damageto theDeflectorand Arms dur-

ing ceiling installation and/or during

application of the finish coating of the

ceiling. It may also be used to locate

the center of the clearance hole by

gently pushing the ceiling material

against the center point of the Protec-

tive Cap.

NOTICE

As long as the Protective Cap remains

in place, the system is considered to

be “Out of Service”.

Step 6. After theceilinghas beencom-

pleted with the 2-1/2 inch (63,5 mm)

diameter clearance hole and in prepa-

ration for installing the Cover Plate As-

sembly, remove and discard the Pro-

tective Cap, and verify that the

Deflector moves up and down freely. If

the Sprinkler has been damaged and

the Deflector does not move up and

down freely, replace the entire Sprin-

kler assembly. Do not attempt to mod-

ify or repair a damaged sprinkler.

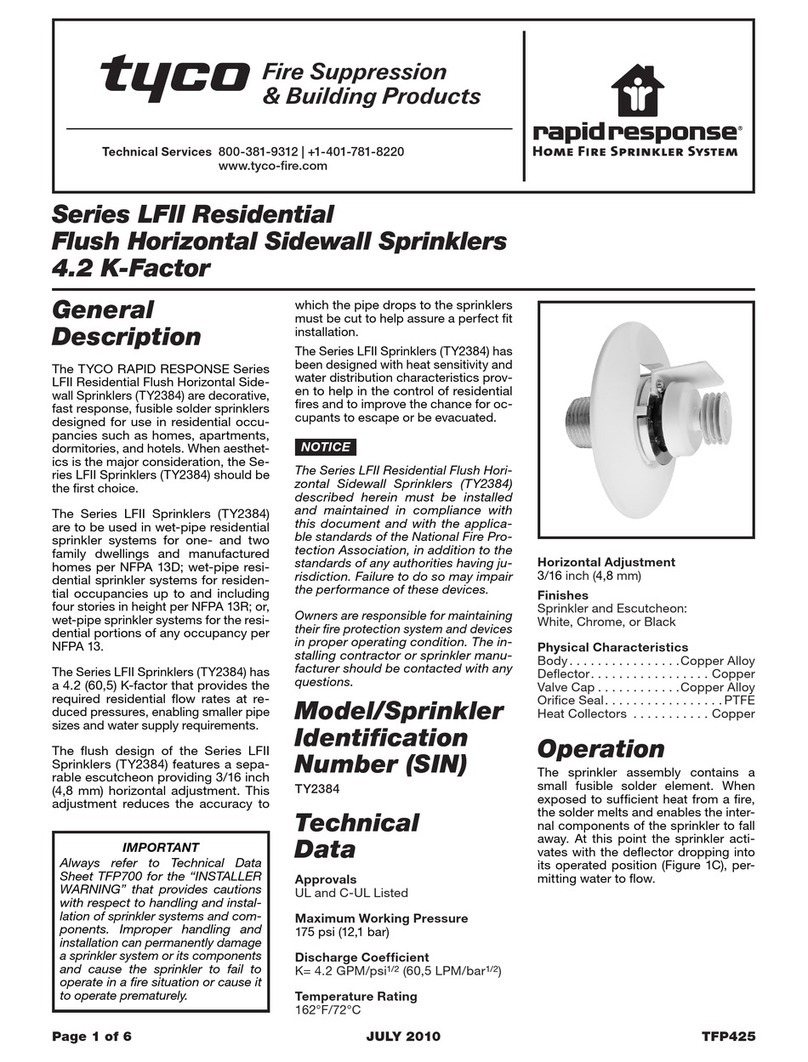

Step 7. When installing an Air and

Dust Seal, refer to Figure 4, otherwise

proceed to Step 8. To attach the Air

and Dust Seal, verify the angle of the

outside edge of the seal is oriented

according to Figure 4. Start the edge

of the Retainer in the grooved slot of

the Air and Dust Seal and continue

around the retainer until the entire Air

and Dust Seal is engaged.

Step 8. Screw on the Cover Plate/Re-

tainer Assembly until the Retainer -

Figure 2 (or Air and Dust Seal - Figure

4) makes contact with the ceiling. Do

not continue to screw on the Cover

Plate/Retainer Assembly such that it

lifts a ceiling panel out of its normal

position. If the Cover Plate/Retainer

Assembly cannot be engaged with the

Support Cup or the Cover Plate/Re-

tainer Assembly cannot be engaged

sufficiently to contact the ceiling, the

Sprinkler Fitting must be repositioned.

Care and

Maintenance

The Tyco®ILLUSION™ must be

maintained and serviced in accord-

ance with the following instructions:

NOTICE

Absence of the Cover Plate Assembly

may delay sprinkler operation in a fire

situation.

When properly installed, there is a

nominal 3/32 inch (2,4 mm) air gap

between the lip of the Cover Plate and

the ceiling, as shown in Figure 2. This

air gap is necessary for proper opera-

tion of the sprinkler by allowing heat

flow from a fire to pass below and

above the Cover Plate to help assure

appropriate release of the Cover Plate

in a fire situation. If the ceiling is to be

repainted after the installation of the

Sprinkler, care must be exercised to

ensure that the new paint does NOT

seal off any of the air gap.

Factory painted Cover Plates MUST

NOT be repainted. They should be re-

placed, if necessary, by factory

painted units. Non-factory applied

paint may adversely delay or prevent

sprinkler operation in the event of a

fire.

Do not pull the Cover Plate relative to

the Enclosure. Separation may result.

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system that

itcontrols,permission toshutdownthe

affectedfireprotectionsystemmustbe

obtained from the proper authorities

and all personnelwho may be affected

by this action must be notified.

Sprinklers that are found to be leaking

or exhibiting visible signs of corrosion

must be replaced.

Automatic sprinklers must never be

painted, plated, coated or otherwise

altered after leaving the factory. Modi-

fied or over heated sprinklers must be

replaced.

Care must be exercised to avoid dam-

age to the sprinklers - before, during,

and after installation. Sprinklers dam-

aged by dropping, striking, wrench

twist/slippage, or the like, must be re-

placed. Also, replace any sprinkler

that has a cracked bulb or that has lost

liquid from its bulb. (Ref. Installation

Section).

If a sprinkler must be removed, do not

reinstall it or a replacement without

reinstalling the Cover Plate Assembly.

If a Cover Plate Assembly becomes

dislodged during service, replace itim-

mediately.

The owner is responsible for the in-

spection, testing, and maintenance of

their fire protection system and de-

vices in compliance with this docu-

ment, as well as with the applicable

standards of the National Fire Protec-

tion Association (e.g., NFPA 25), in

addition to the standards of any other

authorities having jurisdiction. The in-

stalling contractor or sprinkler manu-

facturer should be contacted relative

to any questions.

Automaticsprinklersystemsshouldbe

inspected, tested, and maintained by

a qualified Inspection Service in ac-

cordance with local requirements

and/or national codes.

Page4of6 TFP184

FIGURE 4

OPTIONAL AIR AND DUST SEAL FOR THE ILLUSION (TY5521)

COVER

ASSEMBLY

RETAINER

PLATE

SPRINKLERSUPPORT

CUP CEILING

FACE OF

SHOWN

SEAL

ORIENT

BEVELAS

AIR

SEAL

AND DUST

LIP OF

RETAINER COVER

PLATE