TFP1920

Page 2 of 4

Installation

The installation instructions for the

TYCO CPVC Hanger Head Set Model

SHB1 for different types of wood joist

are defined in the following sections:

• Hanger Head Set — Solid Wood

Joist

• Hanger Head Set — Composite

Wood Joist

NOTICE

The TYCO CPVC Hanger Head Set

Model SHB1 does not meet the UL

requirement for providing vertical

restraint that may result from a sprin-

kler activation. A number of hanger

techniques (not inclusive of the use

of a Hanger Head Set) as described

in Installation Handbook IH-1900 can

be used to provide vertical restraint.

Failure to provide vertical restraint may

result in vertical lift upon sprinkler acti-

vation and the inability of a sprinkler to

spray effectively in the event of a fire.

Installing sprinklers into the sprin-

kler adapter fittings prior to solvent

cementing the adapters to the drop is

unacceptable. Failure to allow sprin-

kler fitting joint to cure before install-

ing sprinklers may result in cement in

sprinkler waterway and inability of the

sprinkler to properly operate in the

event of a fire.

The hanger head set should not be

installed other than side-mount or

attached to anything other than the

side of a solid wood framing member

or structural composite wood joist, with

the fasteners provided, without prior

review and approval of the authority

having jurisdiction. Any other method

of installation may not comply with

NFPA or local requirements. If the

installer attaches the Hanger Head Set

to another type of structural member or

orients the Hanger Head Set in a posi-

tion other than side-mount, fasteners

and fastener methods shall comply

with applicable NFPA and local code

requirements.

