TFP1262

Page 3 of 4

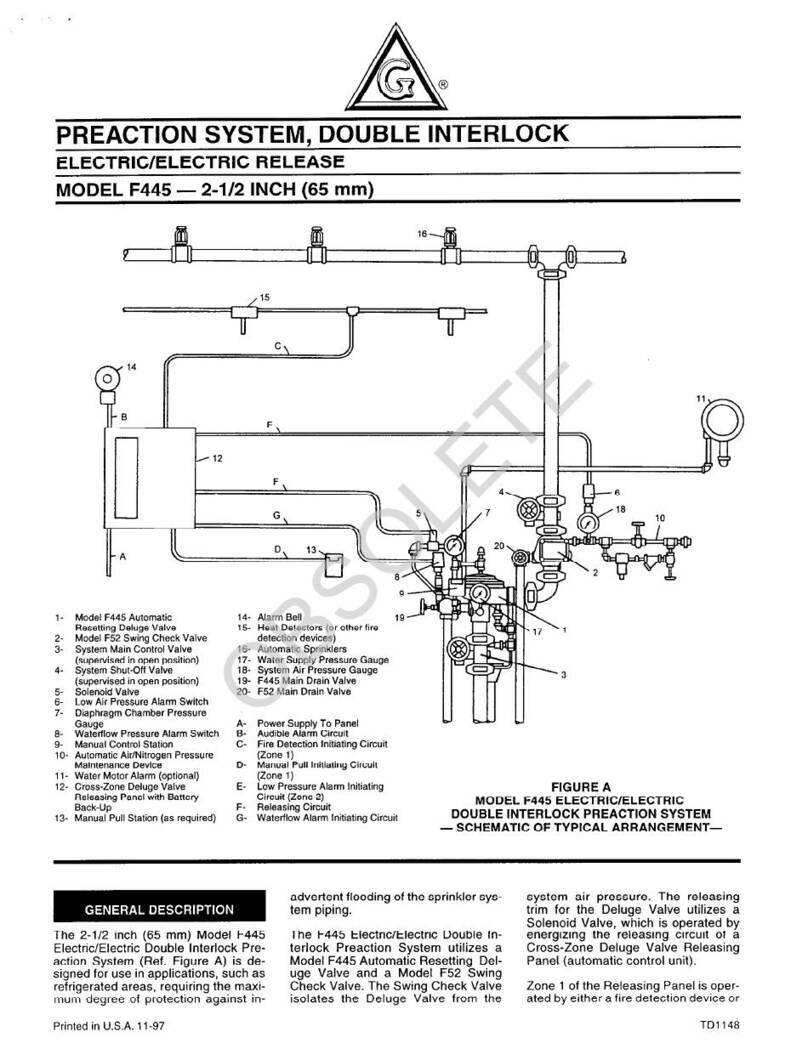

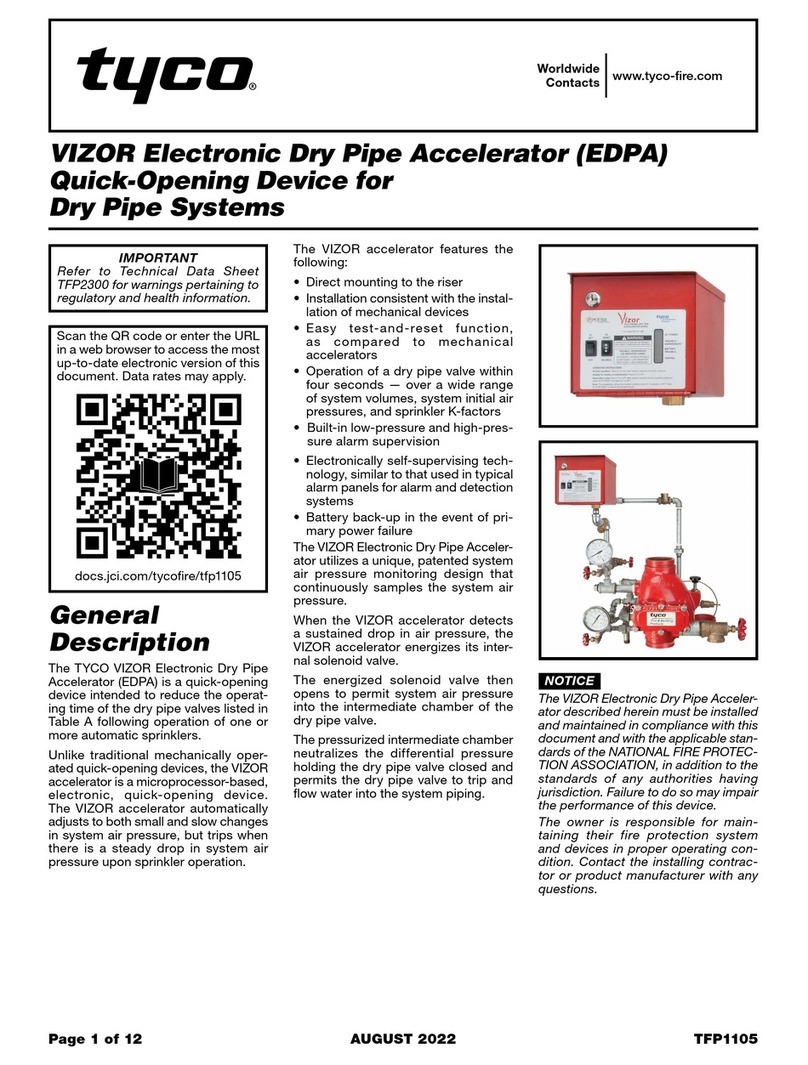

FIGURE 3

MODEL TAV-D AIR VENT DRY

IN-LINE FILTER

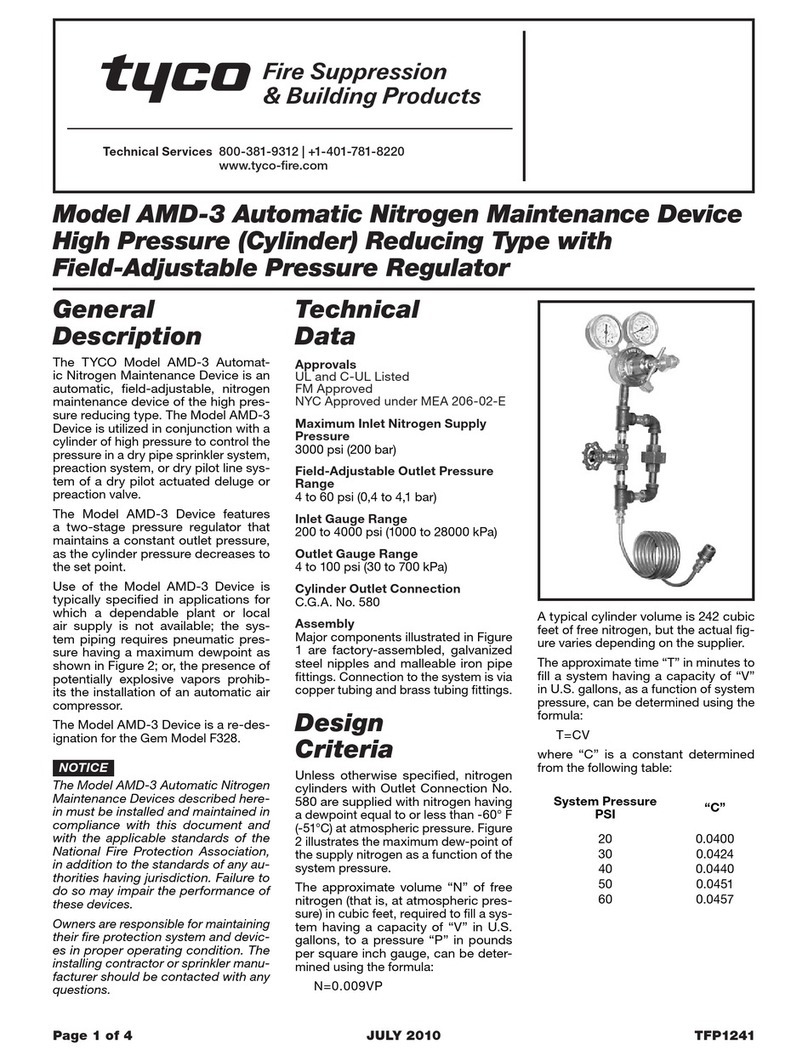

FIGURE 2

MODEL TAV-D AIR VENT DRY

INSTALLATION SCHEMATIC

Installation

The TYCO Model TAV-D Air Vent, Dry

must be installed in accordance with

this section.

