TFP680

Page 2 of 16

Pendent and Upright Sprinklers

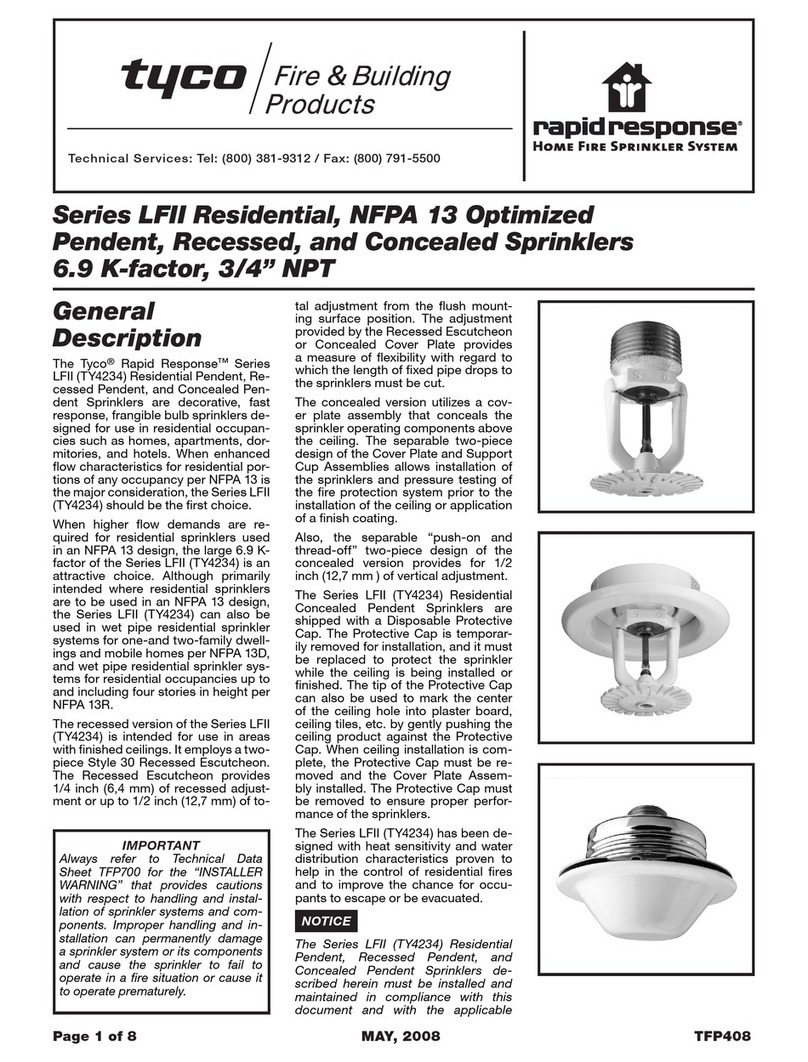

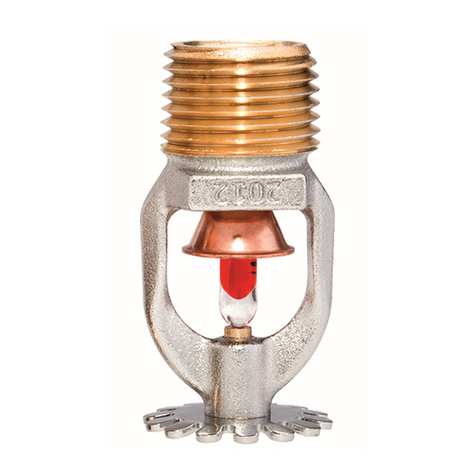

The pendent and upright sprinklers are

standard coverage spray sprinklers avail-

able in either 5.6 or 8.0 K-factor. The

recessed version is intended for use in

areas with a nished ceiling. The two-

piece Style 10 (1/2 inch NPT) or Style 40

(3/4 inch NPT) Recessed Escutcheons

provide 1/2 inch (12,7 mm) of recessed

adjustment or 3/4 inch (19,1 mm) of to-

tal adjustment from the ush pendent

position. The adjustment provided by

the Recessed Escutcheon reduces the

accuracy to which the xed pipe drops

to the sprinklers must be cut.

Conventional Sprinklers

The 5.6 or 8.0 K-factor conventional

sprinklers are intended to be installed

either pendent or upright and, in either

position, they produce a spherical water

discharge pattern with approximately

50% of the discharge upwards and ap-

proximately 50% of the discharge di-

rected downwards.

Conventional sprinklers are generally

used with Ordinary and Extra High haz-

ard Class Systems as dened by the

automatic sprinkler system installation

rules of the country and authority hav-

ing jurisdiction. The NFPA permits the

use of conventional sprinklers (old style

sprinklers) where special construction

features require a unique water distri-

bution; for fur vaults; or, replacement of

similar sprinklers that had been installed

prior to 1955.

Sidewall Sprinklers

The horizontal and vertical sidewall sprin-

klers are designed for installation along

a wall or side of a beam and just beneath

a smooth ceiling. Sidewall sprinklers are

commonly used instead of pendent and

upright sprinklers due to aesthetics or

building construction considerations,

where piping across the ceiling is not

desirable.

