1

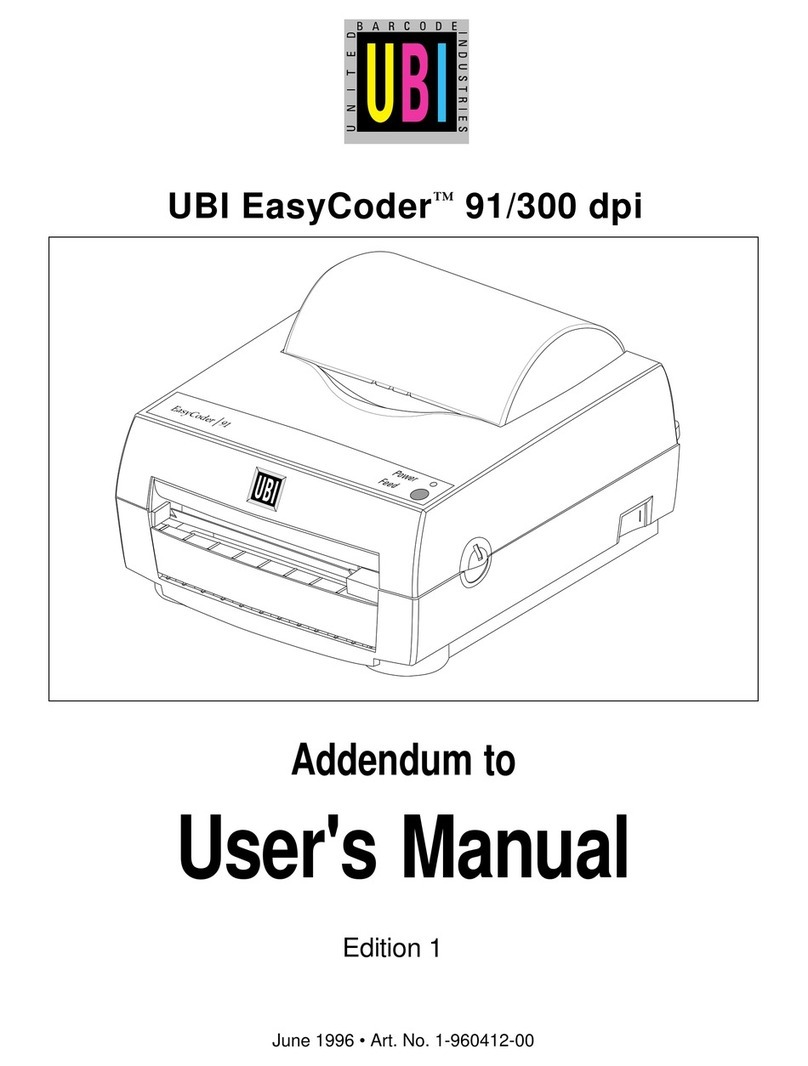

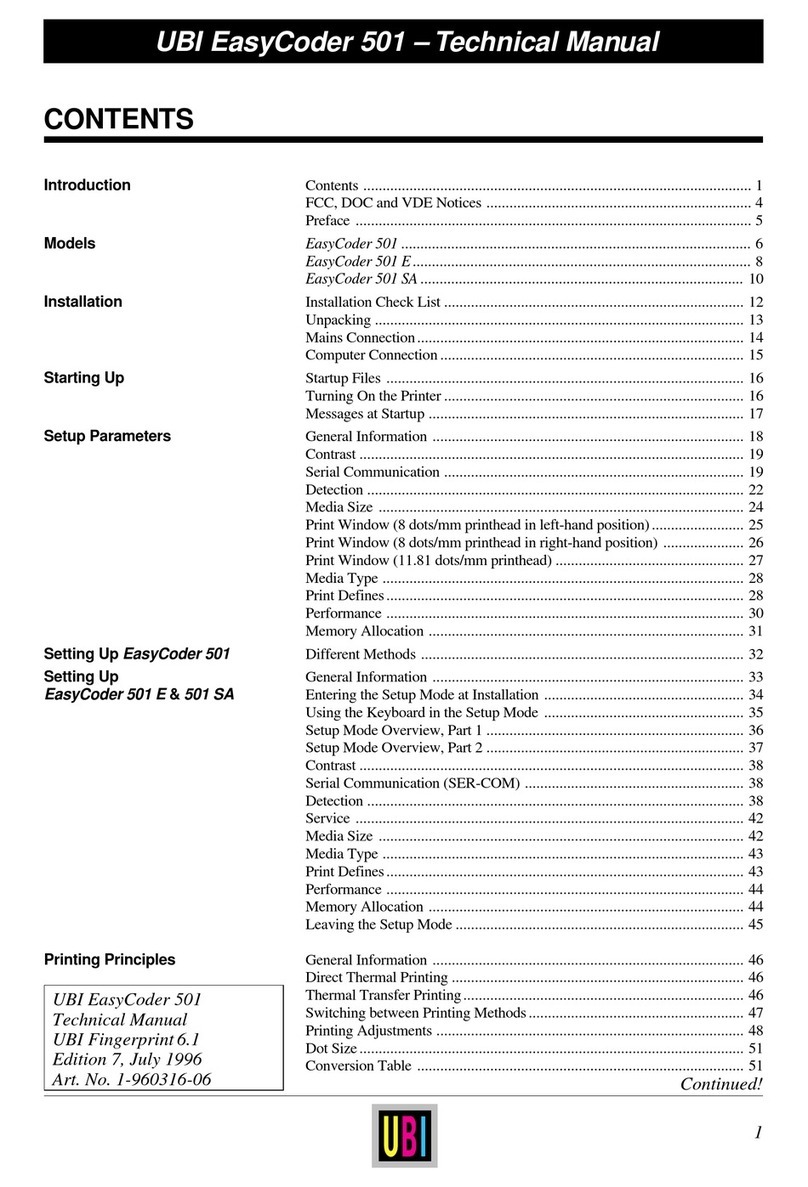

UBI EasyCoder 401 –Technical Manual

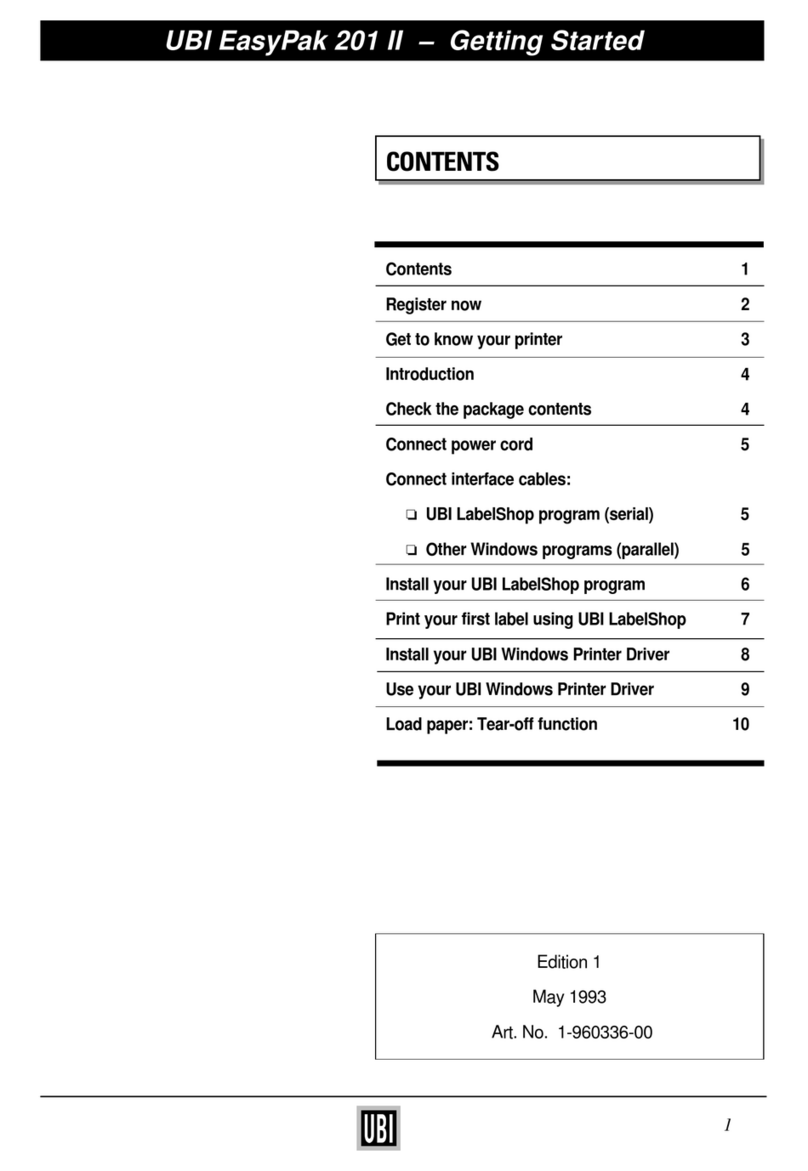

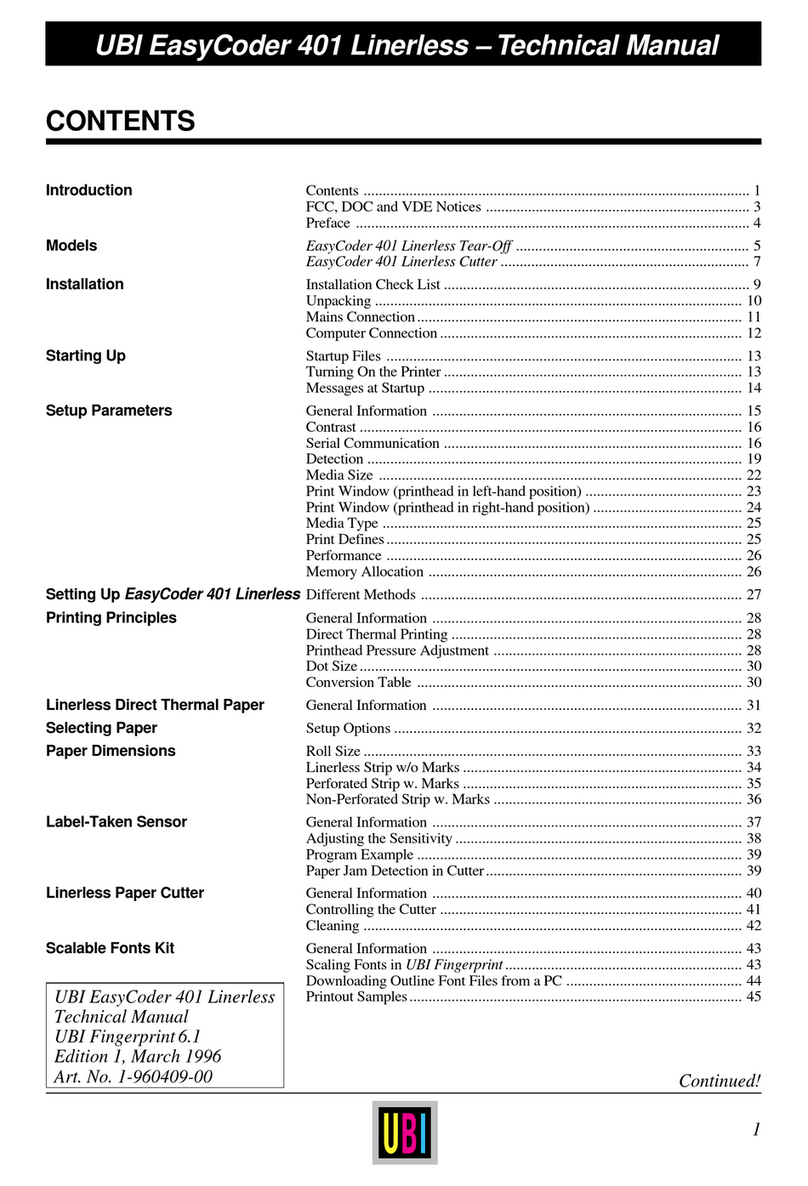

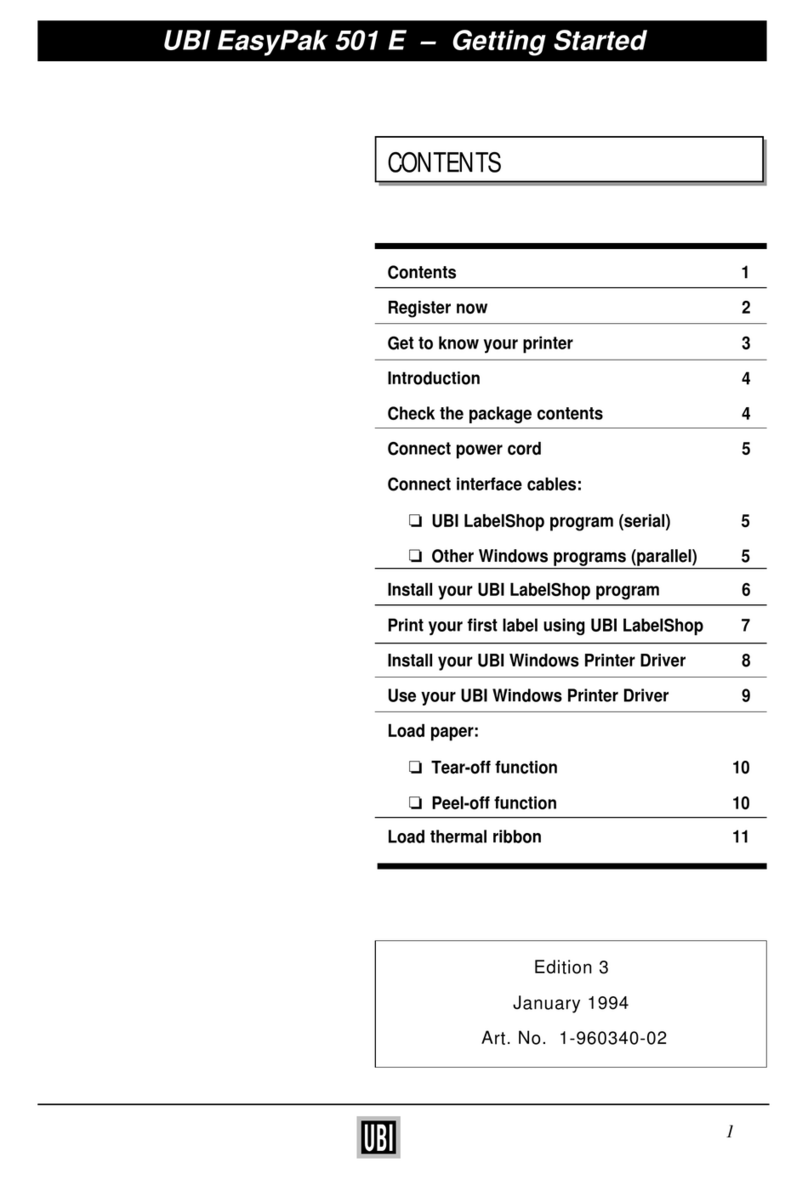

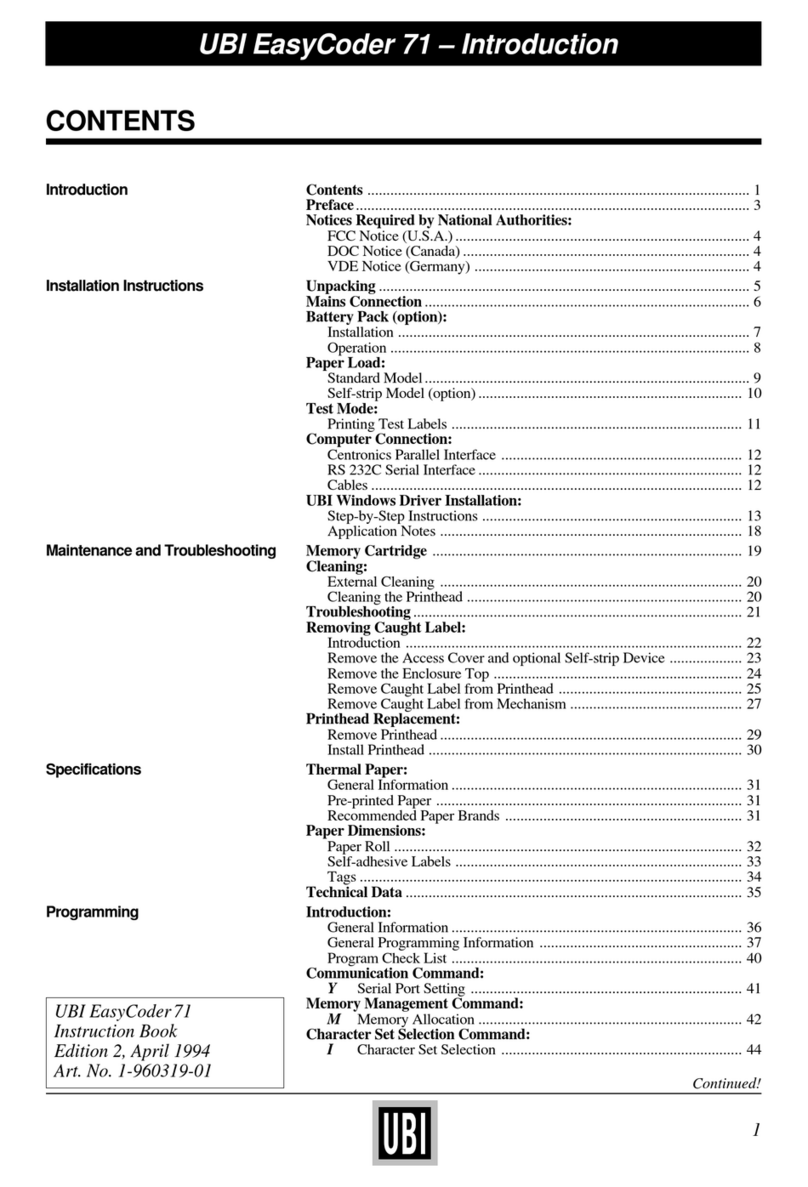

Introduction Contents ..................................................................................................... 1

FCC, DOC and VDE Notices ..................................................................... 3

Preface ....................................................................................................... 4

Installation Installation Check List ................................................................................ 7

Unpacking .................................................................................................. 8

Mains Connection....................................................................................... 9

Computer Connection............................................................................... 10

