Instruction Sheet

Terminating Head 58063–2

For AMPLIMITE* High Density (HDE)–20 408–9414

LOC B

1 of 4

E

2004 Tyco Electronics Corporation, Harrisburg, PA

AllInternationalRightsReserved

AMP and Tyco are trademarks. *Trademark

Other products, logos, and company names used are the property of their respective owners.

TOOLINGASSISTANCE CENTER1–800–722–1111

FAX/PRODUCTINFO1–800–522–6752

For Regional Customer Service, visit our website at

www.tycoelectronics.com

This controlled document is subject to change.

For latest revision, call the FAX/PRODUCT INFO number.

12 JUL 04 Rev A

Connectors

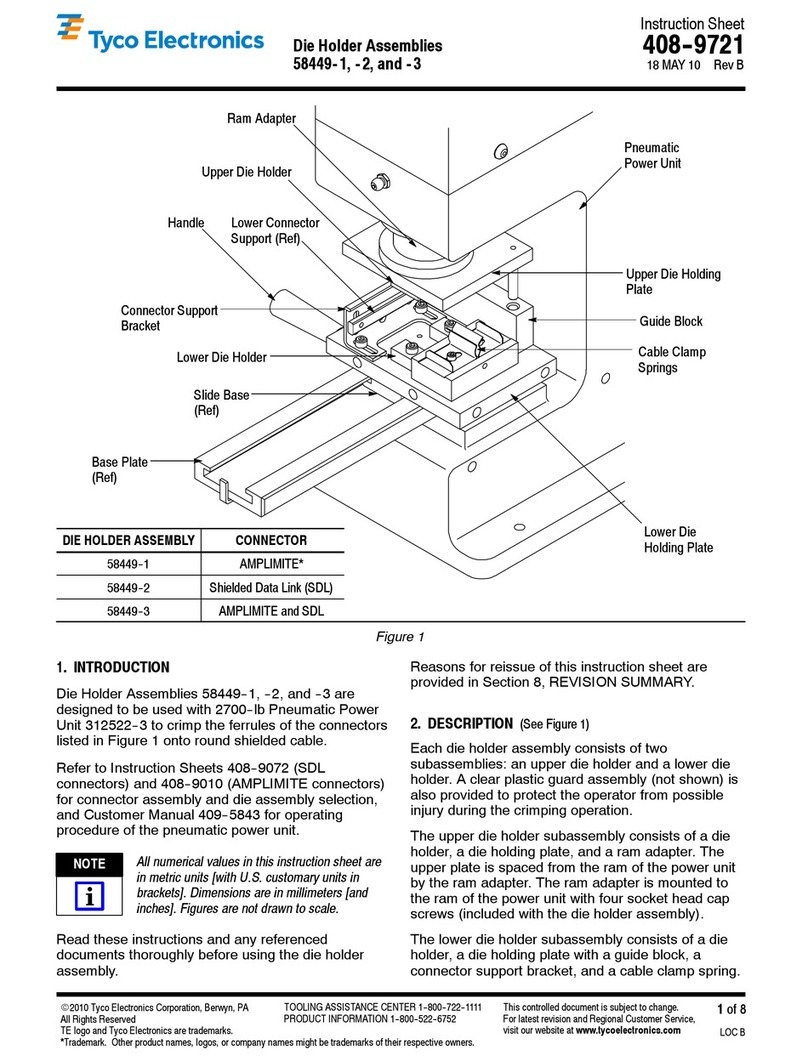

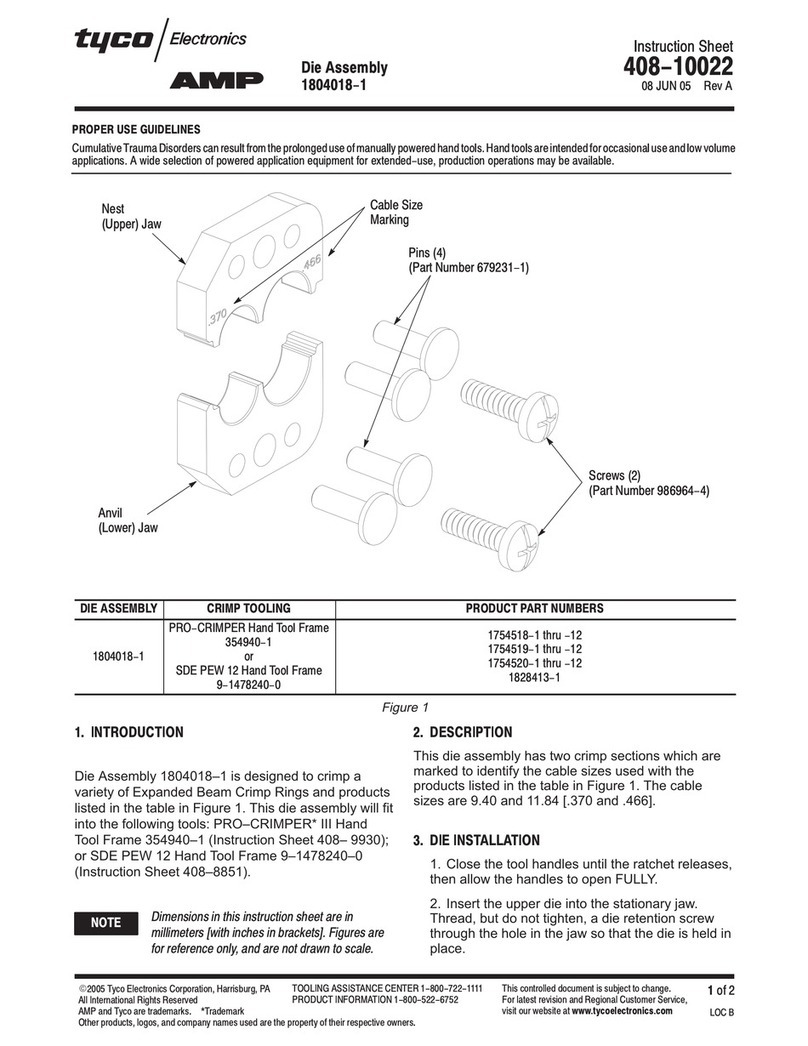

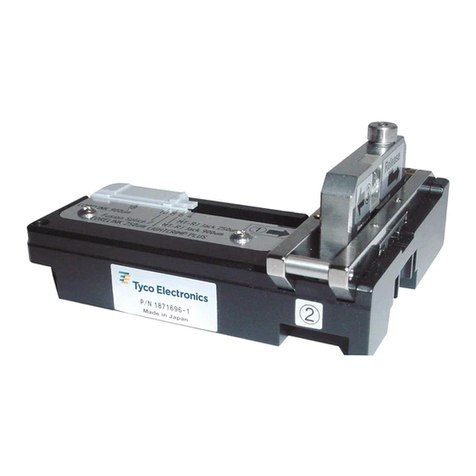

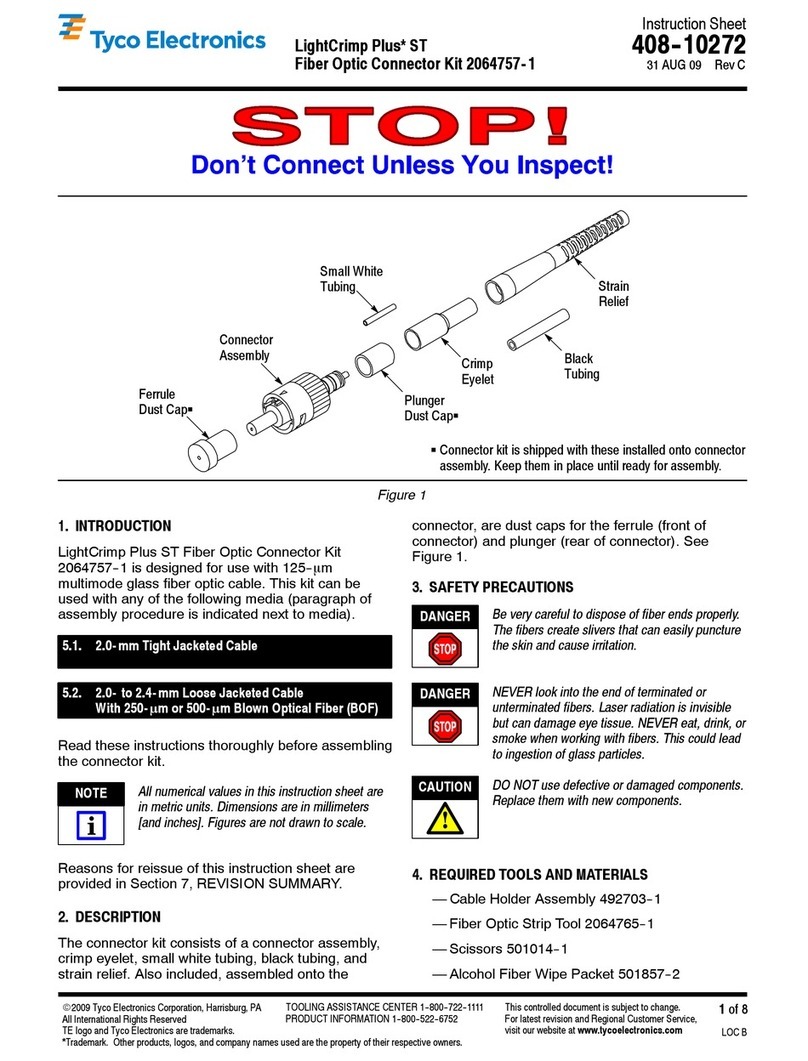

Figure 1

FeedChannel

WireInserter

Adjuster

(InserterRod)

Anti–Backup

Pawl

FeedSlide

WireGuide

1. INTRODUCTION

Terminating Head 58063–2 is designed to terminate

unstripped

discrete wire sizes 30 through 20 AWG

onto AMPLIMITE HDE–20 all plastic connectors

(reference part number 745203–2) and metal shell

connectors (reference part number 745492–2). These

