Parts List

P.2

COVERING:--

TOUGHLON STL 317 FUS

TOUGHLON STL 317 WIG

TOUGHLON STL 203 LIGHT GRAY

LIGHTEX SGX 203 LIGHT GRAY

LIGHTEX SGX 331 CUB YELLOW

LIGHTEX SGX 201 BLACK

LIGHTEX SGX 100 WHITE

LIGHTEX SGX 340 OLIVE DRAB

1.MAIN WING -- 1 pair

2.RETRACTABLE LANDING GEAR -- 1 pair

M2 NUT -- 8 pcs

SCREW PM2x6mm -- 8 pcs

WASHER d2xD5mm -- 16 pcs

MAIN LANDING GEAR COVERS -- 1 pair

PVC PLATE 0.5mm -- 2 pcs

3.WING JOINER 8x20x247mm -- 1 pc.

SCATTER-GUN(A) Ø8x36mm -- 2 pcs

SCATTER-GUN(B) Ø8x31mm -- 2 pcs

4.PUSHROD Ø1.8x85mm w/ Threads (ForAileron) -- 2 pcs

SCREW PB2x25mm -- 4 pcs

SCREW PB2x22mm -- 2 pcs

SCREW PWA2x8mm -- 8 pcs

TRI-HORN M3x14mm (S) PL4111221 -- 2 sets

STRAPER PL4112102 -- 2 pcs

CLEVIS PL4112103 -- 2 pcs

FUEL TUBE Ø6x5mm -- 4 pcs

SERVO MOUNTING PANEL PL5310000 -- 1 pair

*OPTIONAL PARTS A317DTM :

DROP TANKS -- 1 pair

MISSILES -- 1 pair

PLYWOOD(A) 28x23x3mm -- 4 pcs

PLYWOOD(B) 20x23x3mm -- 4 pcs

SCREW PWM2.5x12mm -- 8 pcs

M2.5 NYLON INSERT LOCK NUT -- 8 pcs

WASHER d2.5xD8mm -- 8 pcs

5.PLASTIC RING PL4112023 -- 2 pcs

Y-TYPE PUSHROD Ø1.8x110mm (For Flap) -- 1 pc.

STRAPER PL4112102 -- 1 pc.

CLEVIS PL4112103 -- 2 pcs

FUEL TUBE Ø6x5mm -- 3 pcs

PLYWOOD 3x28x66mm -- 1 pcs

LINKAGE CONNECTOR Ø2.1mm HW7111060 -- 2 sets

6.VERTICAL FIN & RUDDER -- 1 set

FUSELAGE -- 1 pc.

7.STABILIZER & ELEVATOR -- 1 set

STABILIZER TUBE Ø8x180mm -- 1 pc.

8.TAIL LANDING GEAR -- 1 set

COLLAR Ø2.1mm w/ set screw -- 1 set

TAIL WHEEL Ø25mm PL3111250 -- 1 pc.

SCREW PA3x10mm -- 2 pcs

9.PUSHROD Ø1.8x550mm w/ Threads (For Elevator) -- 2 pcs

SCREW PB2x22mm -- 4 pcs

SCREW PB2x20mm -- 2 pcs

TRI-HORN M3x14mm (S) PL4111221 -- 2 sets

CLEVIS PL4112103 -- 2 pcs

FUEL TUBE Ø6x5mm -- 2 pcs

10.PUSHROD Ø1.8x715mm w/ Threads (For Rudder) -- 1 pc.

SCREW PB2x20mm -- 3 pcs

TRI-HORN M3x22mm (S) PL4111301 -- 1 set

CLEVIS PL4112103 -- 1 pc.

FUEL TUBE Ø6x5mm -- 1 pc.

