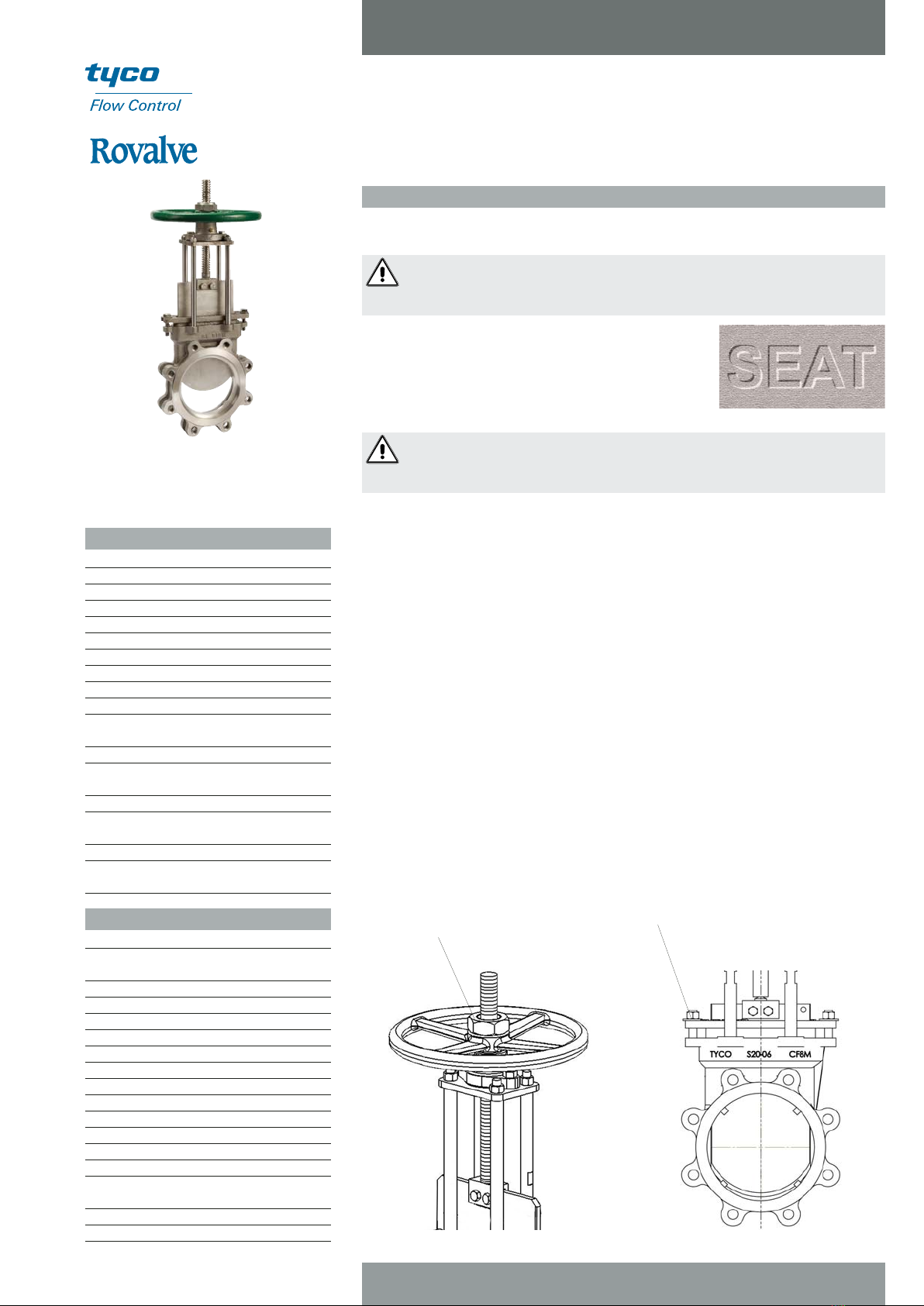

Rovalve S20

Installation and Maintenance Instructions

Tyco reserves the right to change the contents without notice page 9

9. Recommended long term storage procedure

The following are the factory's recommendations for storage procedures to retain maximum

product integrity during long term storage of 1 to 5 years.

Handwheel or bevel gear operated valves

A. Storage facility: The preferred storage

location is a clean, dry protected

warehouse. If valves are to be stored

outside, precautions should be taken to

keep valves clean and dry. Standard

packaging materials provided in valve

shipment can not be considered sufficient

for outdoor storage.

B. Equipment orientation: Valves may be

stored in the vertical or horizontal position.

C. Preparation for storage: Valves may be

stored as shipped, provided the above

Storage Facility and Equipment Orientation

instructions above are followed. If valve

packaging is altered or removed for

receiving inspection, repackage valve as

originally received.

D. Storage inspection: Visual inspection shall

be performed on a semiannual basis and

results recorded. Inspection as a minimum

shall include reviewing the following:

Packaging

Flange Covers

Dryness

Cleanliness

E. Maintenance: Maintenance shall consist of

correcting deficiencies noted during

inspection. All maintenance shall be

recorded. Contact factory prior to

performing any maintenance if valve is still

covered under warranty.

