408- 4539

CERTI- CRIMP Straight Action Hand Tool 90720- 1

3of 4Rev ATyco Electronics Corporation

Wipe excess oil from tool, particularly from the

crimping area. Oil transferred from the crimping

chambers onto certain terminations may affect the

electrical characteristics of an application.

4.3. Periodic Inspection

1. Hand tool should be immersed (handles partially

closed) in a reliable commercial degreasing

compound to remove accumulated dirt, grease,

and foreign matter.

2. Close tool handles until the ratchet releases and

then allow them to open fully. If the handles do not

open quickly and fully, the spring is defective and

must be replaced. Refer to Section 5,

REPLACEMENT AND REPAIR.

3. Inspect tool head for worn, cracked, or broken

dies. If damage is evident, return the tool for

evaluation and repair. See Section 5,

REPLACEMENT AND REPAIR.

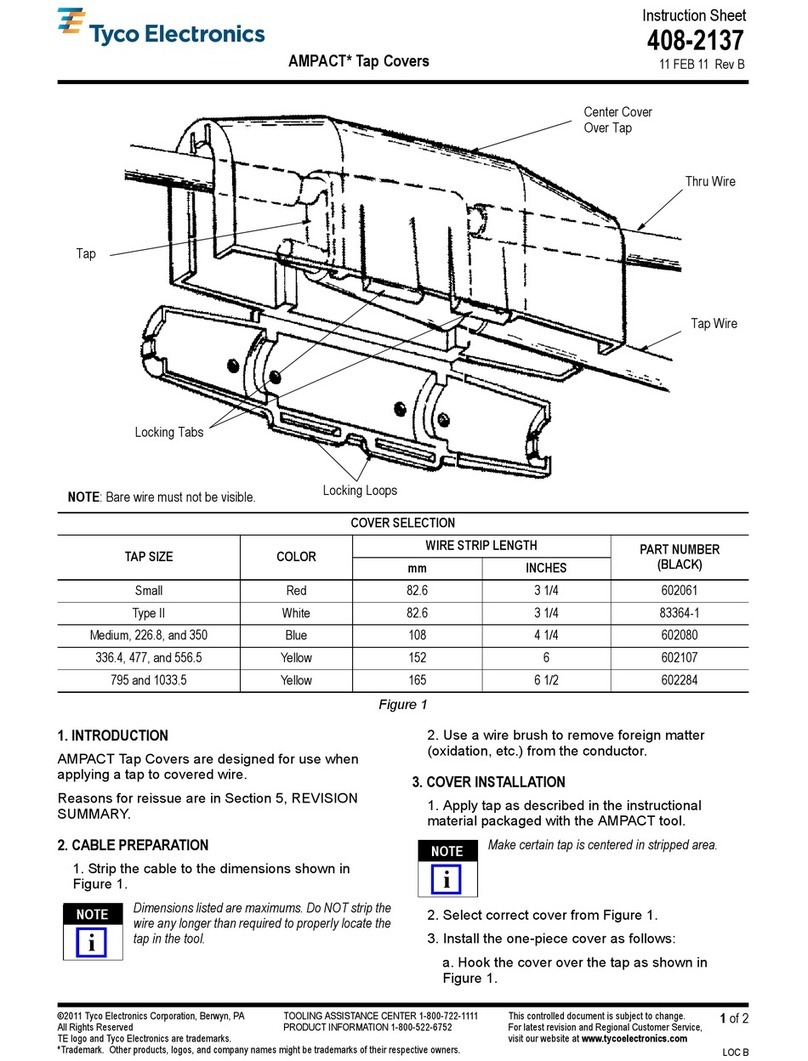

4.4. Crimp Height Inspection

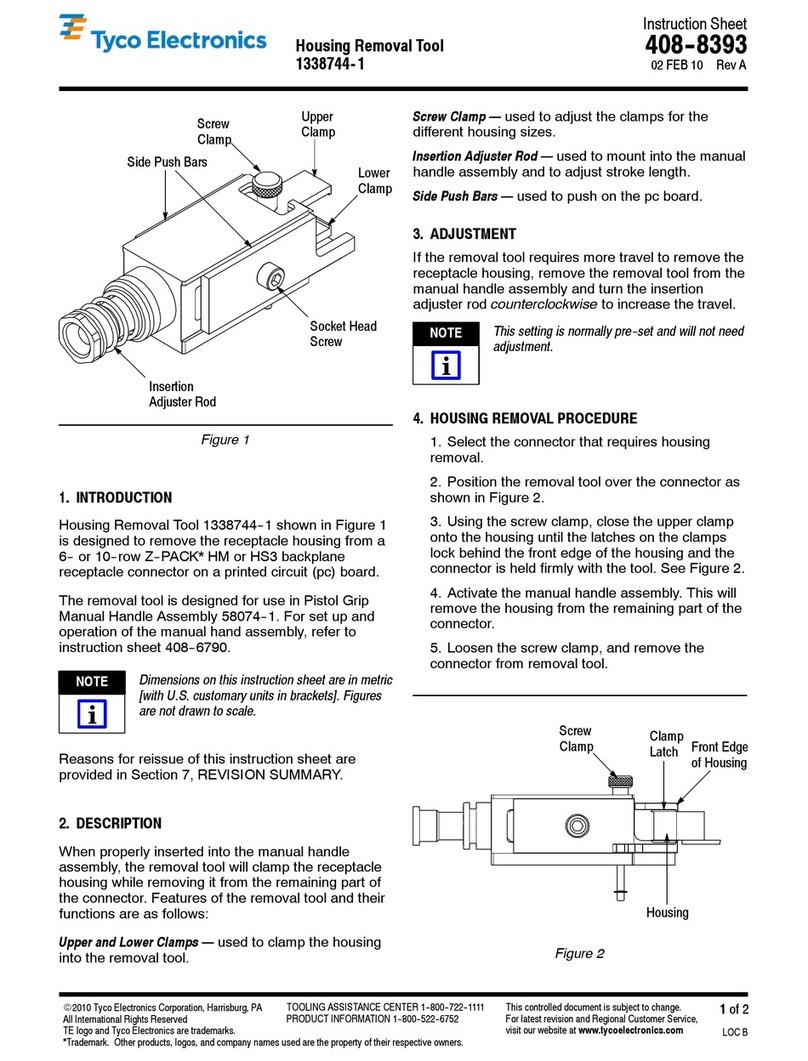

This inspection requires the use of a micrometer with

a modified anvil as shown in Figure 4. Crimp Height

Comparator RS--1019--5LP is recommended.

1. Refer to Figure 4 and select a maximum size

wire for each crimping chamber.

2. Refer to Section 3, CRIMPING PROCEDURE,

and crimp the contact accordingly.

