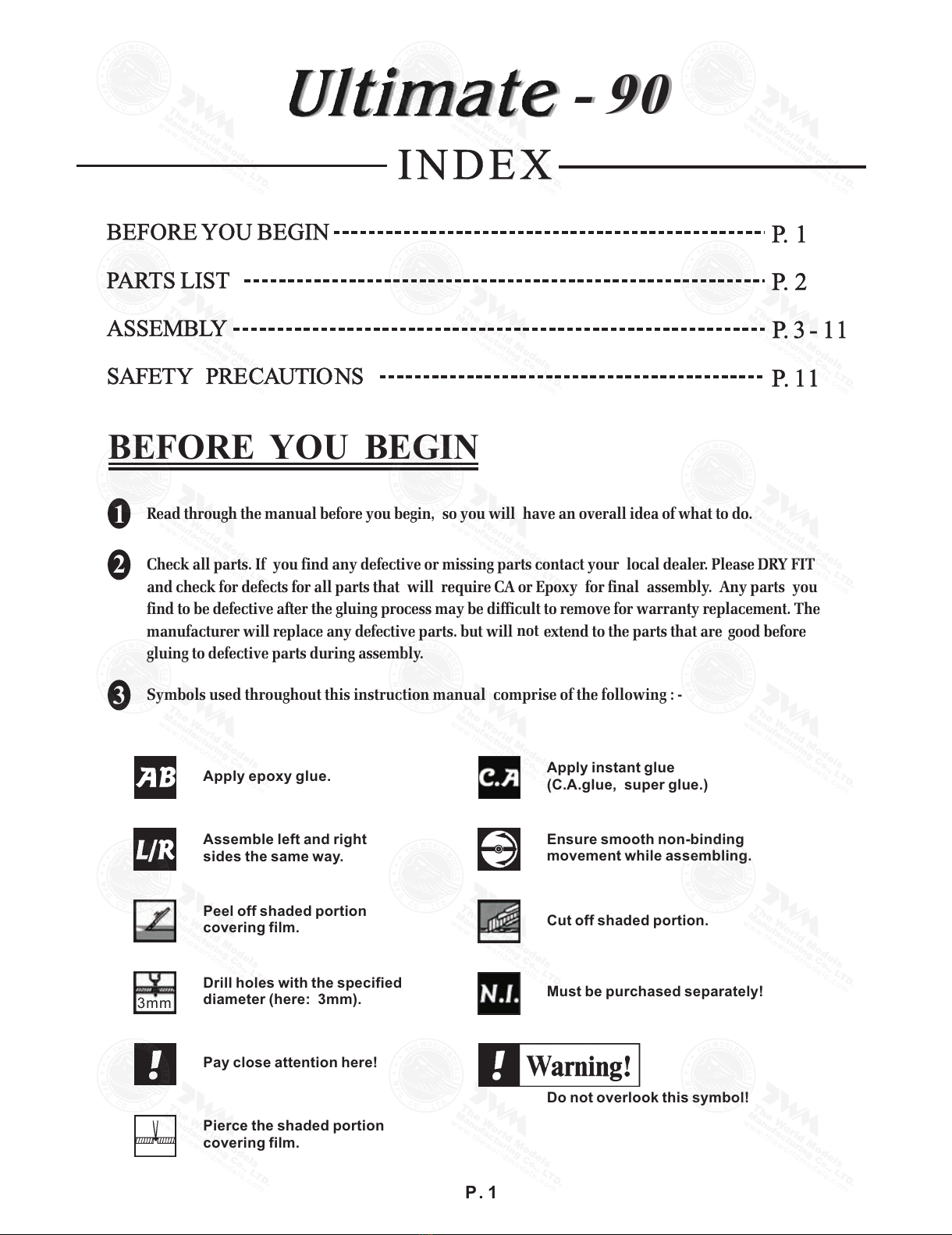

P.2

Parts List

COVERING:--

PURPLE COLOR SCHEME:

TOUGHLON STL 100 WHITE

TOUGHLON STL 201 BLACK

TOUGHLON STL 561 PEARL PURPLE

TOUGHLON STL 370 SILVER

YELLOW COLOR SCHEME:

