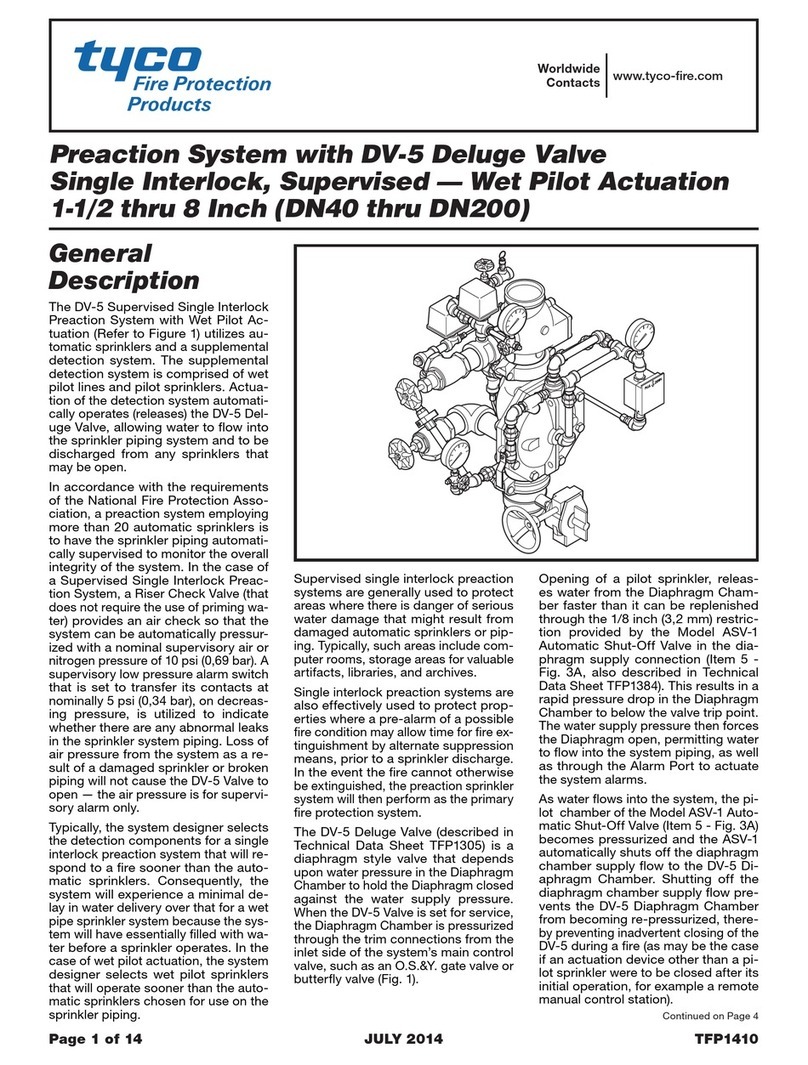

Chamber is pressurized through the

trim connections from the inlet side of

the system’s main control valve, such

as an O.S.&Y. gate valve or butterfly

valve (Fig. 1).

Operation of an electrical detection de-

vice such as a heat sensitive thermo-

stat, smoke detector, or electrical man-

ual control station signals the deluge

valve releasing panel to energize the

Solenoid Valve. In turn, the energized

Solenoid Valve opens to release water

from the Diaphragm Chamber faster

than it can be replenished through the

1/8 inch (3,2 mm) restriction provided

by the Model ASV-1 Automatic Shut-

Off Valve in the diaphragm supply con-

nection (Item 5 - Fig. 2A, also de-

scribed in Technical Data Sheet

TFP1384). This results in a rapid pres-

sure drop in the Diaphragm Chamber

to below the valve trip point. The water

supply pressure then forces the Dia-

phragm open, permitting water to flow

into the system piping, as well as

through the Alarm Port to actuate the

system alarms.

As water flows into the system, the

pilot chamber of the Model ASV-1

Automatic Shut-Off Valve (Item 5 - Fig.

2A) becomes pressurized and the

ASV-1 automatically shuts off the dia-

phragm chamber supply flow to the

DV-5 Diaphragm Chamber. Shutting

off the diaphragm chamber supply flow

prevents the DV-5 Diaphragm Cham-

ber from becoming re-pressurized,

thereby preventing inadvertent closing

oftheDV-5duringafire(asmaybethe

case should the Solenoid Valve be-

come de-energized after its initial op-

eration).

WARNING

The Model DV-5 Supervised Single In-

terlock Preaction System with Electric

Actuation Trim described herein must

be installed and maintained in compli-

ance with this document, as well as

with the applicable standards of the

National Fire Protection Association,

in addition to the standards of any

other authorities having jurisdiction.

Failure to do so may impair the per-

formance of the related devices.

The owner is responsible for maintain-

ing their fire protection system and de-

vices in proper operating condition.

The installing contractor or manufac-

turer should be contacted with any

questions.

