manual pull station. Zone 2 of the Re-

leasing Panel is operated by a Low Air

Pressure Alarm Switch in response to

a loss of system air pressure due to the

opening of an automatic sprinkler. The

Solenoid Valve remains closed until it

is electrically energized by the Releas-

ing Panel.

In order for the Double Interlock Pre-

action System to automatically actu-

ate, two independent events must oc-

cur. Zone 1 of the Releasing Panel

must operate upon automatic opera-

tion of the electric fire detection initiat-

ing circuit or manual operation of the

electric-manual pull initiating circuit,

and Zone 2 of the Releasing Panel

must operate via the Low Air Pressure

Alarm Switch upon loss of air pressure

from the sprinkler system piping, due

to operation of one or more sprinklers.

The Double Interlock Preaction Sys-

tem will automatically actuate only

when both Zone 1 and Zone 2 of the

Releasing Panel have operated, which

in turn will energize the Solenoid

Valve. Accidental loss of system air

pressure (for example: a lift truck acci-

dentally dislodges a sprinkler), or op-

eration of just the fire detection circuit

(for example: an accidental operation

of an electric pull station), will only

cause an alarm, and will not actuate

the system or flood the sprinkler sys-

tem piping.

The 2-l/2 inch (65 mm) Model F445

Electric/Electric Double Interlock Pre-

action System is listed by Underwriters

Laboratories Inc. and Underwriters’

Laboratories of Canada as Double In-

terlock Type Water Control Valves,

and they are approved by Factory Mu-

tual Research Corporation as Refrig-

erated Area Systems for use in refrig-

erated rooms or buildings.

WARNING

The 2-1 I2 inch Model F445 Double

Interlock Preaction System with the

associated trim described herein must

be installed and maintained in com-

pliance with this document, as well as

with the applicable standards of the

National Fire Protection Association,

in addition to the standards of any

other Authorities Having Jurisdic-

tion. Failure to do so may impair the

integrity of the associated devices.

The owner is responsible for main-

taining their fire protection system

and devices in proper operating con-

dition. The installing contractor or

manufacturer should be contacted

relative to any questions.

The 2-l/2 inch (65 mm) Model F445

Electric/Electric Double Interlock Pre-

action System, as well as its associ-

ated trim, is rated for use at a minimum

service pressure of 20 psi (1,4 bar)

and a maximum service pressure of

175 psi (12,l bar).

The following is a list of the Technical

Data Sheets for the valves and de-

vices which are required as part of the

Double Interlock Preaction System:

Deluge Valve . . . . . . TD114

Swing Check Valve . . . . . TD318

Solenoid Valve . . . . . . . TD119

Manual Control Station . . . TD121

Low Air Pressure Alarm

Switch . . . . . . . . . . . . TD213

Waterflow Pressure Alarm

Switch . . . . . . . . . . . . TD213

The following is a list of the Technical

Data Sheets for the recommended

system pressure maintenance devices

to be used as part of the Double Inter-

lock Preaction System:

System Pressure Maintenance De-

vice (select one)

-Air Pressure Reducing Type

. . . . . . . . . . . . . . TDlll

-Nitrogen Press. Reducing Type

. . . . . . . . . . . . . . TD113

System Design Considerations

The automatic sprinklers, as well as

the cross-zone deluge valve releasing

panel (automatic control unit), fire de-

tection devices, manual pull stations,

and signaling devices, which are util-

ized with the Electric/Electric Double

Interlock Preaction System must be

UL Listed, ULC Listed, C-UL Listed, or

FM Approved, as applicable.

NOTE

When the Solenoid Valve is energized

via the cross-zone controlpanel to op-

erate the F445 Valve. the Solenoid

Valve must remain energized in order

for the F445 Valve to remain open.

Because a double interlock preaction

system requires time for a drop in sys-

tem air pressure to occur (concurrently

with the response time for the separate

fire detection system), before it will

allow water to enter the system piping,

this system has characteristics similar

to a dry pipe sprinkler system. There-

fore, the system design considerations

for a dry pipe system are normally ap-

plied to a double interlock preaction

system - including a 30% increase in

-2-

design area and prohibition of gridded

system piping.

The deluge valve, swing check valve,

and all interconnecting piping must be

located in a readily visible and acces-

sible location and in an area which can

be maintained at a minimum tempera-

ture of 4O”F/4”C.

NOTE

Heat tracing is not permitted for the

deluge valve, swing check valve, or

any of the interconnecting piping.

Heat tracing can promote the forma-

tion of hardened mineral deposits

which can prevent system operation.

Heat tracing can also result in dam-

age to the F445 Deluge Valve Dia-

phragm Assembly.

