9 10

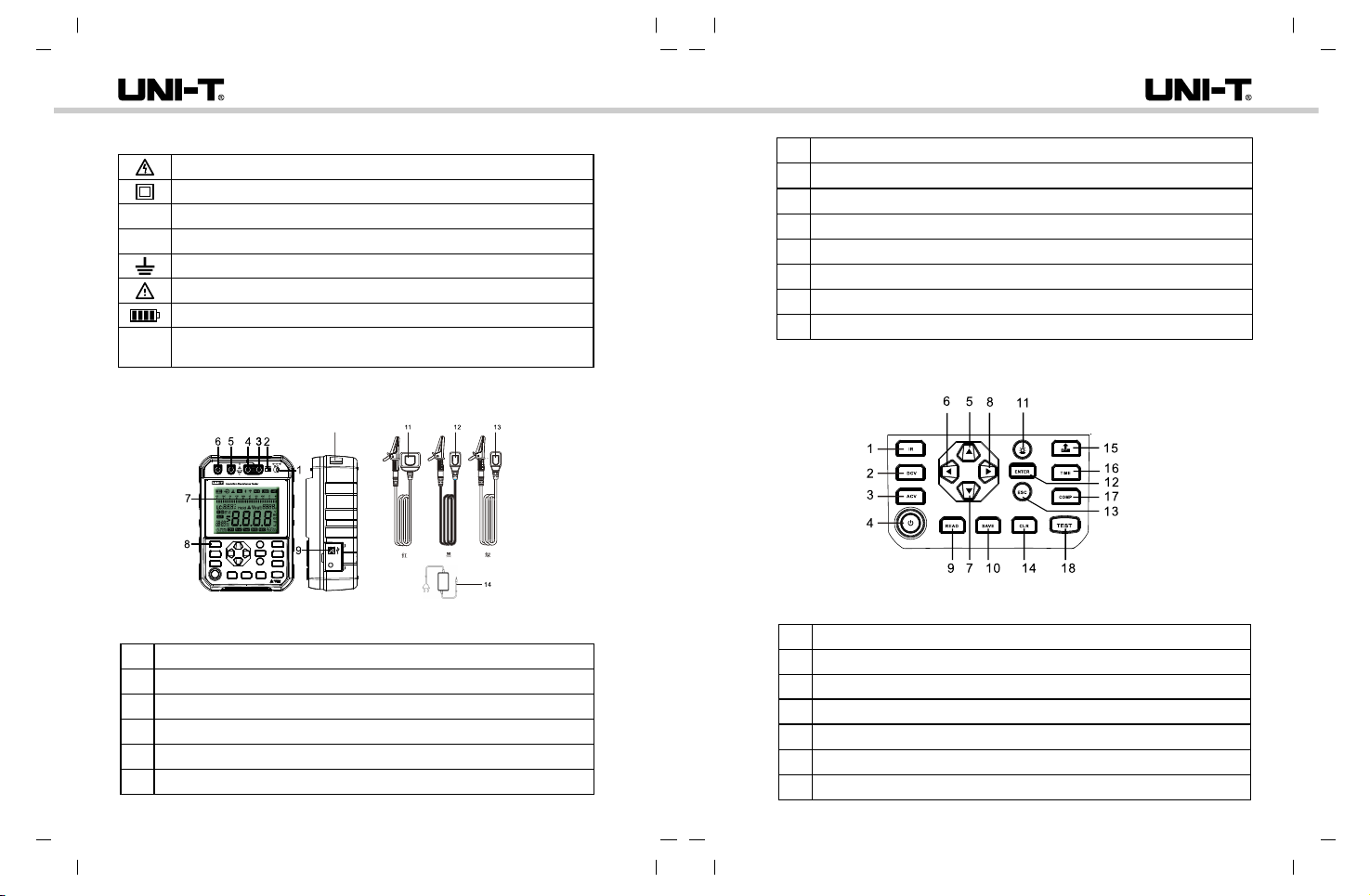

II. Accessories

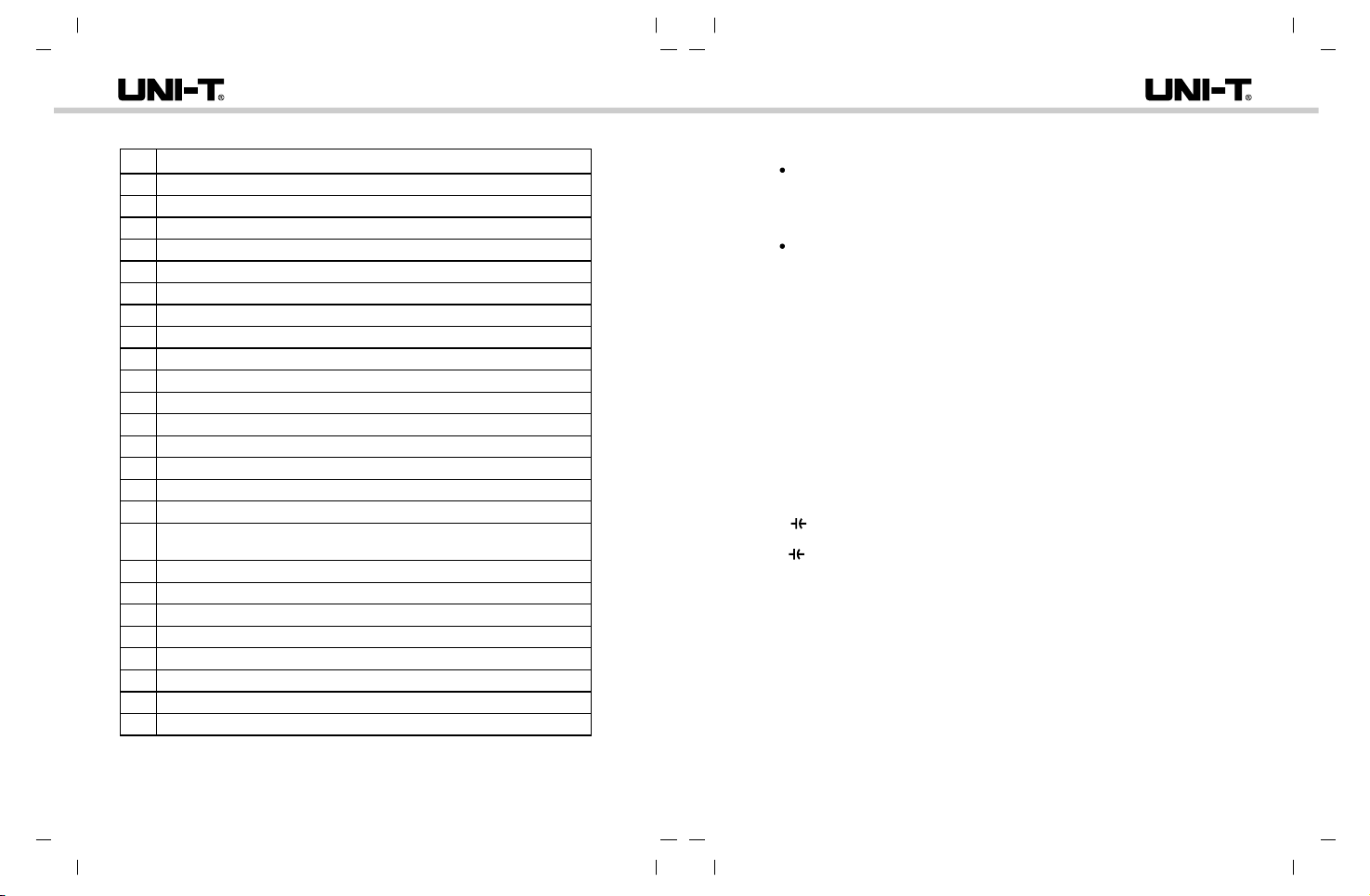

III. Safety Information

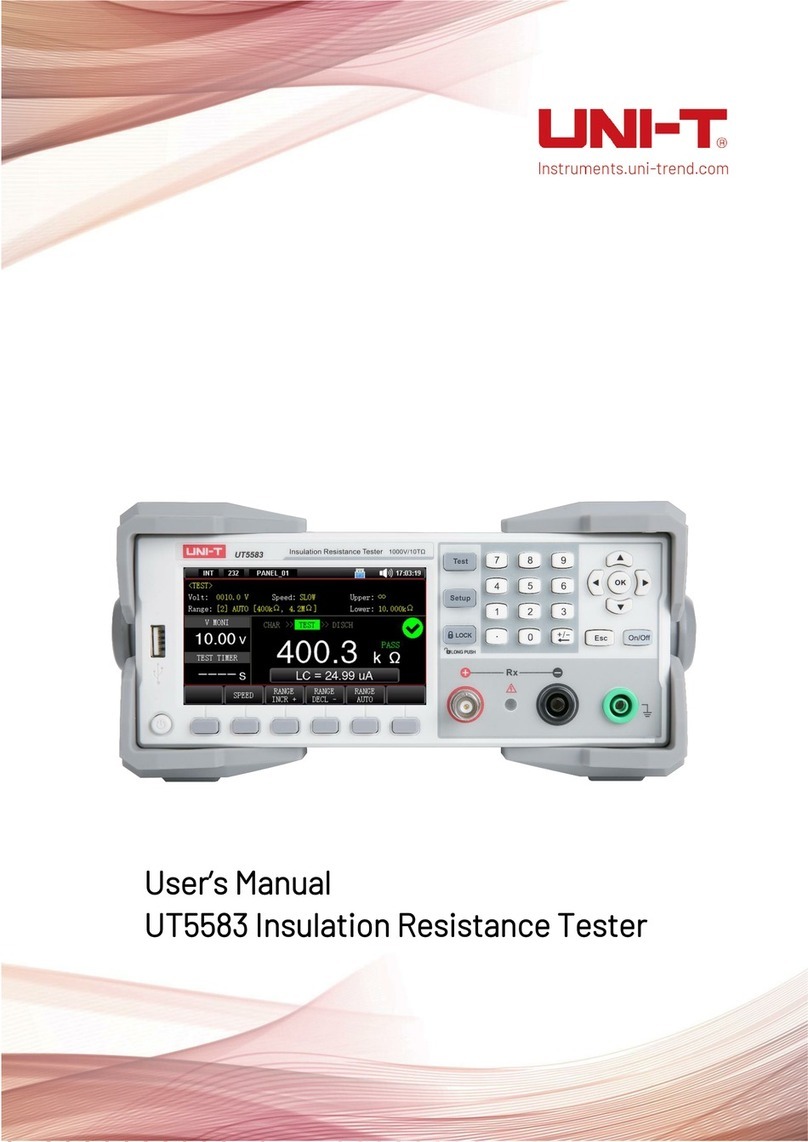

Thank you for purchasing the High-Voltage Insulation Resistance Tester. The

product is designed, manufactured and tested in accordance with IEC61010

Safety Standard (safety requirements of electric measurement products),

Double Insulation, and Overvoltage CAT IV 600V Standard. Before first use,

please read and follow the safety information and the precautions in the user

manual, so as to avoid electric shock or personal injury.

Warning

● Please read the user manual thoroughly and follow the “Safety Information” strictly.

● Keep the user manual with you for use at any time.

● Use the tester according to the operating instructions.

● Follow the operating instructions strictly, failure to follow can cause personal injury and product

damage.

● Please wear insulation gloves before use.

● Do not measure circuit with voltage over 750VAC or 1000VDC.

● It is forbidden to test near inflammable environment, spark cause explosion.

● Do not perform operation with tester surface or user’s hands wet.

● Please avoid short circuit occurs between metal part and test lead when measuring voltage,

otherwise it may cause personal injury.

● Do not exceed the upper range when performing measurement.

● Do not start testing when the test leads are not connected properly.

● Do not open the battery cover during measurement.

● Do not touch the measured circuit during or right after insulation resistance measurement,

