408-1261

HHHT 59239-4, 59239-8, 59287-2, nd 525692

7

of 9Rev

F

Tyco Electronics Corporation

5.2. Periodic Inspection

A. Lubric tion

Lubricate all pins, pivot points, and bearing surfaces

with any good SAE 20 motor oil as follows:

Tool used in daily production — daily

Tool used daily (occasional) — weekly

Tool used weekly — monthly

Wipe excess oil from the tool, particularly from the

crimping area. Oil transferred from the crimping area

onto certain terminations may affect the electrical

characteristics of an application.

B. Visu l Inspection

1. Close the tool handles until the ratchet releases

and then allow them to open freely. If they do not

open quickly and fully, the spring is defective and

must be replaced. See Section 6, REPLACEMENT

AND REPAIR.

2. Inspect the head for worn, cracked, or broken

crimping dies. If damage is evident, return the tool

for evaluation and repair. See Section 6,

REPLACEMENT AND REPAIR.

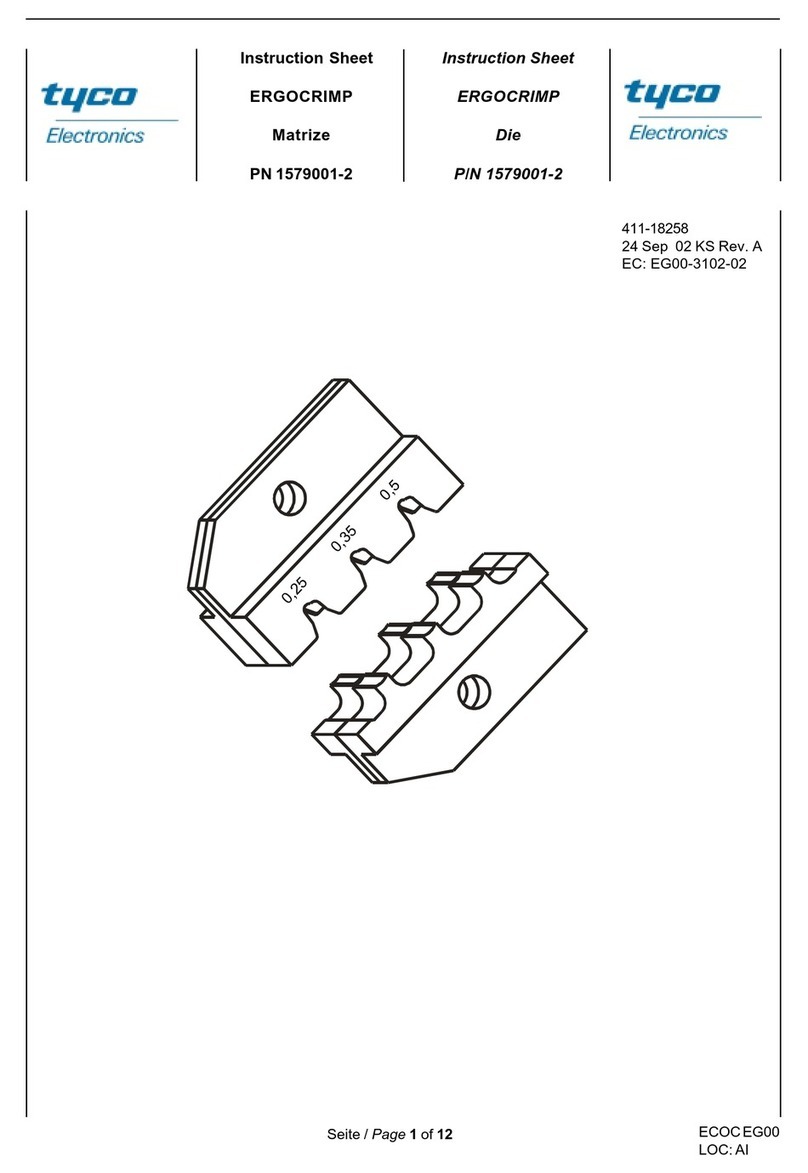

C. G ging the Crimping Ch mber

This inspection requires the use of plug gages

conforming to the dimensions provided in Figure 9.

To gage the crimping chamber, proceed as follows:

If gaging the crimping chamber is not re uired,

inspect the die closure using an alternate

procedure, i.e., the Insulation Crimp Adjustment"

(see Section 4) and Visual Inspection" (see

Paragraph 5.2.B).

1. Remove traces of oil or dirt from the crimping

chamber and plug gage.

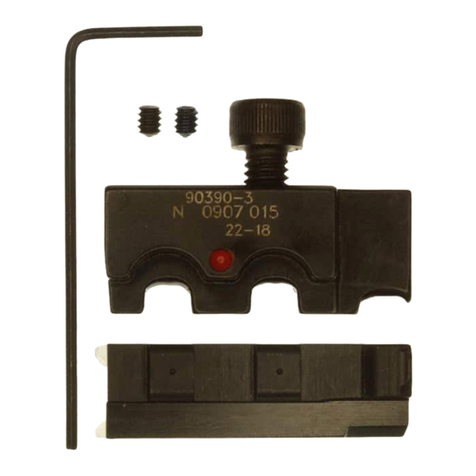

2. Insert each insulation crimp adjustment pin into

Position 1. See Figure 10.

