Page 4

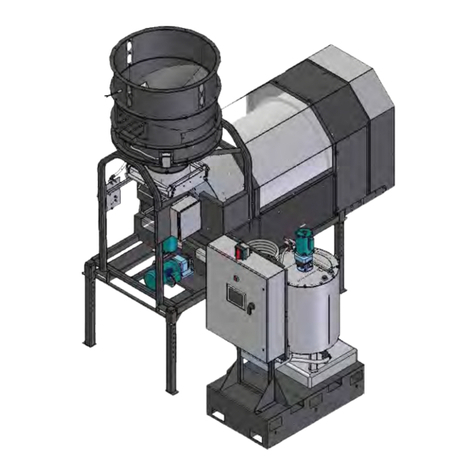

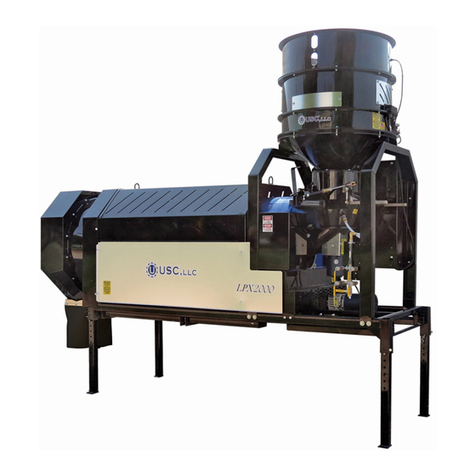

LPX AUTOMATED SEED TREATER

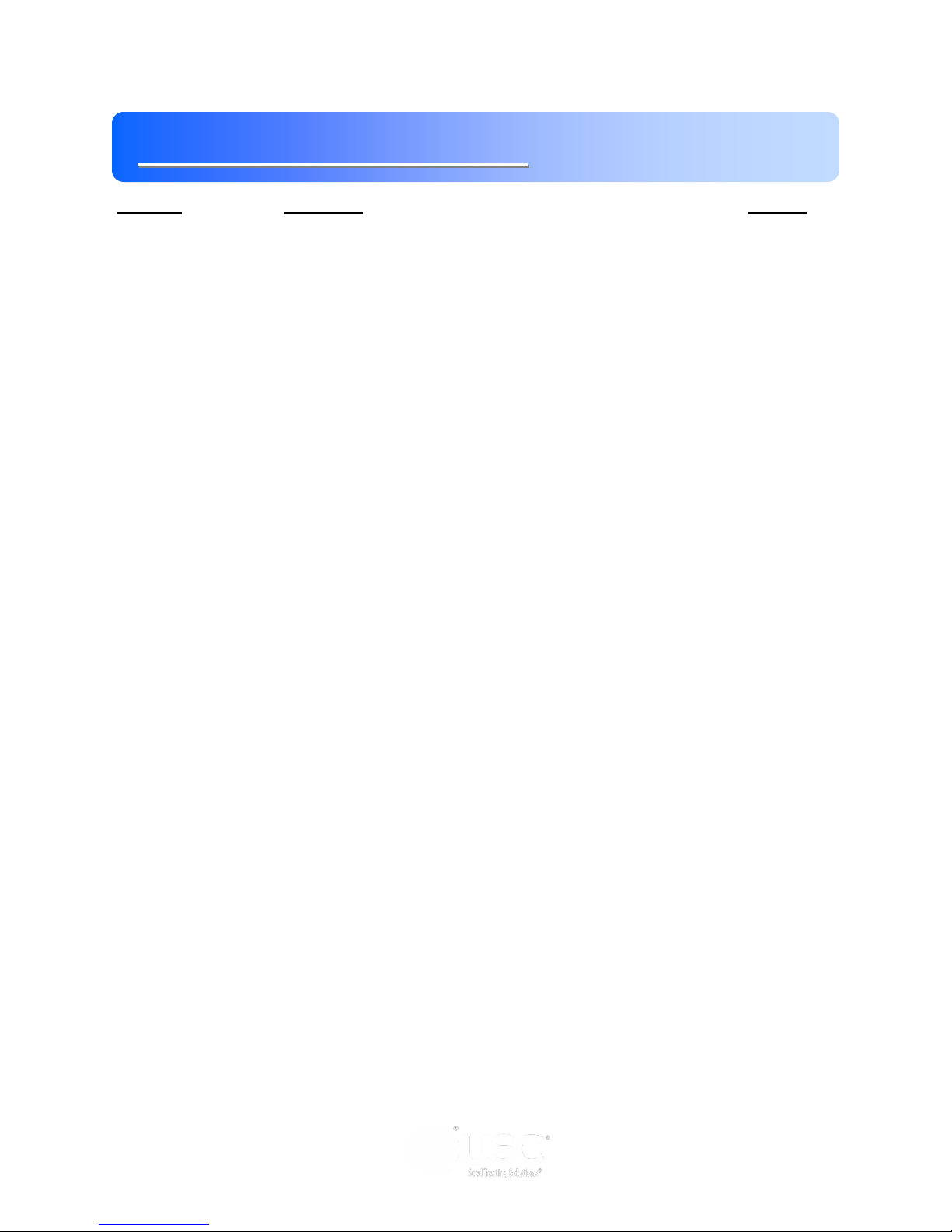

Section Contents Page #

Section A Safety Instructions.....................................................................5

Section B Installation................................................................................12

Section C Mechanical Operation..............................................................18

LPX Treater Overview............................................................18

Seed Wheel............................................................................19

Atomizer Chamber .................................................................20

Rotating Drum .......................................................................21

Pump Stand Overview............................................................22

Mix Tank, Calibration Tube ....................................................23

Peristaltic Pump Heads & Pump Motor .................................24

Flow Meters, Pump Stand Valves ..........................................25

Section D Electrical Operation.................................................................28

Main Screen...............................................................................30

H-O-A Screen.............................................................................33

Utilities Screen...........................................................................37

Security Screen..........................................................................39

Tools & Options Screen.............................................................41

Section E Calibration ................................................................................47

Seed Flow Calibration................................................................47

Pump Calibration .......................................................................50

Flow Meter Calibration...............................................................51

Seed Wheel Calibration .............................................................52

Treating Seed ............................................................................53

Editing & Printing Reports..........................................................55

Downloading Reports.................................................................57

Section F Troubleshooting & Alarms......................................................61

Troubleshooting .........................................................................61

Proximity Switch Adjustment Guide...........................................63

System Alarms - Faults..............................................................64

System Messages......................................................................67

Section G Maintenance .............................................................................68

Section H Storage......................................................................................71

Section I Mechanical Drawings ..............................................................74

Section J Limited Warranty....................................................................139

Table of Contents

Table of Contents