TOUGHLON STL 100 WHITE

TOUGHLON STL 201 BLACK

TOUGHLON STL 330 CADMIUM YELLOW

TOUGHLON STL 370 SILVER

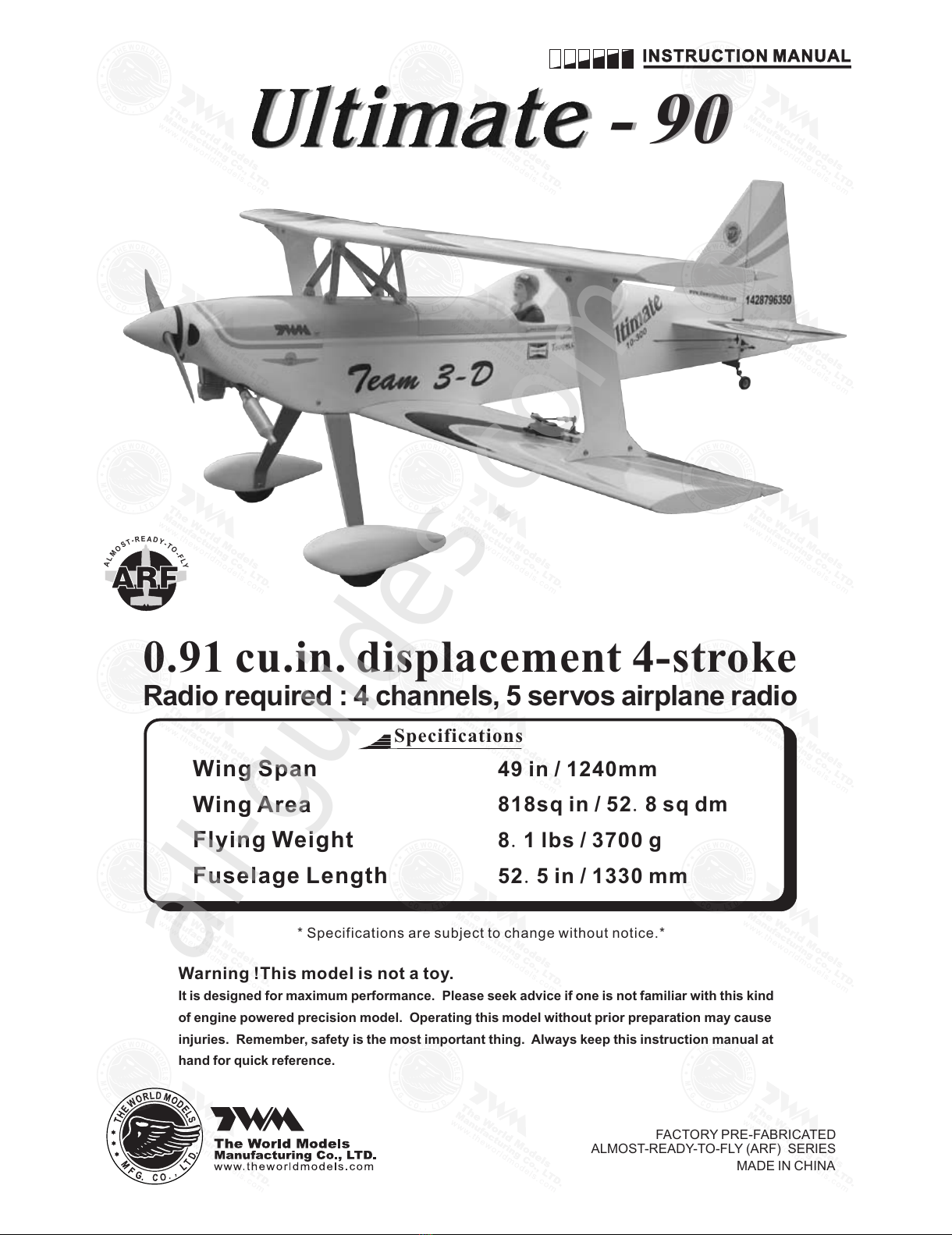

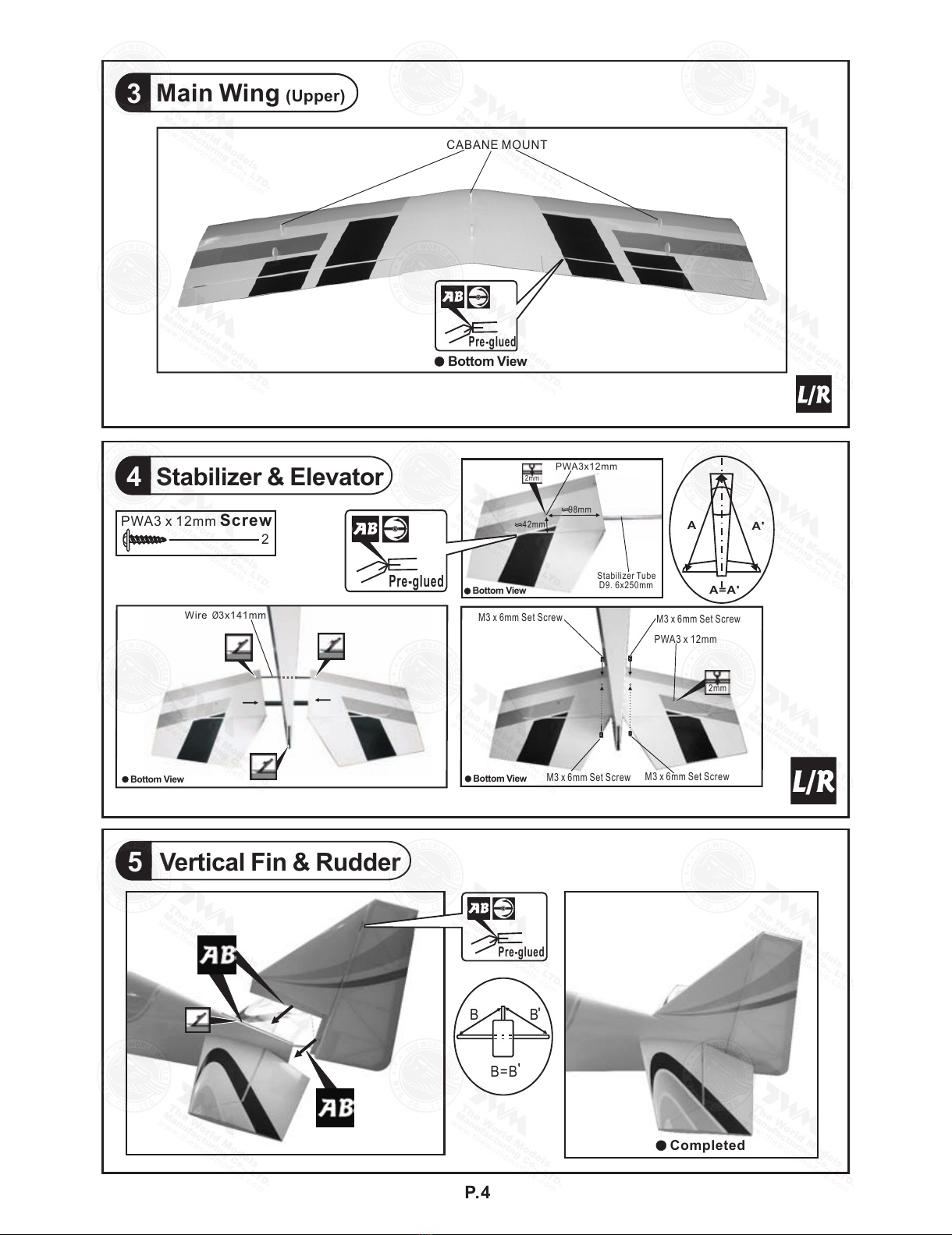

1.MAIN WING(Lower) -- 1 pc.