3. Close the tool handles until the crimping dies

bottom, and hold in this position. DO NOT force

beyond initial contact.

4. Press and hold the locator down.

5. Carefully insert the GO element into the

crimping chamber as shown in Figure 10; DO NOT

force it. For the wire barrel section of the crimping

chamber, the GO element must pass completely

through the crimping chamber. For the insulation

barrel section, the GO element must pass through

the length of the section but will stop against the

wire barrel section.

6. In the same manner, try to insert the NO–GO

element into the crimping chamber as shown in

Figure 10. The NO–GO element may begin entry,

but may not pass through the crimping chamber.

If the crimping chamber conforms to the gage

inspection, the tool is considered dimensionally

correct, and should be lubricated with a THIN coat of

any good SAE 20 motor oil. If not, return the tool for

evaluation and repair. See Section 6,

REPLACEMENT AND REPAIR.

5.3. R tchet Inspection

Check the ratchet to ensure that the ratchet does not

release prematurely, allowing the dies to open before

they have fully bottomed. Proceed as follows:

1. Remove traces of oil or dirt from the bottoming

surfaces of the dies.

2. Obtain a 0.025 mm [.001 in.] shim that is

suitable for checking the clearance between the

bottoming surfaces of the dies.

3. Select a terminal or splice and

maximum

size

wire for the terminal or splice.

4. Position the terminal or splice in the crimping

chamber according to Section 3, CRIMPING

PROCEDURE. Holding the wire in place, squeeze

the tool handles together until the ratchet releases.

Hold the tool handles in this position, maintaining

just enough pressure to keep the dies closed.

5. Check the clearance between the bottoming

surfaces of the dies. If the clearance is 0.025 mm

[.001 in.] or less, the ratchet is satisfactory. If

clearance exceeds 0.025 mm [.001 in.], the ratchet

is out of adjustment and must be repaired. See

Section 6, REPLACEMENT AND REPAIR.

6. REPLACEMENT AND REPAIR

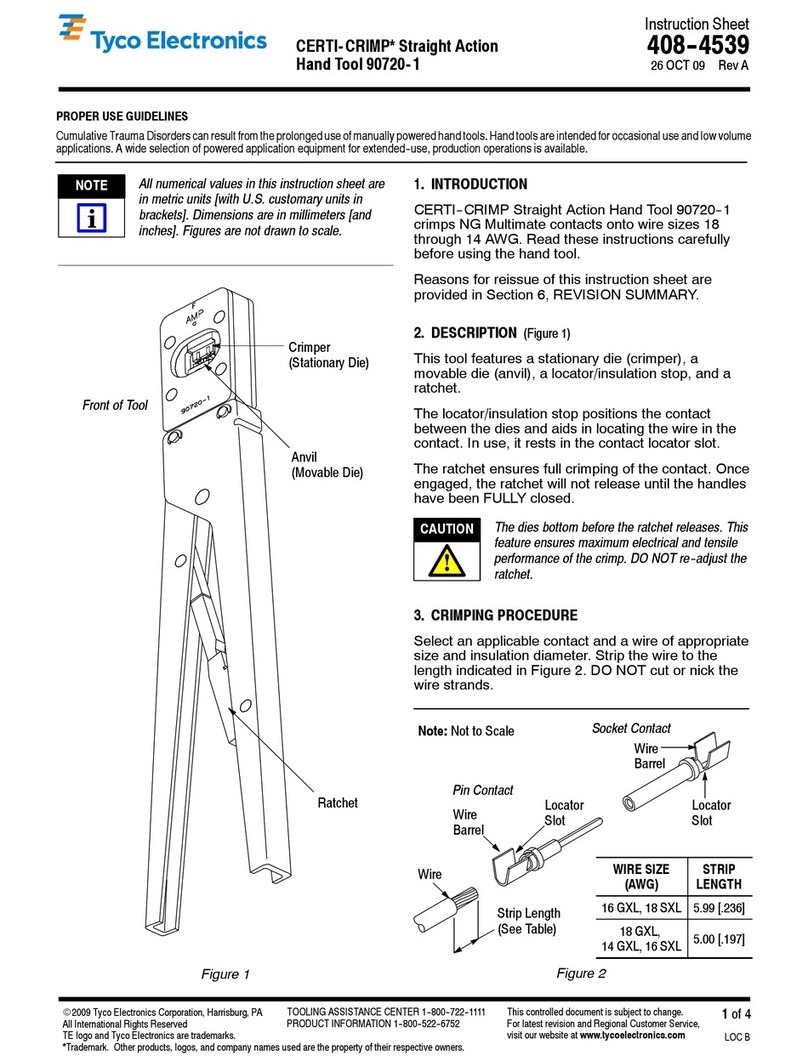

Customer–replaceable parts are listed in Figure 11.

A complete inventory should be stocked and

controlled to prevent lost time when replacement of

parts is necessary. Parts other than those listed

should be replaced by Tyco Electronics to ensure

quality and reliability. Order replacement parts

through your representative, or call 1–800–526–5142,

or send a facsimile of your purchase order to

717–986–7605, or write to:

CUSTOMER SERVICE (038–035)

TYCO ELECTRONICS CORPORATION

PO BOX 3608

HARRISBURG PA 17105–3608

For customer repair service, call 1–800–526–5136.

NOTE

i