Instruction Sheet

Cr mp ng D e Assembl es 408-9279

E

2006 yco Electronics Corporation, Harrisburg, PA

All International Rights Reserved

yco is a trademark. * rademark

Other products, logos, and company names used are the property of their respective owners. LOC B

1

of 5

OOLING ASSIS ANCE CEN ER 1-800-722-1111

PRODUC INFORMA ION 1-800-522-6752 his controlled document is subject to change.

For latest revision and Regional Customer Service,

visit our website at

www.tycoelectron cs.com

25 JUL 06 Rev B

90390-3 and 90391-3

PROPER USE GUIDELINES

Cumulative raumaDisorderscanresultfromtheprolongeduseofmanuallypoweredhandtools.Handtoolsareintendedforoccasionaluseandlowvolume

applications. A wide selection of powered application equipment for extended-use, production operations is available.

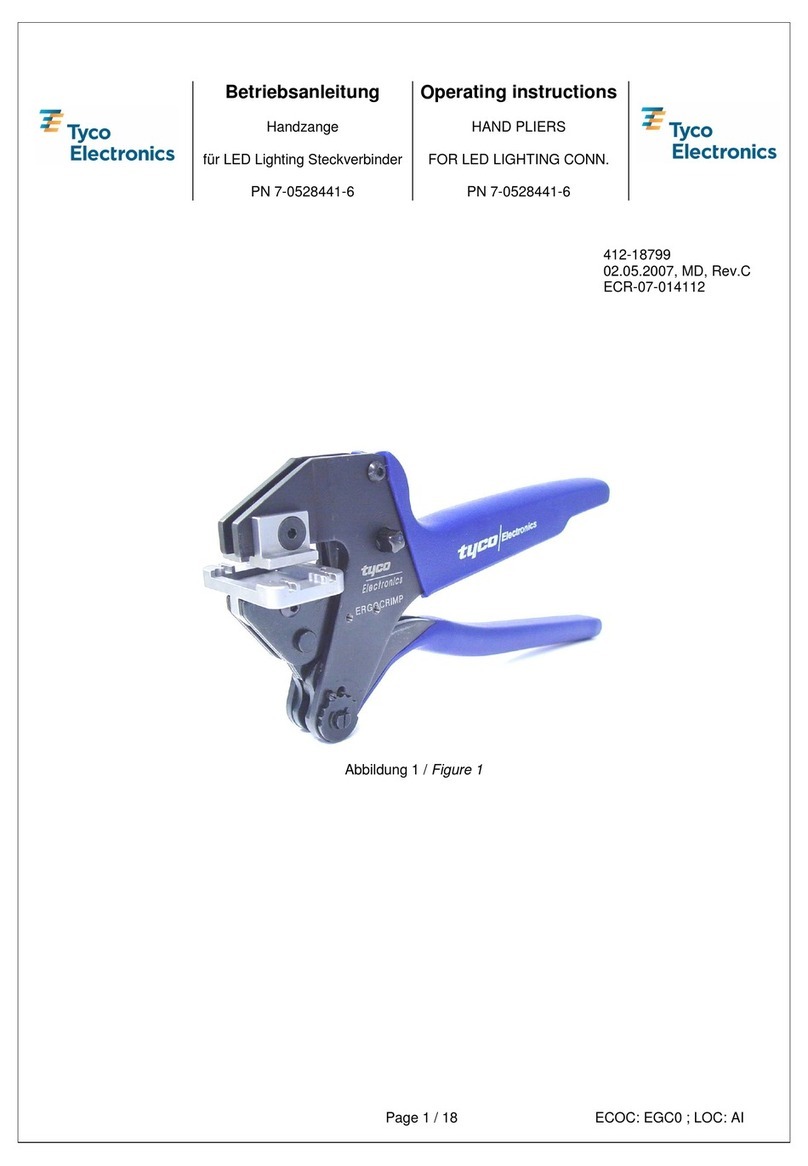

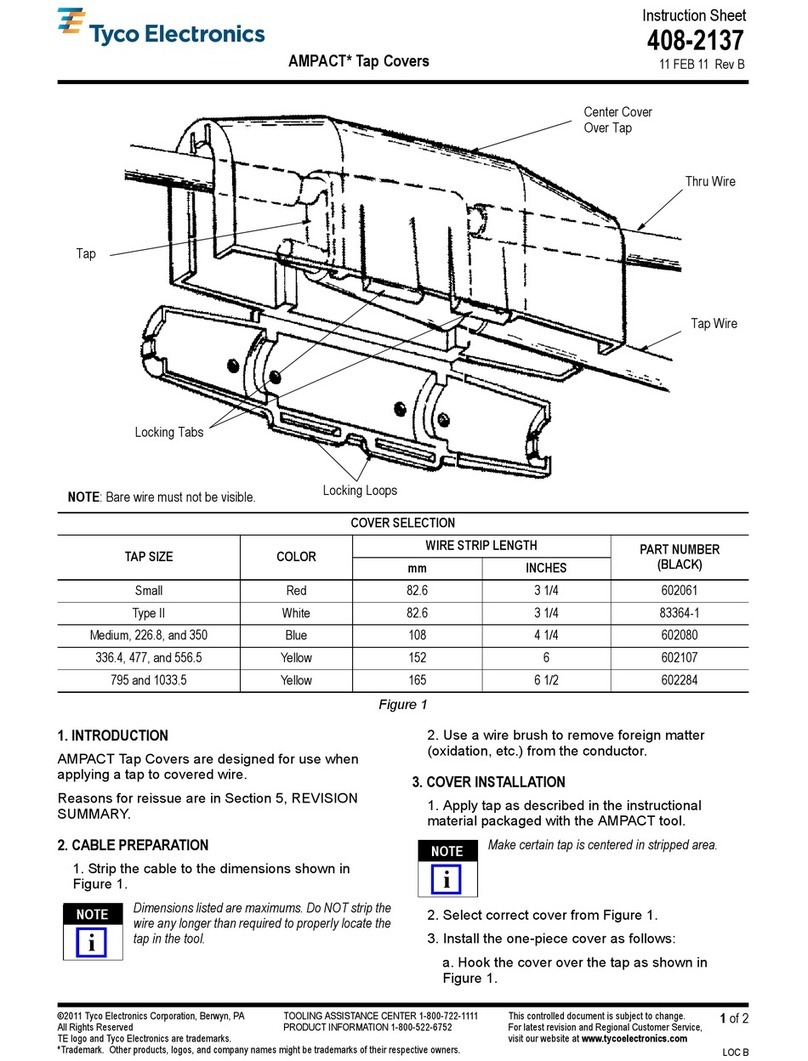

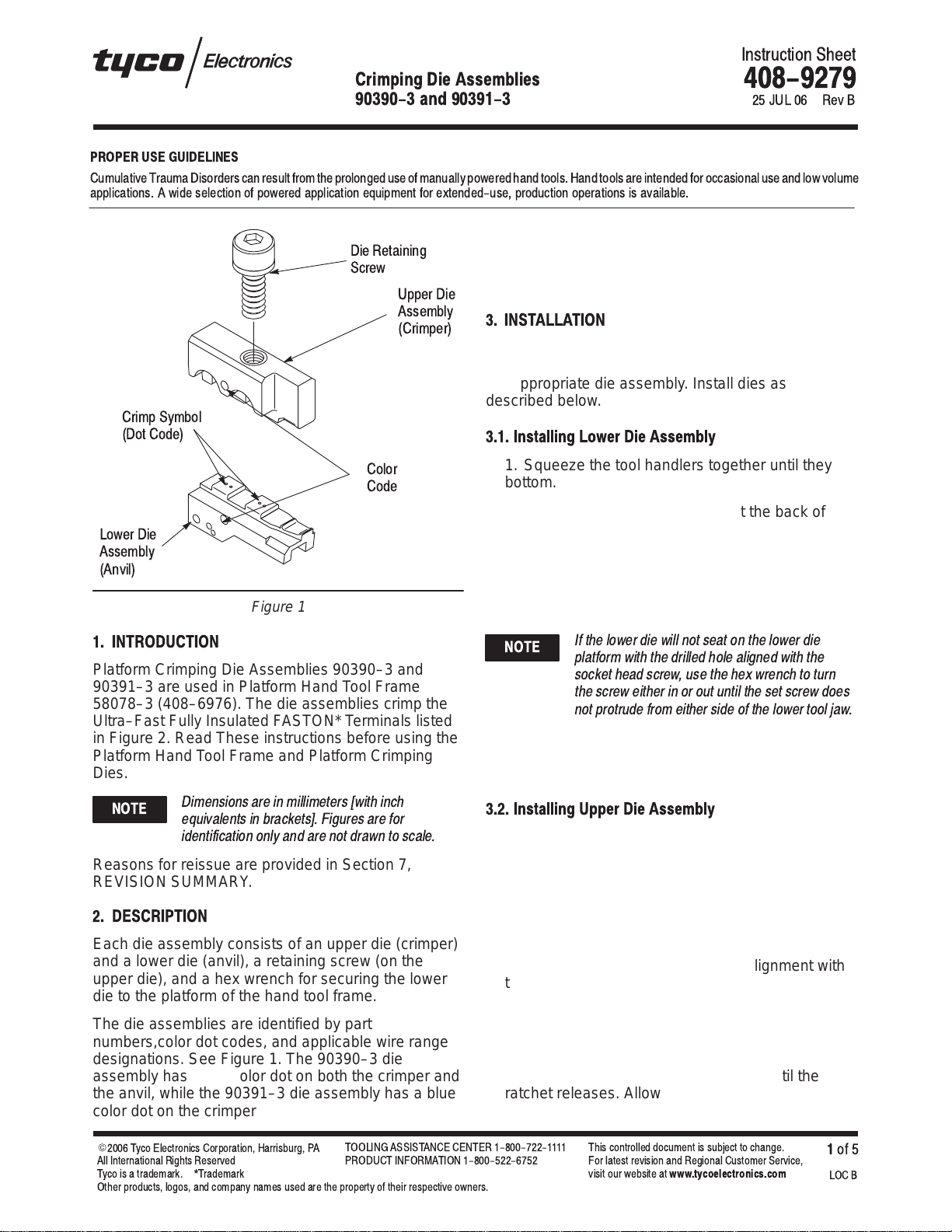

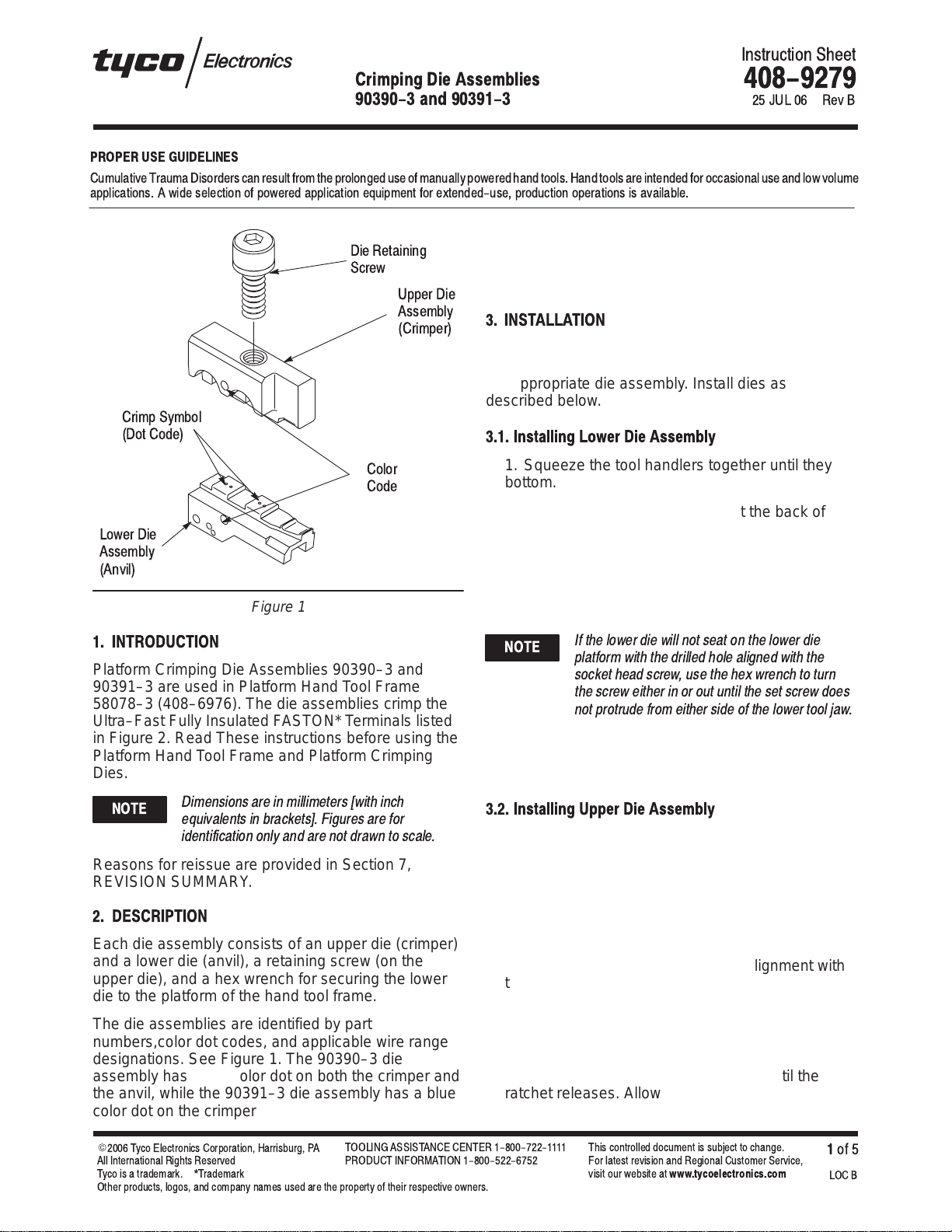

Figure 1

Die Retaining

Screw

Upper Die

Assembly

(Crimper)

Lower Die

Assembly

(Anvil)

Color

Code

Crimp Symbol

(Dot Code)