2.SCREW PM2x20mm -- 6 pcs

STRAPER -- 2 pcs

CLEVIS -- 2 pcs

FUEL TUBE 6x5mm -- 4 pcs

TRI-HORN M3x14mm(L) -- 2 sets

PUSHROD 1.8x70mm w/Threads(For Aileron) -- 2 pcs

WOOD BLOCK 9x10x21mm(For Aileron) -- 2 pcs

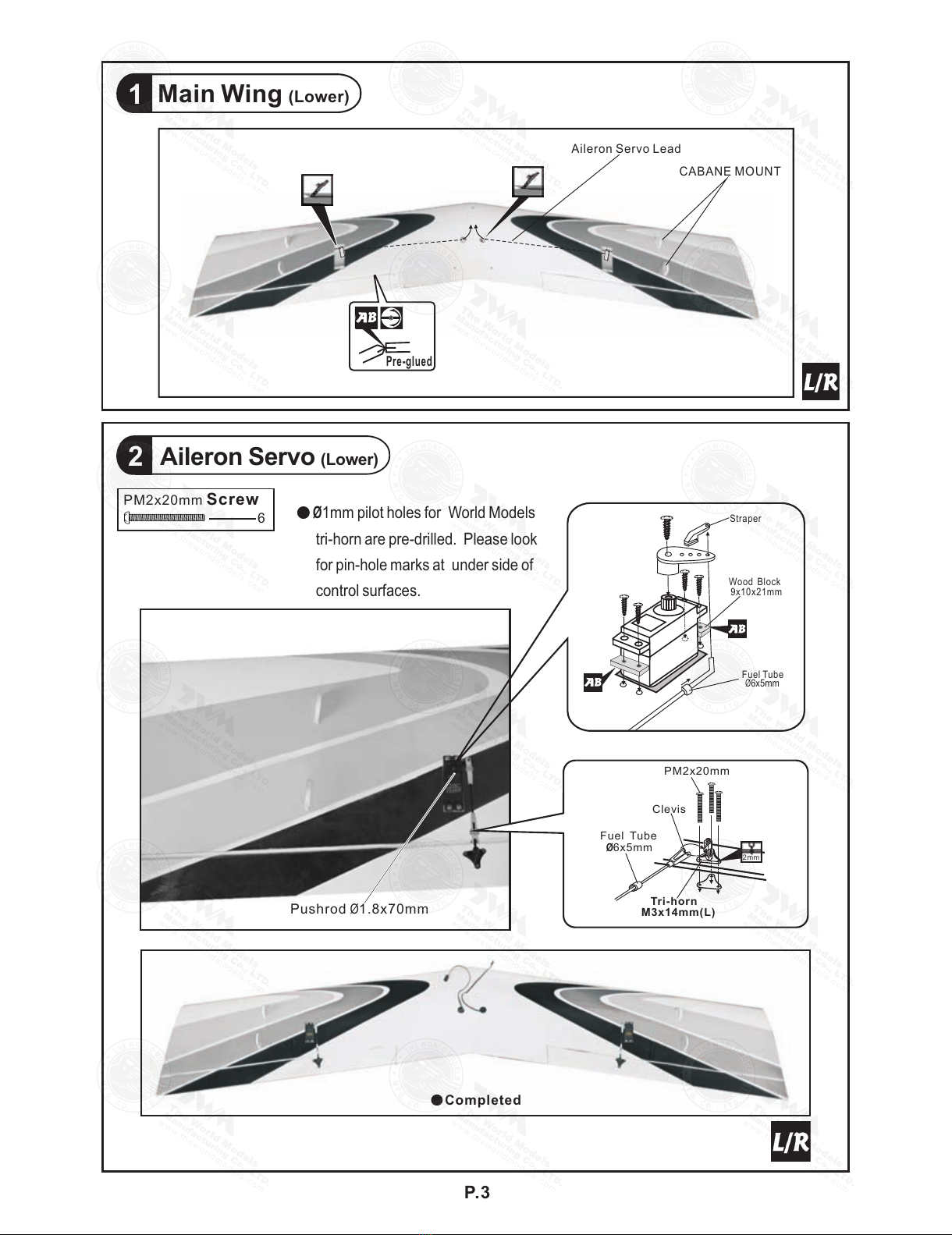

3.MAIN WING(Upper) -- 1 pc.

4.STABILIZER & ELEVATOR -- 1 set

F

USELAGE -- 1 p c.

STABILIZER TUBE 9.6x250mm -- 1 pc.

SCREW PWA3x12mm -- 2 pcs

WIRE 3 x141mm --

1 pc.