Technical

Data

Approvals

UL and C-UL Listed. FM Approved.

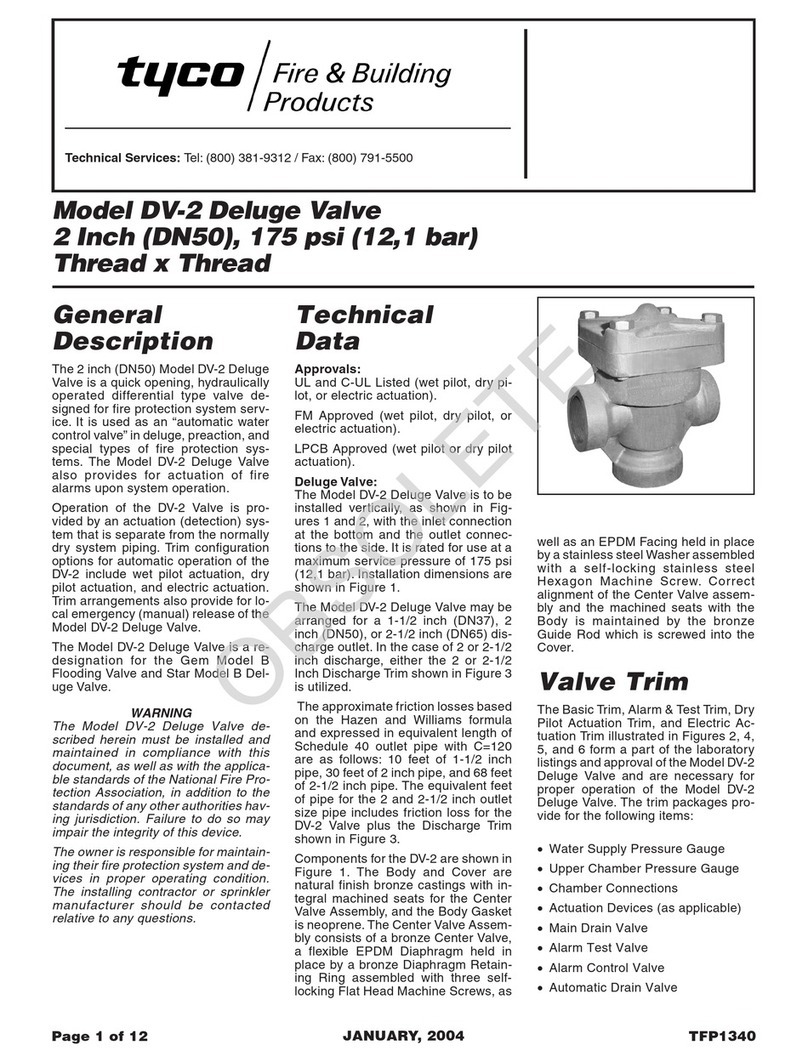

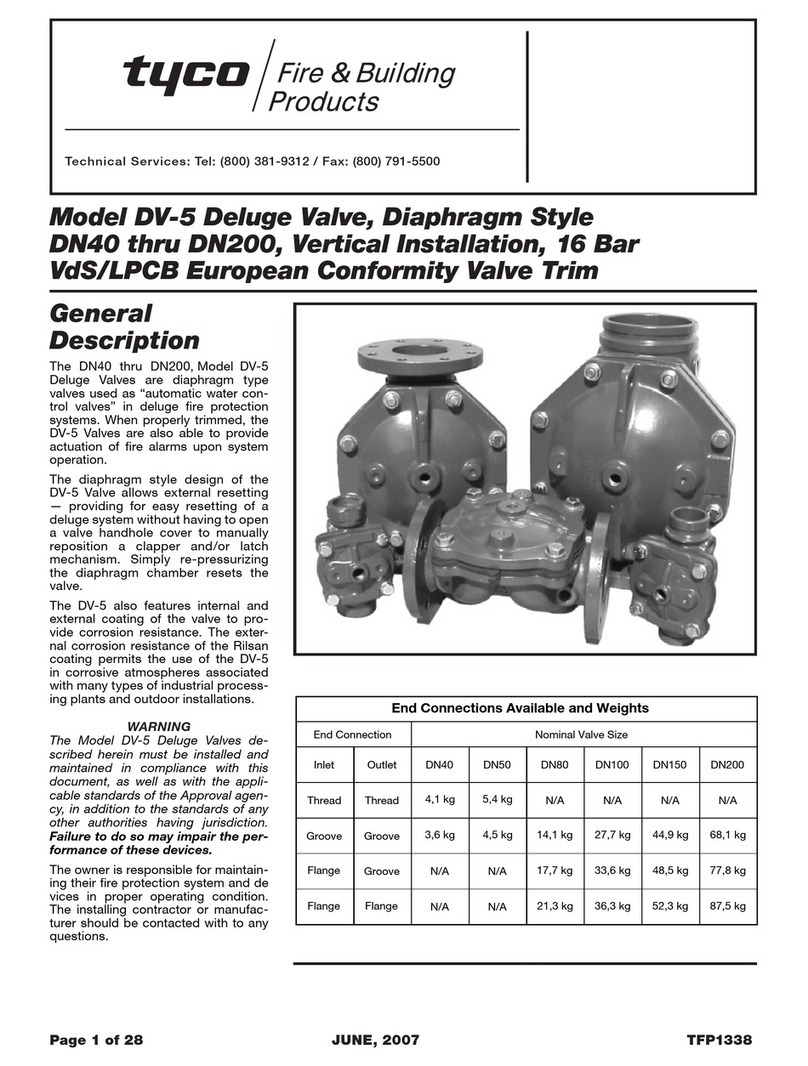

Deluge Valve

Model DV-5.

Riser Check Valve

Model CV-1FR.

NOTE

1-1/2 inch (DN40) risers utilize a 2 inch

(DN50) Riser Check valve in combina-

tion with the 1-1/2 inch (DN40) Model

DV-5 Deluge Valve.

Valve Trim

The Supervised Single Interlock Pre-

action System With Electric Actuation

Trim (Fig. 2A/2B) forms a part of the

laboratory listings and approvals. The

trim is necessary for proper operation

of the DV-5 Valve.

Each package of trim includes the fol-

lowing items:

•Water Supply Pressure Gauge

•Diaphragm Chamber

Pressure Gauge

•Diaphragm Chamber Connections

•Manual Control Station

•Main Drain Valve

•System Drain Valve

•Alarm Test Valve

•Automatic Drain Valve

•System Air Pressure Gauge

•Air Supply Connections

•Low Air Pressure Supervisory

Switch

•Waterflow Pressure Alarm Switch

To ease field assembly of the trim ar-

rangement, the trim components are

provided partially assembled as

showninFigure2B.

The trim arrangement is provided with

galvanized or black nipples and fit-

tings. The galvanized trim is intended

for non-corrosive or corrosive condi-

tions, whereas the black trim is princi-

pally intended for use with AFFF sys-

tems.

NOTE

When the system pressure is greater

than 175 psi (12,1 bar), provision is to

be made to replace the standard order

300 psi (20,7 bar) Water Pressure

Gauges, shown in Figure 2A/2B with

separately ordered 600 psi (41,4 bar)

Water Pressure Gauges.

Detection System

In order for a single interlock preaction

system to be hydraulically calculated

as a wet pipe system, as opposed to a

dry pipe sprinkler system, the detec-

tion system must be designed to oper-

ate sooner than the automatic sprin-

klers on the sprinkler piping.

The Supervised Single Interlock Pre-

action System With Electric Actuation

Trim provides for electric operation of

the DV-5 Valve by a detection system

consisting of electrical devices such as