connectors contain insulation displacement contacts.

The head must be used with one of the following

power units (for operating procedure, refer to the

instructions packaged with the power unit).

Power Unit Instruction Sheet (408) or

Customer Manual (409)

Pistol Grip Manual Handle

Assembly 58074–1 408–6790

Pistol Grip Pneumatic Handle

Assembly 58075–1 408–6789

Pneumatic Power Bench

Assembly 58338–1 408–9393

Electric Power Unit 931800–1 409–5746

Dimensions in this instruction sheet are in metric

units [with U.S. customary units in brackets].

Figures are not drawn to scale.

Reasons for reissue of this instruction sheet are

provided in Section 7, REVISION SUMMARY.

2. DESCRIPTION (Figure 1)

Features of the head and their function are as follows:

Wire inserter—forces the wire into the slotted beams

of the contact.

Wire guide—holds the connector properly in relation

to the wire.

Adjuster (inserter rod)—is a piston for, and regulates

the travel of, the wire inserter.

Feed slide—automatically advances the connector

after each termination.

Anti–backup pawl—prevents the connector from

moving out of position after it has been advanced by

the feed slide.

After the head is installed onto the power unit, it

serves as a guide and support for the connector

during termination. The arrow on the top of the head

indicates the direction that the connector will move in

the head. The wires are terminated onto the

connector using the insulation displacement

technique.

3. TERMINATION PROCEDURE

Make sure that the connector matches the wire size

to be terminated, then refer to Figure 2, and proceed

as follows:

1. Align the side of the connector with the side of

the head (so that it will move in the direction of the

arrow), and

slowly

slide the connector into the feed

channel. Stop when the desired contact position

aligns with the wire slot.

If the connector cannot be inserted into the head

or if the connector is too loose in the head, refer

to Paragraph 4.2 for wire guide adjustment.

2. Insert the wire into the wire slot until the wire

bottoms on the head.

3. Center the wire in the wire slot, then actuate the

power unit until the wire inserter bottoms (the wire

inserter will retract, and the connector will advance

to the next contact position).

NOTE

NOTE