11.ENGINE MOUNT PL5111050 -- 1 set

SOCKET HEAD SCREW M4x25mm -- 4 pcs

WASHER d4xD9mm -- 4 pcs

BLIND NUT M4 HW1304125 -- 4 pcs

DOWEL D6x10mm -- 4 pcs

12.FUEL TANK 380cc -- 1 set

CABLE TIE 1.5x5x400mm -- 1 pc.

DOUBLE-SIDE TAPE 40x100mm -- 1 pc.

BATTERY TIE 200x13mm -- 1 pc.

SPONGE 80x200x10mm -- 1 pc.

13.SOCKET HEAD SCREW M3x30mm -- 4 pcs

M3 NUT -- 8 pcs

WASHER d3xD7mm -- 8 pcs

THROTTLE PUSHWIRE Ø1.2x330mm -- 1 pc.

PLASTIC TUBE d2xD3x240mm -- 1 pc.

PLYWOOD 2x48.2x92.8mm -- 1 pc.

14.COWLING --1 pc.

TRANSPARENT 3D TEMPLATE -- 1 pc.

SCREW PWA2.6x12mm -- 4 pcs

SILICON GROMMET d1.5xD6.5mm PL1265035 -- 4 pcs

SPINNER Ø89mm PH22W0890 -- 1 set

15.LINKAGE CONNECTOR Ø2.1mm HW7111060 -- 1 set

16.PUSHROD CONNECTOR PL4410010 -- 1 set

PUSHROD Ø1.8x100mm (For Elevator) -- 1 pc.

STRAPER PL4112102 -- 2 pcs

FUEL TUBE Ø6x5mm -- 2 pcs

SPONGE 80x200x10mm -- 1 pc.

17.SCREW HM3x35mm -- 2 pcs

WASHER d3.2xD12mm -- 2 pcs

18.CANOPY -- 1 pc.

SCREW PWA2.3x8mm -- 4 pcs

SILICON GROMMET d1.5xD6.5mm PL1265035 -- 4 pcs

PILOT PC001050A -- 1 pc.

