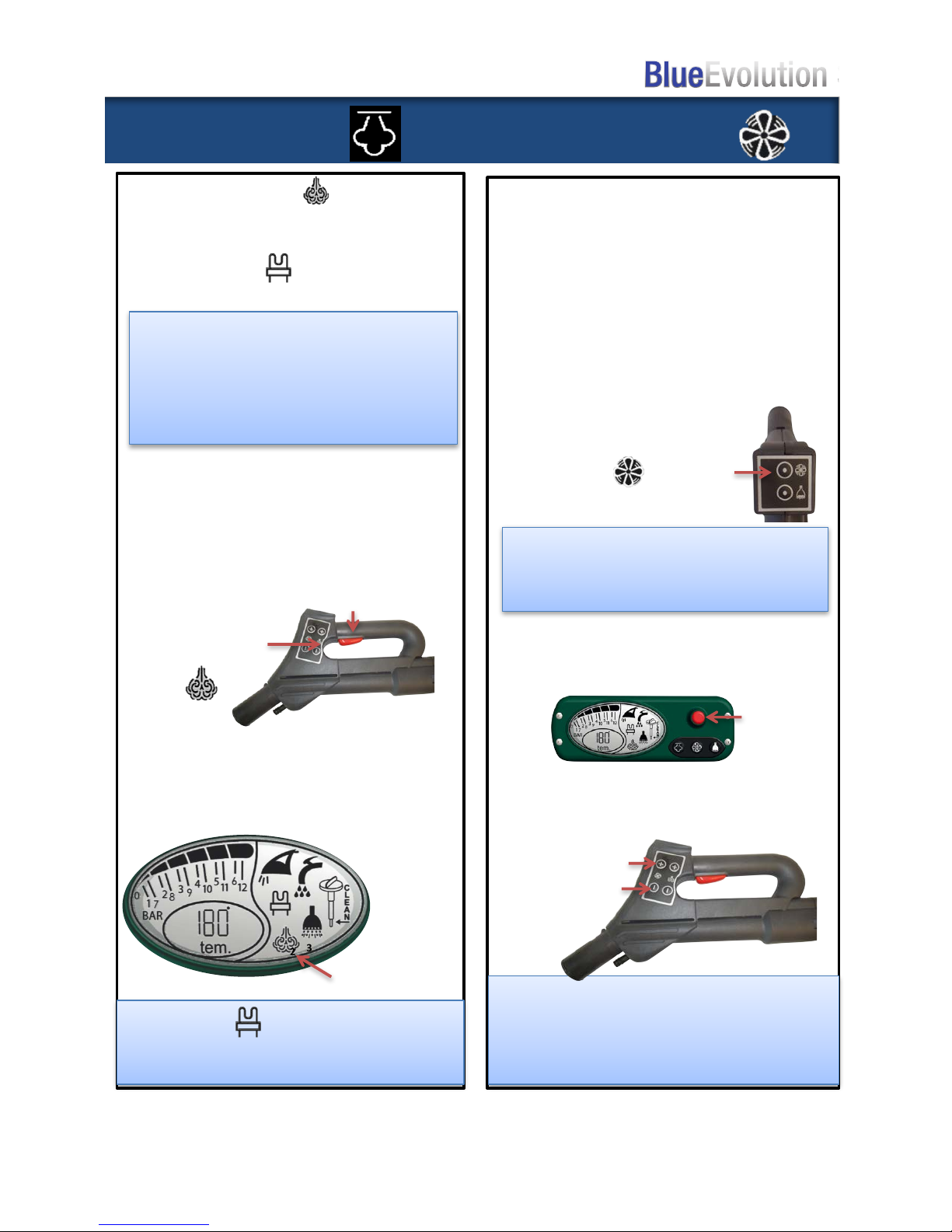

The Blue Evolution’s Extraction feature

allows the user to clean with hot water.

Extraction increases cleaning

performance, and when used with the

Vacuum,leaves arelatively dry surface.

ØActivate the Extraction by pushing

the button on the hose handle.

ØTurn ON the Vac u um by pushing

vacuum symbol on the hose

handle.

ØThe symbol will illuminate on

the display while the Blue Evolution

is in Extraction mode.

ØYou will he ar th e pump when

activated.

ØExtraction spray can be increased or

decreased in 10% increments by

pushing button on the console.

ØDefault Setting: 60%

Ø010 -Lowest Setting minimum

amount of water

Ø100 -Highest Setting Maximum

amount of water

ØTo turn OFF the Extraction and

return to Steam only, push the

button on the hose handle.