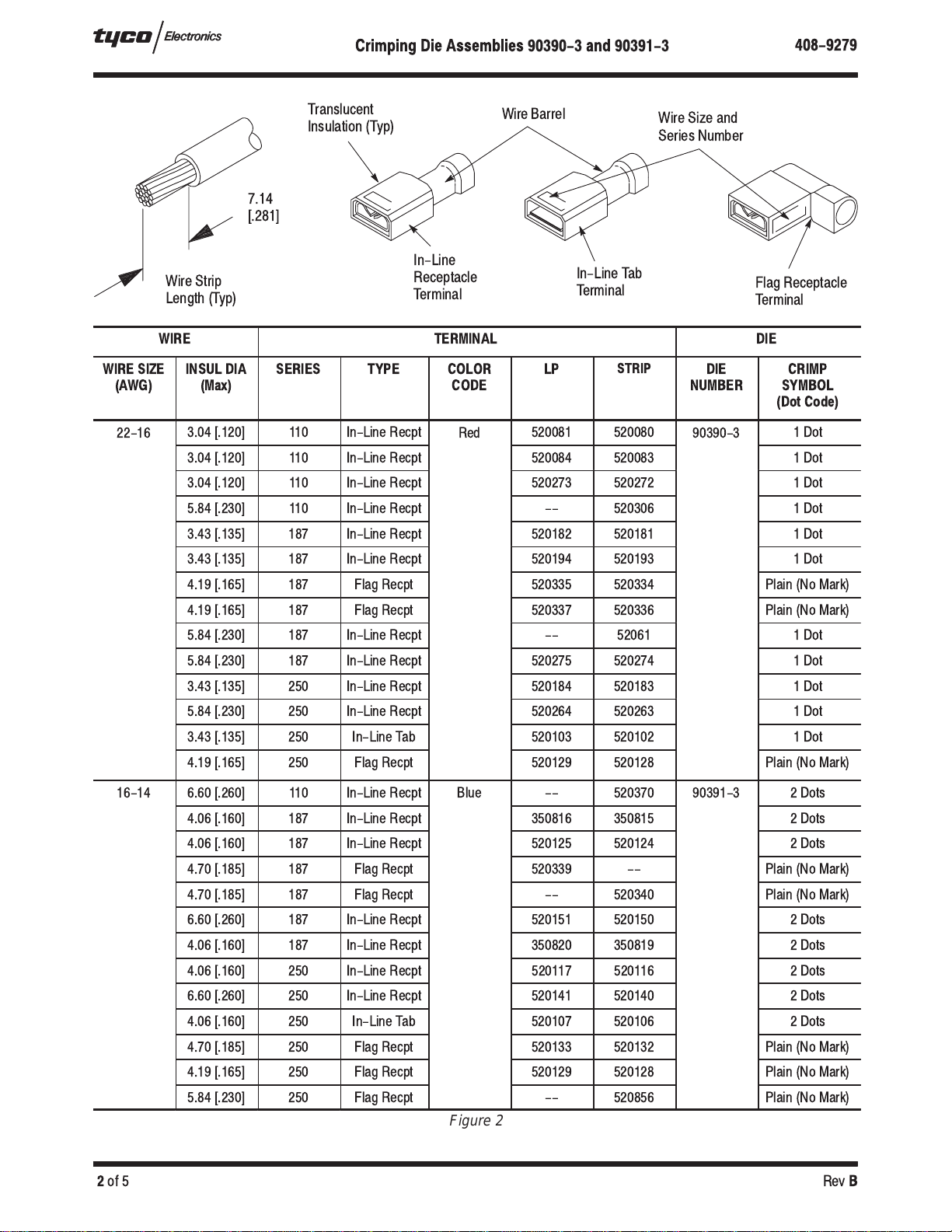

1. INTRODUCTION

Platform Crimping Die Assemblies 90390–3 and

90391–3 are used in Platform Hand Tool Frame

58078–3 (408–6976). The die assemblies crimp the

Ultra–Fast Fully Insulated FASTON* Terminals listed

in Figure 2. Read These instructions before using the

Platform Hand Tool Frame and Platform Crimping

Dies.

Dimensions are in millimeters [with inch

equivalents in brackets]. Figures are for

identification only and are not drawn to scale.

Reasons for reissue are provided in Section 7,

REVISION SUMMARY.

2. DESCRIPTION

Each die assembly consists of an upper die (crimper)

and a lower die (anvil), a retaining screw (on the

upper die), and a hex wrench for securing the lower

die to the platform of the hand tool frame.

The die assemblies are identified by part

numbers,color dot codes, and applicable wire range

designations. See Figure 1. The 90390–3 die

assembly has a red color dot on both the crimper and

the anvil, while the 90391–3 die assembly has a blue

color dot on the crimper and the anvil. The color

coding on the die assembly corresponds to the color

coding on translucent insulation of the Ultra–Fast

FASTON terminal for easier identification when

crimping.

3. INSTALLATION

Determine the part number of the terminal you are

crimping, then refer to the table in Figure 2 and select

the appropriate die assembly. Install dies as

described below.

3.1. Install ng Lower D e Assembly

1. Squeeze the tool handlers together until they

bottom. Then allow them to open fully.

2. Hold the hand tool frame so that the back of the

tool is facing you and note the socket head screw

located in the lower die platform. See Figure 3.

3. Slide the lower die onto the lower platform,

ensuring that the drilled holes on the side of the

lower die line up with the socket head screw.

If the lower die will not seat on the lower die

platform with the drilled hole aligned with the

socket head screw, use the he wrench to turn

the screw either in or out until the set screw does

not protrude from either side of the lower tool jaw.

4. With the lower die in place, turn the socket head

screw (on the die platform) clockwise until snug.

Do NOT overtighten.

3.2. Install ng Upper D e Assembly

1. Remove the die retaining screw from the die

assembly.

2. Position the upper die in upper die platform of

the tool. Thread the die retaining screw through the

mounting hole in the top of tool and tighten the

screw until it is snug but NOT secured.

3. While guiding the upper die into alignment with

the lower die, slowly close the tool handles until the

dies bottom.

4. Tighten the upper die retaining screw until the

die is secure.

5. Squeeze the tool handles together until the

ratchet releases. Allow the tool handles to open

fully. The tool is now ready for use.

NOTE

NOTE