reduction in the time for the Dry Pilot Actuator to open fol-

lowing the operation of one or more automatic sprinklers.

With the optional Double Interlock Accelerator Trim

(Fig. 8), the communication between the system air pres-

sure and the Dry Pilot Actuator is made directly through

the Double Interlock Accelerator Trim.The S430 Accelera-

tor automatically adjusts to small as well as slow changes

in system pressure, but trips when there is a rapid and

steady drop in pressure (such as will occur when a sprin-

kler operates).Upon tripping, the S430 Accelerator will re-

lieve system air pressure from the Dry Pilot Actuator

faster than it can be replenished through the 3/32 inch

(2.4 mm) diameter orifice in the clapper of the 1/2 inch

Swing Check Valve (Item A6 - Fig. 8), resulting in quick

opening of the Dry Pilot Actuator following a sprinkler op-

eration.

The Model S430 Accelerator is described in Product Data

Sheet 2-5.4.10.

DESIGN CRITERIA

System Design Considerations

The automatic sprinklers, as well as the releasing panel,

fire detection devices, manual pull stations, and signaling

devices, which are utilized with the Model A Preaction

Valve must be UL Listed, ULC Listed, C-UL Listed, or FM

Approved, as applicable. Releasing panels which may be

considered for use with the Model A Preaction Valve in-

clude the Potter Electric PFC Series 100RC, PFC Series

2000RC, and PFC Series 4410. Information on the vari-

ous types of Solenoid Valves that are to be separately or-

dered for use with the Model A Preaction Valve is given in

Product Data Sheet 2-5.1.31.

NOTE

Approval by Factory Mutual is contingent on the use of an

FM Approved 24 VDC Solenoid Valve. FM only approves

solenoid valves for use in non-hazardous locations.

Because a double interlock preaction system requires

time for a drop in system air pressure to occur (in addi-

tion to responding to a separate heat detection system),

before it will allow water to enter the system piping, this

system has characteristics similar to a dry pipe sprinkler

system.Therefore, the system design considerations for a

dry pipe system are normally applied to a double inter-

lock preaction system — including a 30% increase in de-

sign area; quick opening devices for system capacities of

500 gallons (1890 litres) or more; a maximum 1 minute

water delivery time for system capacities of 750 gallon

(2850 litres) or more; and, prohibition of gridded system

piping.

The preaction valve, and all interconnecting piping must

be located in a readily visible and accessible location and

in an area which can be maintained at a minimum tem-

perature of 40°F/4°C.

NOTE

Heat tracing is not permitted for the preaction valve, or

any of the interconnecting piping. Heat tracing can pro-

mote the formation of hardened mineral deposits which

can prevent system operation. Heat tracing can also re-

sult in damage to the Model A Preaction Valve Differen-

tial Assembly.

In planning the installation, consideration must also be

given to the disposal of the large quantities of water

which may be associated with draining the system, per-

forming a flow test, or performing a system trip test.

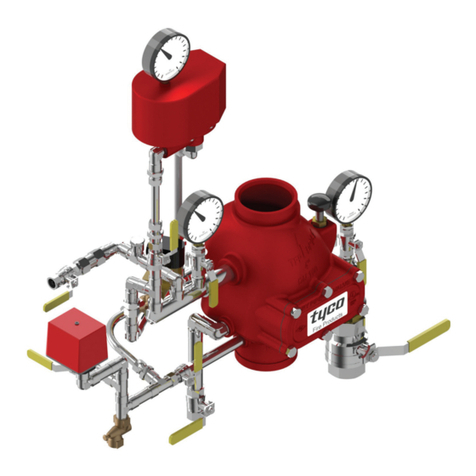

Installation configuration and clearance dimensions are

given in Figure 10.The flanged inlet and outlet connec-

tions are faced and drilled per ANSI Standard B16.1, un-

less otherwise specified when ordered.

In order to readily perform the System Inspection Proce-

dure described in the Maintenance and Service section, it

is recommended that a System Shut-Off Valve and Sys-

tem Trip Test Flow Valve be installed above the Model A

Preaction Valve, as shown in Figure 1. The System Shut-

Off Valve should be a listed or approved (as appropriate)

indicating valve with a supervisory switch to monitor the

normally open position.

System Air Pressure Requirements

Figure 5 shows the minimum Electric/Pneumatic Double

Interlock Preaction System air pressure requirement as a

function of the water supply pressure.Use of an automat-

ic air or nitrogen maintenance device is recommended

and may be required by the Authority Having Jurisdiction.

NOTE

The dew point of the air or nitrogen must be maintained

below the lowest ambient temperature to which the Dou-

ble Interlock Preaction System piping will be exposed, or

as required by the Authority Having Jurisdiction. Accumu-

lation of water in the connection to the Dry Pilot Actuator

will lower the air pressure at which the Dry Pilot Actuator

will open and possibly prevent proper operation. Also, in-

troduction of moisture into the system piping that is ex-

posed to freezing temperatures can create ice build up

which could prevent proper operation of the system.

INSTALLATION

The Model A Preaction Valve must be installed in accord-

ance with the following instructions. Proper operation of

the Double Interlock Preaction System depends upon it

being installed in accordance with the instructions given

below. Failure to follow these instructions may prevent the

devices from functioning properly as well as void listings,

approvals, and the manufacturer’s warranties.

1. All pipe thread connections must be free of scale and

burrs before installation. Use pipe thread sealant spar-

ingly on male pipe threads only.

2. The Model A Preaction must be installed vertically as

shown in Figure 10.

3. Install the Electric/Pneumatic Double Interlock Preaction

Trim as as shown in Figures 6 and 7.

Care must be taken to make sure that check valves,

globe valves, etc. are installed with the flow arrows in

the proper direction.

Drain tubing to the Drip Funnel must be installed with

smooth bends that will not restrict flow.

4. The Differential Chamber Supply Connection shown in

Figure 10 must be connected to the water supply side of

the System Main Control Valve to facilitate setting of the

Model A Preaction Valve.

5. Connect the Air Supply Connection shown in Figure 7 to

an air or nitrogen supply. Use of an automatic air or ni-

trogen maintenance device is recommended and may

be required by the Authority Having Jurisdiction. The

Air Supply Connection is to be plugged when an alter-

nate air supply is provided to the system, as may be re-

quired for refrigerated spaces.

Refer to Figure 5 for Double Interlock Preaction System

air pressure requirements.

6. Install, as applicable, the optional Double Interlock Ac-

celerator Trim as shown in Figure 8.

STAR SPRINKLER INC.

2-4.1.10 Page 5