2 pcs

COLLAR Ø5.1mm w/ set screw -- 4 sets

SCREW HM4x16mm -- 4 pcs

SCREW PM5x43mm -- 2 pcs

SCREW PWA2.3x8mm -- 14 pcs

SCREW KA2.3x8mm -- 4 pcs

M5 NUT -- 2 pcs

WASHER d5xD12mm -- 4 pcs

QUICK RELEASE NYLON RIVET PL1208042 -- 4 pcs

WHEEL PANTS -- 1 pair

WHEEL PANT DECORATIVE COVER -- 1 pair

PLASTIC WHEEL COLLAR d5.1xD9x3mm -- 2 pcs

ALUMINUM PLATE 1mm -- 2 pcs

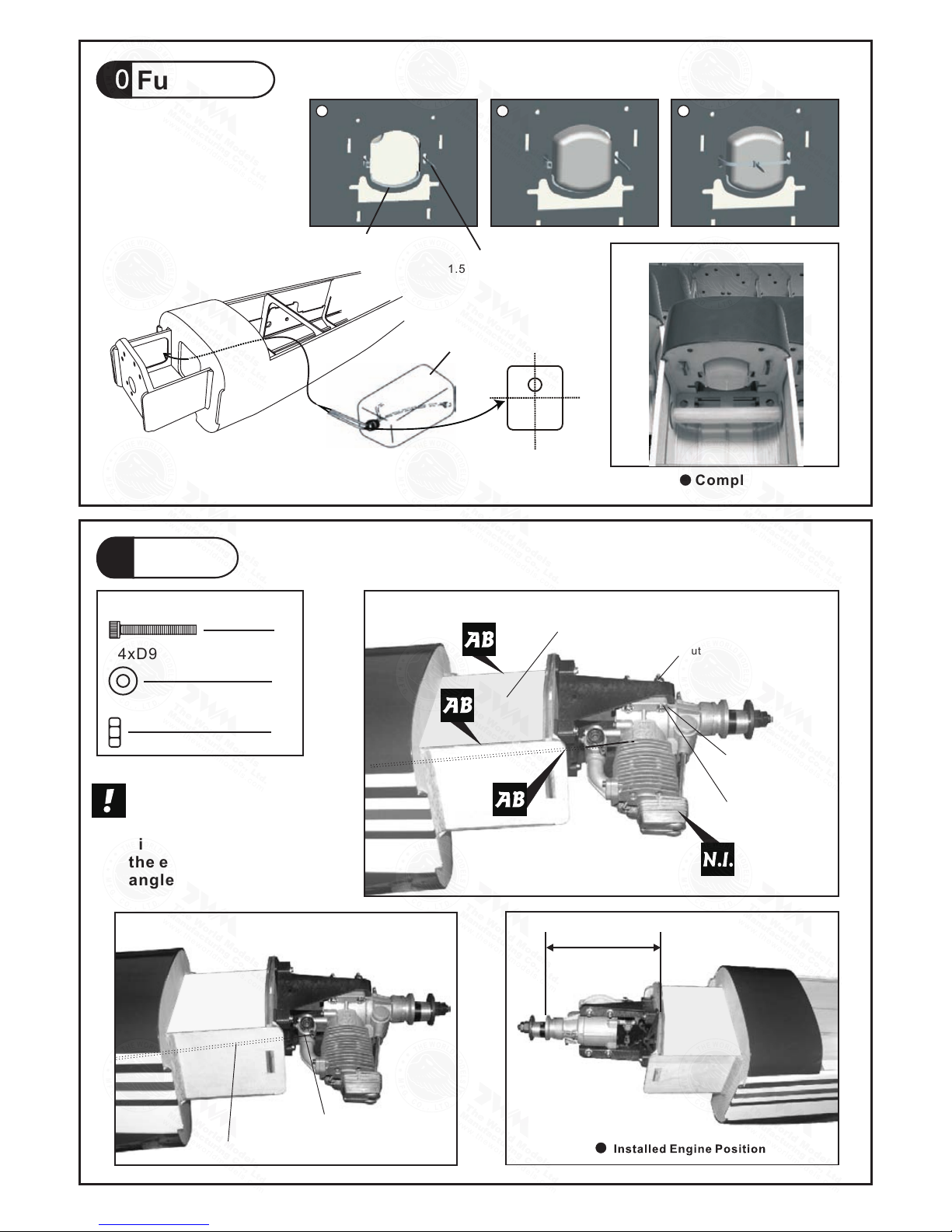

9. ENGINE MOUNT PL5111070 -- 1 set

SOCKET HEAD SCREW M4x25mm -- 4 pcs

WASHER d4xD12mm -- 4 pcs

M4 BLIND NUT -- 4 pcs

WOODEN DOWEL Ø5.5x8mm (For Firewall) -- 4 pcs

10. FUEL TANK 380cc PL1111380 -- 1 set

DOUBLE-SIDED TAPE 40x100mm -- 1 pc.

CABLE TIE 1.5x5x400mm -- 1 pc.

11. SOCKET HEAD SCREW M4x30mm -- 4 pcs

WASHER d4xD9mm -- 8 pcs

M4 NUT -- 8 pcs

PLYWOOD 2x93.8x120mm (Engine Box Upper Plate) (F21) -- 1 pc.

THROTTLE PUSHWIRE Ø1.2x350mm -- 1 pc.

PLASTIC TUBE d2xD3x140mm -- 1 pc.

12. LINKAGE CONNECTOR Ø2.1mm HW7111060 -- 1 set

13. BALSA 6x6x41 (For Elevator & Rudder Servo Stand) (F43) -- 4 pcs

PLYWOOD 3x57x154.6mm (For Elevator Servo)( F44A) -- 1 pc.

