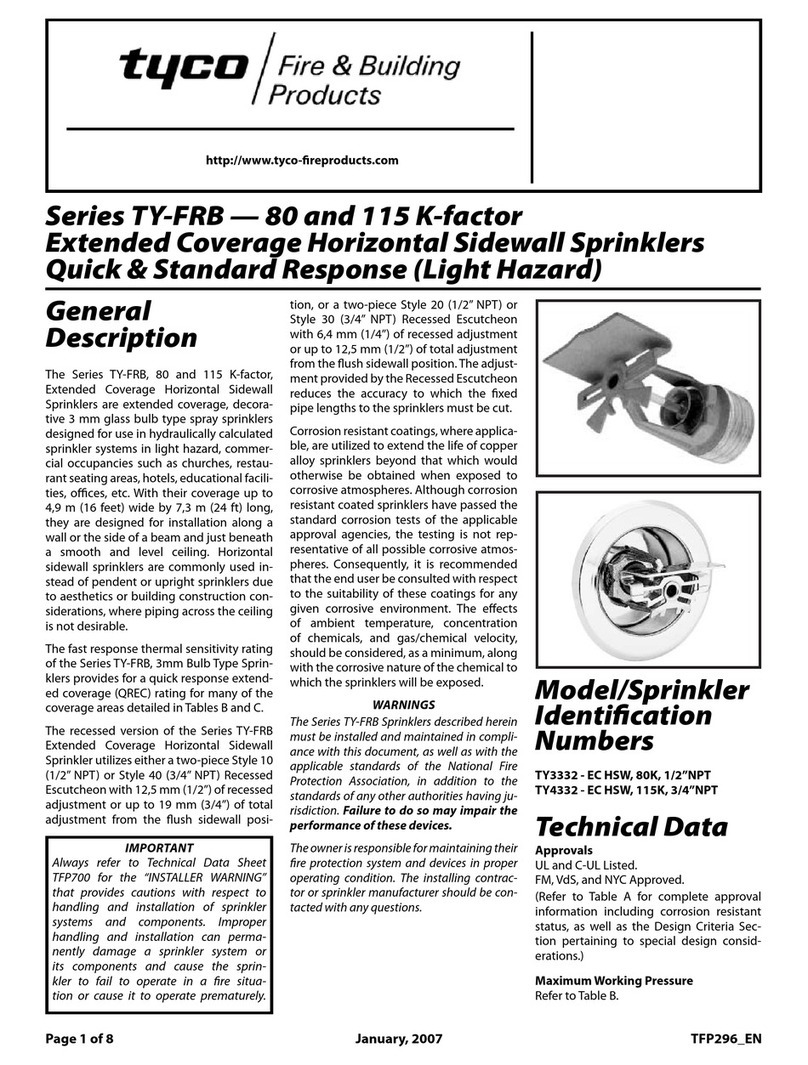

Style 65 One-Piece Flush Escutcheon

Style 401 Two-Piece Deep Escutcheon

1/2 Inch and 3/4 Inch NPT

Page 1 of 4 AUGUST 2018 TFP777

IMPORTANT

Refer to Technical Data Sheet

TFP2300 for warnings pertaining to

regulatory and health information.

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions

with respect to handling and instal-

lation of sprinkler systems and com-

ponents. Improper handling and

installation can permanently damage

a sprinkler system or its compo-

nents and cause the sprinkler to fail

to operate in a fire situation or cause

it to operate prematurely.

