IN8377 - 02 OF 12

Trade Van Racking

SAFETY AND PRODUCT INFORMATION - READ CAREFULLY BEFORE FITTING AND RETAIN FOR FUTURE USE

NOTICE

Van Guard Accessories Ltd and/or its distributors does not accept liability for products which have not been fitted in

accordance with the fitting instructions provided.

Please refer to the vehicle manufacturers handbook to establish the maximum payload capacity for your vehicle. Do not

exceed this limit.

FITTING (A)

A.01. Please be aware that the responsibility for drilling holes into your vehicle to install fixings lies with the installer(s).

It is crucial to exercise caution to avoid damaging components such as the fuel line, tyres, fuel tank, wiring loom, exhaust,

batteries, bodywork, and brake lines.

A.02. You must exercise extra caution when installing racking in electric or hybrid vehicles. For these vehicles, it is highly

recommended to engage an experienced installer to ensure secure attachment of the racking. Additionally, do not under

any circumstances drill through the vehicle flooring if there are batteries or wires beneath.

A.03. When attaching the racking unit to the side of a vehicle, it is recommended that the fixing brackets are securely

fastened to the inner steel skin of the vehicle. Relying solely on a plywood lining for fixing is insufficient.

A.04. Take care when affixing to the side of a vehicle to ensure there is ample space between the inner and outer layers to

avoid puncturing the outer skin of the vehicle. When drilling, use as short a drill bit as possible to prevent damaging the

vehicle.

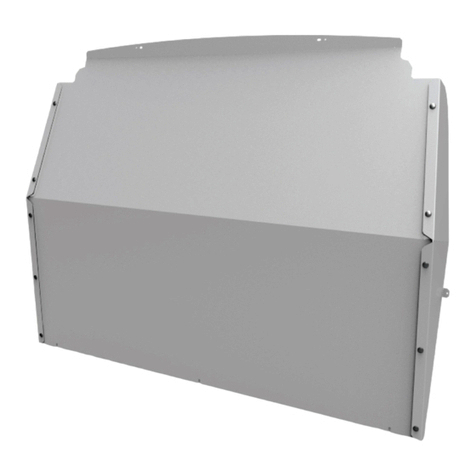

A.05. This product must only be fitted to vehicles with a full bulkhead present.

A.06. Always use corrosion protection when drilling holes to prevent rust and maintain the vehicle's structural integrity.

A.07. This product must be fixed in place, even if it is not to be fitted inside a vehicle.

A.08. Wear the appropriate protective equipment (safety glasses & gloves) while fitting this product to ensure your safety

during the installation process.

DRIVING (B)

B.01. Be aware that the addition of the racking system may affect the van's center of gravity, potentially impacting its

handling characteristics. Drive cautiously and adapt to any changes in vehicle dynamics.

B.02. After first fitting of the van racking and whenever the van racking is refitted to the vehicle, racking, accessories and

loads shall be checked the first time after a short period of driving, 50 km or 30 minutes maximum, for tight fit and

function ability and tightened if necessary.

LOADING/SECURING (C)

C.01. Do not exceed the specified load limits of the racking system.

C.02. Do not exceed the vehicle's maximum payload capacity, remembering to factor in the weight of the racking system

in your calculations.

C.03. Do not climb or stand on any part of the racking system.

C.04. Exercise caution when loading and unloading items from the racking system to prevent personal injury and damage

to the product.

LOADING/SECURING (C)

C.05. Personal injury and damage to property can occur when cargo is not properly secured during various driving

maneuvers such as braking, accelerating, taking turns, or making sudden swerves. Inadequate load securing may lead to

cargo tipping or shifting, which can have serious consequences. To mitigate these risks, follow these guidelines:

◦Ensure all objects in the load area are properly secured to prevent tipping and sliding.

◦Prior to each journey, thoroughly inspect and confirm that the load is securely fastened.

◦Incorporate dividers and rubber mats within shelves to prevent movement.

When it comes to load securing, it's crucial to adhere to relevant laws and road traffic regulations to promote safety and

ensure compliance with the law.

MAINTENANCE (D)

D.01. Regularly check all fixings for tightness.

D.02. Regularly inspect all components for signs of wear or damage. Replace lost, damaged, or worn parts immediately.

D.03. Any changes made to the product as well as the use of spare parts or accessories other than those supplied by the

manufacturer will lead to the lapsing of the manufacturer’s warranty and liability for any material damage or accidents.

FINISHING (E)

E.01. The fitter, end user and anyone using the product must receive and read both this document and the supplied fitting

instructions. Retain both the fitting instructions and this document for future use.

E.02. Ensure all packaging is disposed of responsibly.

E.03. Ensure product is disposed of responsibly at its end of life.

E.04. Always comply with applicable safety rules and regulations when fitting and using this product.

EN