Service Manual UPO1000X Series

Instruments.uni-trend.com

Exterior Cleaning

Clean the exterior surfaces of the chassis with a dry lint-free cloth or a soft-bristle brush. If any dirt remains, use a

cloth or swab dipped in a 75% isopropyl alcohol solution. Use a swab to clean narrow spaces around controls and

connectors. Do not use abrasive compounds on any part of the chassis that may damage the chassis.

Clean the On/Standby switch using a cleaning towel dampened with deionized water. Do not spray or wet the switch

itself.

Caution:Avoid the use of chemical cleaning agents which might damage the plastics used in this instrument.

Use only deionized water when cleaning the front-panel buttons. Use a 75% isopropyl alcohol solution as a

cleaner for cabinet parts. Before using any other type of cleaner, consult UNI-T Service Center or

representative.

Inspection - Exterior. Inspect the outside of the instrument for damage, wear, and missing parts. Immediately repair

defects that could cause personal injury or lead to further damage to the instrument.

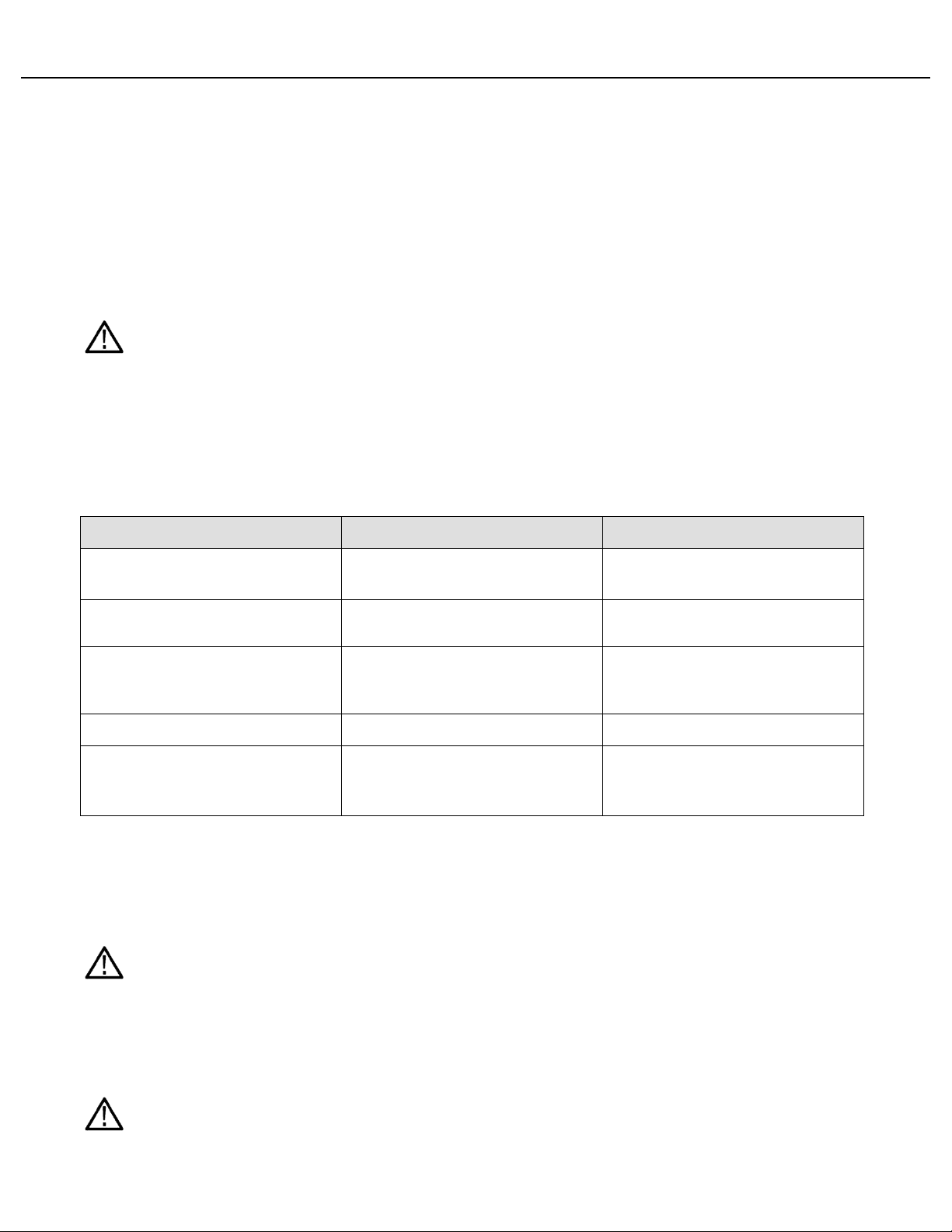

Table 1:External Inspection Checklist

Cabinet, front panel, and cover

Cracks, scratches, deformations,

damaged hardware.

Repair or replace defective module.

Missing, damaged, or loose knobs

Repair or replace missing or defective

knobs.

Broken shells, cracked insulation, and

deformed contacts.

Dirt in connectors.

Repair or replace defective modules.

Clear or brush out dirt.

Carrying handle and cabinet feet

Repair or replace defective module.

Missing items or parts of items, bent

pins, broken or frayed cables, and

damaged connectors.

Repair or replace damaged or missing

items, frayed cables, and defective

modules.

Screen Cleaning

Please use wet tissue or a soft cloth to wipe the dust from the screen and surface.

If the display screen is very dirty, please use a cloth to dipped in distilled water, 75% isopropyl alcohol solution or

glass cleaner to slightly wipe the sceen surface. Only use enough water to wet the cloth or to wipe. Avoid excessive

force, which may damage the display surface.

Caution:Improper cleaner and cleaning way will cause damage to the screen.

Do not use abrasive cleaner or surface cleaner to clear the LCD.

Do not spray water on the LCD surface.

Do not excessive force to wipe the LCD.

Caution: To prevent moisture inside the instrument during external cleaning, do not spray any cleaning

solution onto the screen or instrument directly.