5.VERTICAL FIN & RUDDER -- 1 set

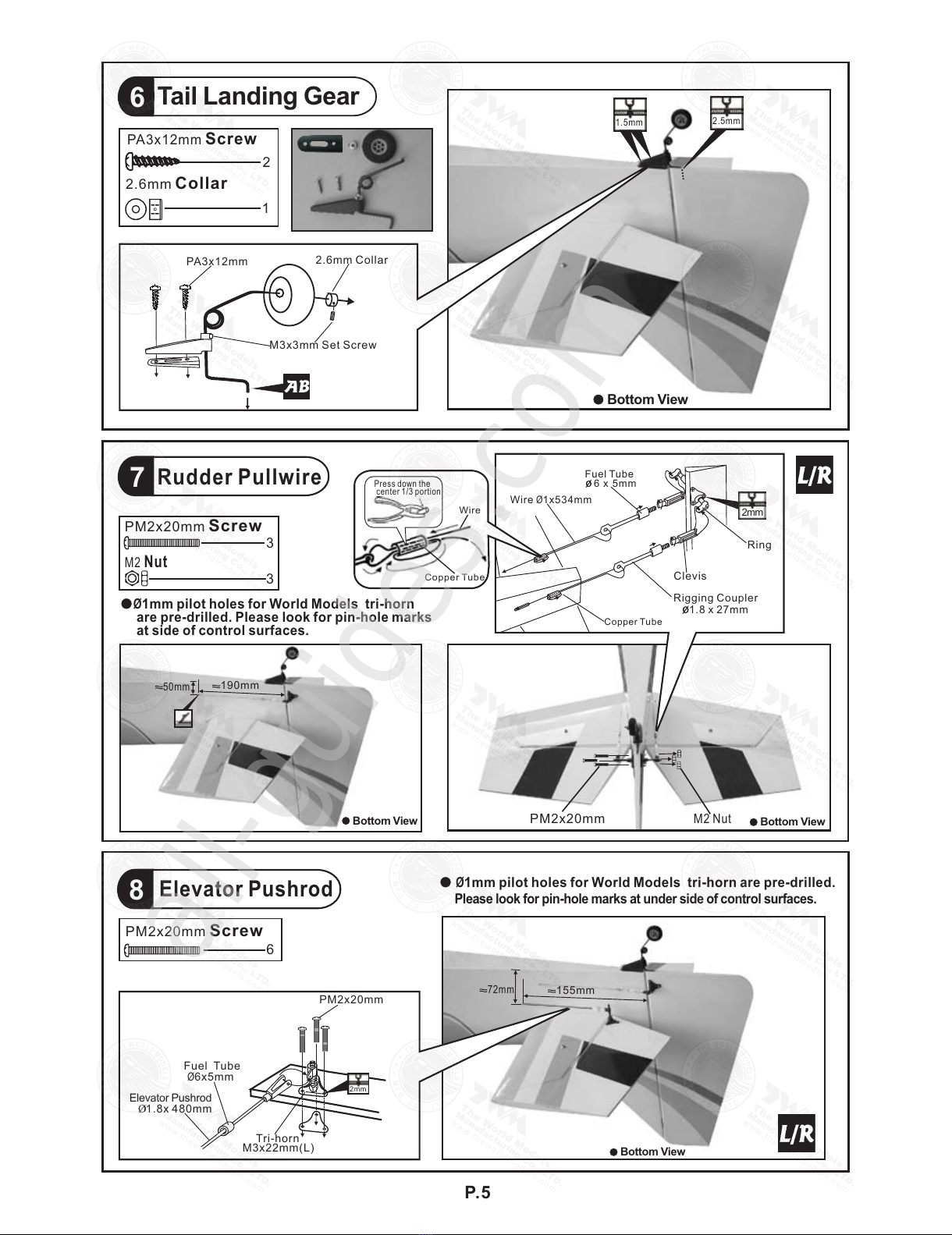

6.TAIL LANDING GEAR -- 1 set

WHEEL 25mm -- 1 pc.