Step 1. The Model TAV-D Air Vent is

equipped with a ball valve to be con-

nected to the re sprinkler riser. The

contractor must install a 1 in. outlet

(welded or mechanical) to connect the

vent assembly to the sprinkler system

on the system side of the main control

valve as shown in Figure 2. The ball

valve must remain in the closed posi-

tion until the TYCO Nitrogen Generator

is commissioned.

Step 2. Install the vent assem-

bly in a level position. The recom-

mended mounting height is between

5 ft to 10 ft (2 m to 3 m) above the n-

ished oor.

Note: Piping to the vent assembly

cannot be installed in a configura-

tion that would trap water and prevent

drainage to the sprinkler system; a

water trap impedes the ability of the

vent assembly to vent oxygen from the

fire sprinkler system.

Step 3. Inspection of the vent assem-

bly should be performed after installa-

tion and hydrostatic testing of the re

sprinkler system. Inspection should

be performed periodically thereaf-

ter in accordance with the applicable

NATIONAL FIRE PROTECTION ASSO-

CIATION (NFPA) codes and standards

and/or the authority having jurisdiction.

Note: Inspection must include the con-

dition of the in-line filter and checking

for blockage in the “Y” strainer and the

restricted venting orifice.

Care and

Maintenance

The TYCO Model TAV-D Air Vent, Dry

must be maintained and serviced in

accordance with this section.

Before closing a re protection system

main control valve for maintenance

work on the re protection system that

it controls, permission to shut down

the affected re protection systems

must rst be obtained from the proper

authorities. All personnel who may

be affected by this decision must be

notied.

Inspection, testing, and maintenance

must be performed in accordance

with the requirements of the NFPA, and

any impairment must be immediately

corrected.

The owner is responsible for the inspec-

tion, testing, and maintenance of their

re protection system and devices in

compliance with this document, as well

as with the applicable standards of any

authorities having jurisdiction. Contact

the installing contractor or product

manufacturer with any questions.

Inspection Instructions

Step 1. The Model TAV-D Air Vent must

be inspected annually at minimum.

While the isolation ball valve is in the

open position check for air/water leaks

and ensure the pressure gauge is dis-

playing normal system pressure.

Step 2. While the isolation ball valve is

in the closed position inspect the con-

dition of the inline lter and for block-

age in the “Y” strainer and restricted

venting orice. Twist the black Filter

Housing clockwise until it can be

removed to expose the lter element.

Step 3. Replace the In-Line Filter

element if a visual inspection reveals a

signicant collection of debris.

In-Line Filter Replacement

Instructions

Step 1. Close the isolation ball valve.

Step 2. Depressurize the housing by

pressing the pressure relief valve on

the bottom of the in-line lter housing

shown in Figure 3.

Step 3. Remove the lower section of

the In-Line Filter housing by turning the

lter housing counterclockwise.

Note: A rubber o-ring seal is located

between the upper and lower sections

of the filter housing.

Step 4. Remove the old lter by turning

the lter counterclockwise.

Step 5. Replace with a new lter, TYCO

Model TFLT Replacement Filter Kit.

The lter is secured to the housing by

turning the lter clockwise.

Note: Ensure the filter housing is

secured only finger/hand tight.

Step 6. Install the rubber o-ring/seal on

the lower section of the lter housing.

Step 7. Re-install the lter housing by

turning the lter housing clockwise.

Note: Ensure the filter housing is

secured only finger/hand tight.

Step 8. Open the isolation ball valve.

1 IN.

OUTLET

REQUIRED

NITROGEN

SUPPLY

DRY/PREACTION

SPRINKLER

VALVE

MODEL TAV-D

MANUAL VENT

RISER

FILTER

HOUSING

FILTER

PRESSURE

RELIEF

VALVE