otherwise it may cause electric shock.

● Please stop testing if dirt or carbide susceptible to damaging insulation characteristic is found

with test lead or port.

● Please do not short-circuit or connect test lead when measuring insulation resistance, misoperation

may accidentally cause test to be stopped or LED to be lit off. Top end of test lead will discharge

when test lead is short-circuited or connected, please note that certain discharge can deteriorate

the product performance.

● Please check the tester and the test lead before use for any damage or defect. Please stop

using the tester if test lead or casing insulation is damaged, LCD shows nothing, or the tester

cannot work normally.

● It is forbidden to use the tester without battery cover set in place, otherwise it may pose a risk

of electric shock.

● Keep fingers behind the finger guard when perform measurement, do not touch exposed wire,

connector, alligator clip, etc. to avoid electric shock.

● The output voltage at right position before measurement, it is forbidden to switch over the output

voltage during measurement to avoid product damage.

● If the battery power indicator shows less than one “segment” of power left, please charge or

replace the battery immediately to ensure measurement accuracy. Remove the battery if the

product is not used for a long time. Power off the tester before opening the battery cover.

● Do not alter the internal wiring without authorization to avoid product damage and safety hazard.

● Do not store or use the tester in flammable and explosive environments, or environments with

high temperature, high humidity, and strong electromagnetic field.

● Please clean the casing using soft cloth and mild detergent, do not use abrasive or solvent to

avoid casing corrosion and product damage.

● If insulation on probe is damaged, replace a new one which should meet EN 61010-031 standard,

rated follow parameters of the product or better.

● Before each use verify tester operation by measuring a known voltage.

● Indoor use only

Red high-voltage test lead: 1 pc

Green test lead: 1 pc Black test lead: 1 pc

0℃~35℃; <75%rh

-20℃~60℃; <80%rh

<2000m

2

CAT Ⅳ 600V

IEC61010-1; EN IEC 61010-2-034;

BS EN 61010-1; BS EN IEC 61010-2-034

230mm(L)x161mm(W)x90mm(D)

About 1800g (including battery)

Dimensions

Weight

Test leads

Operating environment

Storage environment

Altitude

Pollution degree

CAT rating

Safety standards

Please check if any accessory in the package is missing or damaged:

1. User manual: 1 pc

2 Test lead (red, black, green: 1 for each): 3 pcs.

3 USB cable: 1 pc.

4 Lithium battery charger (model: CS36M168200M1; specification:

Input:100-240Vac (Fluctuations+10%), 50/60Hz, 0.8A,Output: 16.8Vdc, 2A:

.

1 pc (UT512E)

5 Lithium battery pack (installed inside the tester, model: UT-M18, .

specification: 14.8V, 5200mAh): 1 pc (UT512E)

6 Adapting charging stand (optional accessory, model: UT-W12, for UT512E only).

7 8 PCS LR14 alkaline batteries (UT512D).

8 Carrying strap:1pc.

If any missing or damaged accessory occurs, please contact with the supplier

immediately.

UT512D/E User ManualUT512D/E User Manual