Worldwide

Contacts

www.tyco-fire.com

General

Description

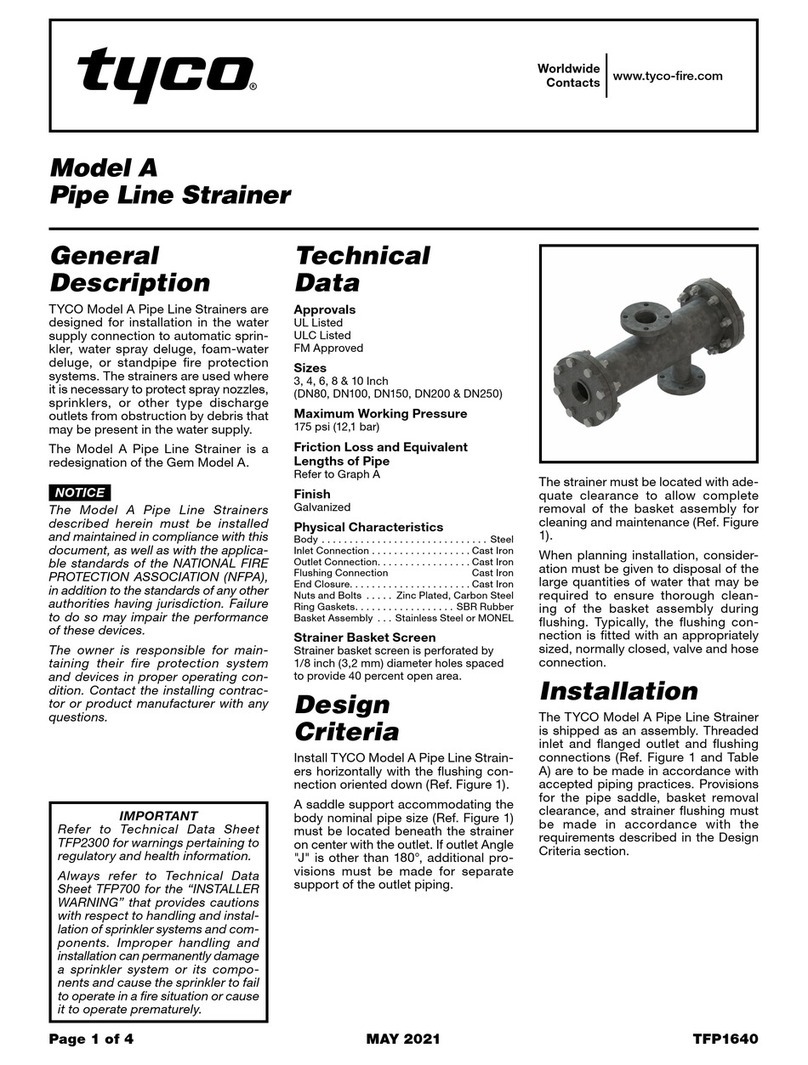

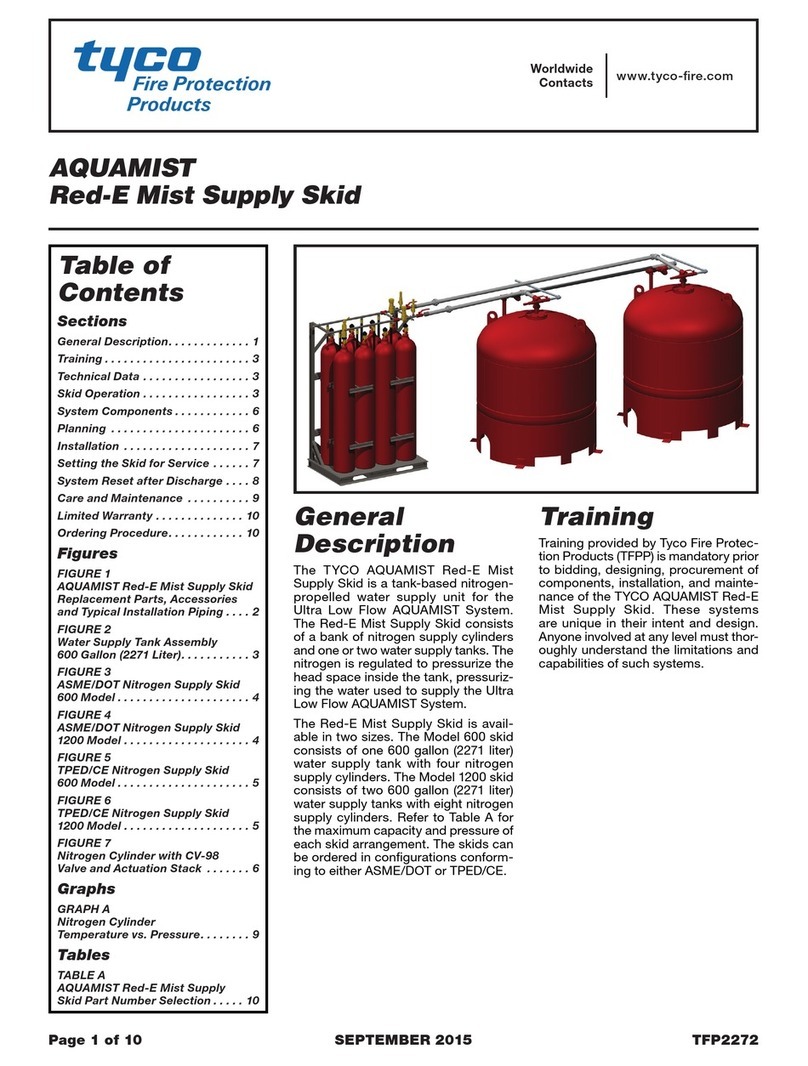

The TYCO Styles 65 and 401 Escutch-

eon Plates illustrated in Figures 1 and 2

are designed for use with pendent and

horizontal sidewall automatic sprin-

klers in fire protection systems where

the piping is installed above a ceiling or

behind a wall. They are used to improve

the overall appearance of the installa-

tion by concealing the clearance holes