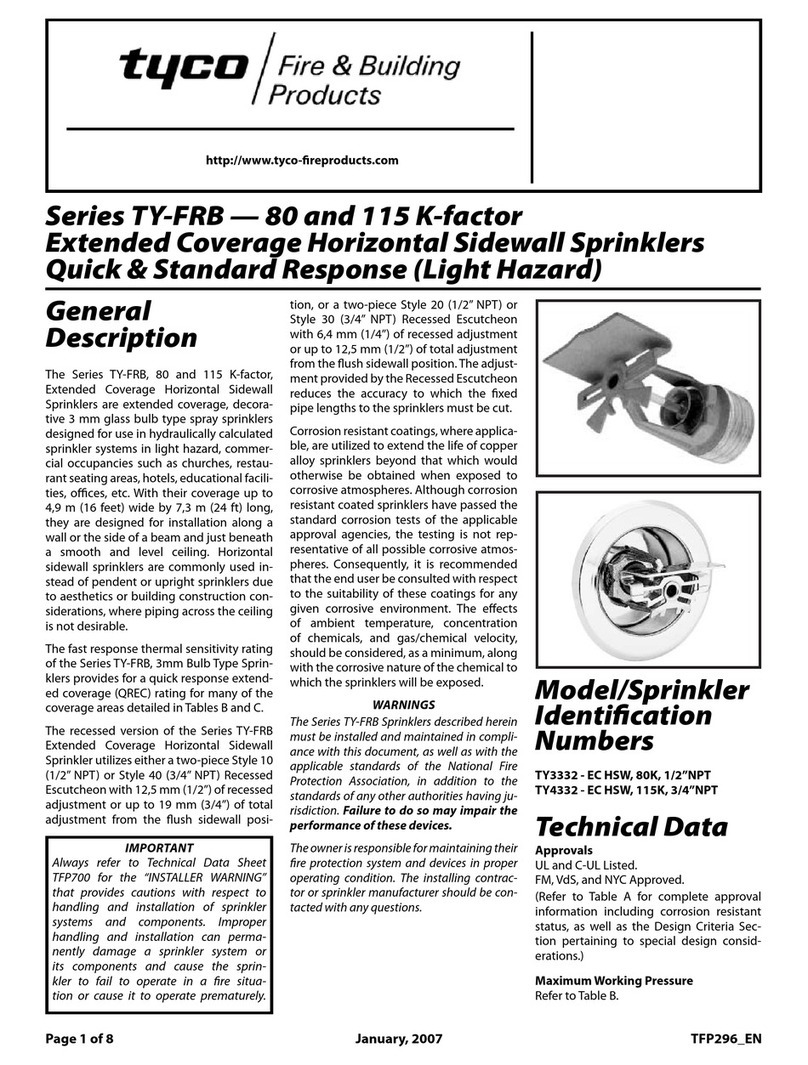

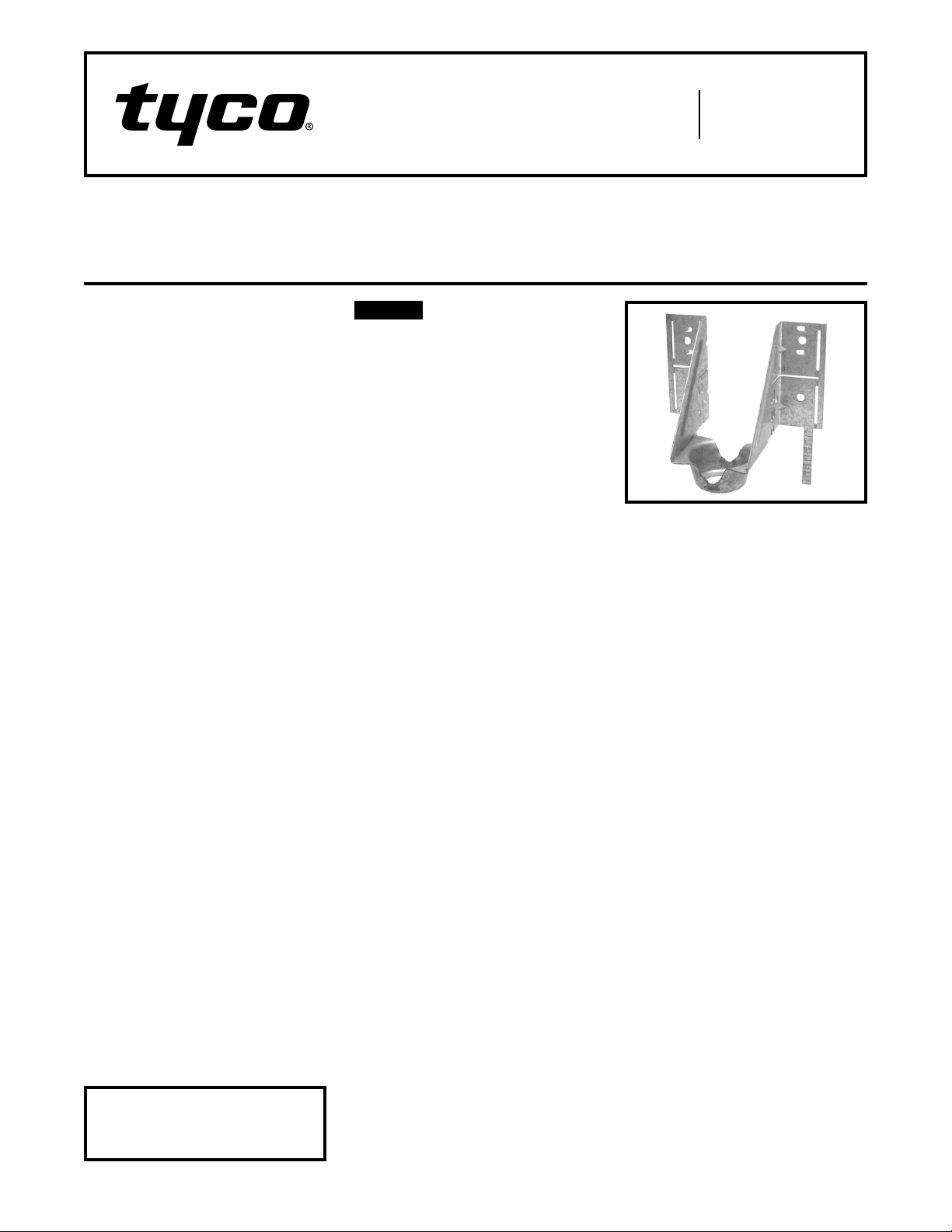

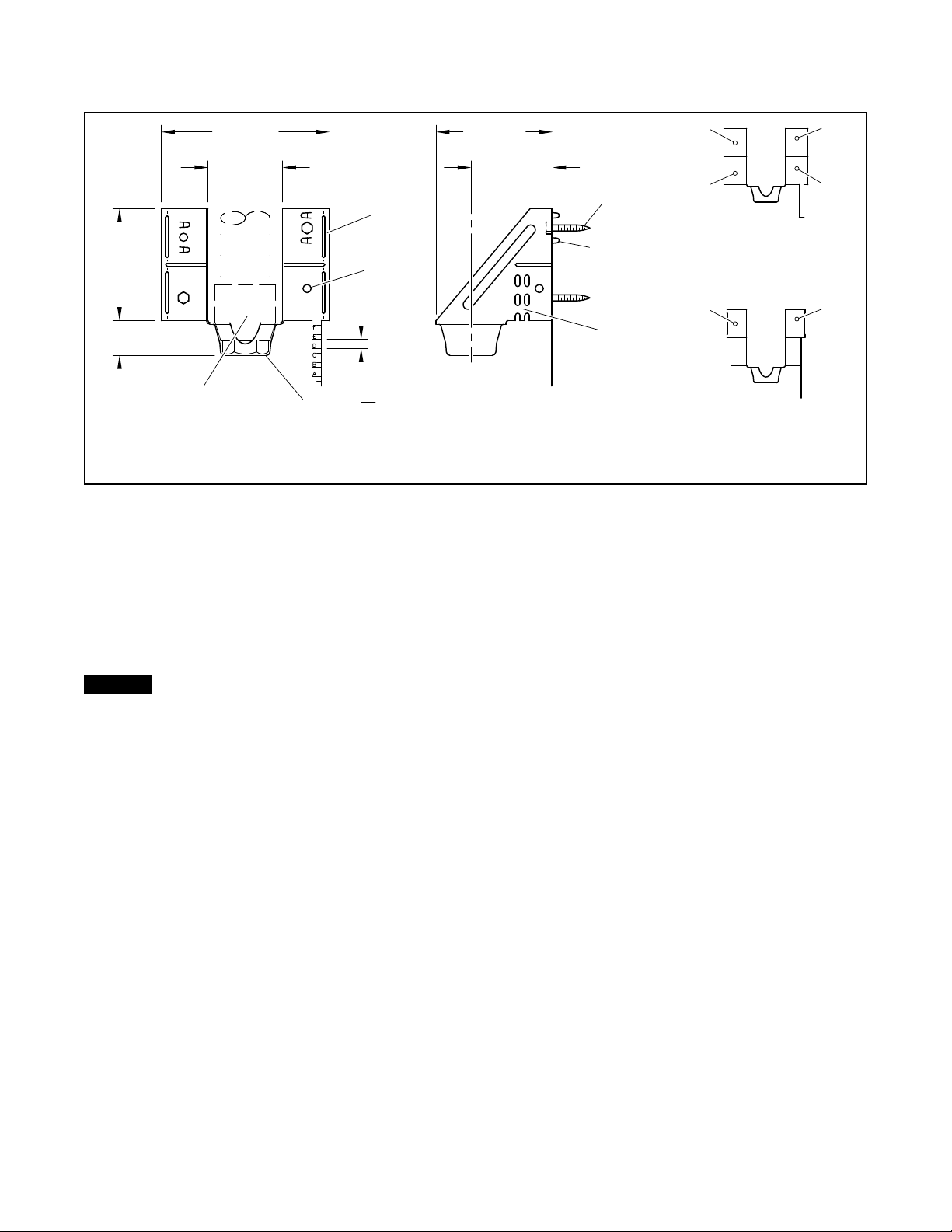

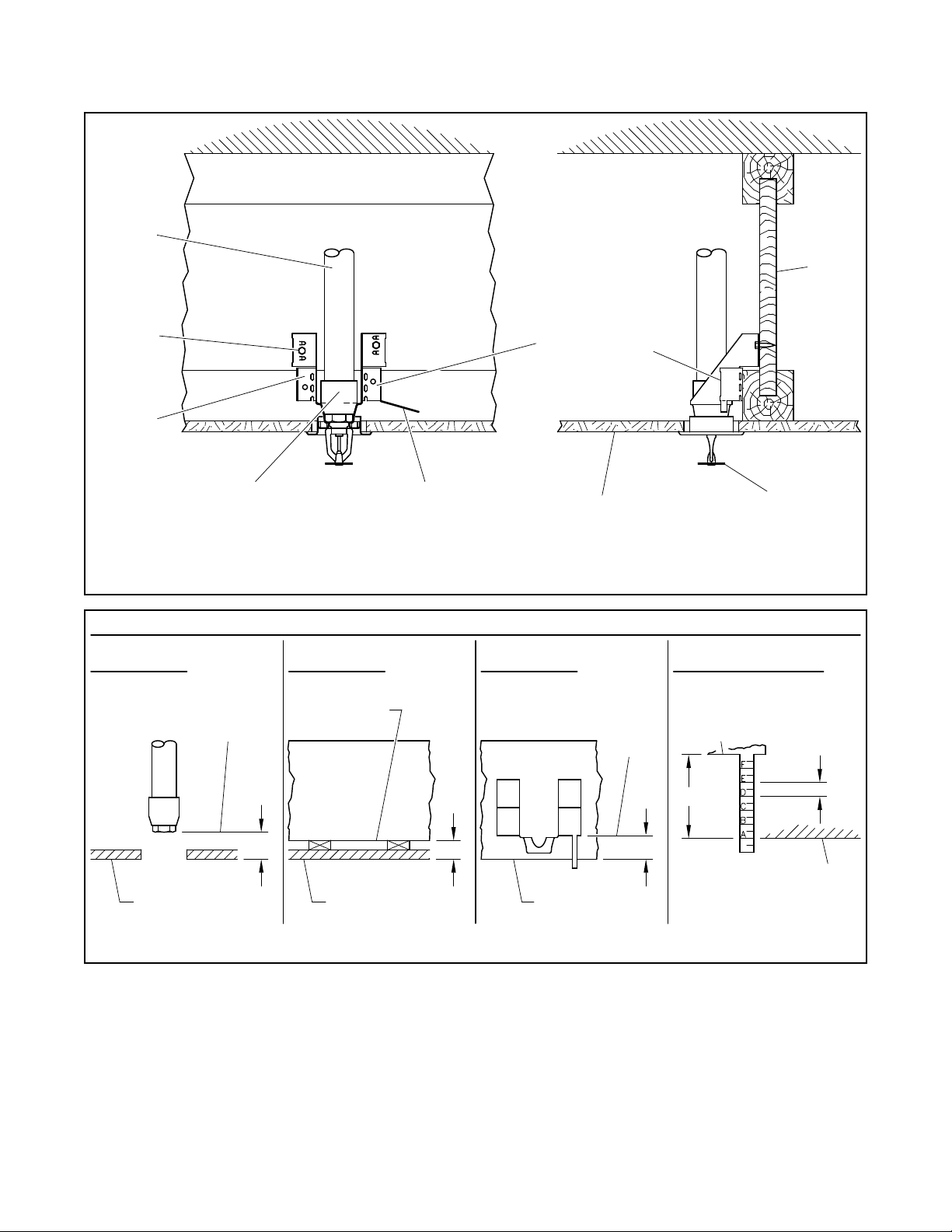

Hanger Head Set - Solid Wood Joist

Step 1. Position the hanger head set

against the vertical solid wood joist

surface (side-mount).

Step 2. Set the depth using the gradu-

ated markings on an offset gauge as

shown in Figure 3.

Step 3. Secure the hanger head set to

the wooden surface using the two #10

x 1 in. hex head lag screws.

Note: The screws are provided. See

Figure 1.

Step 4. Cut and install the CPVC sprin-

kler drop making sure the face of the