COLLAR 2.6mm w/set screw -- 1 set

SCREW PA3x12mm -- 2 pcs

7.SCREW PM2x20mm -- 3 pcs

M2 NUT -- 3 pcs

FUEL TUBE 6x5mm -- 2 pcs

CLEVIS -- 2 pcs

WIRE 1x534mm(For Rudder) -- 2 pcs

TRI-HORN M3x22mm (L)(w/o-Base For Rudder) -- 2 sets

RIGGING COUPLER 1.8x27mm w/Threads(For Rudder) -- 2 pcs

COPPER TUBE d2.5xD3.2x8mm(For Rudder) -- 2 sets

8.SCREW PM2x20mm -- 6 pcs

FUEL TUBE 6x5mm -- 2 pcs

CLEVIS -- 2 pcs

TRI-HORN M3x22mm(L) -- 2 sets

PUSHROD 1.8x480mm w/Threads(For Elevator) -- 2 pcs

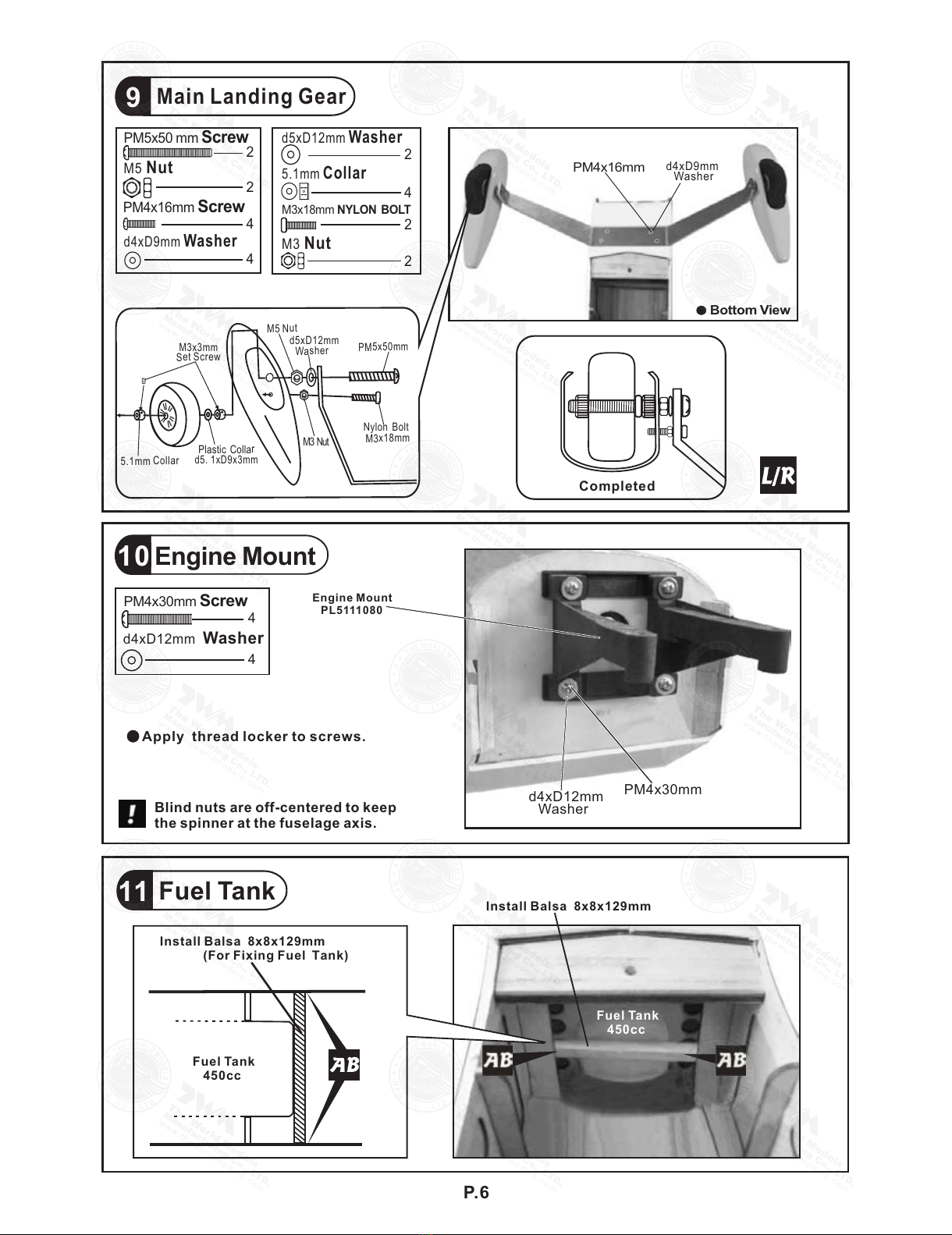

9.MAIN LANDING GEAR -- 1 pair

WHEEL PANTS -- 1 pair

SCREW PM5x50mm -- 2 pcs

M5 NUT -- 2 pcs

M3 NUT -- 2 pcs

NYLON BOLT M3x18mm -- 2 pcs

PLASTIC COLLAR d5.1xD9x3mm -- 2 pcs

SCREW PM4x16mm -- 4 pcs

WASHER d4xD9mm -- 4 pcs

WASHER d5xD12mm -- 2 pcs

WHEEL 76mm -- 2 pcs

COLLAR 5.1mm w/set screw --

4 sets

10.ENGINE MOUNT PL5111080 -- 1 set

SCREW PM4x30mm -- 4 pcs

WASHER d4xD12mm -- 4 pcs

11.FUEL TANK 450cc -- 1 set

B

ALSA 8

x8x129mm(For F

ixing F

uel T

ank)

-- 1

p

c.