required for the connecting piping and

fittings to the sprinkler.

The Escutcheon Plates are available

in two styles: Style 65 flush one-piece

(non-adjustable), and Style 401 deep

two-piece (adjustable).

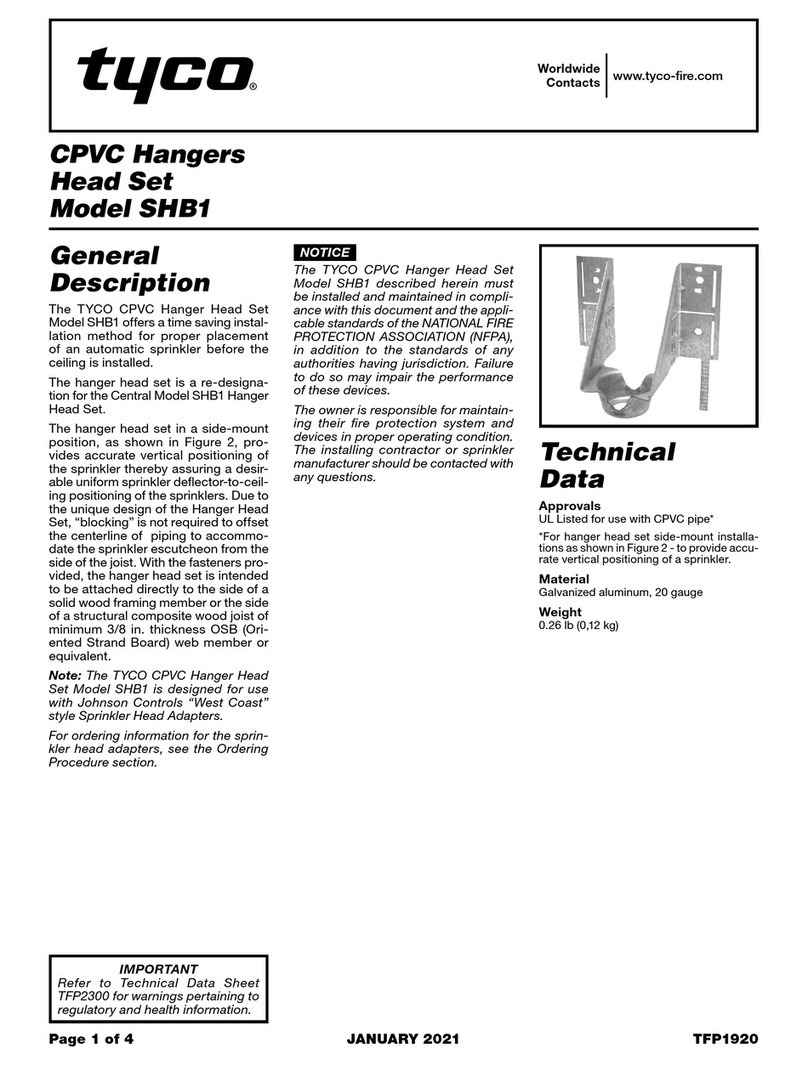

The flush one-piece (non-adjustable)

Style 65 Escutcheon Plates (Fig. 1) are

used where the position of the sprin-

kler “escutcheon plate seating surface”

(relative to the ceiling line or wall) can

be fixed by adjusting the length of the

interconnecting piping.