BALSA 6x6x143.6mm (For Elevator Servo) (F45B) -- 1 pc.

BALSA 6x6x150.3mm (For Elevator Servo) (F45C) -- 1 pc.

PLYWOOD 3x61x144.6mm (For Rudder Servo) (F44) -- 1 pc.

BALSA 6x6x131.5mm (For Rudder Servo) (F45) -- 1 pc.

BALSA 6x6x140.7mm (For Rudder Servo) (F45A) -- 1 pc.

COPPER TUBE d2.5xD3.2x8mm -- 2 pcs

STRAPER PL4112102 -- 1 pc.

FUEL TUBE Ø6x5mm -- 1 pc.

SPONGE 60x70x160mm (For Radio Equipment) -- 1 pc.

PUSHROD Ø1.8x100mm (For Elevator) -- 1 pc.

RIGGING Z BEND Ø1.8x27mm (For Rudder ) HW4201303 -- 2 pcs

PUSHROD CONNECTOR 4x9x20mm PL4410010 -- 1 set

14. COWLING -- 1 pc.

TRANSPARENT 3D TEMPLATE -- 1 pc.

SPINNER Ø70mm PH24W0700 / PH24B0700 -- 1 set

SCREW PWA2.6x12mm -- 4 pcs

SILICON GROMMET d1.5xD6.5mm -- 4 pcs

15. WING TUBE Ø22x814mm -- 1 pc.

WIRE Ø0.8mm -- 2 pcs

SELF-TIGHTENING LATCHING PIN -- 2 pcs

16. CANOPY -- 1 pc.

PILOT PC001085A -- 1 pc.

SCREW PM2.5x25mm -- 2 pcs

SCREW PWA2.3x8mm -- 6 pcs

SILICON GROMMET d1.5xD6.5mm -- 6 pcs

WASHER d2.5xD8mm -- 2 pcs

DOUBLE-SIDED TAPE 900mm -- 1 pc.

PLASTIC PLATE (For Pilot Stand) -- 1 pc.

17. DECALS: A156DEC -- 1 set

A156SPO25891108