3. Measure the wire barrel crimp height as shown

in Figure 4. If the crimp height conforms, the tool is

considered dimensionally correct. If not, return the

tool for evaluation and repair (see Section 5,

REPLACEMENT AND REPAIR).

For additional information concerning the use of the

micrometer, refer to instruction sheet 408--7424.

4.5. Ratchet Inspection

The ratchet of the hand tool should be checked to

ensure it does not release prematurely, allowing the

dies to open before they have fully bottomed. Obtain

a 0.025 [.001] shim that is suitable for checking the

clearance between the bottoming surfaces of the

dies. Proceed as follows:

1. Select the maximum size wire for the tool and

strip it to the dimension given in Figure 2.

2. Select the appropriate crimping chamber.

3. Position the contact and wire between the dies

as described in Section 3, CRIMPING

PROCEDURE.

4. Hold the wire in place and squeeze the tool

handles together until the ratchet releases. Hold

the tool handles in this position, maintaining just

Modified

Anvil

Position Point on

Center of Wire Barrel

Opposite Seam Crimp Height

(See Table)

WIRE CRIMPING CRIMP

CONTACT SIZE

(AWG)

INSULATION

DIAMETER

CHAMBER

MARKING

HEIGHT

+0.05

[+.002]

Socket

638090--1

18

2.26--3.18

18 1.37

[.054]

or

Pin

638112--1 16--14

.

