2

I. INTRODUCTION

SX-6000-05 series is a POS terminal for retail (scanning) market, grocery convenient stores,

variety, specialty, supermarkets, etc.

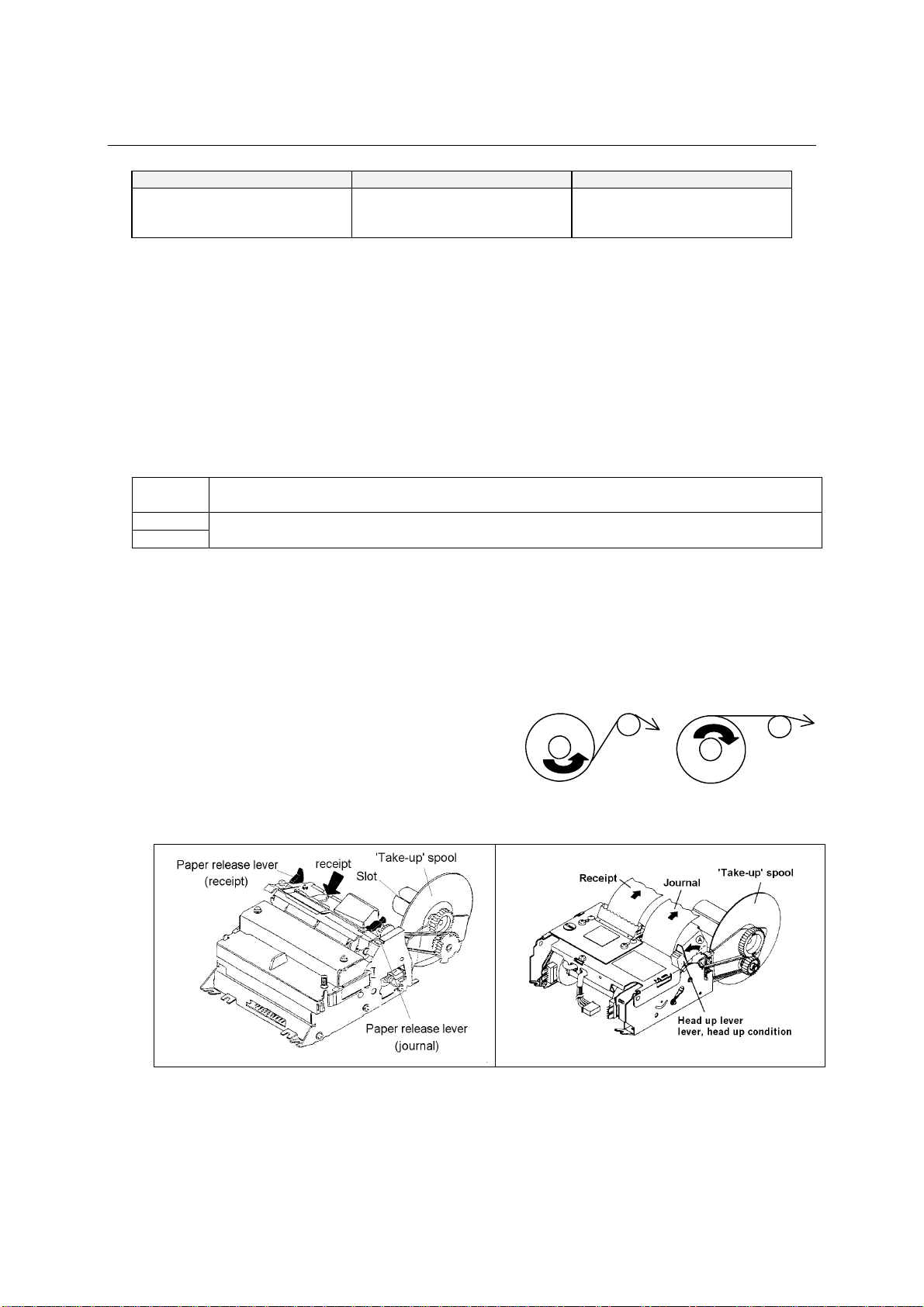

SX-6600 2-station dot matrix printer model (44.5 mm, 3.0 lines/sec., 24 char.)

SX-6700 2-station thermal printer model (44.5 mm, 14 lines/sec., 24 char.)

SX-6750 1-station thermal printer model (80 mm, 21.5 lines/sec., 46 char.)

Major Features

•Scanning system with 18 digits random PLU code having 22 digits PLU descriptor

•Standard 2238 PLUs, Max. 61693 PLUs (option)

•99 group-As, 99 group-Bs and 10 main group-As

•Bottle deposit / bottle return function by using 341 R. PLU (Recyclable PLU)

•Store / Vendor Coupon PLU function

•User friendly PLU programming in R & SP positions

•300 quantity discount tables for mix and match, multi-buy registrations, etc.

•1024 customer files make records of telephone number or VAT number, name and address - these

information are issued on receipts for delivery service market, etc. (optional 1st RAM board required)

•3 age limitation tables - item linked to age limitation table can be sold when entered customer's

birthday is over the programmed limit

•99 cashiers with its own full transaction memory

•2048 amount tracks with one store memory and external amount track function

•ESF (Electronic Stored & Forward) function with record selection (optional 1st RAM board required)

•Euro currency system

•25 media keys + 10 preset tender keys

•10 arrangement keys (50 key steps)

•Card Functions

- Card payment

- Cashier sign on by card

- Arrangement card

- Amount track card

- Adjustment card

•IRC (Inter Register Communication)

- Up to 32 units including an ECR master or PC as IRC master (Tensai2000) via NA-720

- Flash reports and flash downloading

- 8 slip printers TP-420/422/522/620/722, CBM-233/1000 via NA-710/730

•PC batch communication, programming loader module PLM 2000

•Scale link