sprinkler head adapter is flush with the

inside of the head set cup.

Step 5. Insert the sprinkler inlet pipe

threads through the head set cup and

thread into the CPVC adapters using

the instructions provided in the tech-

nical data sheet for the sprinkler, and

Technical Data Sheet TFP700 for the

“INSTALLER WARNING”.

Hanger Head Set - Composite

Wood Joist

Step 1. Use a pliers to break off the

breakaway tabs as shown in Figure 4.

Step 2. Use the pliers to bend the lower

hanger mounting flange to a 90 degree

angle as shown in Figure 4.

Step 3. Position the hanger head set

against the composite wood joist web

member (side-mount).

Step 4. Set the depth using the grad-

uated markings of an offset gauge as

shown in Figure 3.

Step 5. Secure the hanger head set to

the wooden surface using the two #10

x 1 in. hex head lag screws.

Note: The screws are provided. See

Figure 1.

Step 6. Cut and install the CPVC sprin-

kler drop making sure the face of the

sprinkler head adapter is flush with the

inside of the head set cup.

Step 7. Insert the sprinkler inlet pipe

threads through the head set cup and

thread into CPVC adapters using the

instructions provided in the techni-

cal data sheet for the sprinkler, and

Technical Data Sheet TFP700 for the

“INSTALLER WARNING”.