A recessed version of the horizontal

sidewall sprinkler can be achieved by

using the Style 10 Recessed Escutcheon.

NOTICE

The Series TY-B and TY-FRB Sprinklers

described herein must be installed and

maintained in compliance with this docu-

ment and with the applicable standards

of the National Fire Protection Associa-

tion, in addition to the standards of any

authorities having jurisdiction. Failure

to do so may impair the performance

of these devices.

The owner is responsible for maintaining

their fire protection system and devices in

proper operating condition. Contact the

installing contractor or product manu-

facturer with any questions.

Sprinkler

Identification

Number (SIN)

TY-B Stainless Steel

Standard Response

TY8191 – Upright 5.6K, 1/2"NPT

TY8291 – Pendent 5.6K, 1/2"NPT

TY9191 – Upright 8.0K, 3/4"NPT

TY9291 – Pendent 8.0K, 3/4"NPT

TY8691 – C/UP 5.6K, 1/2"NPT

TY9691 – C/UP 8.0K, 3/4"NPT

TY8391 – HSW 5.6K, 1/2"NPT

TY8491 – VSW 5.6K, 1/2"NPT

TY-FRB Stainless Steel

Quick Response

TY8181 – Upright 5.6K, 1/2"NPT

TY8281 – Pendent 5.6K, 1/2"NPT

TY9181 – Upright 8.0K, 3/4"NPT

TY9281 – Pendent 8.0K, 3/4"NPT

TY8681 – C/UP 5.6K, 1/2"NPT

TY9681 – C/UP 8.0K, 3/4"NPT

TY8381 – HSW 5.6K, 1/2"NPT

TY8481 – VSW 5.6K, 1/2"NPT

TY-B SMO

Standard Response

TY8192 – Upright 5.6K, 1/2"NPT

TY8292 – Pendent 5.6K, 1/2"NPT

TY8692 – C/UP 5.6K, 1/2"NPT

TY8392 – HSW 5.6K, 1/2"NPT

TY8492 – VSW 5.6K, 1/2"NPT

TY-FRB SMO

Quick Response

TY8182 – Upright 5.6K, 1/2"NPT

TY8282 – Pendent 5.6K, 1/2"NPT

TY8682 – C/UP 5.6K, 1/2"NPT

TY8382 – HSW 5.6K, 1/2"NPT

TY8482 – VSW 5.6K, 1/2"NPT

TY-B Titanium

Standard Response

TY8193 – Upright 5.6K, 1/2"NPT

TY8293 – Pendent 5.6K, 1/2"NPT

TY8693 – C/UP 5.6K, 1/2"NPT

TY8393 – HSW 5.6K, 1/2"NPT

TY8493 – VSW 5.6K, 1/2"NPT

TY-FRB Titanium

Quick Response

TY8183 – Upright 5.6K, 1/2"NPT

TY8283 – Pendent 5.6K, 1/2"NPT

TY8683 – C/UP 5.6K, 1/2"NPT

TY8383 – HSW 5.6K, 1/2"NPT

TY8483 – VSW 5.6K, 1/2"NPT

Technical

Data

Approvals

Refer to Tables A, B, C, and D

Maximum Working Pressure

175 psi (12,1 bar)

Temperature Rating

Refer to Tables A, B, C, and D

Physical Characteristics

• Stainless Steel

The frame is free machining ANC4A

Stainless Steel, per BS 3146 PT 2. The

Deector is Type 316L (UNS 31603)

Stainless Steel per ASTM A479/479M

or BS EN 10088 WN1.4401/4404. The

Compression Screw and Button are

Type 316L (UNS 31603) Stainless Steel

per ASTM A479/479M or BS EN 10088

WN1.4404. The Sealing Assembly con-

sists of a Disc Spring that is sealed on

both its inside and outside faces with a

TEFLON Gasket. The Disc Spring is 1/2

Hard Beryllium Nickel (UNS NO3360)

Gold Plated per MIL G-45204, Type

3, Class 2. The bulb is glass.

• SMO

The Frame, Deector, Compression

Screw, and Button are 254 SMO

Duplex Stainless Steel per UNS

S31254. The Sealing Assembly con-

sists of a Disc Spring that is sealed

on both its inside and outside faces

with a TEFLON Gasket. The Disc

Spring is 1/2 Hard Beryllium Nickel

(UNS NO3360) Gold Plated per MIL

G-45204, Type 3, Class 2. The bulb

is glass.

• Titanium

The Frame is Titanium, Grade 2 per

UNS R50400. The Deector is Tita-

nium, Grade 2 per ASTM B265-03.

The Compression Screw is Titani-

um, Grade 5 per ASTM B348-03.

The Button is Titanium, Grade 2 per

ASTM B348. The Sealing Assem-

bly consists of a Disc Spring that is

sealed on both its inside and out-

side faces with a TEFLON Gasket.

The Disc Spring is Titanium 6AL/4V

Ti per AMS4911J. The bulb is glass.