heat sensitive thermostats, smoke de-

tectors, and/or electric manual pull sta-

tions. Information on the various types

of separately ordered Solenoid Valves

that may be used with this trim pack-

age is given in Technical Data Sheet

TFP2180. Nominal installation dimen-

sions for the Supervised Single Inter-

lock Preaction System With Electric

Actuation Trim are shown in Figure 3.

NOTES

Approval by Factory Mutual is contin-

gent on the use of an FM Approved

24VDC Solenoid Valve (P/N 52-287-1-

024 or P/N 52-287-1-124). FM only

approves solenoid valves for use in

non-hazardous locations.

Consult with the Authority Having Ju-

risdiction regarding installation criteria

pertaining to electric actuation cir-

cuitry.

The Supervised Single Interlock Pre-

action System With Electric Actuation

Trim is provided with a Model ASV-1

Automatic Shut-Off Valve (Item 5 - Fig.

2A); consequently, the release circuit

of the releasing panel need only pro-

vide the standard ten minutes of alarm

condition intended to energize the So-

lenoid Valve. After the ten minute du-

ration, should the Solenoid Valve be-

come de-energized and close

(especially while operating under bat-

tery back-up), the Automatic Shut-Off

Valve will have already automatically

closed thereby preventing the DV-5

Diaphragm Chamber from becoming

re-pressurized and preventing an in-

advertent closing of the DV-5 during a

fire event.

System Air Pressure Requirements

The supervisory air (nitrogen) pres-

sure is to be 10 plus or minus 2 psi

(0,69 plus or minus 0,07 bar). The use

of a higher supervisory pressure is

subject to approval by the Authority

Having Jurisdiction, and it should be

understood that the use of a higher

supervisory pressure may increase

water delivery time. The use of a lower

supervisory pressure may prevent

clearing the alarm of the Supervisory

Low Pressure Alarm Switch (Item P3 -

Fig. 2A), which is factory set to alarm

at5plusorminus1psi(0,34plusor

minus 0,07 bar) on decreasing pres-

Page 9 of 14

TFP1420