Page 5

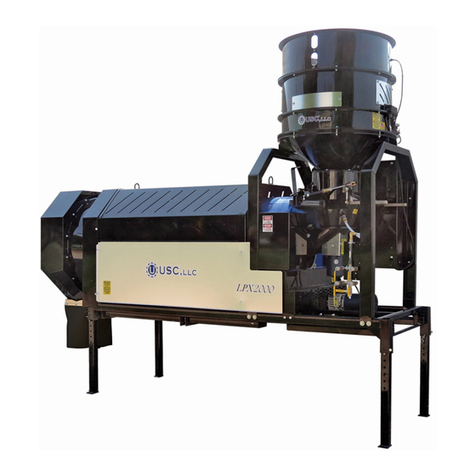

TD-09-06-1064 LPV 100 SEED TREATER

Notice is used to notify people of important installation, opera-

tion or maintenance information which is not hazard related.

NOTICE

Mandatory Lockout Power Symbol. Disconnect, lockout

and tagout electrical and other energy sources before inspect-

ing, cleaning or performing maintenance on this equipment.

International Safety Alert Symbol. The exclamation point (!)

surrounded by a yellow triangle indicates that an injury hazard

exists. However, it does not indicate the seriousness of po-

tential injury. The exclamation point (!) is also used with the

DANGER, WARNING and CAUTION symbols so the potential

injury is indicated.

Electrocution Hazard Symbol. This symbol indicates that

an electrocution hazard exists. Serious injury or death could

result from contacting high voltage.

LOCKOUT / TAGOUT PROCEDURES

Lockout/Tagout is the placement of a lock/tag on an energy isolating device in

accordance with an established procedure. When taking equipment out of service to

perform maintenance or repair work, always follow the lockout / tagout procedures as

outlined in ANSI Z344.1 and/or OSHA Standard 1910.147. This standard “requires

employers to establish a program and utilize procedures for affixing appropriate

lockout devices or tagout devices to energy isolating devices and to otherwise disable

machines or equipment to prevent unexpected energizing, start-up, or release of

stored energy in order to prevent injury to employees.”

EMERGENCY STOP

There is an Emergency Stop push button on all LPV Seed Treaters which

is located on the Treater Control Panel. The LPV Automated Treater has

an additional Emergency Stop pushbutton on the Main Control Panel.

Actuators of emergency stop shall be colored RED. The background

immediately around the device actuator shall be colored YELLOW.

The actuator pushbutton operated device shall be of the palm or

mushroom head type.

International Electrocution Hazard. This symbol indicates

that an electrocution hazard exists. Serious injury or death

could result from contacting high voltage.