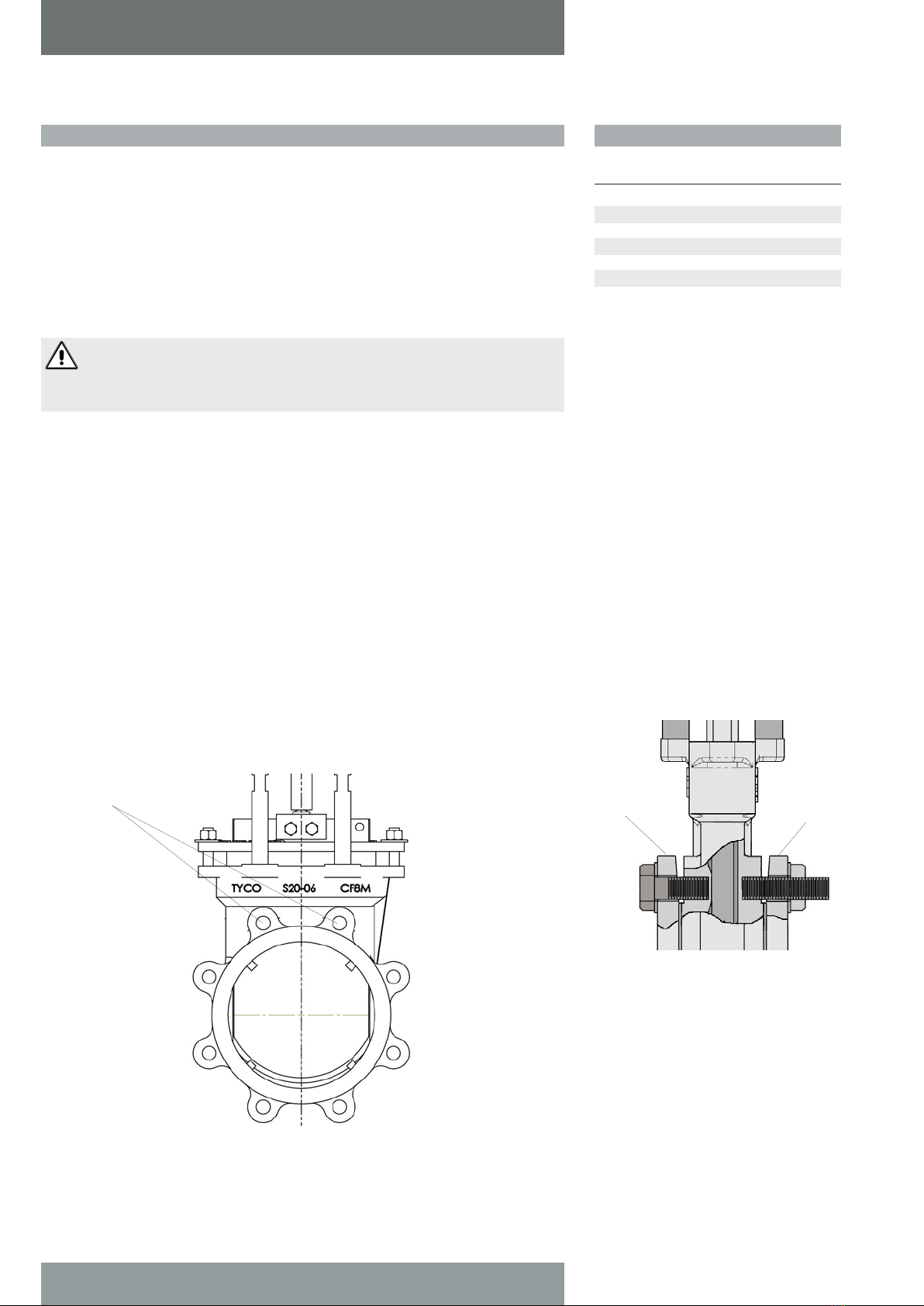

Cylinder operated valves

A. Storage facility: The preferred storage

location is a clean, dry protected

warehouse. If valves are to be stored

outside, precautions should be taken to

keep valves clean and dry. Standard

packaging materials provided in valve

shipment can not be considered sufficient

for outdoor storage.