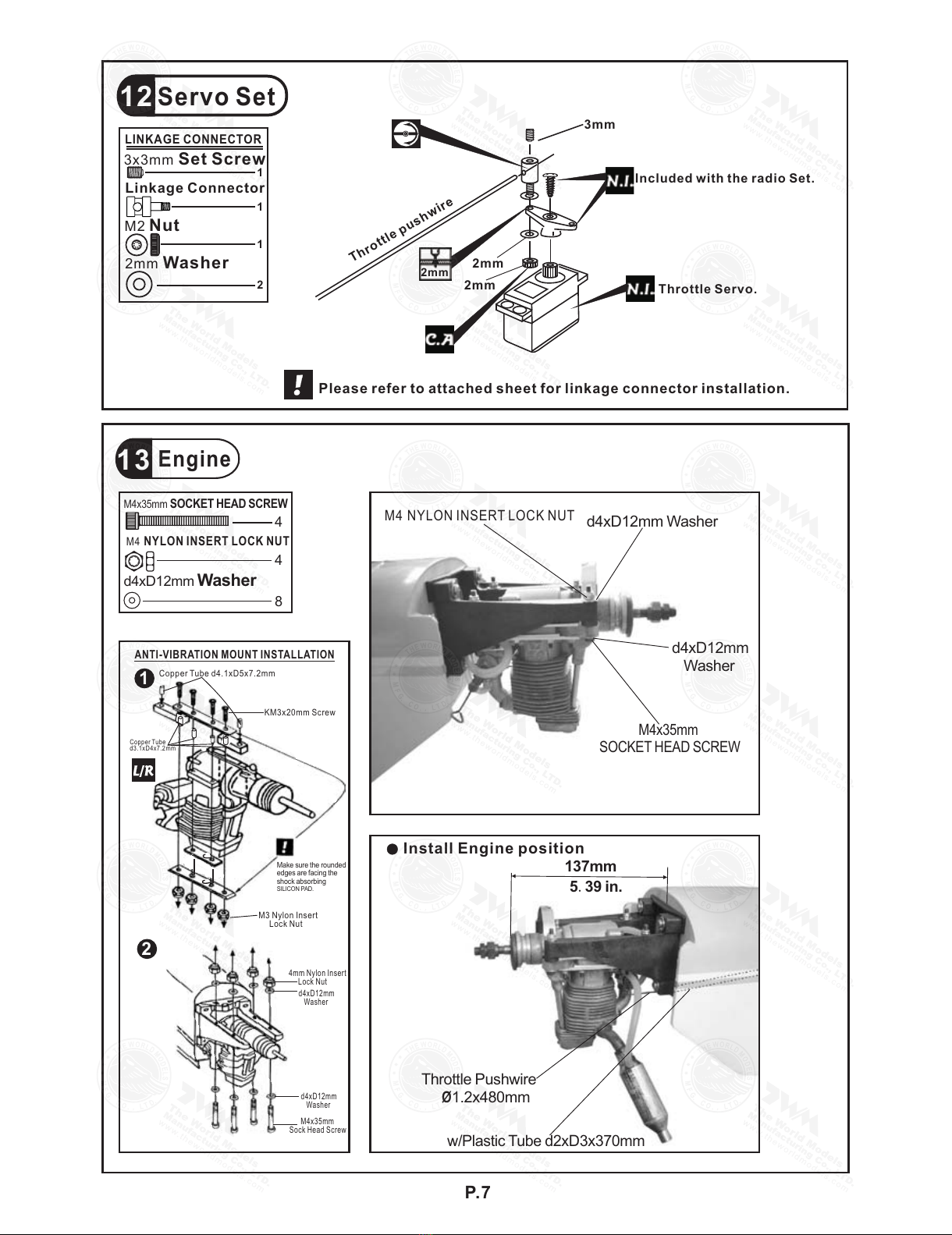

12.LINKAGE CONNECTOR 2.1mm -- 1 set

13.THROTTLE PUSHWIRE 1.2x480mm -- 1 set

w/Plastic tube d2xD3x370mm -- 1 pc.

ALUMINUM PLATE(For Engine Mount) -- 1 pc.

ANTI-VIBRATION MOUNT PL5214094 -- 1 set

INCLUDE:SOCKET HEAD SCREW M4x35mm -- 4 pcs

S CREW K M3x20mm -- 8 p cs

W ASHER d 4xD12mm -- 8 p cs

M 3 N YLON I NSERT L OCK U T --8 pc s

M 4 N YLON I NSERT L OCK U T --4 pc s

14.FUEL TUBE 6x5mm -- 1 pc.

STRAPER

-- 1 pc .

PUSHROD

CONNECTOR --

1

set

PUSHROD 1.8x70mm(For Elevator

Servo) -- 1 pc .

COPPER TUBE d2 .5xD3 .2x8mm(For Rudder) -- 2 pcs

RIGGING Z BEND 1.8x27mm(For Rudder) -- 2 pcs

PLYWOOD

5x61x121mm For Rudder Servo ) -- 1 pc .

(

BALSA 6x6x61mm(For Rudder &

Elevator Servo Stand) -- 4 pcs

PLYWOOD

5x61x126mm(For Elevator and Throttle Servo) -- 1 pc.

SPONGE

60x70x120mm -- 1 pc .

15.CANOPY -- 1 pc.

SCREW PM3x16mm -- 2 pcs

WASHER d3xD7mm 2 pcs

--

SCREW PWA2 .3x8mm -- 4 pcs

DOUBLE-SIDED TAPE -- 1 pc .

SILICON GROMMET d1 .5xD6 .5mm -- 4 pcs

PILOT PC001085A/B -- 1 set

16.COWLING -- 1 set

TRANSPARENT DUMMY COWLING -- 1 pc.