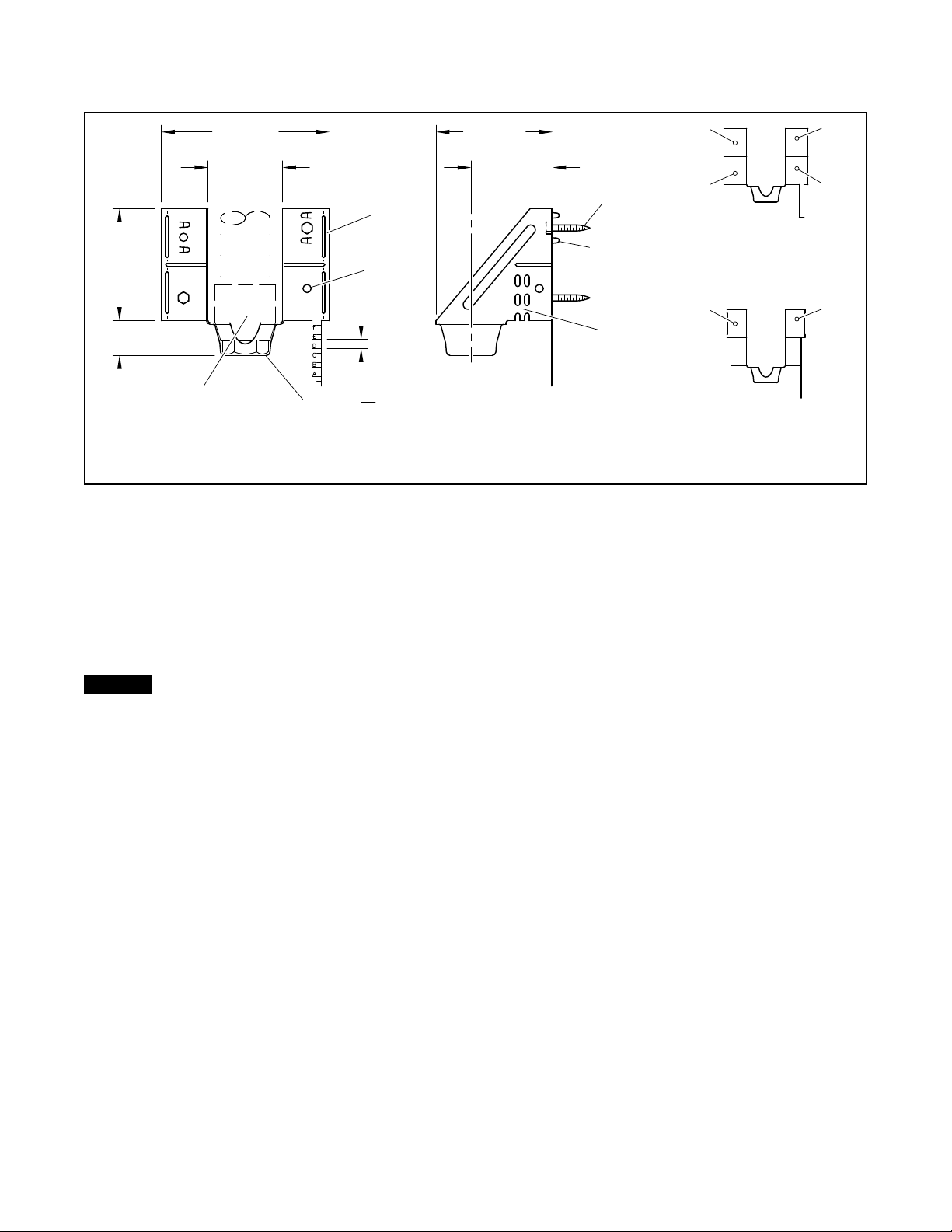

3"

1"

(76,2 mm)

2"

(50,8 mm)

2-3/16"

(55,6 mm)

BUILT-IN

OFFSET GAUGE

IN 1/4" (6,3 mm)

SCREW

HOLES

BREAK-

AWAY

TABS

(114,3 mm)

LOCATING

TABS

#10 x 1"

HEX HEAD

LAG SCREW

(2 PROVIDED)

SPRINKLER HEAD

ADAPTER FLUSH WITH

HEAD SET

3

4

1 2

ON SOLID WOOD JOISTS,

USE SCREW POSITIONS

1 + 2, 1 + 4, or 2 + 3

ON COMPOSITE WOOD JOISTS,

USE SCREW POSITIONS 1 + 2

LOWER

FLANGE

BEND

AREA

FIGURE 1

MODEL SHB1 HANGER HEAD SET

(NOMINAL DIMENSIONS)