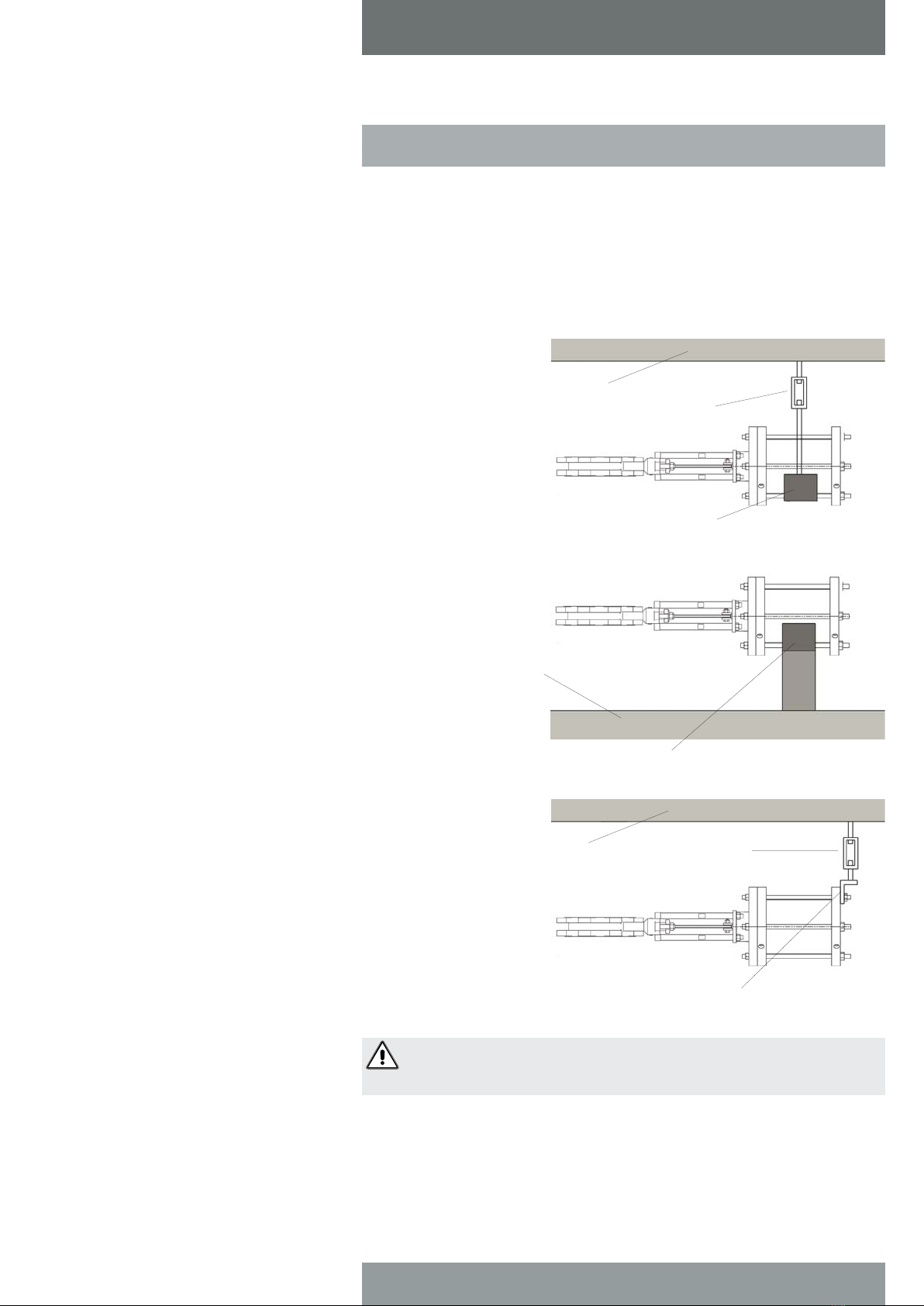

B. Equipment orientation: The preferred

orientation for optimum protection is with

the valve fully opened and the cylinder in

the vertical position. This position gives the

best support to the cylinder rod and helps

reduces the chance of a "flat spot"

developing on the cylinder seals. An

acceptable alternate position for valves

with cylinder diameters of less than 6" is

with the cylinder in the horizontal position.

C. Preparation for storage: Valves may be

stored as shipped, provided the above

Storage Facility and Equipment Orientation

instructions above are followed. If valve

packaging is altered or removed for

receiving inspection, repackage valve as

originally received.

D. Cylinder storage

These cylinder storage instructions are not

intended to replace the instructions of the

specific cylinder manufacturer and are to

be used as a guide only. If specific

instructions are required, please contact

our office.

For storage of up to 3 years; Squirt a high

quality grade of hydraulic oil or synthetic

lubricant into the cylinder ports and operate

cylinder 6-12 times on a yearly basis.

For storage 3-5 years; lubricate as above.

Additionally, extend cylinder rod until the

valve is fully closed. Coat cylinder rod with

high quality heavy grease or synthetic

lubricant. Retract cylinder rod until valve is

fully open, drawing lubricant into rod end of

cylinder. Securely plug cylinder ports with

pipe plugs, if cylinder is not pre-piped to

control accessories. If cylinder is prepiped

to accessories, plug all input and output

ports of accessories.

E. Storage inspection: Visual inspection shall

be performed on a semiannual basis and

results recorded. Inspection as a minimum

shall include reviewing the following:

Packaging

Flange Covers

Dryness

Cleanliness

F. Maintenance: Maintenance shall consist of

correcting deficiencies noted during

inspection. All maintenance shall be

recorded. Contact factory prior to

performing any maintenance if valve is still

covered under warranty.