In planning the installation, considera-

tion must also be given to the disposal

of the large quantities of water which

may be associated with draining the

system or performing a flow test.

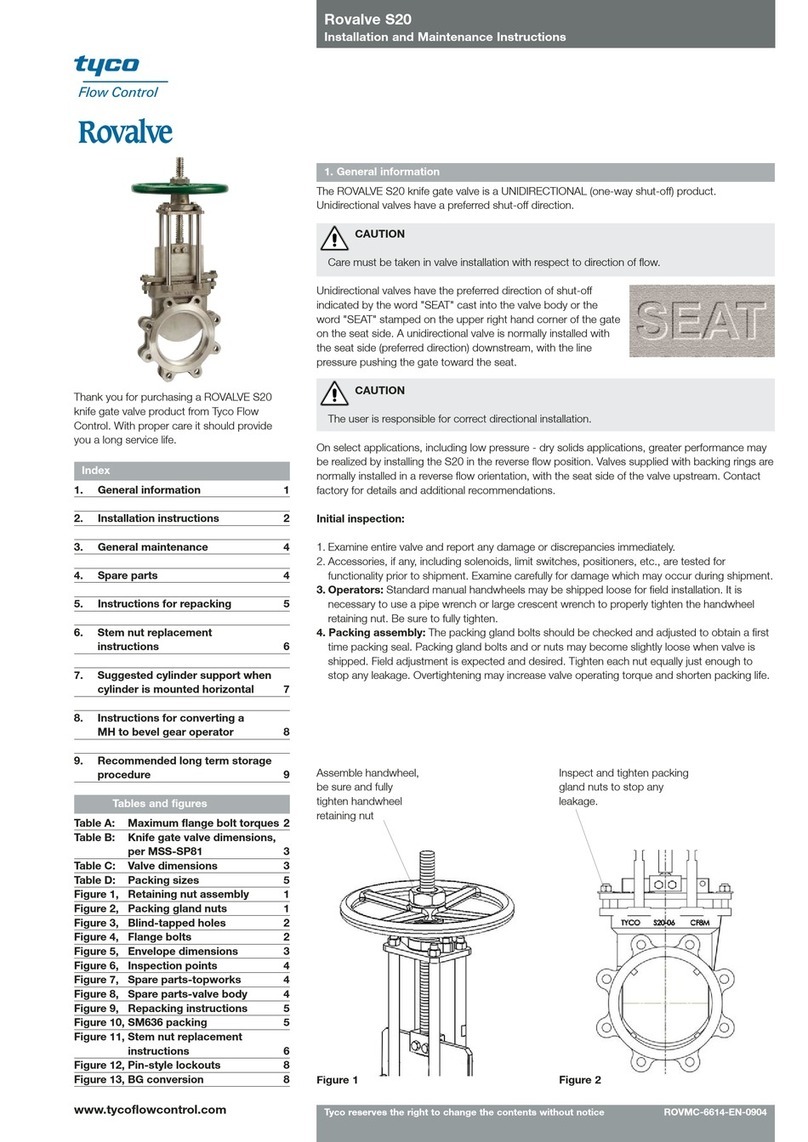

Installation configuration and clear-

ance dimensions are given in Figure B.

The grooved inlet and outlet connec-

tions of the F445, as well as the F52

Swing Check Valve are cut in accord-

ance with Gruvlok standard groove

specifications for steel pipe, and they

are suitable for use with grooved end

pipe couplings that are listed or ap-

proved for fire protection service.

In order to readily perform the System

Inspection Procedure described in the

Care and Maintenance section, it is

recommended that a System Shut-Off

Valve be installed above the Model

F52 Swing Check Valve, as shown in

Figure A. The System Shut-Off Valve

should be a listed or approved (as ap-

propriate) indicating valve with a su-

pervisory switch to monitor the nor-

mally open position.

System Air Pressure Requirements

The recommended system air pres-

sure for the Electric/Electric Double

Interlock Preaction System is nomi-

nally 15 psi (1,O bar), irrespective of

the water supply pressure. The use of

a higher system air pressure may in-

crease water delivery time, and the

use of a lower system air pressure may

prevent clearing the alarm of the Low

Air Pressure Alarm Switch (Item 19 -

Fig. C) on increasing pressure. The

Low Pressure Alarm Switch is field set

to alarm at nominally 12 psi (0,8 bar)

on decreasing pressure. It is recom-

mended that the system air pressure

be maintained by one of the following

methods.

l A maximum 200 psi (13,8 bar) plant

air supply in combination with the

Model F324 Air Maintenance Device

described in TDl 11.

l A maximum 3000 psi (206.9 bar)