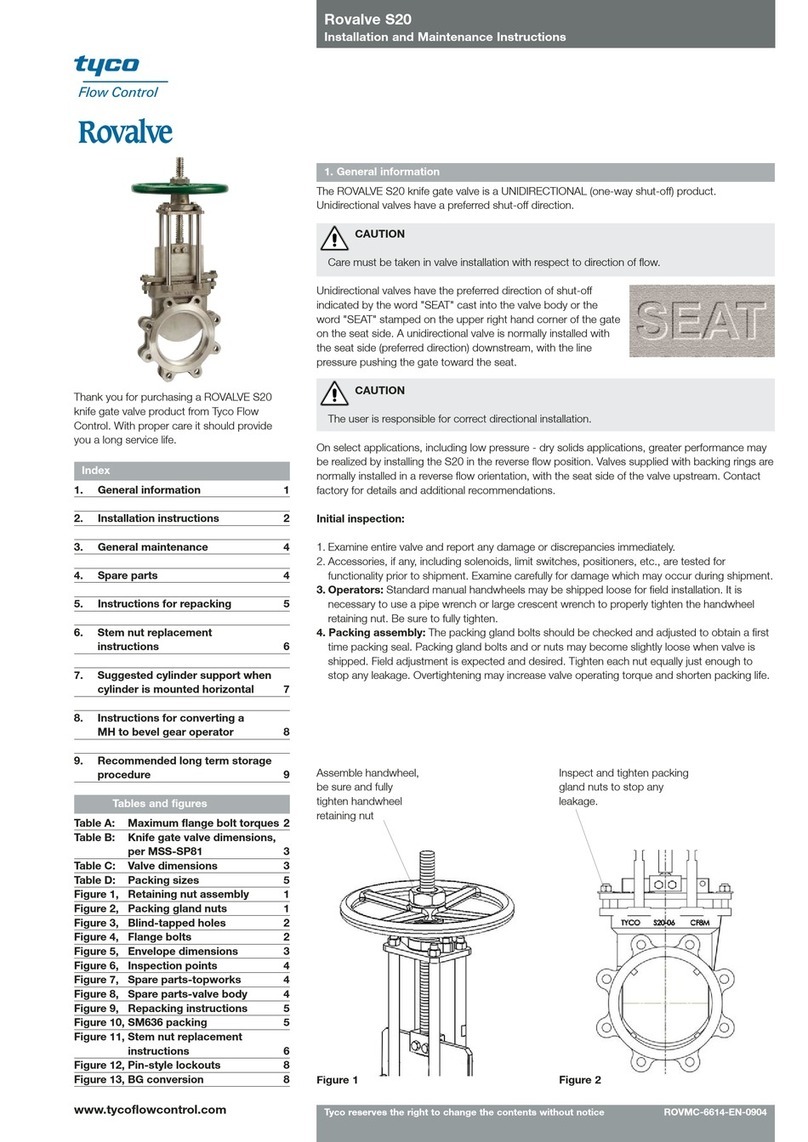

The two-piece Style 401 Escutcheon

Plates (Ref. Figure 2) are used where

it is necessary to position the sprinkler

away from the ceiling/wall surface so

that spray will not be adversely affected

by protruding obstructions such as

light fixtures and HVAC diffusers.

The adjustment provided by the Style

401 Escutcheon Plates reduces the

accuracy to which the length of the

fixed pipe drops or horizontal pipe

runs to the sprinklers must be cut, and

it provides additional flexibility in the

interconnecting pipe.

The separable, two-piece design of

the Style 401 allows installation of the

sprinklers and pressure testing of the

fire protection system/evaluation of

leak tightness prior to installation of a

suspended ceiling or application of the

finish coating to a fixed ceiling. They

also permit the removal of suspended

ceiling panels, for access to build-

ing service equipment, without having

to first shut down the fire protection

system and remove sprinklers.

NOTICE

The Style 65 and 401 Escutcheons

described herein must be installed

and maintained in compliance with

this document, as well as with the

applicable standards of the NATIONAL

FIRE PROTECTION ASSOCIATION, in

addition to the standards of any other

authorities having jurisdiction. Failure

to do so may impair the performance

of these devices.

The owner is responsible for main-

taining their fire protection system

and devices in proper operating con-

dition. Contact the installing contrac-

tor or product manufacturer with any

questions.

Technical

Data

Approvals

With reference to NFPA 13, listings/approv-

als are not required for metallic escutcheons

used for non-recessed applications.

Finishes

Chrome, Signal White, or Brass

Material

Carbon Steel

STYLE 65

ONE-PIECE ESCUTCHEON

STYLE 401

TWO-PIECE ESCUTCHEON