19.DECALS: A317DEC -- 1 set

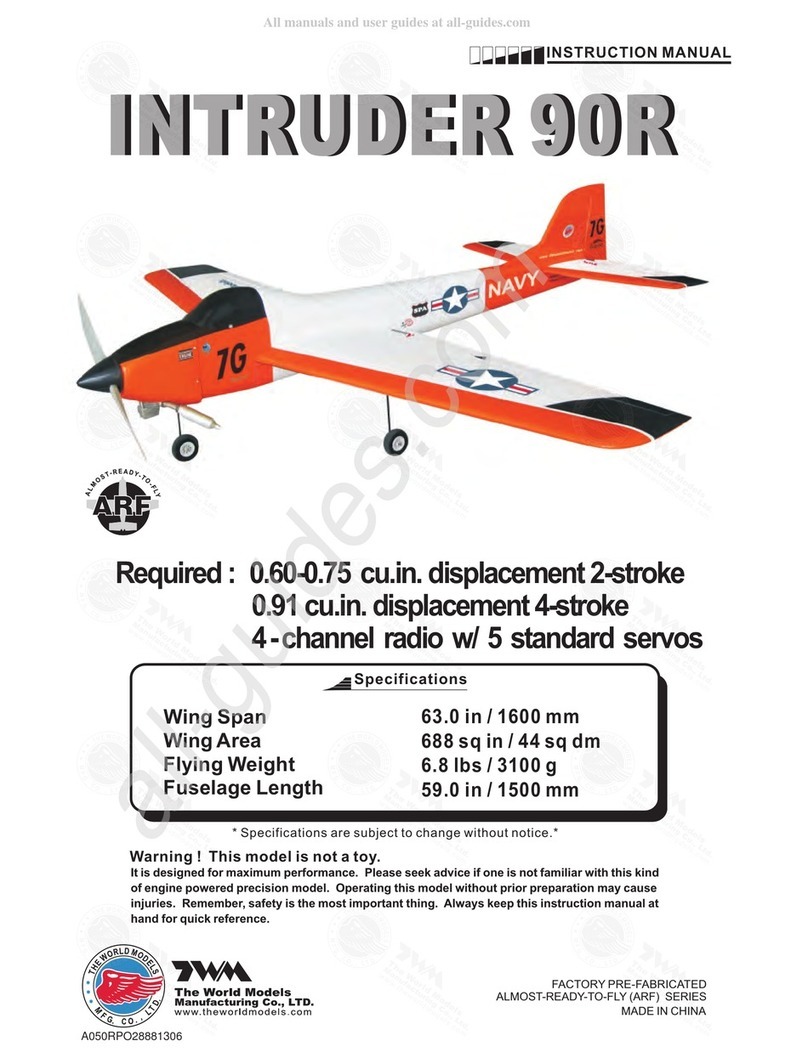

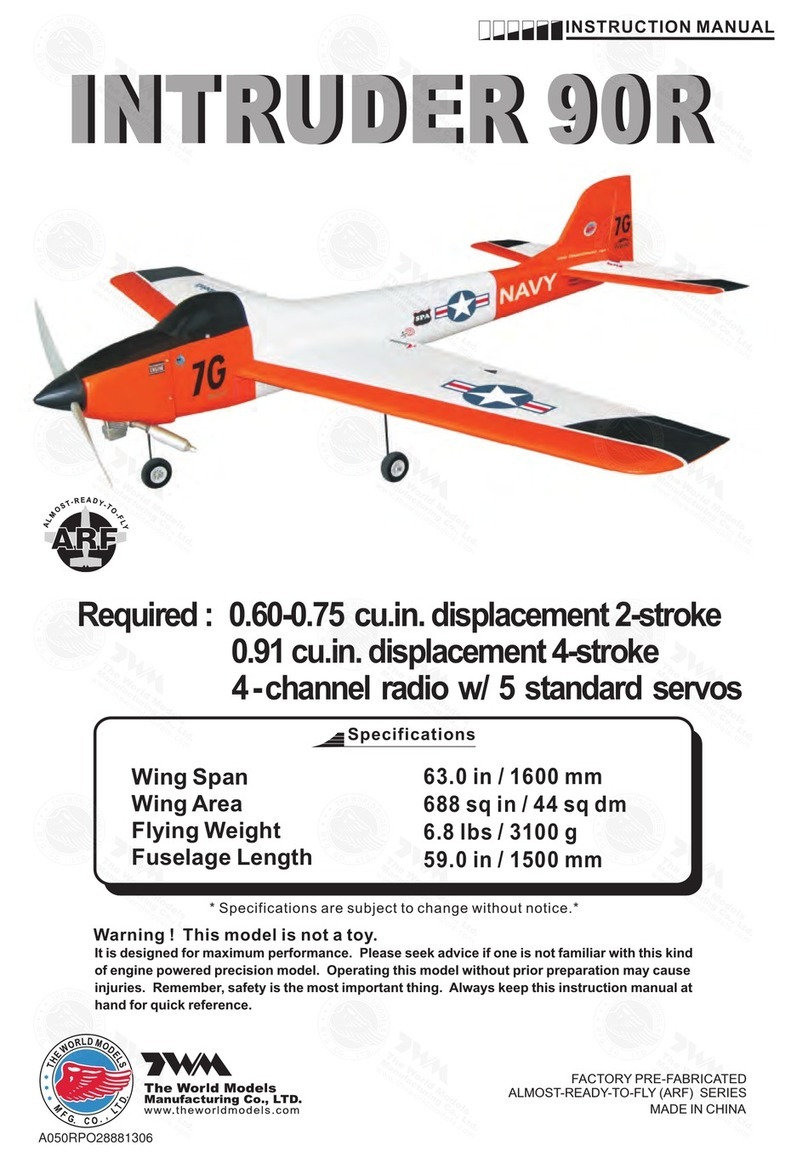

A317PO24531116