Starting Up Startup Files ............................................................................................. 11

Turning On the Printer .............................................................................. 11

Messages at Startup .................................................................................. 12

Setup Parameters General Information ................................................................................. 13

Contrast .................................................................................................... 14

Serial Communication .............................................................................. 14

Detection .................................................................................................. 17

Media Size ............................................................................................... 19

Print Window (printhead in left-hand position) ......................................... 20

Print Window (printhead in right-hand position) ....................................... 21

Media Type .............................................................................................. 22

Print Defines............................................................................................. 22

Performance ............................................................................................. 23

Memory Allocation .................................................................................. 23

Setting Up

EasyCoder 401

Different Methods .................................................................................... 24

Printing Principles General Information ................................................................................. 25

Direct Thermal Printing ............................................................................ 25

Thermal Transfer Printing......................................................................... 25

Switching between Printing Methods........................................................ 26

Printing Adjustments ................................................................................ 27

Dot Size.................................................................................................... 28

Conversion Table ..................................................................................... 28

Direct Thermal Paper General Information ................................................................................. 29

Pre-printed Paper ...................................................................................... 29

Transfer Ribbons and General Information ................................................................................. 30

Receiving Face Material Transfer Ribbon Types ............................................................................. 30

Receiving Face Materials.......................................................................... 30

Selecting Paper/Ribbon Setup Options ........................................................................................... 31

Thermal Transfer Printing......................................................................... 31

Direct Thermal Printing ............................................................................ 32

Paper Dimensions Roll Size ................................................................................................... 33

Non-Adhesive Strip .................................................................................. 34

Self-Adhesive Strip .................................................................................. 35

Self-Adhesive Labels................................................................................ 36

Tickets with Gap ...................................................................................... 37

Tickets with Black Mark .......................................................................... 38

CONTENTS

UBI EasyCoder 401

Technical Manual

UBI Fingerprint 6.1

Edition 4, January 1997

Art. No. 1-960369-03 Continued!