.

[.089--.125] 16--14 1.55

[.061]

Figure 4

enough tension on the handles to keep the dies

closed.

5. Check the clearance between the bottoming

surfaces of the dies. If the clearance is 0.025 [.001]

or less, the ratchet is satisfactory. If clearance

exceeds 0.025 [.001], the ratchet is out of

adjustment and must be repaired. See Section 5,

REPLACEMENT AND REPAIR.

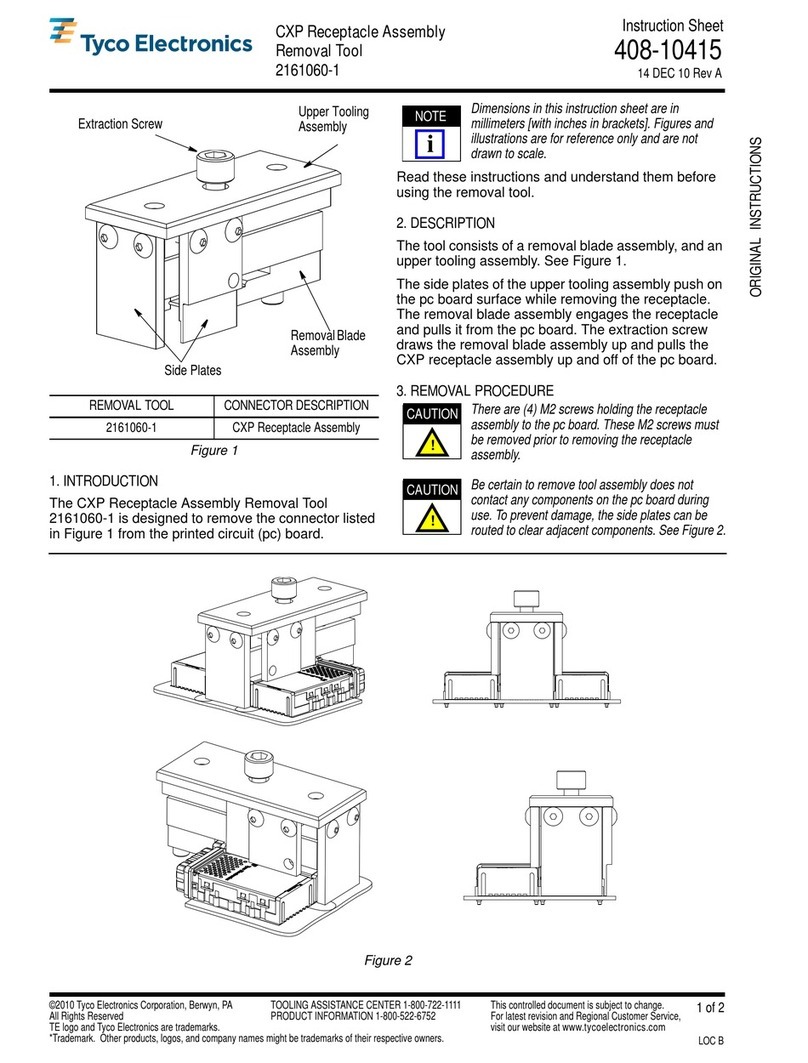

5. REPLACEMENT AND REPAIR

DO NOT remove the retaining pins; otherwise,

permanent damage will result to the tool.

Customer--replaceable parts are listed in Figure 5.

A complete inventory should be stocked and

controlled to prevent lost time when replacement of

parts is necessary. Parts other than those listed

should be replaced by Tyco Electronics to ensure

quality and reliability. Order replacement parts

through your representative, or call 1--800--526--5142,

or send a facsimile of your purchase order to

717--986--7605, or write to:

CUSTOMER SERVICE (038--035)

TYCO ELECTRONICS CORPORATION

PO BOX 3608

HARRISBURG PA 17105--3608

For customer repair service, call 1--800--526--5136.

6. REVISION SUMMARY

Revisions to this instruction sheet include:

SUpdated instruction sheet to corporate

requirements

CAUTION

!