Vacuu m

Extraction

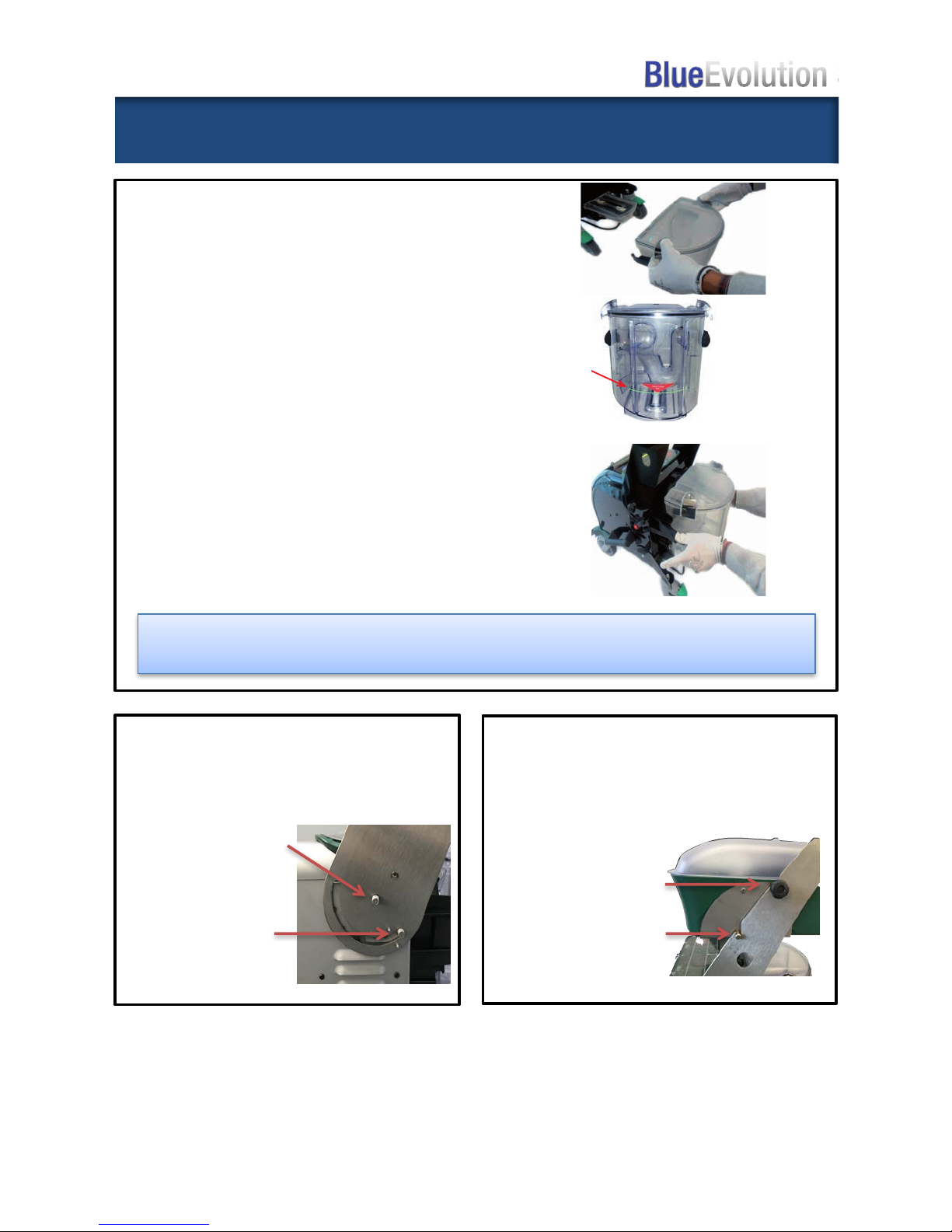

Extraction Shut Down

After Each Use:

It is important to clean accessories and

brushes.

ØRun the vacuum for 30 seconds to

remove any water from the hose.

ØUse hot soapy and water to clean

brushes and nozzles.

ØEmpty and use hot soapy water to

clean the collection tank and

remove all debris.

ØIf using the Blue Evolution on an

extremely dirty or greasy surface,

clean hose after use by activating

the vacuum mode and suck water

through the hose on low suction.

ØIf working in a healthcare

environment, the hose can be

cleaned with a disinfection

solutions.

Every 3 Months

ØCheck Boiler cap and descale (see

Page 13).

ØDescale the reservoir tanks and

boiler. (see page 12).

ØCheck HEPA filter clean or replace.

(see page 10).

ØCheck O-Rings on hose and

extension wands. If damaged,

replace.

Every Year

ØReplace HEPA filter

ØChange the O-Rings on the hose

and extension wands (page 10)

6