TFP110 5

Page 5 of 12

the batteries, slide the battery assem-

bly into the housing, and plug the

harness connector into the VIZOR

accelerator circuit board.

For the optional 90-hour batteries,

mount the remote battery enclosure

horizontally and within 10 feet of the

VIZOR accelerator. Splice the battery

cable, see Figure 5, connect the cable

to the batteries, then plug the battery

assembly into the VIZOR accelera-

tor harness. Lastly, plug the harness

connector into the VIZOR accelerator

circuit board.

Step 4. Close and lock the cover.

Step 5. Push S1 to the OFF position.

Step 6. In order to minimize an inad-

vertent primary (A/C) power loss and

to facilitate maintenance, it is recom-

mended that a dedicated circuit be

hard-wired to the VIZOR accelerator.

The following notications occur:

•

The green AC LED lights, the amber

trouble / supervisory LED lights,

the red tripped LED lights, and the

buzzer sounds.

•

Assuming the batteries are charged,

the amber battery Trouble LED

remains unlit.

Step 7. Optionally conduct trip tests of

the VIZOR accelerator and the dry pipe

valve in accordance with the Care and

Maintenance section.

Step 8. Optionally, and/or if required

by local jurisdiction, hard-wire moni-

toring circuits to the Trouble and high/

low supervisory contacts using 14 to

18 AWG wire.

Step 9. Push S1 to the SET position.

Step 10. Verify proper operation of the

VIZOR accelerator using the “No Flow

Trip Test for Accelerator Only” proce-

dure described in the Care and Main-

tenance section.

Setting

Procedure

As soon as possible after an opera-

tion, reset and restore to service the

Dry Pipe Valve (listed in Table A) and

the TYCO VIZOR Electronic Dry Pipe

Accelerator in accordance with the fol-

lowing procedure.

NOTICE

Completely drain the system before

proceeding.

After setting a fire protection system,

notify the proper authorities and advise

those responsible for monitoring pro-

prietary and/or central station alarms.

Step 1. Push S1 to the OFF position.

Step 2. Silence the internal audible

alarm at any time by momentarily

pushing S2 to the SILENCE position.

Step 3. Locate all of the system’s low

point drain valves to help facilitate

resetting of the system. Refer to the

appropriate dry valve data sheet for

valve resetting procedures.

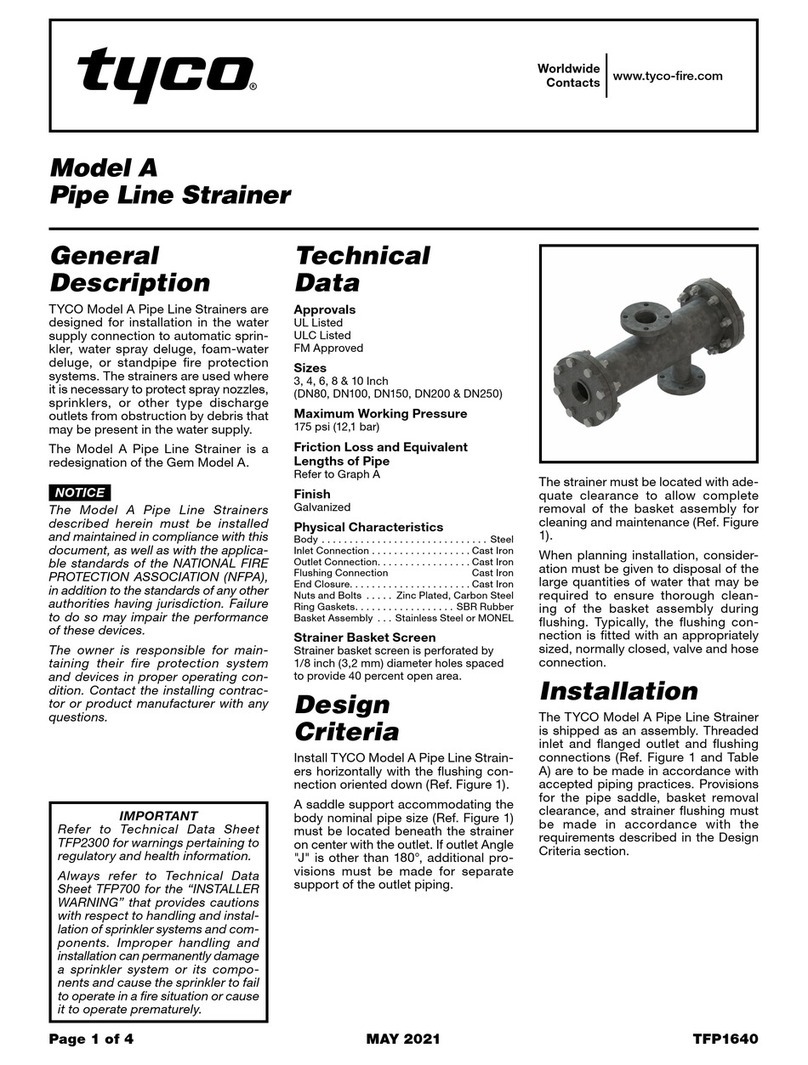

Step 4. Clean the strainer by removing

the clean-out plug and strainer basket.

Step 5. Follow the resetting procedure

for the installed dry pipe valve. When

the procedure calls for the system

piping to be pressurized with air, start

to pressurize the system and then

proceed to Step 6.

Step 6. When the system reaches an

air pressure of approximately 10 psi

and while the system is in the process

of reaching its intended pressure,

“blow-down” each drain valve. Be sure

to include the low body drains at the

dry pipe valve and the Inspector’s test

connection.

To “blow-down”, open each drain valve

individually, and when water stops

draining, close the drain valve. This

blow-down procedure assures that

complete draining of the system can

be more easily accomplished.

Step 7. When the system reaches the

normal intended air pressure, wait

approximately 30 seconds to allow for

stabilization of the air pressure within

the piping. Momentarily push button

S2 on the VIZOR to the RESET posi-

tion to clear the red tripped LED, and

then push button S1 the SET position.

Step 8. Open the inspector’s test con-

nection (ITC), verify that the VIZOR has

tripped. A momentary burst of air from

the dry pipe valve’s automatic drain

valve indicates that the VIZOR accel-

erator has tripped. Verify that the time-

to-trip for the accelerator is essentially

the same as in previous tests.

This procedure also clears scale and

debris from the pipe and ttings that are

connected to the VIZOR accelerator.

Step 9. Push S1 to the OFF position,

allow the system to automatically return

to its intended pressure via its auto-

matic air supply. After waiting approxi-

mately 30 seconds, momentarily push

S2 to the RESET position, and then

push S1 to the SET position.

Step 10. Partially open the main

control valve. Slowly close the system

main drain valve as soon as water dis-

charges from the drain connection.

Step 11. Depress the plunger on the

dry pipe valve’s automatic drain valve

to verify that it is open and that no water

discharges. The absence of water dis-

charge from the automatic drain valve

is an indication of a properly set water

seat within the dry pipe valve.

If water is discharging, see the Care

and Maintenance section within the

technical data sheet for the dry pipe

valve to determine/correct the cause of

the leakage problem.

If there are no leaks, fully open the

system main control valve.

The system is now set for service.