SPINNER 62mm(w/alu .back plate ) -- 1 set

SCREW PWA2 .6x12mm -- 4 pcs

SILICON GROMMET d1 .5xD6 .5mm --

4

pcs

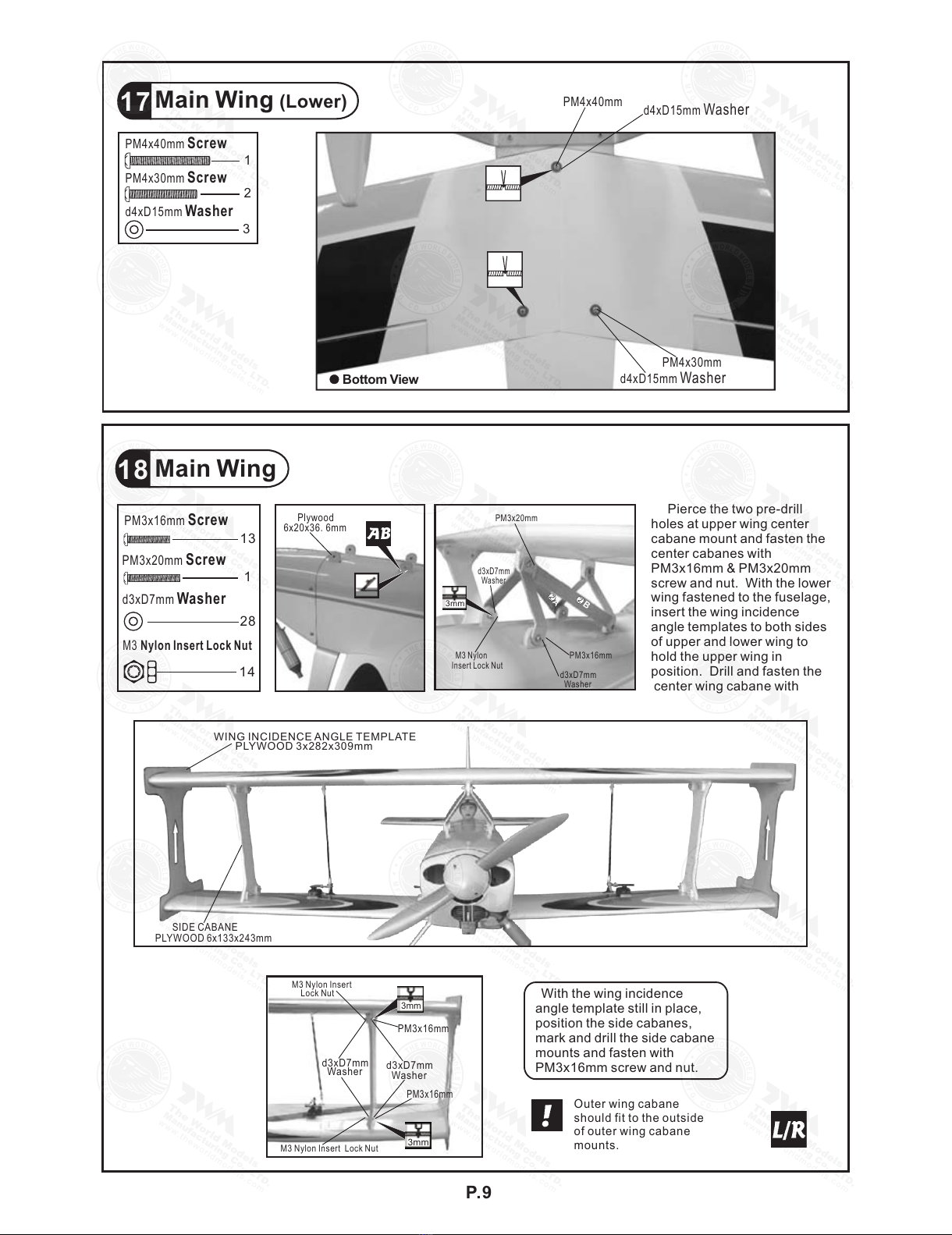

17.SCREW PM4x40mm -- 1 pc.

SCREW

PM4x30mm --

2

pcs

WASHER

d4xD15mm --

3

pcs

18.PLYWOOD 6x133x243mm Side Cabane) -- 2 pcs

(

PLYWOOD 6x20x36 .6mm -- 4 pcs

CENTER WING CABANE -- 1 set

PLYWOOD 3x282x309mm(Wing Incidence Angle Template) -- 2 pcs

SCREW PM3x16mm -- 13 pcs

SCREW PM3x20mm -- 1 pc .

WASHER d3xD7mm -- 28 pcs

M3 NYLON INSERT LOCK NUT -- 14 pcs

19.SCREW PM2x10mm -- 8 pcs

CLEVIS -- 4 pcs

FUEL TUBE 6x5mm -- 4 pcs

HORN -- 4 sets

PUSHROD M2xD4x212mm w/Threads(For Aileron ) -- 2 pcs

20.DECALS -- 1 set